Addition and reduction material composite machining center

A compound machining center and machining center technology, which is applied in the field of mechanical processing, can solve problems such as unsatisfactory use effects, and achieve ideal use effects, good processing quality, and high processing efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

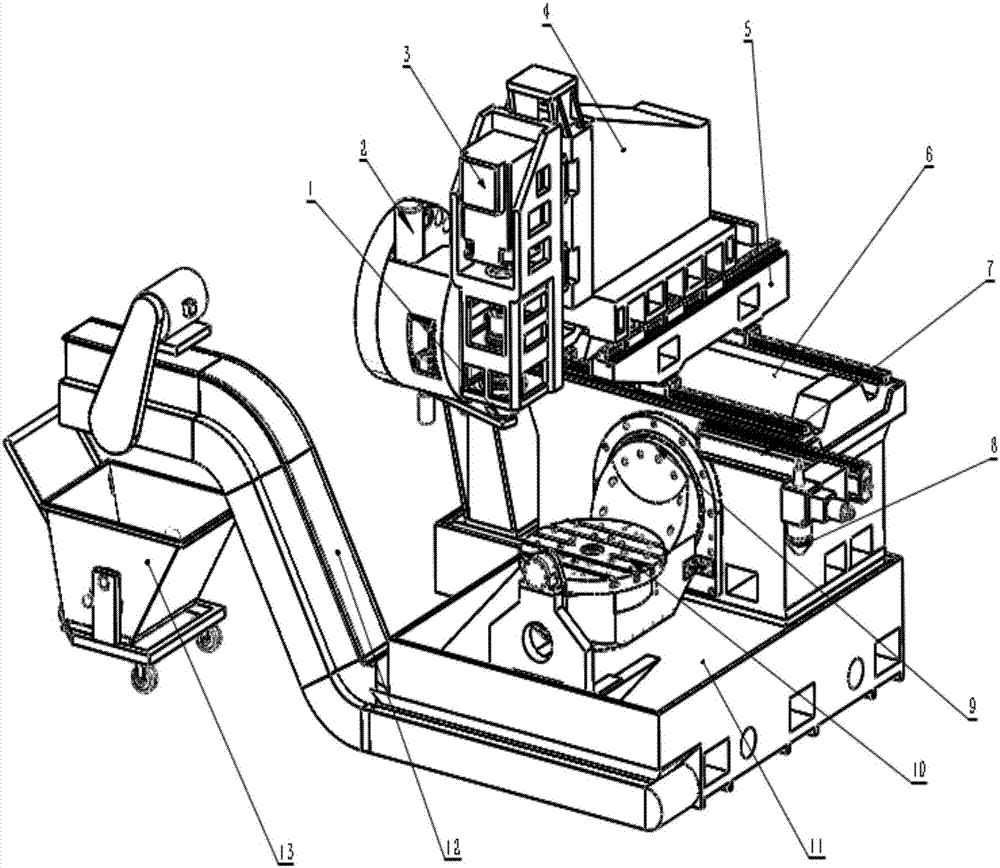

[0014] Embodiments of the present invention, such as figure 1 As shown, a compound machining center for adding and subtracting materials includes a five-axis subtractive machining center and a laser additive printing device; the five-axis subtractive machining center includes a square base 11 and a bed 6 on the rear of the top surface of the base 11 , the bed saddle 5 that is erected on the bed 6 through the guide rails laid in the X axis, the ram 4 that is erected on the saddle 5 through the guide rails laid in the Y axis, and the ram 4 that is erected on the bed saddle 5 through the guide rails laid in the Z axis. The spindle box 3 on the front side of the pillow 4, the spindle 1 located in the spindle box 3, the tool magazine 2 located on the left side of the spindle box 3; a workpiece clamping platform is arranged between the front side of the bed 6 and the top of the base 11, The workpiece clamping platform is provided with a rotary C-axis 10 vertically arranged on the ro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com