Correlation rotor of horizontal hard bearing dynamic balancer and calibration method thereof

A technology of hard support and balancing machine, which is applied in static/dynamic balance testing, machine/structural component testing, instruments, etc. It can solve problems affecting the performance of the whole machine, no verification standards and methods, etc., so as to achieve quality change, The effect of small position error and accurate calibration result

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] Below, the present invention is described in detail with reference to accompanying drawing and embodiment:

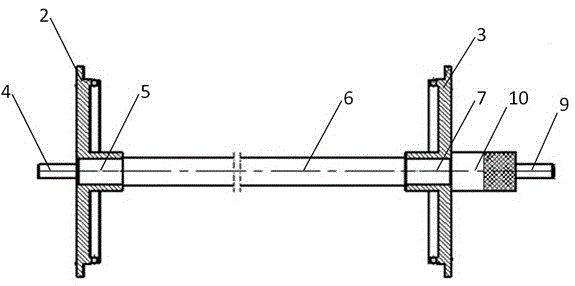

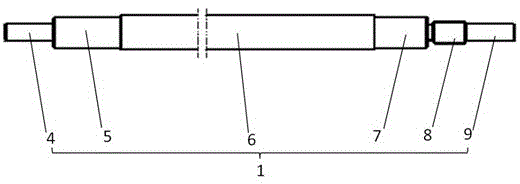

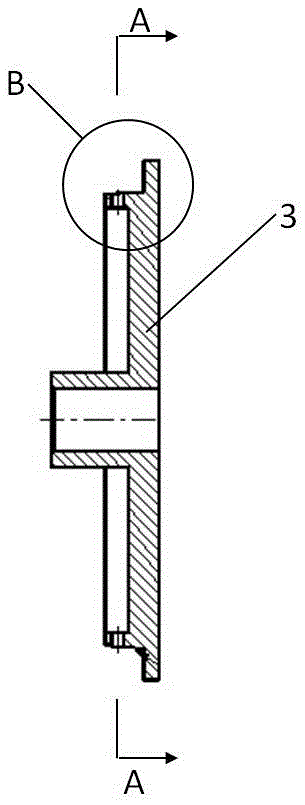

[0045] like Figure 1~6 As shown, a calibration rotor of a horizontal hard-supported dynamic balancing machine includes a mandrel 1. The mandrel 1 includes a left support section 4 supported on the bearing frame of the balancing machine from left to right, and interferes with the center hole of the left end cover 2. Fitted interference fit section 5, axially limited spacer section 6, clearance fit section 7 that is clearance-fitted with the center hole of the right end cover 3, threaded section 8 that cooperates with the lock nut 10, and right support section 9, the An assembly ring 11 is formed on the opposite end faces of the left end cover 2 and the right end cover 3, and a limit plate 15 is formed on the outer wall. The outer ring of the assembly ring 11 is a conical surface. The assembly ring 11 forms a plurality of threaded holes in the radial direction to ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Taper | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com