External-conical-surface-contained standard calibration rotor for dynamic balancing machine

A technology of dynamic balancing machine and outer cone surface, which is used in static/dynamic balance testing, machine/structural component testing, instruments, etc. It can solve problems affecting the performance of the whole machine, avoid measurement errors, and reduce system measurement. effect of error

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] Hereinafter, the present invention will be described in detail with reference to the drawings and embodiments:

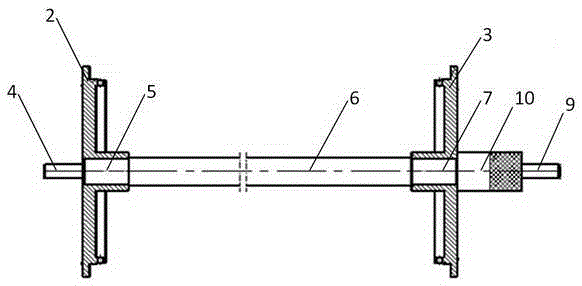

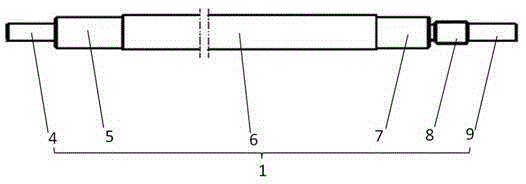

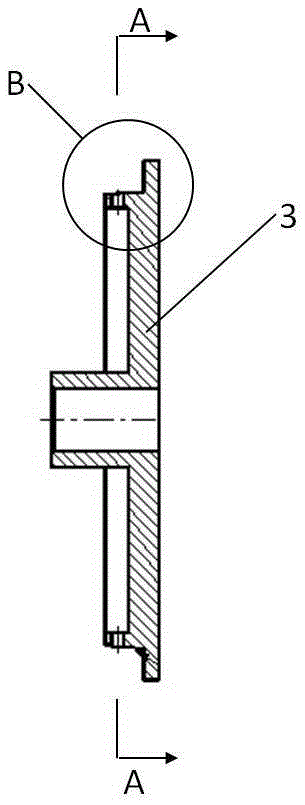

[0025] Such as Figure 1~6 As shown, a standard proofreading rotor for a dynamic balancing machine with an outer cone includes a core shaft 1. The core shaft 1 includes, from left to right, a left support section 4 supported on a bearing frame of the balancing machine, and a center hole of the left end cover 2. The interference fit section 5 of the interference fit, the axial limit limit section 6, the clearance fit section 7 that fits with the center hole of the right end cover 3, the thread section 8 that fits with the lock nut 10, the right support section 9, Assembling rings 11 are formed on the opposite end surfaces of the left end cover 2 and right end cover 3, a limit plate 15 is formed on the outer wall, the outer ring of the assembling ring 11 is a conical surface, and the assembling ring 11 is radially formed with a plurality of matching test weights ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com