Drilling jig for speed reducer connecting cover

A drilling jig and connecting cover technology, applied in drilling/drilling equipment, clamping, manufacturing tools, etc., can solve the problems of low production efficiency and difficulty in ensuring the position of holes, and achieve high production efficiency and high positional accuracy. The effect of small error and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

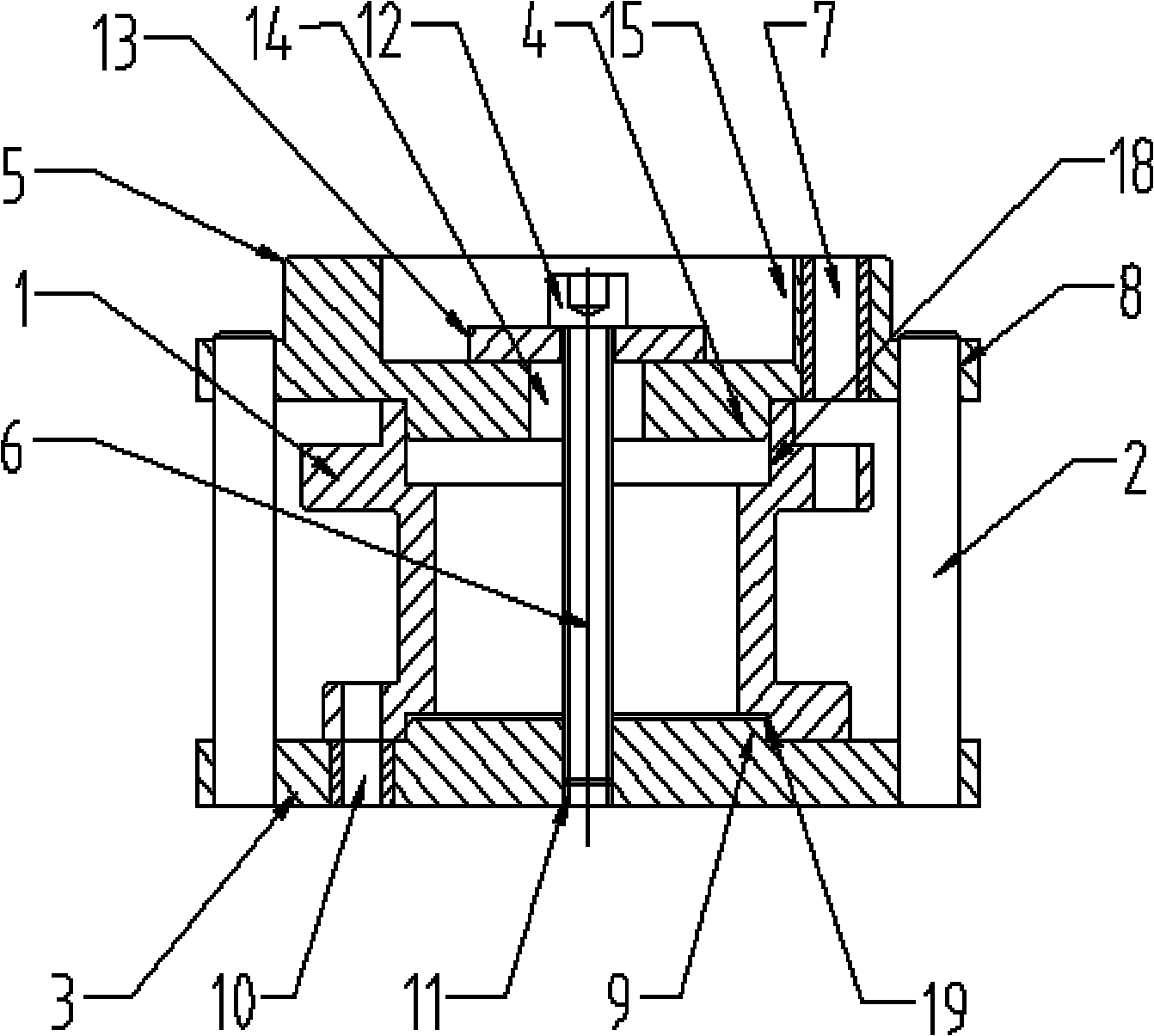

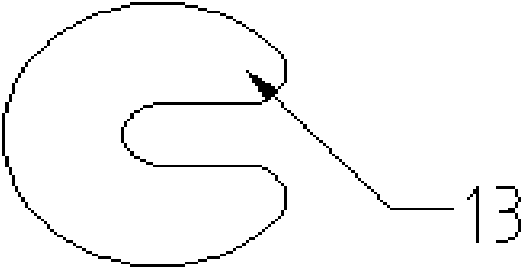

[0013] Embodiment 1: A drilling jig for the connection cover of the reducer, see the attached figure 1 And attached figure 2 , including the reducer connection cover 1, the bottom surface of the reducer connection cover 1 is provided with a lower formwork 3, and the lower formwork 3 is provided with a positioning boss 9, a guide hole 10, a threaded hole 11 and a guide post 2 perpendicular to the lower formwork 3, The center of the reducer connection cover 1 is provided with a clamping device 6, the clamping device 6 is composed of a hexagon socket head cap screw 12 and an opening gasket 13, an upper template 5 is provided on the reducer connection cover 1, and a positioning plate 5 is provided on the upper template 5. The boss 4, the guide hole 7 and the guide post hole 8, the upper template 5 is slidably connected with the guide post 2 through the guide post hole 8, and the upper surface of the upper template 5 is provided with a through hole 14 and The counterbore 15 that ...

Embodiment 2

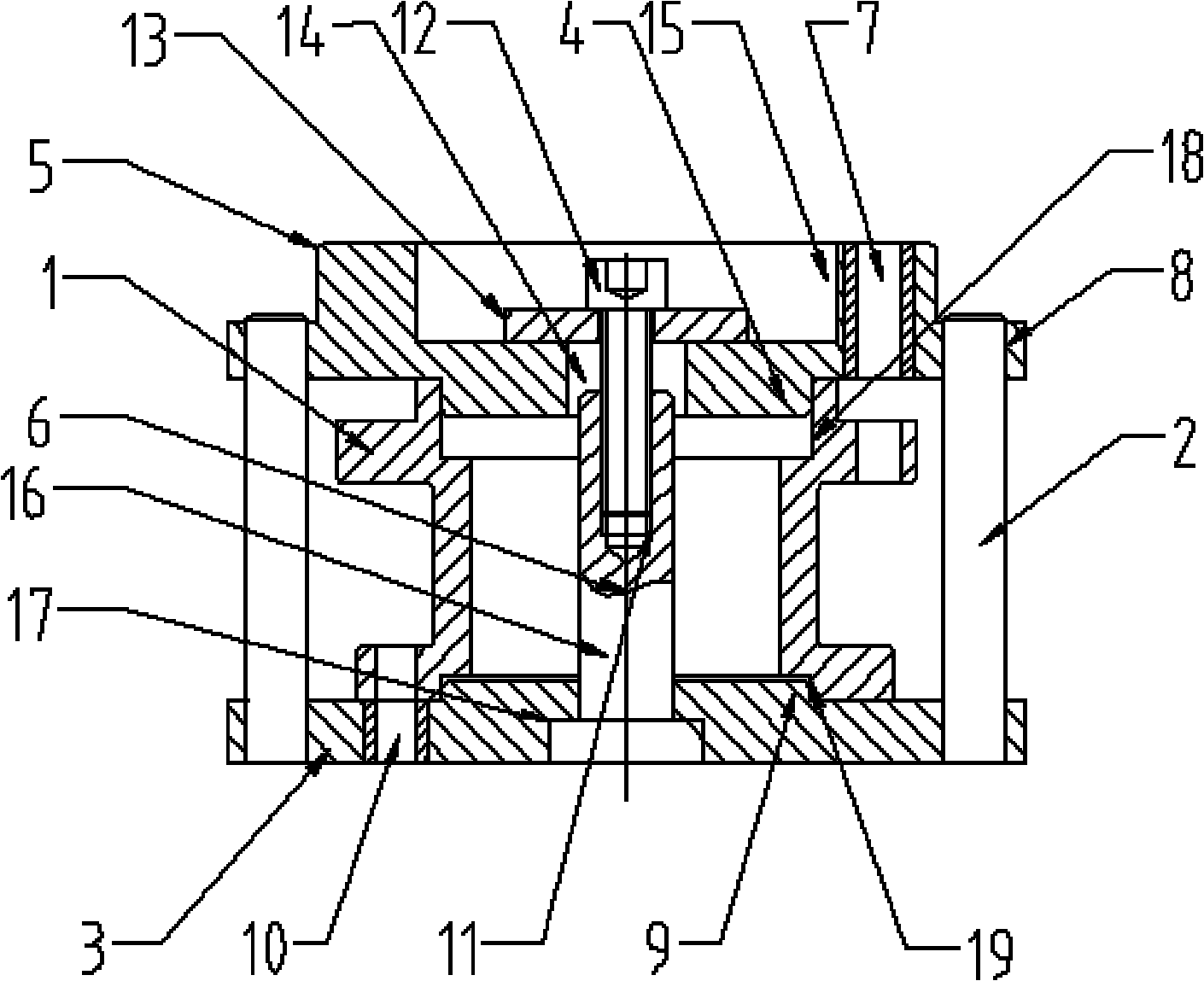

[0015] Embodiment 2: Another gear reducer connection cover drilling jig, as attached image 3 As shown, the lower template 3 is provided with a stepped hole 17, and the lower template 3 is provided with a column 16 of a stepped shaft, the column 16 and the stepped hole 17 are interference fit, and the threaded hole 11 is located at the top of the column 16, and the remaining structures and processing methods are the same as Example 1 is the same.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com