Acid-free descaling system capable of obtaining excellent surface appearance and descaling method

A technology for surface morphology, acid-free descaling, applied in workpiece surface treatment equipment, metal processing equipment, metal rolling, etc. To achieve the effect of excellent oil storage and lubrication performance, excellent oil storage and lubrication performance, and low surface roughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] This embodiment takes the continuous descaling of 510L hot-rolled beam steel coils with a thickness of 6mm and a width of 1500mm as an example. Excellent processing and forming performance, no quality defects such as roughening on the surface during stamping or roll forming; on the other hand, it also needs to have better coating performance. Corrosion ability. The surface roughness of the descaled rolls produced only by the jet descaling process is likely to be too high, which not only easily leads to damage to the roughening of the workpiece and the mold during forming, but also makes the appearance quality of the painted film poor and the corrosion resistance not to standard.

[0041] This embodiment will take the following method, including the following steps:

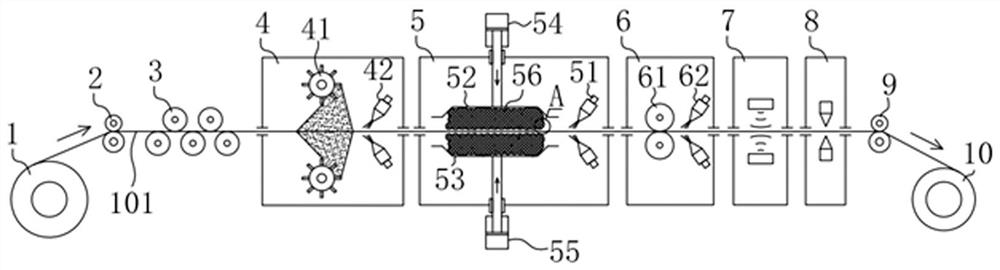

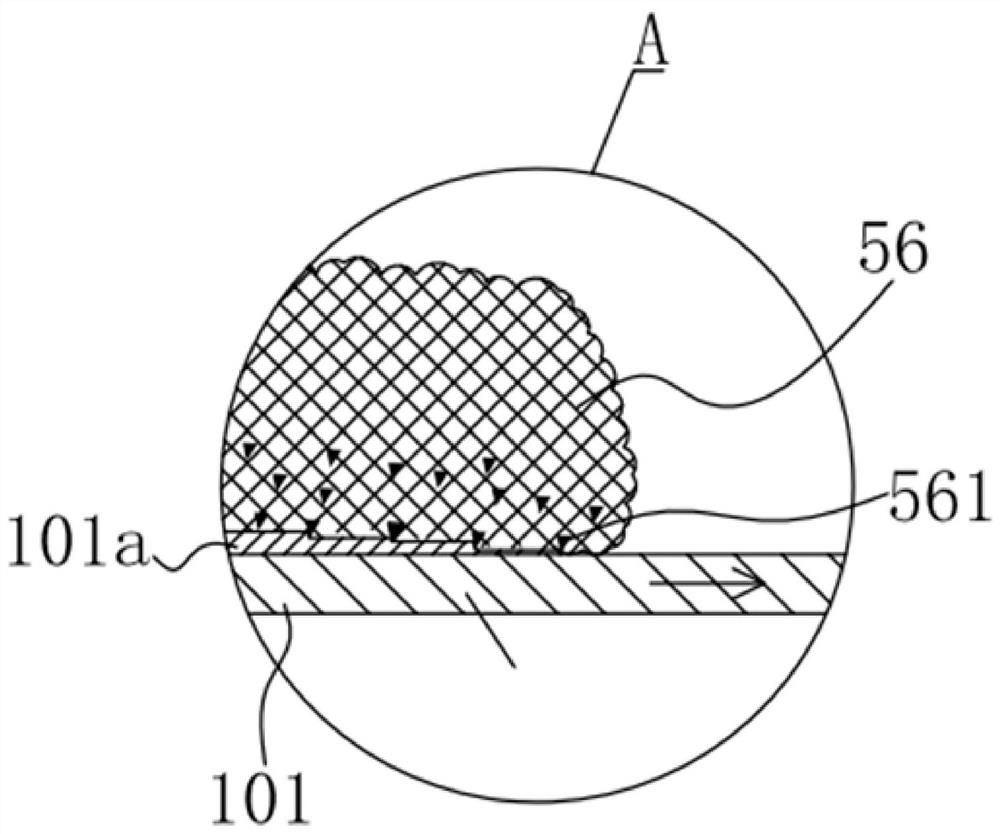

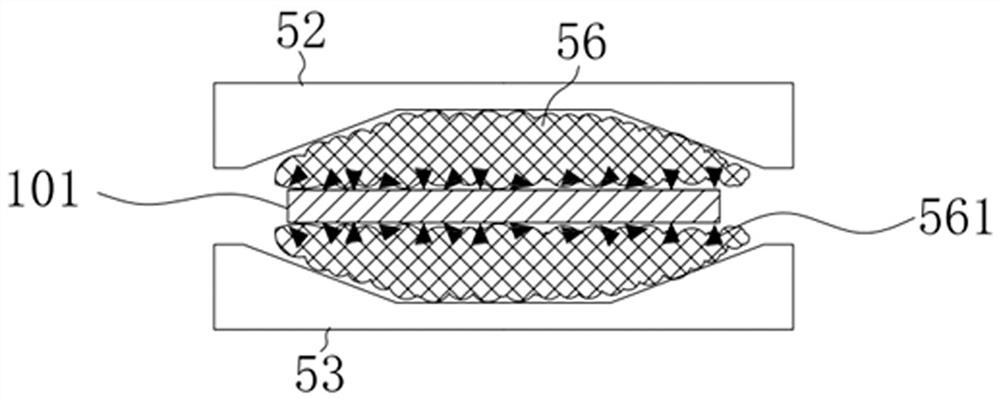

[0042] S1: After the hot-rolled steel plate is uncoiled by the uncoiler 1, it is sent to the straightening machine 3 by the first pinch diverting roller 2. After the hot-rolled steel plate is strongly str...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com