Digital control machine with magnetic suspension track girder

A technology of CNC machine tools and track beams, applied in the direction of motor vehicles, metal processing machinery parts, sliding/floating railway systems, etc., to achieve the effect of smooth control and high-precision positioning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

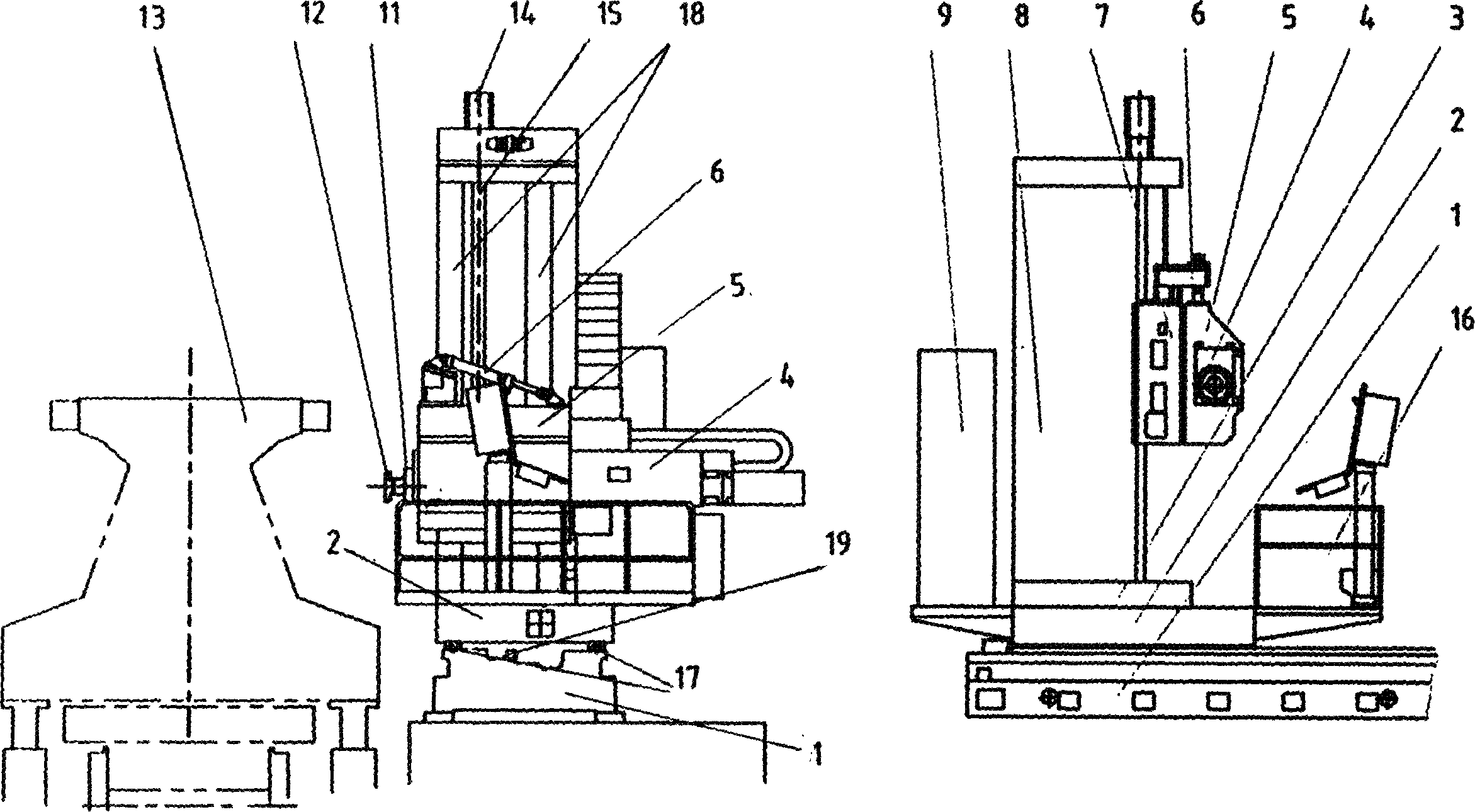

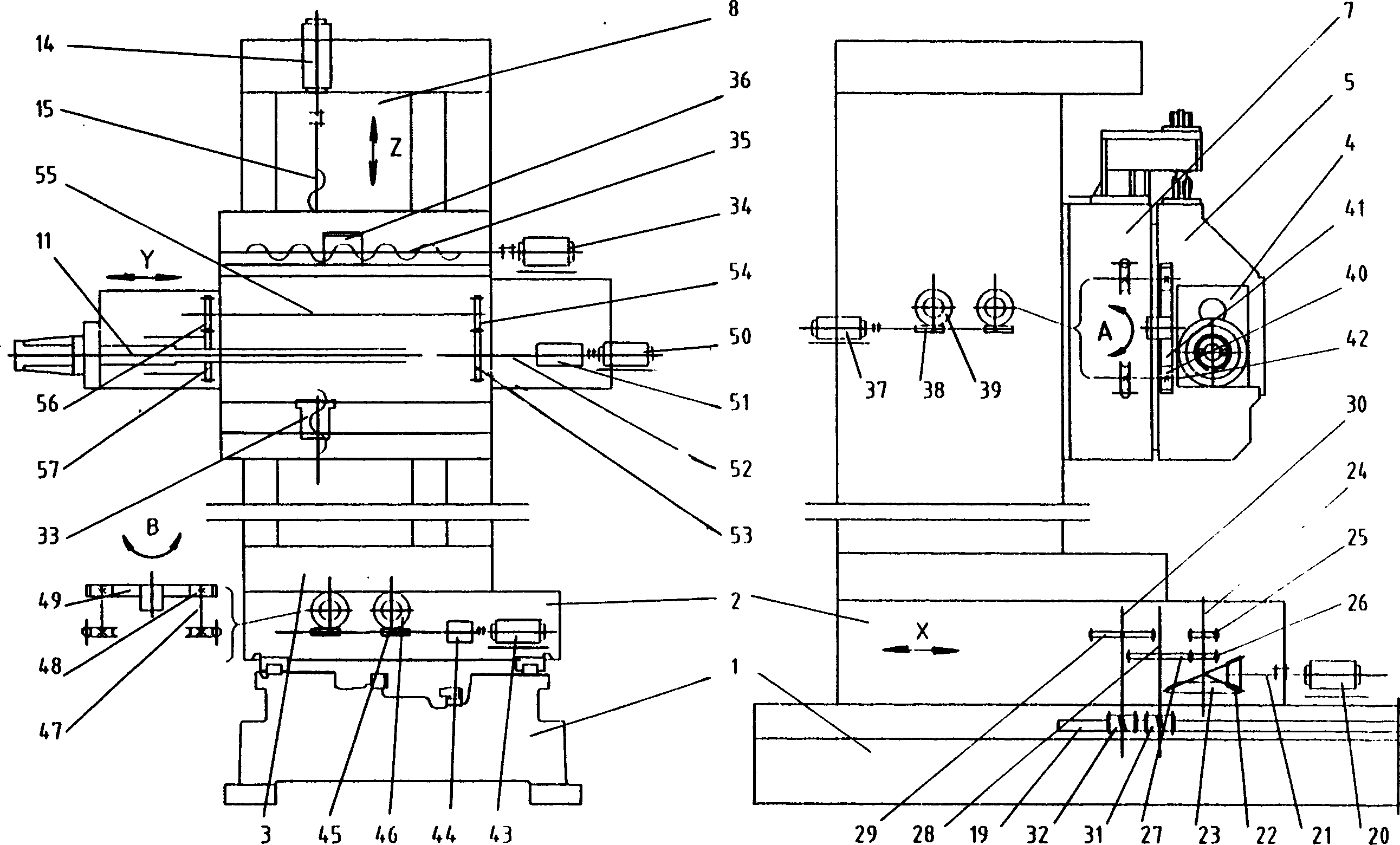

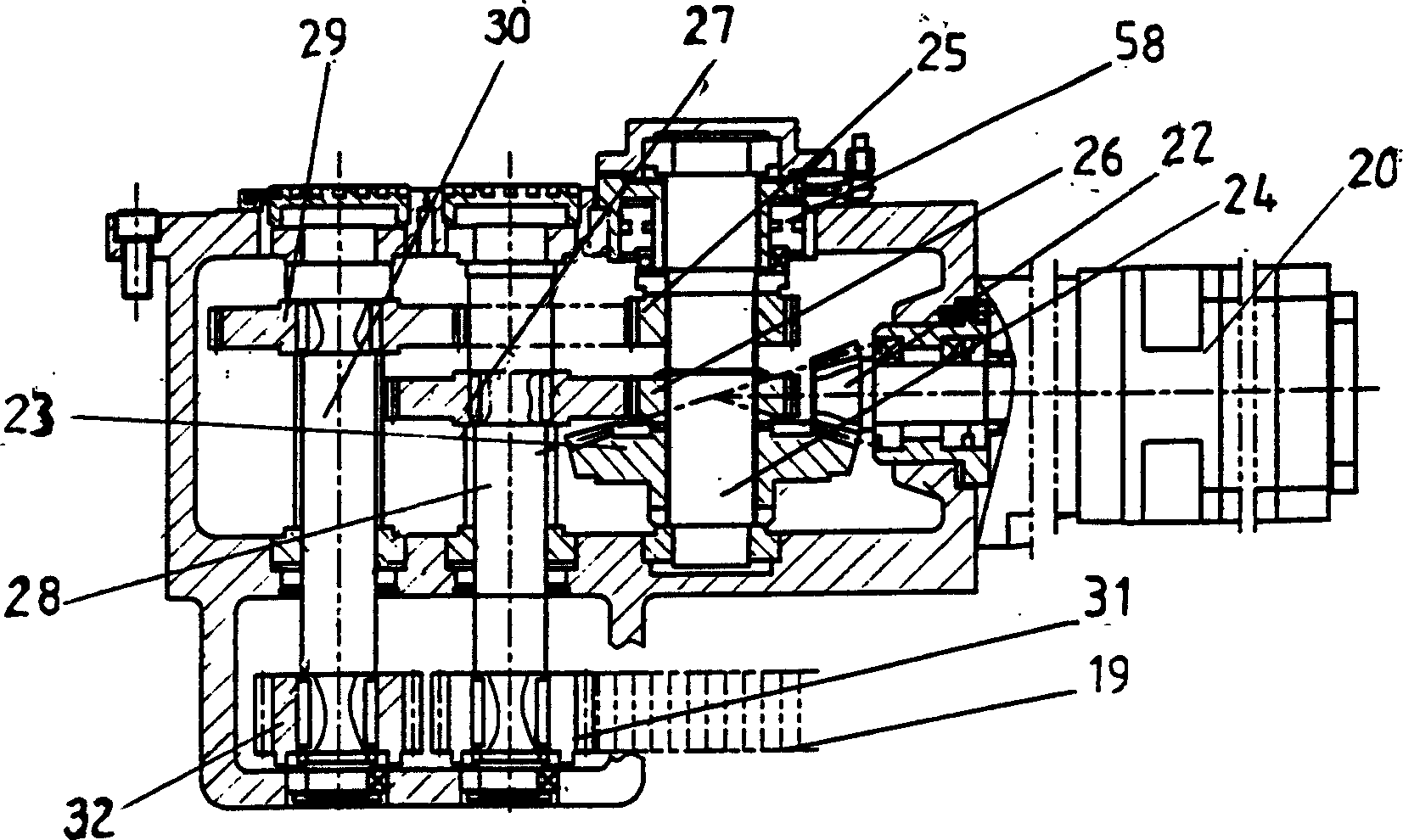

[0017] See first figure 1 . As can be seen from the figure, the magnetic suspension track beam CNC machine tool of the present invention includes a bed 1, a column 8, a spindle box 5, a ram 4, a main shaft 11, a control system 9, and an operation station 16. It is characterized in that the bed 1 is 36 meters long, The upper full length of the bed 1 is provided with two linear rolling guide rails 17, and a row of precision racks 19 is fixed on the full length of the inner side of the bed 1. A column slide 2 is arranged on the linear rolling guide rail 17 of the bed 1, which can move along the entire length of the guide rail 17 through the transmission of the rack 19, forming the X-axis. The column slider 2 is equipped with an X-axis anti-backlash transmission mechanism and a B-axis rotary mechanism; a column swivel seat 3 is arranged on the column slider 2, and the B-axis rotary mechanism can rotate relative to the column slider 2 in a horizontal plane, forming a B shaft; Col...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com