Manufacturing method for bottom die of drill bit with composite synneutic diamond plate

A technology of composite drill bits and polycrystalline diamond, which is applied in the field of manufacturing polycrystalline diamond composite drill bit bottom molds, can solve the problems of high manufacturing cost, low mold precision, and large manual modeling errors, and achieve convenient parameter adjustment, The effect of reducing labor intensity and reducing human error

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example

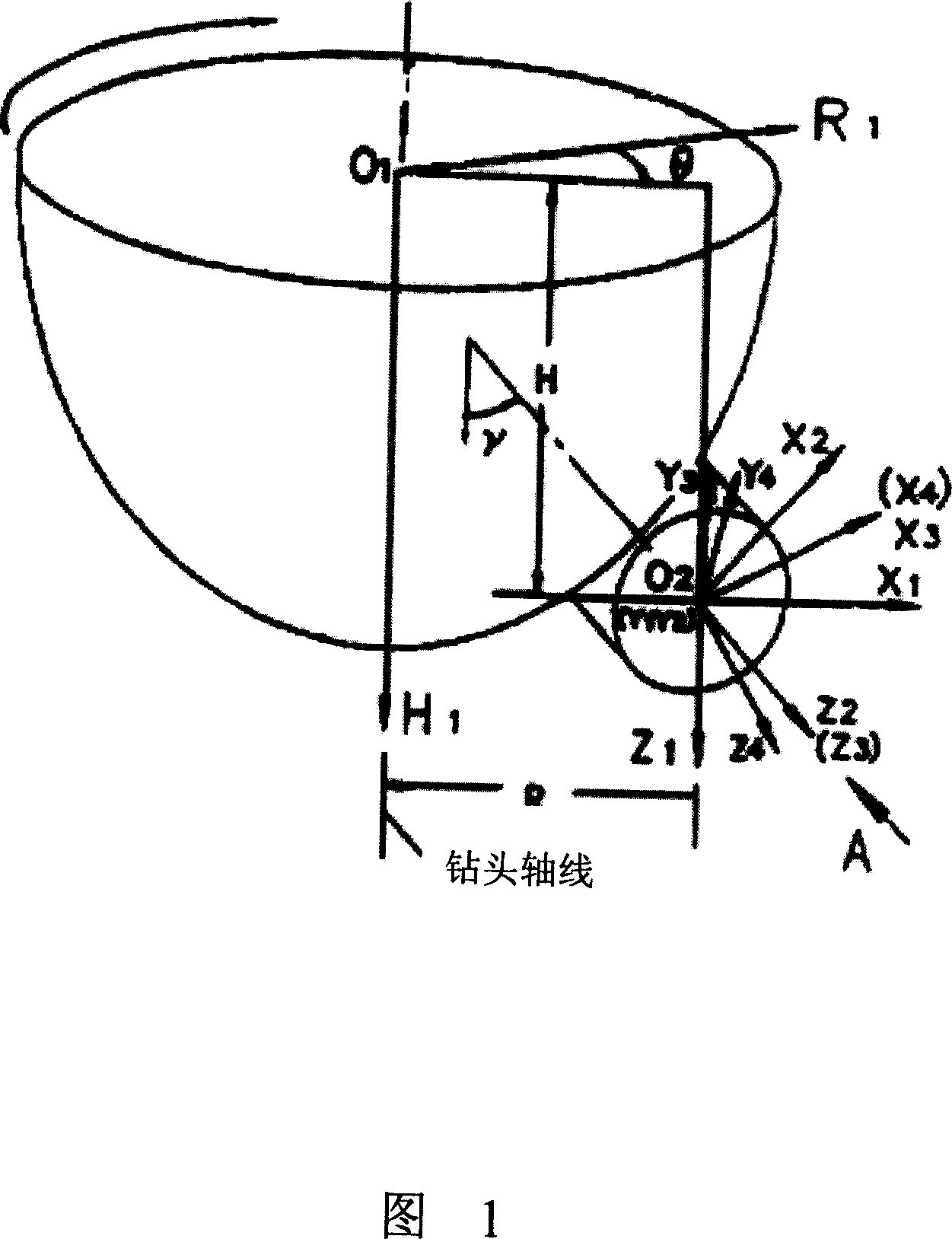

[0023] (1) Decompose the physical characteristics of the bottom mold of the polycrystalline diamond compact drill bit, and decompose it into the graphite blank of the bottom mold, the crown of the polycrystalline diamond compact drill bit, the position positioning of a single cutting tooth, and the position positioning combination of all cutting teeth of a single blade , the shape of the tooth socket, and the shape of the flute are six main features.

[0024] (2) Use the Pro / E software with feature modeling function to establish the graphite blank feature of the bottom mold of the drill bit bottom mold, that is, use the Pro / E software to select the function of creating-entity-adding material-stretching under the feature option, Draw a circle according to the size of the blank, input the stretching distance after confirmation, and create a part drawing, so as to obtain the characteristics of the bottom mold blank.

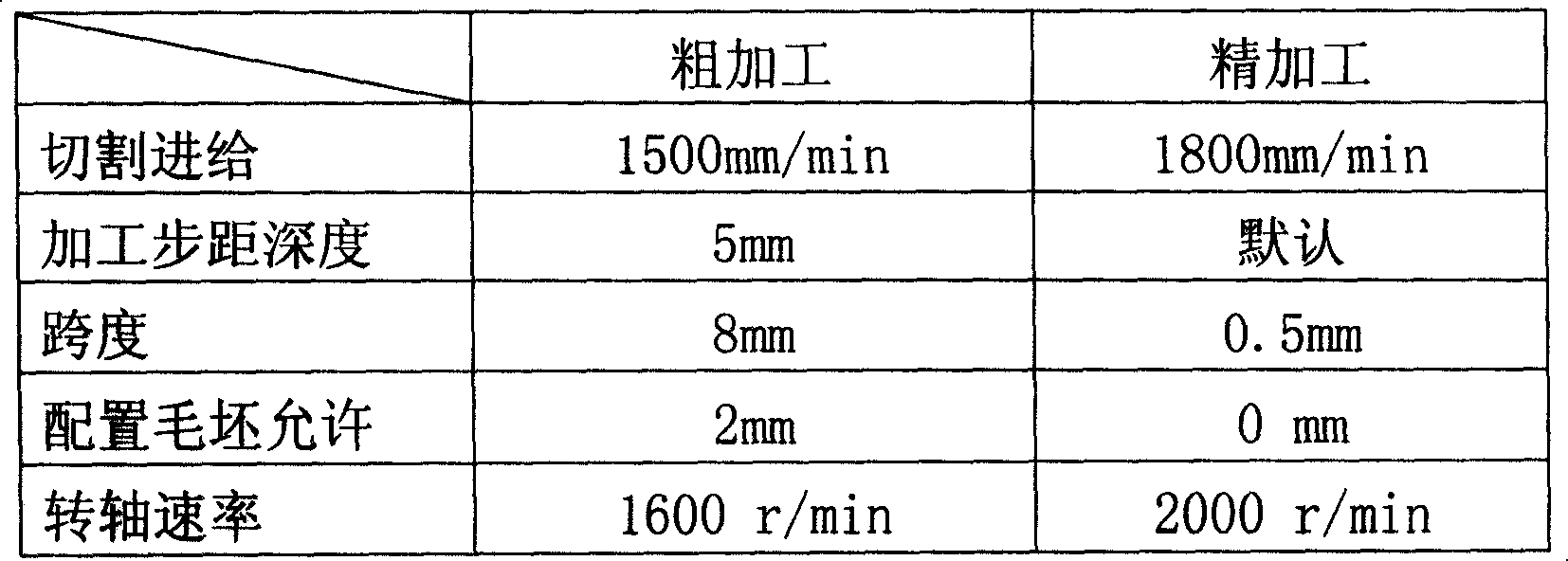

[0025] (3) Use the Pro / E software with feature modeling functi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com