Hygienic product raw material fixed-point application and absorber forming device and technology

A technology for hygiene products and molding devices, which can be used in absorbent pads, applications, clothing, etc. It can solve the problems that polymers cannot be sprayed in time and accurately, and achieve the effects of reducing production costs, improving performance, and reducing dosage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

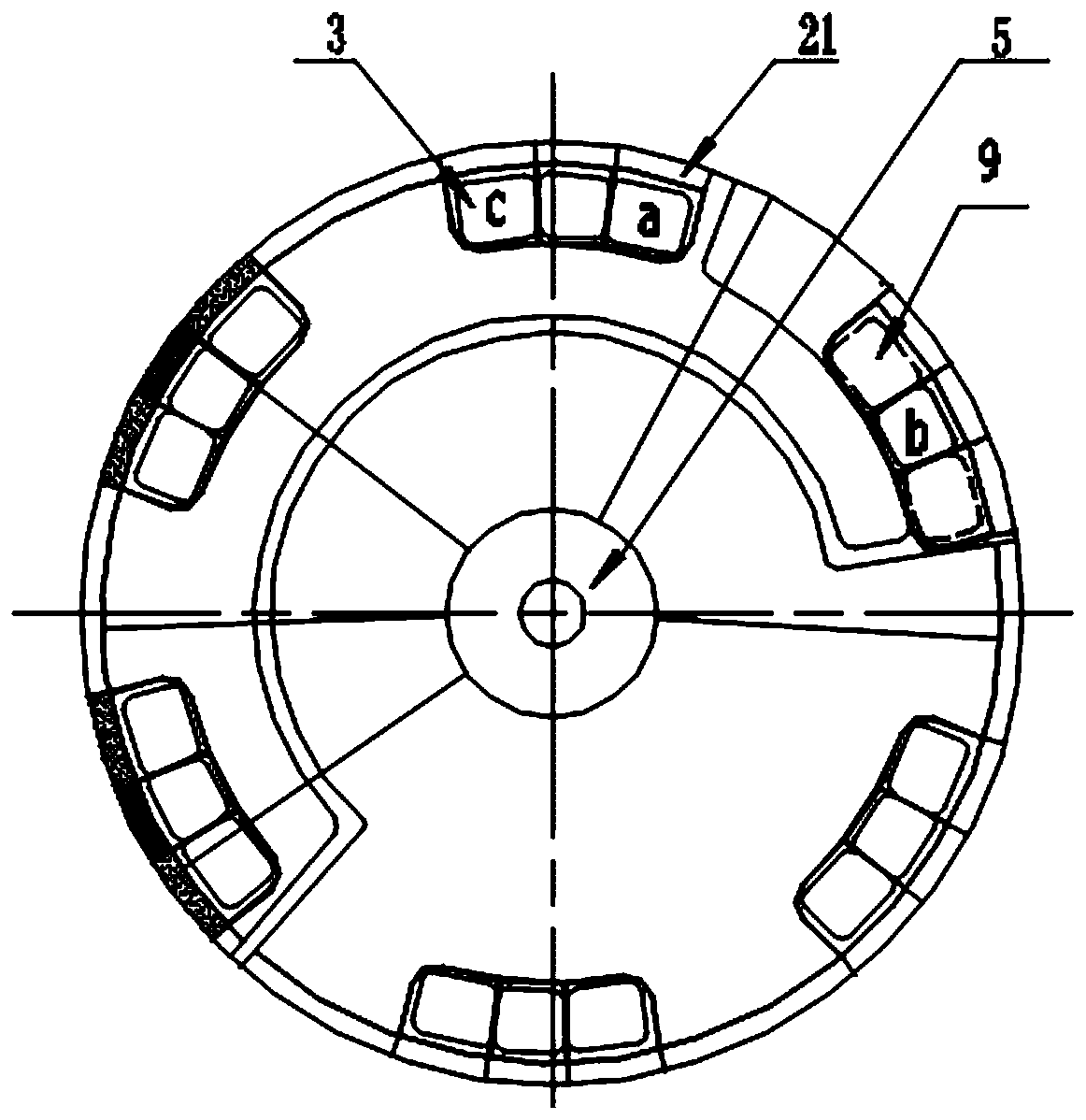

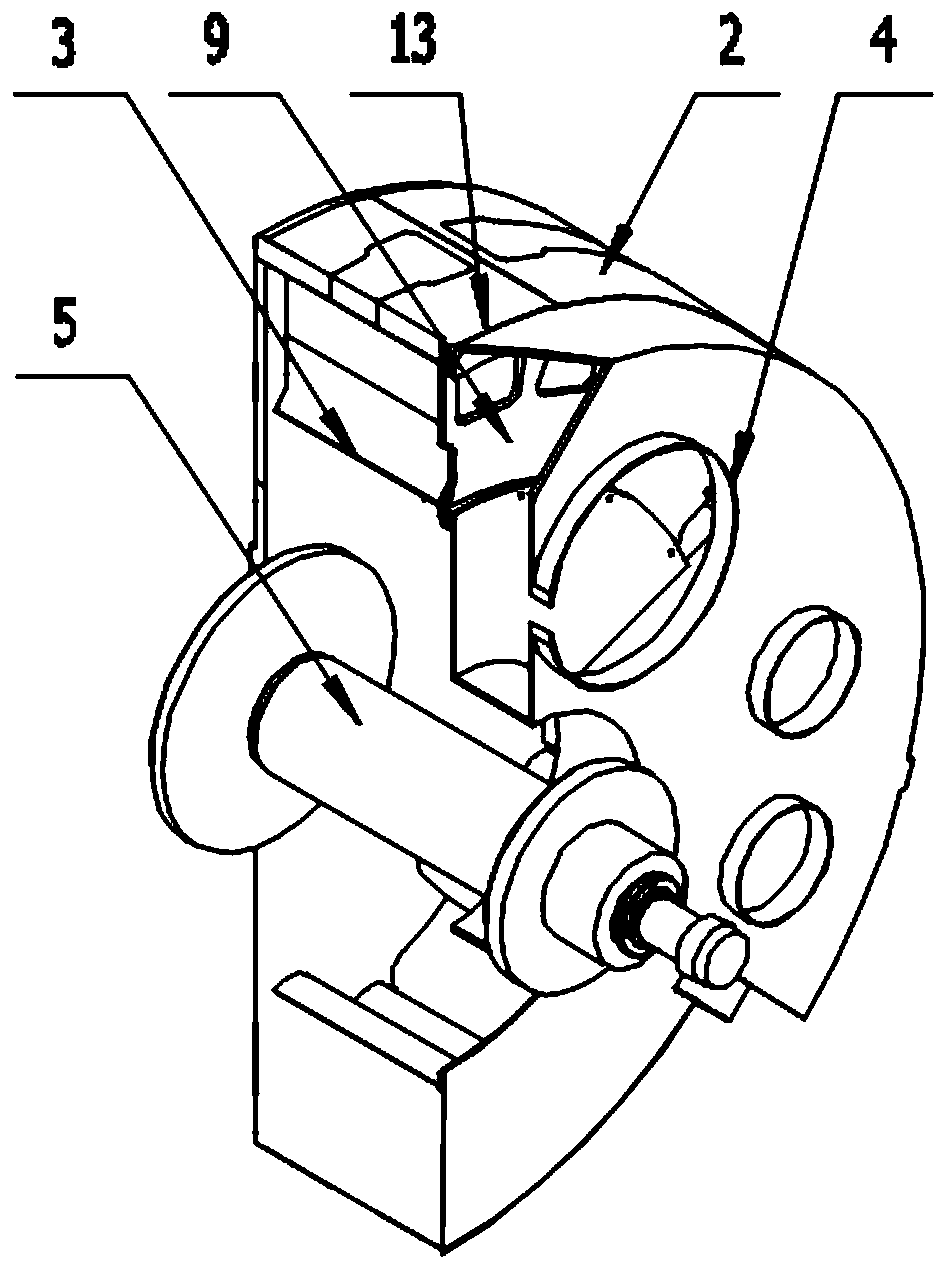

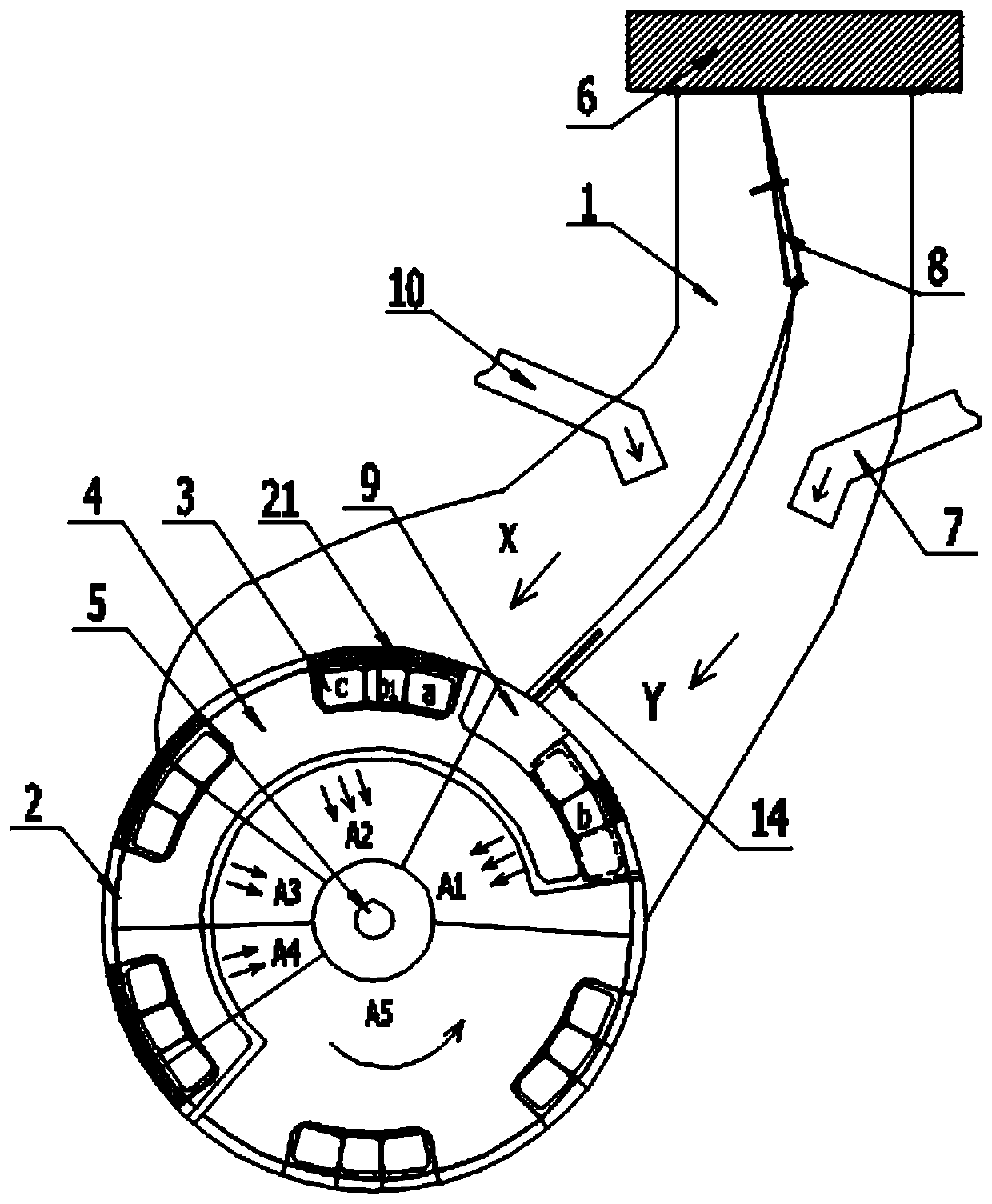

[0052] Such as image 3 As shown, the wood pulp fluff pulp application device 6, the first macromolecule application device 7 and the second macromolecule application device 10 are set on the described pile bin 1, and the wood pulp fluff pulp application device 6 can be composed of one or more The wood pulp fluff pulp application device is composed of each application device can work independently.

[0053] Such as image 3 As shown, the velvet collection bin 1 can be composed of one or more velvet collection bins. When multiple fleece collection bins are set, each fleece collection bin can independently transport wood pulp fluff pulp (or wood pulp fluff pulp and polymer materials) as required. When the fleece collection bin 1 is an independent bin body, an adjustment partition 8 is set in the fleece collection bin 1 to separate the fleece collection bin 1 into two channels X and Y, and a part is used to transport wood pulp fluff pulp and polymers to Forming the membrane as...

Embodiment 2

[0059] Wood pulp fluff pulp application device 6, the first macromolecule application device 7, the second macromolecule application device 10 and the third macromolecule application device 11 are set on the cashmere collection bin 1, and the wood pulp fluff pulp application device 6 can be composed of one or It is composed of multiple wood pulp fluff pulp application devices, and each application device can work independently.

[0060] Such as Figure 4 When the velvet collection bin 1 is an independent bin body, the first adjustment partition 8 and the second adjustment partition 12 are arranged in the velvet collection bin 1 to separate the velvet collection bin 1 into X, Y, and Z channels, Each channel can independently convey wood pulp fluff pulp and macromolecules. A first flashboard 14 and a second flashboard 15 are arranged between the fleece bins 1. By adjusting the position of the first flashboard 14 and the second flashboard 15 position, so that there is a little g...

Embodiment 3

[0066] Such as Figure 5 As shown, the wood pulp fluff pulp application device 6, the first macromolecule application device 7 and the second macromolecule application device 10 are set on the described pile bin 1, and the wood pulp fluff pulp application device 6 can be composed of one or more The wood pulp fluff pulp application device is composed of each application device can work independently.

[0067] Such as Figure 5 As shown, the velvet collection bin 1 can be composed of one or more velvet collection bins. When multiple fleece collection bins are set, each fleece collection bin can independently transport wood pulp fluff pulp (or wood pulp fluff pulp and polymer materials) as required. When the fleece collection bin 1 is an independent bin body, an adjustment partition 8 is set in the fleece collection bin 1 to separate the fleece collection bin 1 into two channels X and Y, and a part is used to transport wood pulp fluff pulp and polymers to Form the membrane ass...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com