Connected node of horizontal member and foundation of thin steel-plate shear wall

A technology of horizontal components and connecting nodes, applied in the direction of building structure, construction, etc., can solve problems such as the inability to effectively balance the tension field, and achieve the effect of improving gripping ability, good pull-out resistance and large cross-section.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] The preferred embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

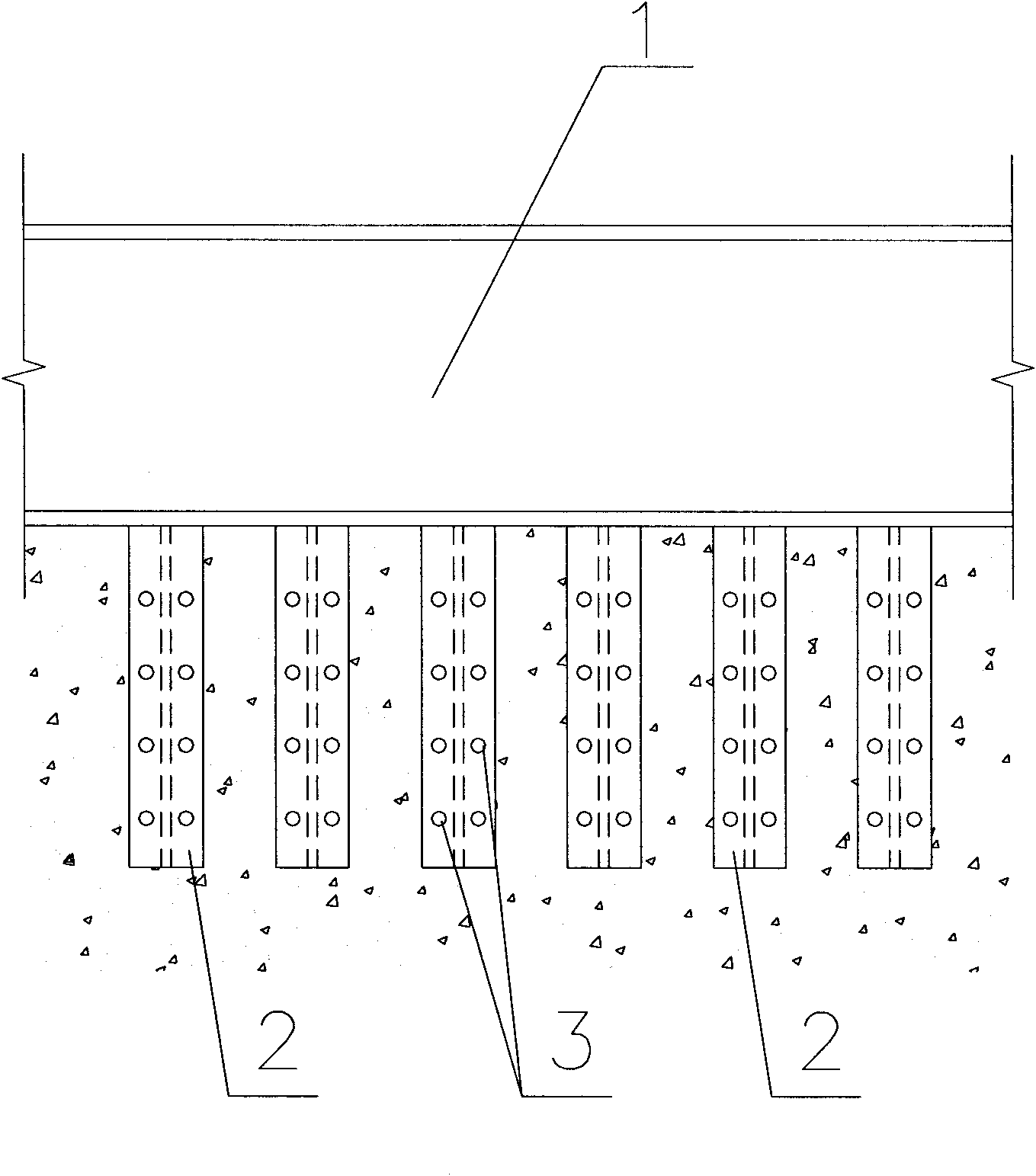

[0011] Such as figure 1 Shown: the lower side of the bottom horizontal member 1 of the thin steel plate shear wall is welded with anchors 2 arranged vertically and evenly spaced. The anchors 2 are arranged along the length centerline of the horizontal member and embedded in the foundation concrete. Shear keys 3 are respectively welded on the parallel front and rear surfaces of the horizontal member, and the shear keys are evenly spaced. The anchors shown in the figure are I-beams, and steel plates and channel steels can also be used to arrange any interface steel. The anchorage length is determined according to calculation. Through the gaps of each anchor piece, the foundation reinforcement is arranged through. The shear key 3 can adopt a stud or a truncated steel bar head, which improves the gripping ability of the anchor in concrete. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com