Prefabricated prestressed concrete hollow soil nail and its construction method

A construction method and concrete technology, which can be applied in basic structural engineering, construction, sheet pile walls, etc., can solve the problems of reducing the effect of soil on soil nails, easily disturbing the surrounding soil, and difficult to ensure the quality of soil nails. Large bearing capacity, small disturbance and good crack resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

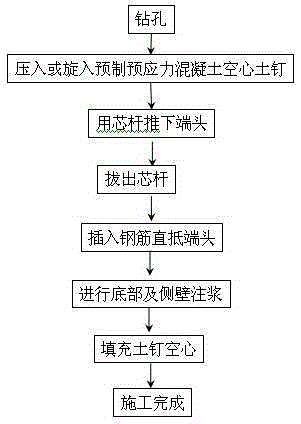

[0051] to combine Figure 1 to Figure 7 , the construction steps are introduced as follows:

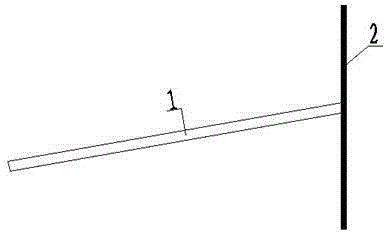

[0052] Step 1: Mechanical lead hole 1, the hole diameter is required to be no more than 60% of the diameter of the soil nail, and the angle between the soil nail hole and the horizontal angle is 10°. See the schematic diagram of the section figure 2 shown;

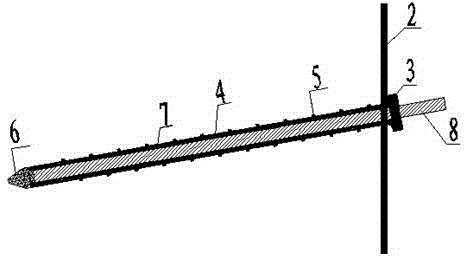

[0053] Step 2: Press the core rod 8 of the prefabricated prestressed concrete hollow soil nail into the lead hole. There are spiral blades 5 on the side wall of the soil nail. See image 3 shown;

[0054] Step 3: Use the mandrel to push the end away from the soil nail by 1.5m, then remove the mandrel, insert the steel bar 9 into the bottom of the soil nail until it reaches the end, see Figure 4 As shown, the corresponding sectional view is shown in Figure 5 shown;

[0055] Step 4: Insert the grouting pipe and perform bottom grouting. After the bottom grouting body 13 of the soil nail is formed, perform side wall grouting t...

Embodiment 2

[0060] It is basically the same as Example 1, except that the prefabricated prestressed concrete hollow soil nail has a wedge-shaped edge, and the cross-sectional schematic diagram after pushing down the end of the soil nail, pulling out the core rod, and inserting the steel bar is shown in Figure 8 shown, the corresponding section see Figure 9 As shown, the cross-sectional schematic diagram of the completed construction is shown in Figure 10 shown.

Embodiment 3

[0062] Step 1: Mechanical lead hole 1, the hole diameter is required to be no more than 60% of the diameter of the soil nail, and the angle between the soil nail hole and the horizontal angle is 10°. See the schematic diagram of the section figure 2 shown;

[0063] Step 2: Press the core rod 8 of the prefabricated prestressed concrete hollow soil nail into the lead hole. There are spiral blades 5 on the side wall of the soil nail. See image 3 shown;

[0064] Step 3: Fix the end, pull out the core rod, and carry out side grouting of soil nails. See the schematic diagram of the section Figure 11 shown.

[0065] Step 4: Use the core rod to push the end of the soil nail 1.5m away, then remove the core rod, insert the steel bar 9 into the bottom of the soil nail until it reaches the end, and perform grouting at the bottom of the soil nail. Figure 12 shown;

[0066] Step 5: After the grouting is completed, fill the hollow of the soil nail with plain concrete to form the core...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com