Thrust spring support for limiting rolling and slipping of rolling shaft

A technology of sliding limit and thrust spring, which is applied in the direction of building and building structure, etc., can solve the problems of unsafe overall structure and damage of rods in the area near the support.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] In order to better understand the technical content of the present invention, specific embodiments are given together with the attached drawings for description as follows.

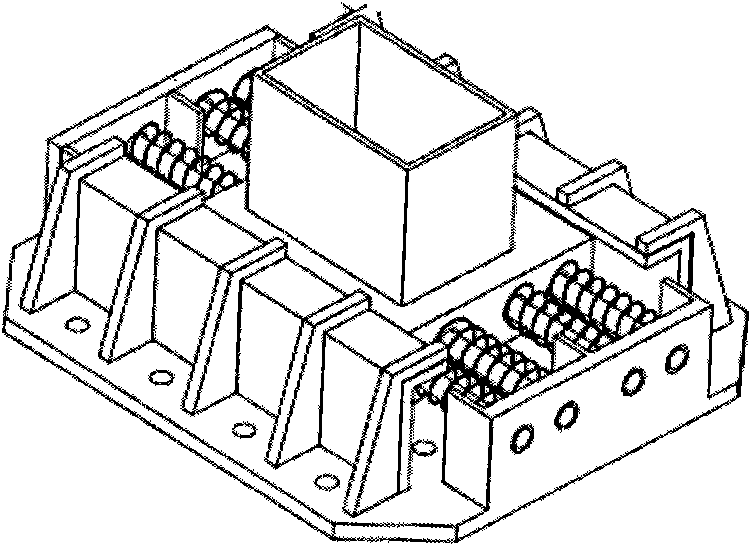

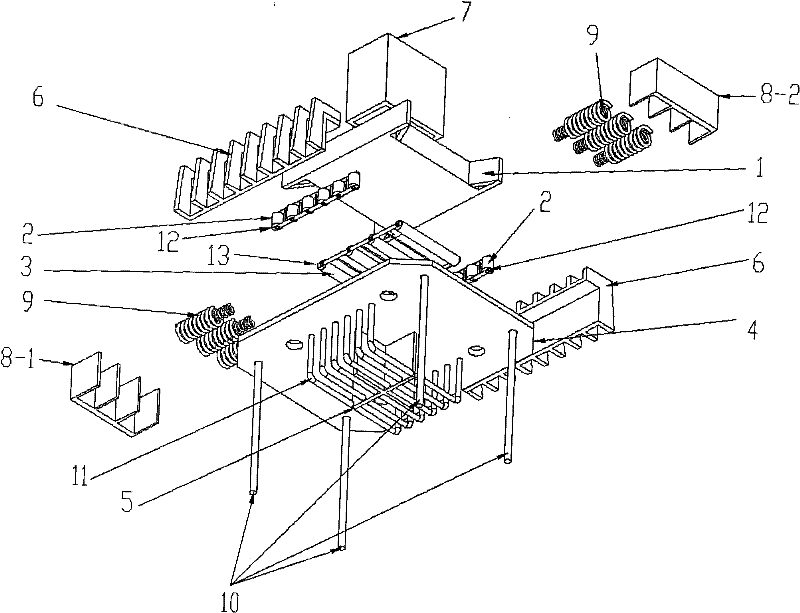

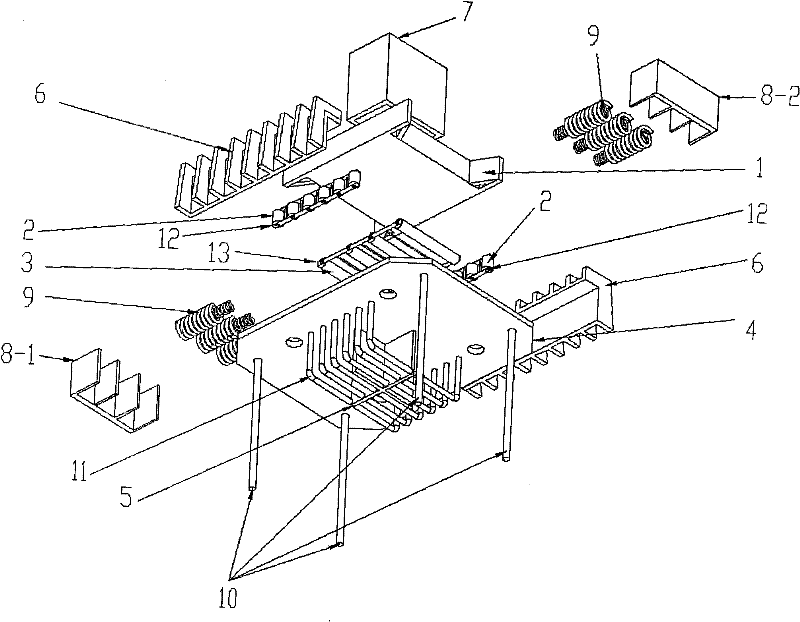

[0011] Please refer to figure 1 and figure 2 , figure 1 Shown is a schematic diagram of the structure of the roller shaft rolling slip limit thrust spring support in a preferred embodiment of the present invention, figure 2 Shown is a schematic diagram of the exploded structure of the roller shaft rolling slip limit thrust spring support in a preferred embodiment of the present invention. The present invention proposes a roller shaft rolling slip limit thrust spring support, which includes a support bottom plate 4, a support card seat 6, a short column lower box 1 and a support short column 7, and the support card seat 6 The short column lower box 1 is snapped onto the support bottom plate 4, the support short column 7 is arranged on the short column lower box 1, and the front and rear sides o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com