A kind of preparation method of composite material for flexible circuit board

A flexible circuit board, composite material technology, applied in circuit substrate materials, printed circuits, printed circuit components, etc., can solve the problems of limited application, limited dielectric performance, poor thermal performance, etc., to achieve excellent dielectric performance, achieve Design and processing requirements, the effect that is conducive to processing and application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0029] The invention provides a method for preparing a composite material for a flexible circuit board, comprising:

[0030] A) Whisker Ba 2 Ti 9 o 20 Powder, silica gel and solvent are mixed and dried to obtain a mixture;

[0031] B) compressing and crushing the mixture to obtain composite particles; ball milling and drying the composite particles to obtain powder particles;

[0032] C) Pressing and sintering the powder particles to obtain a composite material for a flexible circuit board.

[0033] Whisker: refers to a fiber that is formed naturally or grown in the form of a single crystal under artificially controlled conditions (main form), its diameter is very small (micron order), and does not contain defects (grain boundaries, dislocations) that usually exist in materials , holes, etc.), its atomic arrangement is highly ordered, so its strength is close to the theoretical value of a complete crystal.

[0034] Preparation of flexible substrate materials Mix ceramic p...

Embodiment 1

[0061] Weigh TiCl4 and KOH as mineralizers, put them in a glass beaker with distilled water, adjust the concentration of Ti ion solution to 0.1-1mol / L, and stir for 30min under a magnetic stirrer, during which the pH of the solution is controlled at 12-14; Place the obtained mixed solution in an ultrasonic wave and vibrate for 1 hour to disperse the powder evenly in the solution; place the solution after ultrasonic vibrating in a 150ml high-pressure reaction kettle, the filling rate of the solution is 50-90%, and the reaction temperature is 140- 180°C, the reaction time is 4-8h; finally, the obtained mixed solution is separated in an ion separator to obtain nano-whisker Ti0 2 .

[0062] The above obtained Ti0 2 with Ba(OH) 2 Carry out hydrothermal reaction, carry out proportioning according to molar ratio Ti:Ba is 5:1, put the obtained mixed solution in the autoclave, the solution filling ratio is 80%, hydrothermal reaction temperature is 140-200 ℃, hydrothermal The reactio...

Embodiment 2~6

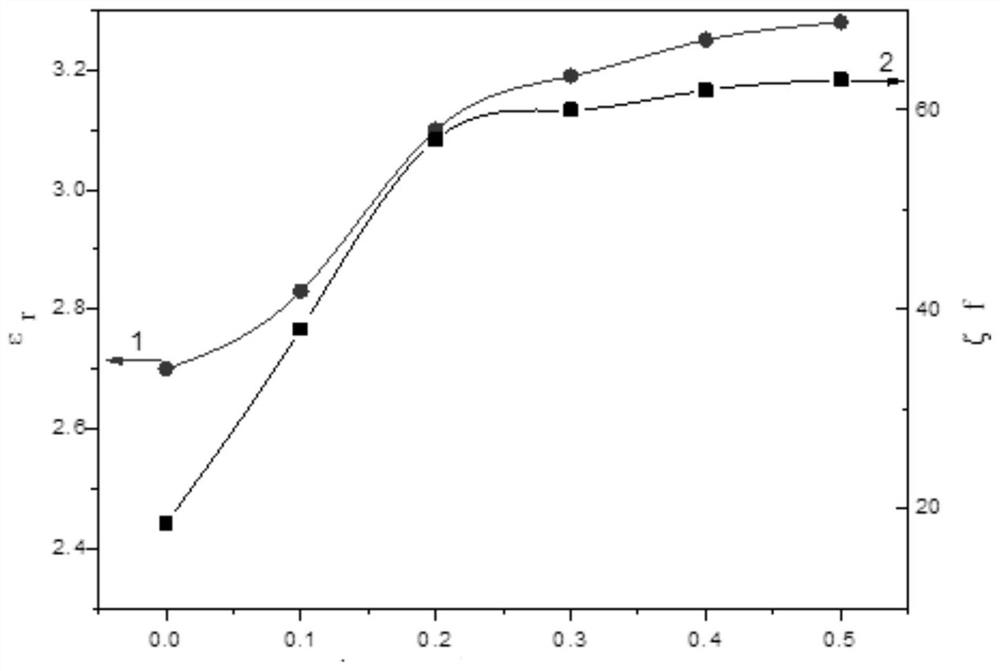

[0067] According to the method disclosed in Example 1, silica gel, whisker Ba 2 Ti 9 o 20 Powder, as embodiment 2~embodiment 6, such as figure 1 as shown, figure 1 is the relationship curve of the dielectric constant εr of the filled composite material with different whisker-like PTEF fillings, where 1 is the dielectric constant curve, and 2 is the resonant frequency temperature coefficient curve, from figure 1 It can be shown that with the increase of the amount of PTEF added, Ba 2 Ti 9 o 20The dielectric constant of ceramics increases continuously. With the addition of PTEF, it increases from 0 to 0.5, the εr of the composite material increases to 3.28, and the temperature coefficient of resonant frequency increases to 62ppm / ℃, indicating that compared with particles, whiskers can further improve the composite material. The dielectric properties of the material. At the same time, after PTEF is combined with the whisker material, in the two-phase system, the overlap bet...

PUM

| Property | Measurement | Unit |

|---|---|---|

| resonant frequency temperature coefficient | aaaaa | aaaaa |

| dielectric properties | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com