Machining method for small NdFeB magnetic ring with high verticality requirement

A NdFeB, verticality technology, used in metal processing equipment, manufacturing tools, parts of grinding machine tools, etc., can solve the problem of large cylindricity tolerance, difficult motor stable operation, and adverse effects of drilling positioning accuracy, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

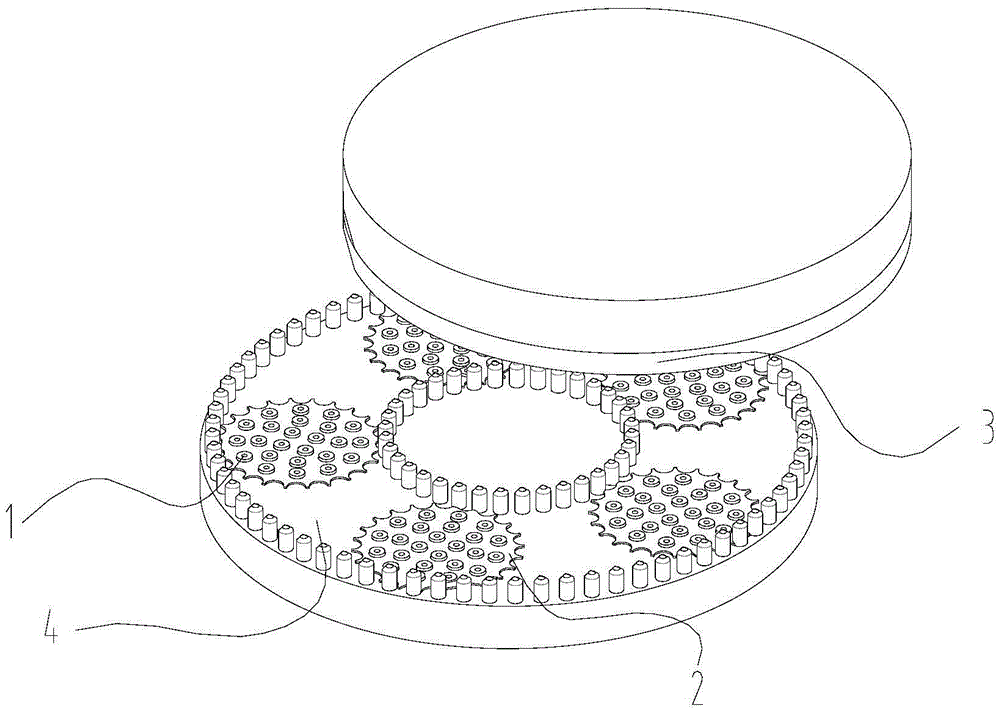

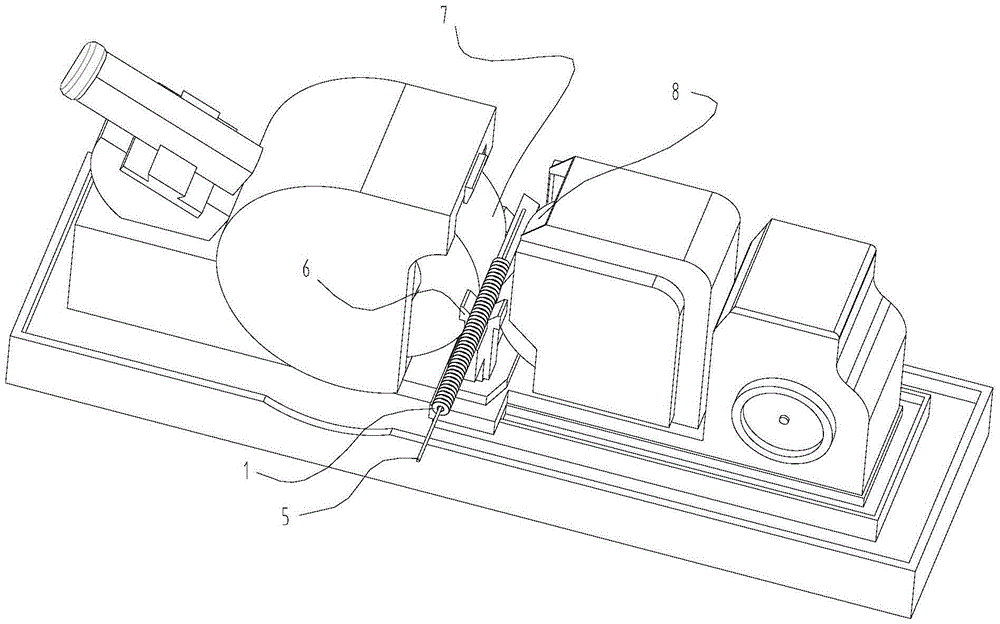

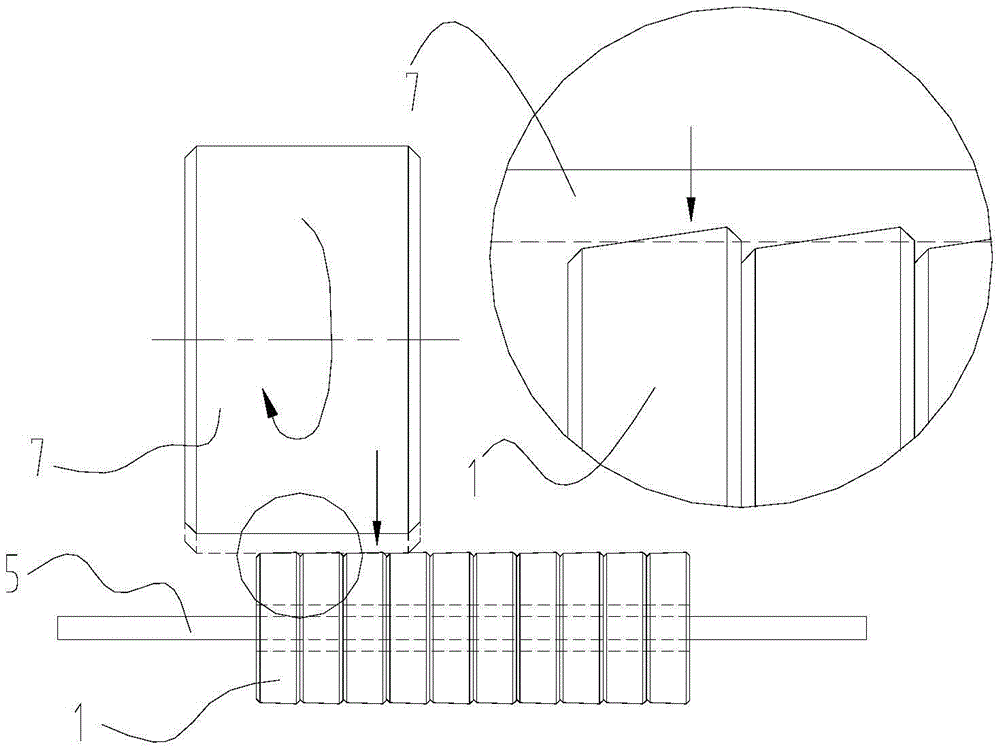

[0029] Example: such as Figure 1-Figure 5 As shown, a processing method for small NdFeB magnetic rings with high verticality requirements, the outer diameter of the small NdFeB magnetic ring 1 is recorded as D, the inner diameter is recorded as d, and the thickness is recorded as H. NdFeB small The upper tolerance of the inner diameter of the magnetic ring 1 is marked as a, and the lower tolerance of the inner diameter of the NdFeB small magnetic ring 1 is marked as b, including the following steps:

[0030] ① Grinding the small magnetic column by centerless grinding → drilling the inner hole → cutting the thickness step to prepare the semi-finished NdFeB small magnetic ring. The outer diameter of the NdFeB small magnetic ring semi-finished product is recorded as D1, and the inner diameter is recorded as d1 , the thickness is recorded as H1, where D1=D+0.1mm, d1=d-0.1mm, H1=H+0.05mm;

[0031] ② Use the high-precision double-sided grinding machine model YM-380WL produced by S...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com