Bamboo cutting board processing technology

A processing technology and cutting board technology, which is applied in the field of bamboo cutting board drilling assembly processing technology, can solve unsatisfactory problems, achieve high product stability, reduce labor intensity, and ensure the effect of factory environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

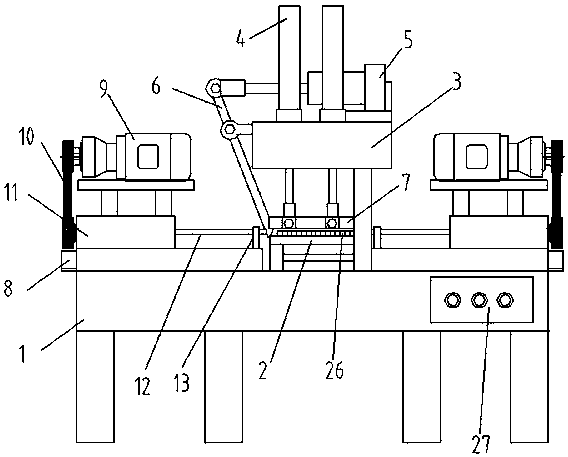

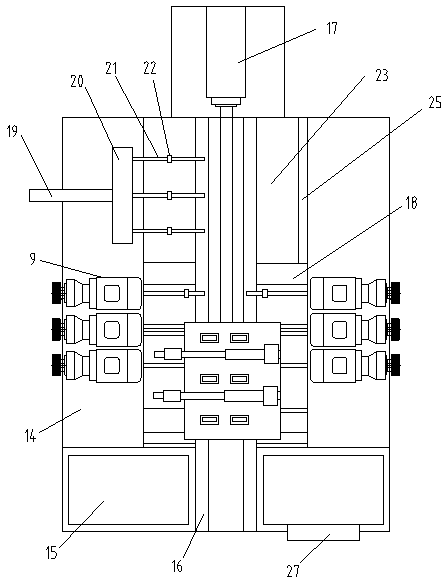

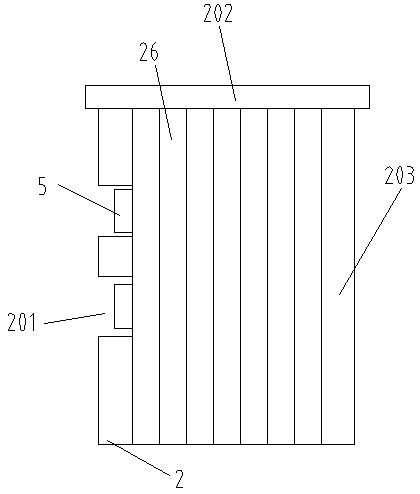

[0033] Example 1, see figure 1 —— Figure 5 , bamboo cutting board processing equipment, including frame platform 1, a bamboo strip positioning mechanism for positioning bamboo strips, a drilling device for drilling after bamboo strips are positioned, and a chip blowing device for blowing chips after bamboo strips are drilled, The middle of the frame platform 1 slides back and forth through the first driving device to be provided with a bamboo strip press-fitting workbench 2, and the position near the front end of the bamboo strip press-fit workbench 2 is provided with a bamboo strip positioning mechanism, so that the bamboo strip press-fit workbench 2 And the bamboo bar positioning mechanism can realize forward and backward movement, and the two sides of the rack platform 1 are respectively provided with side worktables 14 by sliding left and right through the second drive device, and several sets of drilling devices are respectively provided in the front and rear directions ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com