Method for manufacturing nanometer paster

A manufacturing method and nanotechnology, applied in nanotechnology, nanotechnology, photoengraving process of patterned surface, etc., can solve the problem of unable to meet the needs of the industry, unable to meet the needs of mass production and low cost, unable to meet the needs of mass production, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] In order to explain the features of the present invention in detail, the following three preferred embodiments are illustrated in conjunction with the accompanying drawings as follows:

[0035] See Figure 1 to Figure 5 , The manufacturing method of nano sticker provided by the first preferred embodiment of the present invention includes the following steps:

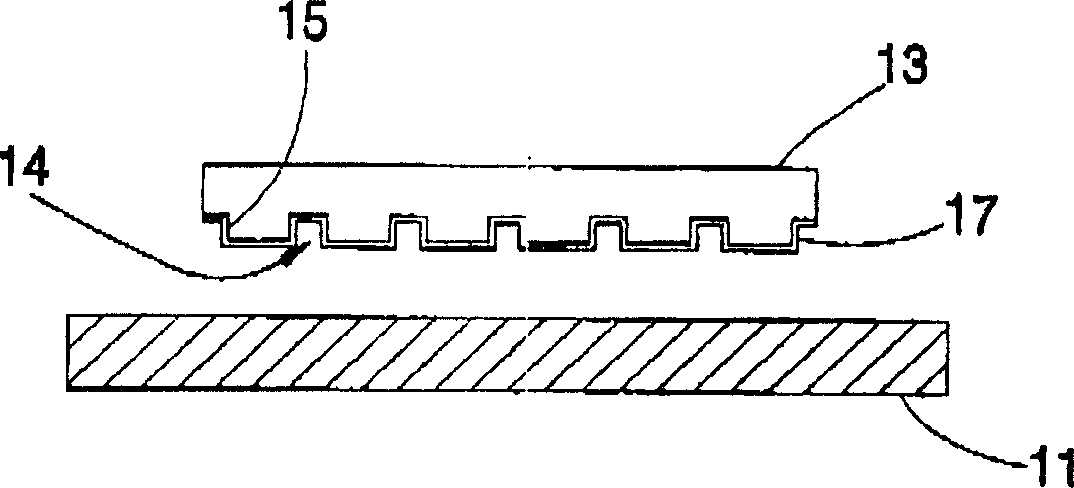

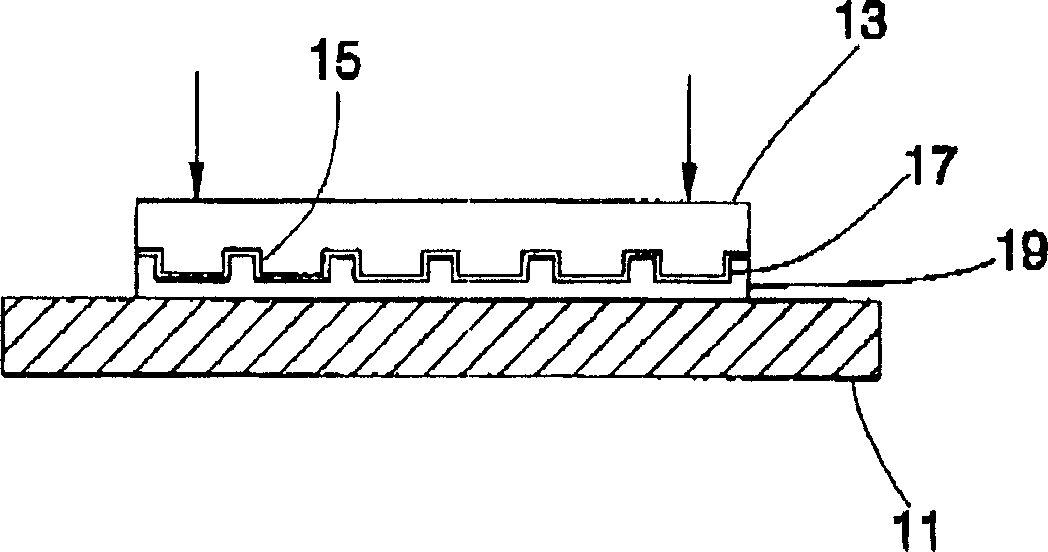

[0036] a) In a vacuum environment, a substrate 11 and a mold 13 are prepared. The mold 13 is in the shape of a transparent plate and is located above the substrate 11, and the bottom of the mold 13 has a pressing surface 14 on the surface of the pressing surface 14 Nano-embossing 15, with a layer of release agent 17 on the surface of the nano-embossing 15, in a state as figure 1 Shown

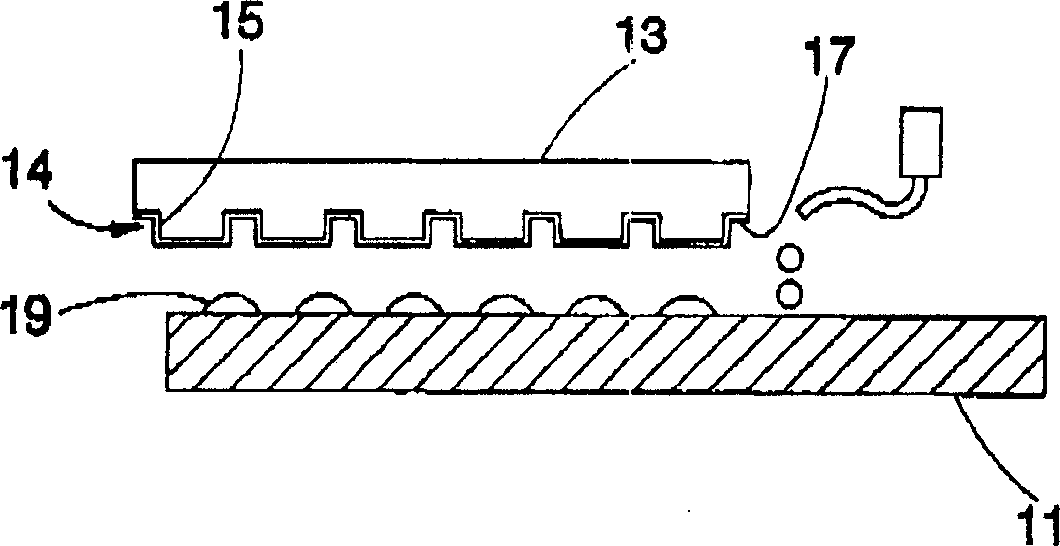

[0037] b) A liquid imprinting layer 19 is placed on the substrate 11. In this embodiment, it is a polymer. The imprinting layer 19 can be cured after being irradiated by ultraviolet light, and its state is as figure 2 As shown in the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com