Dynamic alloy bar straightening mechanism, system and method, and dynamic alloy bar automatic straightening method

A technology of alloy bar and straightening mechanism, which is applied in the direction of metal processing equipment, forming tools, manufacturing tools, etc., can solve the problems of high strength of metal materials, increase of equipment tonnage, large tensile force, etc., and meet the requirements of precision and operation Convenient and meet the effect of mass production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

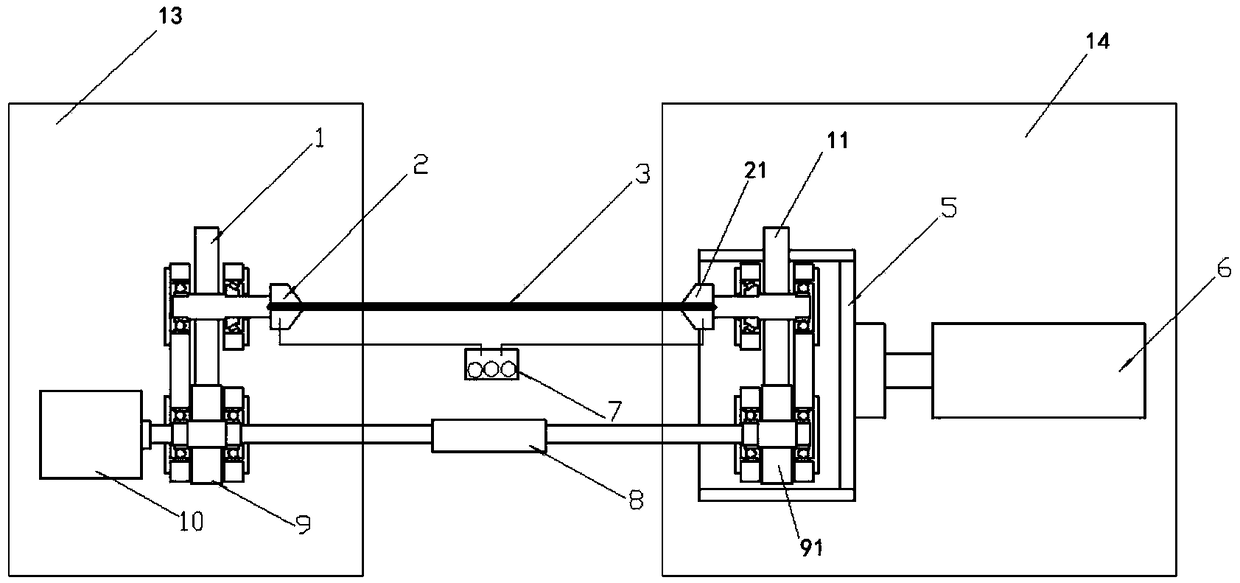

[0043] like figure 1 As shown, in this embodiment, a dynamic alloy bar straightening system includes the dynamic alloy bar straightening mechanism, the first rotating chuck 2 and the first large gear 1 are fixed on the fixed base 13 through bearings Above, the deceleration motor 10 is fixed on the fixed base 13, the first pinion 9 is fixed on the fixed base 13 through bearings; the second rotary chuck 21 and the second large gear 11 are fixed on the sliding seat 5 through bearings, and the second small The gear 91 is fixed on the sliding seat 5 through a bearing, and the sliding seat 5 is slidably connected to the stretching base 14 ; the hydraulic device 6 is fixed on the stretching base 14 .

[0044] When the system of this embodiment is in use, it includes the following steps:

[0045] S1: Fix the alloy bar on the first rotary chuck 2 and the second rotary chuck 21;

[0046]S2: The user adjusts the current according to the alloy grade and diameter of the alloy rod to make...

Embodiment 2

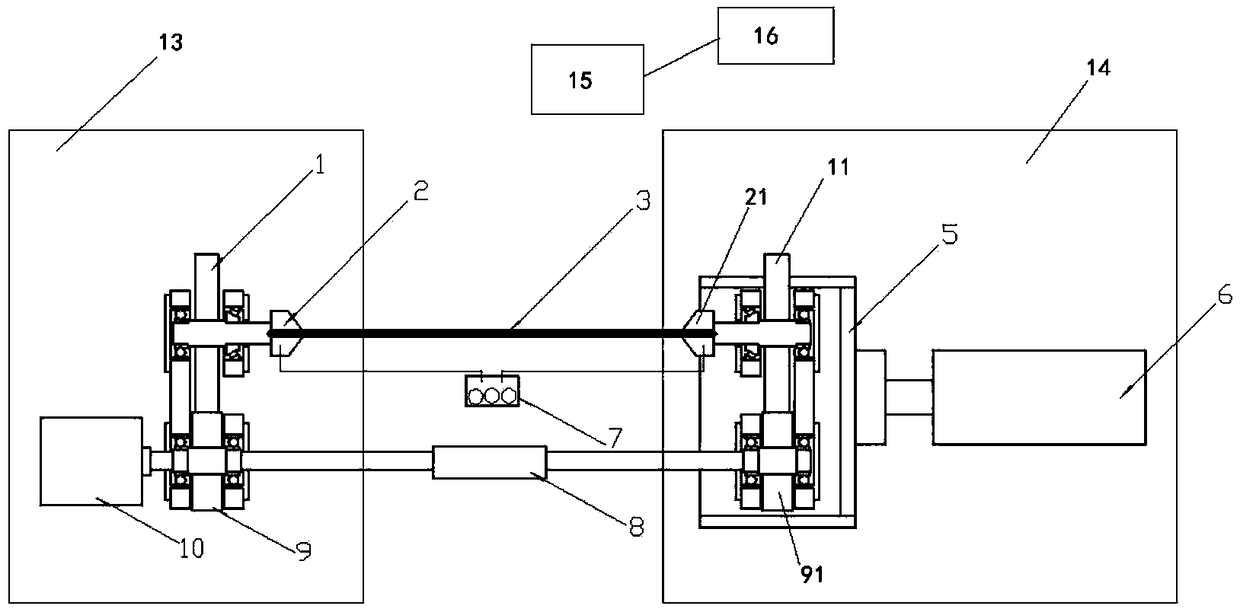

[0059] like figure 2 As shown, in this embodiment, a dynamic alloy rod straightening system includes the dynamic alloy rod straightening mechanism, a PLC controller 15, and a client terminal 16 electrically connected to the PLC controller 15; the first The rotary chuck 2 and the first large gear 1 are fixed on the fixed base 13 through bearings, the reduction motor 10 is fixed on the fixed base 13, and the first pinion 9 is fixed on the fixed base 13 through bearings; the second rotary chuck 21, The second large gear 11 is fixed on the sliding seat 5 through a bearing, the second pinion 91 is fixed on the sliding seat 5 through a bearing, and the sliding seat 5 is slidably connected to the stretching base 14; the hydraulic device 6 is fixed on the stretching base 14 Above, the PLC controller 15 is electrically connected to the current controller 7, and the PLC controller 15 is also electrically connected to the hydraulic device 6, the reduction motor 10, and the power supply....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com