High-rise type suspension type micro-vibration equipment construction structure and construction structure

A micro-vibration and suspension technology, applied in infrastructure engineering, vibration suppression adjustment, building components, etc., can solve the problems of non-detachable, long cycle, heavy pollution, etc., and achieve the effect of easy transportation, short cycle and less demand for workers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

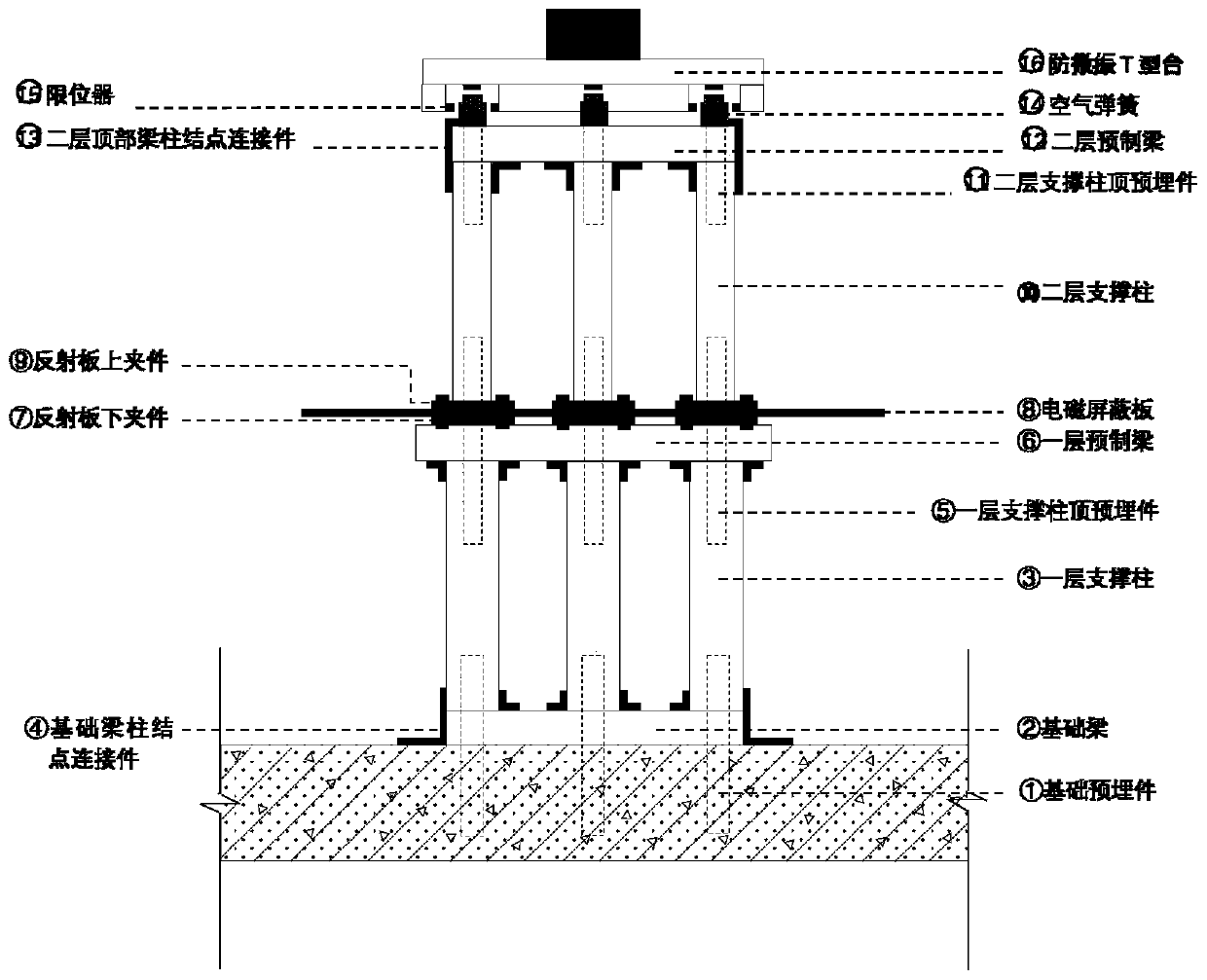

[0033] see figure 1, a towering suspended micro-vibration equipment construction structure, including: a rigid support structure, including a foundation beam structure, a first-floor support structure and a second-floor support structure, the foundation beam and the first-floor support structure are connected by a first-floor support beam 3, a The supporting structure on the first floor is connected to the supporting structure on the second floor through the supporting beams 10 on the second floor, and the supporting columns (3) on the first floor are connected to the foundation beams. There are six concrete columns with circular cross-sections in total, which are used to resist the vertical load on the upper part and ensure the stability of the structural members The air flotation control system includes the air flotation system 14 and the limiter 15. The air flotation system 14 is an air spring, which is composed of a mechanical height valve, a main air chamber, an additional...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com