A kind of aluminum-wood composite formwork system for building

A technology of aluminum-wood composite and formwork system, which is applied in the direction of construction, building structure, formwork/formwork components, etc., can solve the problems of non-reusable use, waste of resources, large labor costs, etc., and achieve simplified formwork installation and disassembly operation process, Realize the effects of supplementary reinforcement and simplification of production and processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

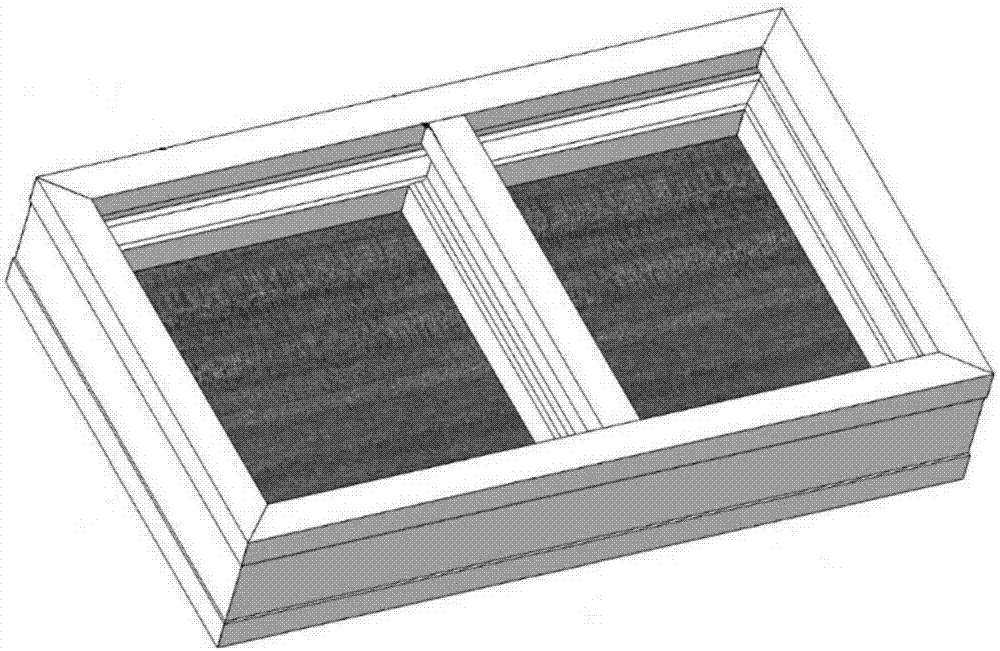

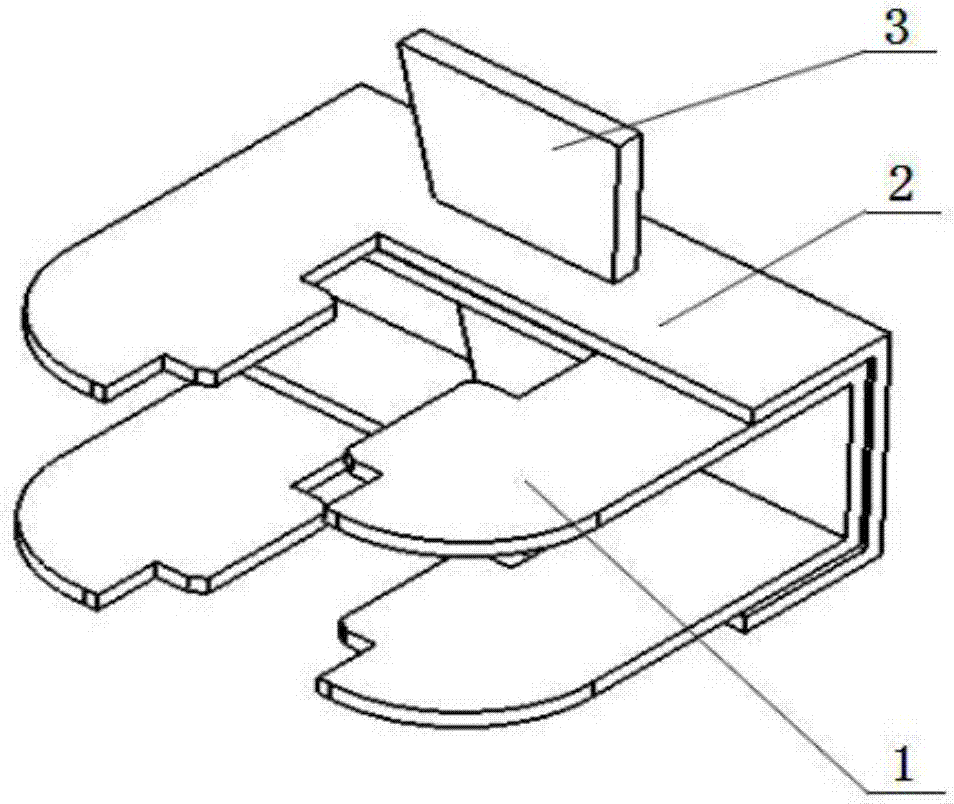

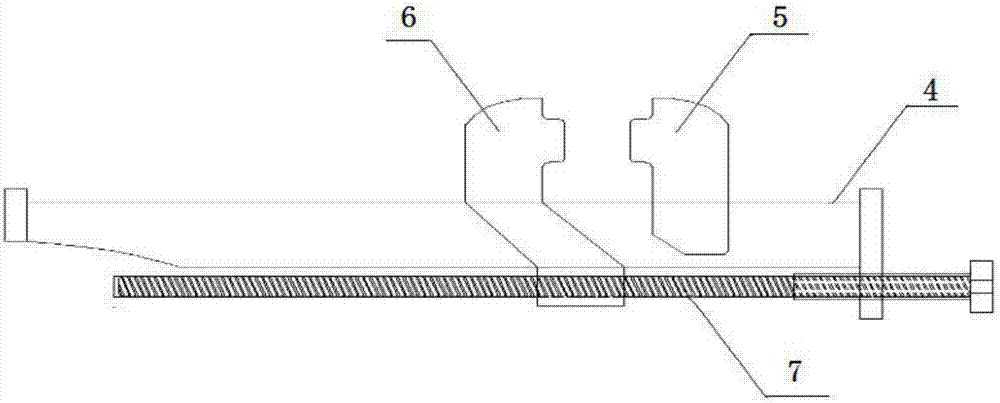

[0035] An aluminum-wood composite formwork system for construction is composed of a formwork system, a support system and a reinforcement system. The feature of the invention is that the formwork system is composed of a wall formwork, a beam formwork, a top formwork and a core tube formwork; wherein the wall formwork is divided into The wall panel is aluminum frame wood formwork structure and the wall panel is the main and secondary wood formwork structure; the aluminum frame wood formwork structure wall panel is composited into an aluminum frame through an aluminum alloy frame and a reinforced profile, combined with ordinary laminates and high-strength decorative thin-walled panels wall panels. The aluminum frame wood formwork structure wall panel is to make the aluminum frame wall panel frame through the aluminum alloy frame profile, and then weld the new aluminum alloy reinforcement between the frames to form the wall panel skeleton, and then install the corresponding size l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com