Metal foil piece type current detection resistor and manufacturing process thereof

A technology of current detection resistors and manufacturing process, which is applied in the direction of non-adjustable metal resistors, resistors, and resistor manufacturing. It can solve the problems of reduced power resistance of resistors, large temperature coefficient of resistors, and long heat dissipation paths, etc., to improve power. , to ensure integrity, to improve the effect of the temperature coefficient index

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

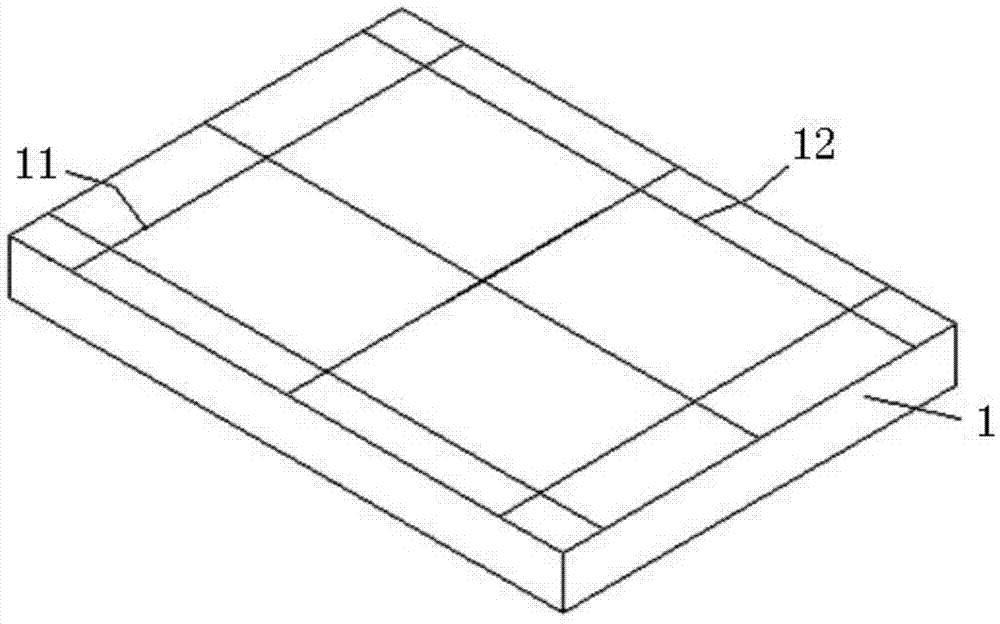

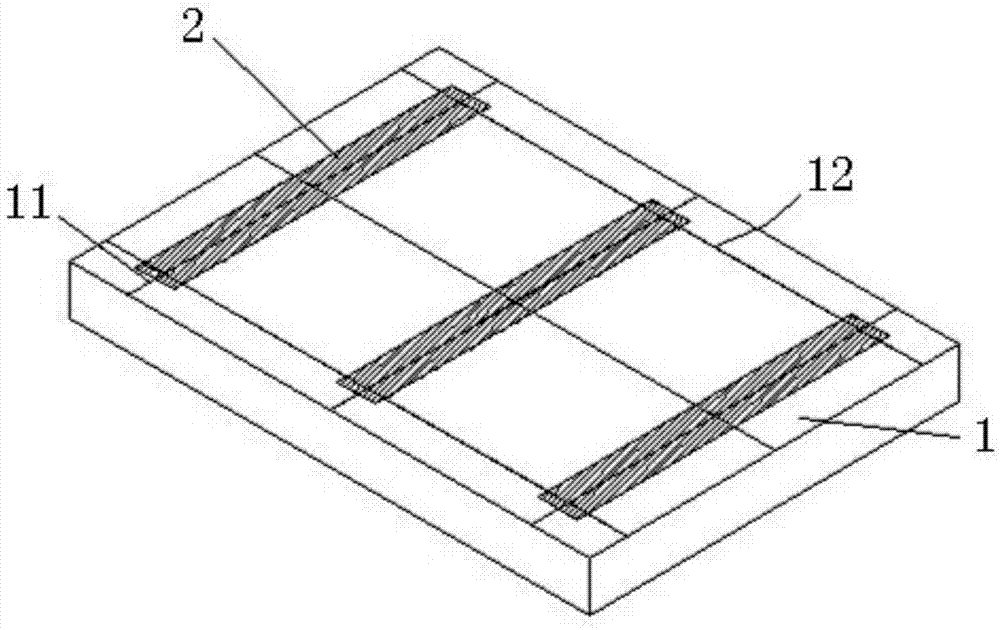

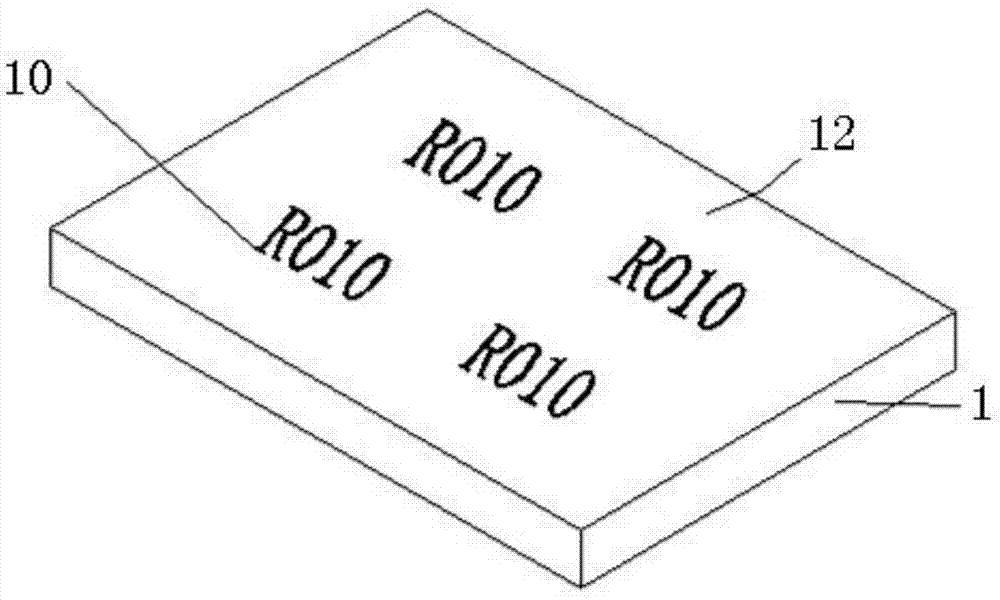

[0060] Embodiment 1: see attached Figure 15 and 16 As shown, a metal foil current detection resistor includes a square block insulating substrate 1, the insulating substrate 1 has a front side and a back side, wherein a product logo 10 is printed in the center on the front side of the insulating substrate 1, and the logo The material is resin paste, and front electrodes 3 are symmetrically printed by screen printing on both sides of the front side of the insulating substrate 1 extending along the X-axis direction (ie, the width direction), and the electrode material of the front electrode is resin paste; On the back of the insulating substrate 1 and on both sides extending along the X-axis direction, there are back electrodes 2 symmetrically printed by screen printing. The electrode material of the back electrodes is resin paste, and the back electrodes on the back of the insulating substrate are 2 also correspond to the front electrodes 3 on the front side of the insulating...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com