Preparation method and application of a flexible resistive film frequency selective surface

A frequency-selective surface, resistive film technology, applied in resistor manufacturing, resistors, resistors manufactured by photolithography, etc., can solve the problems of slow engraving machine engraving speed, limited application range, complex process, etc., to meet the requirements of wave absorbing design. The effect of demand, mature technology and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

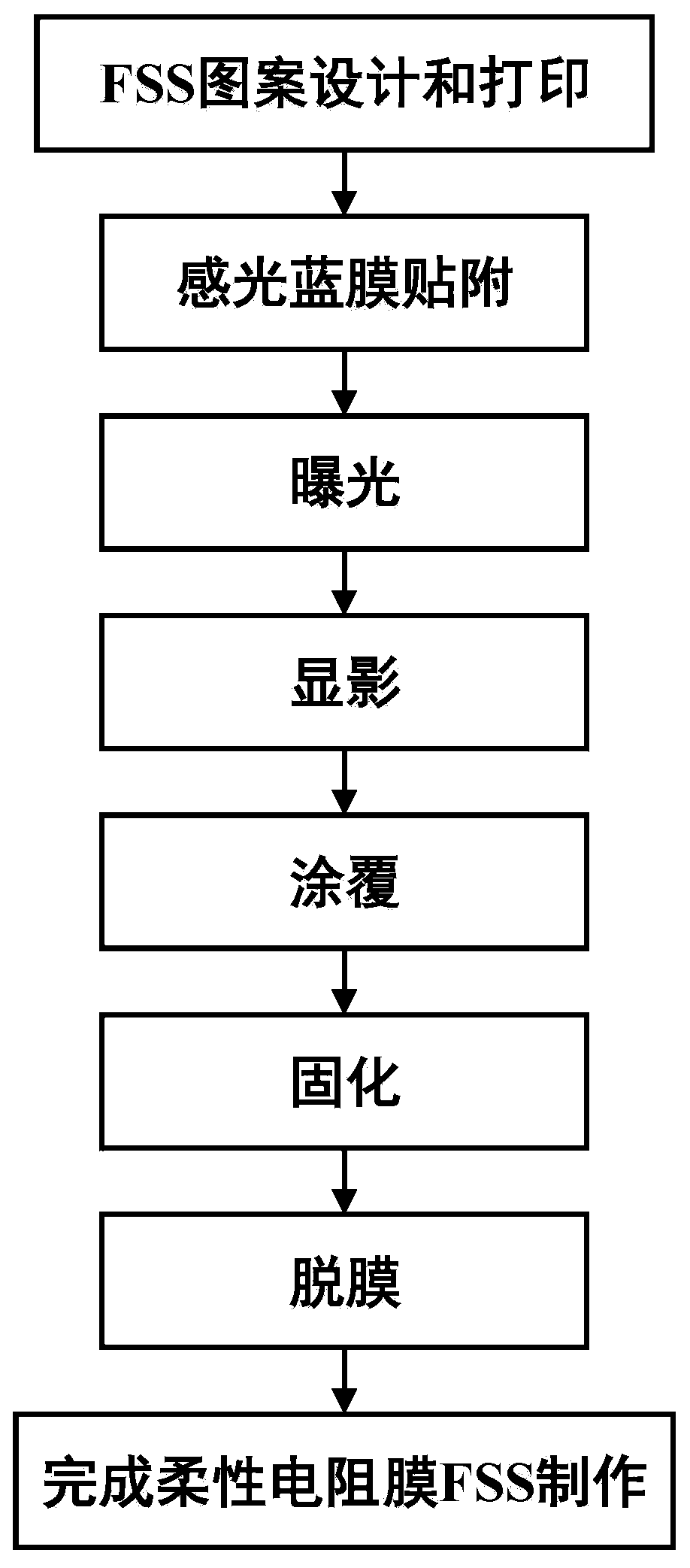

[0036] A method for preparing a flexible resistive film frequency selective surface provided by the invention comprises the following steps:

[0037] (1) Printing the set frequency selective surface pattern on the photosensitive film, and the photosensitive film is pasted on the surface of the flexible medium substrate to obtain the photosensitive film printed with the frequency selective surface pattern.

[0038] (2) sequentially exposing and developing the photosensitive film printed with the frequency-selective surface pattern, developing and removing part of the photosensitive film, revealing the frequency-selective surface pattern on the surface of the flexible medium substrate, and obtaining the developed flexible medium substrate;

[0039] (3) Coating resistive conductive carbon paste on the surface of the flexible medium substrate after the development, sintering and curing the flexible medium substrate of the coated conductive carbon paste, and the cured conductive car...

Embodiment 1

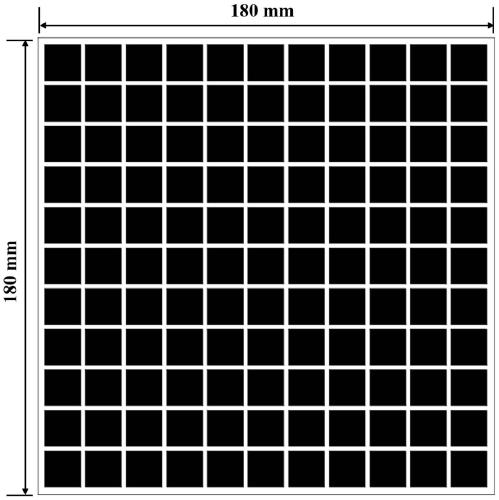

[0065] for preparation figure 2 Frequency-selective surface patterning of the flexible resistive film of the pattern shown. The length of the pattern multiplied by the width is 180mm*180mm. The preparation method of this embodiment comprises the following steps:

[0066] S1: Cropped slightly larger than figure 2 For 0.15mm thick FR4 with the size shown, a layer of photosensitive blue film is pasted on the surface through a laminating machine; the thickness of the photosensitive blue film is 0.2mm.

[0067] S2: processed by AutoCAD and Photoshop to get figure 2 In the printing pattern of FSS, the FSS pattern is printed on the film slightly larger than the size of the FSS pattern through a large inkjet printer;

[0068] S3: Transfer the designed FSS pattern to FR4 coated with blue film through a large-scale printing machine;

[0069] S4: exposing the flexible FR4 with the frequency selective surface pattern transferred;

[0070] S5: Prepare the developing solution, plac...

Embodiment 2

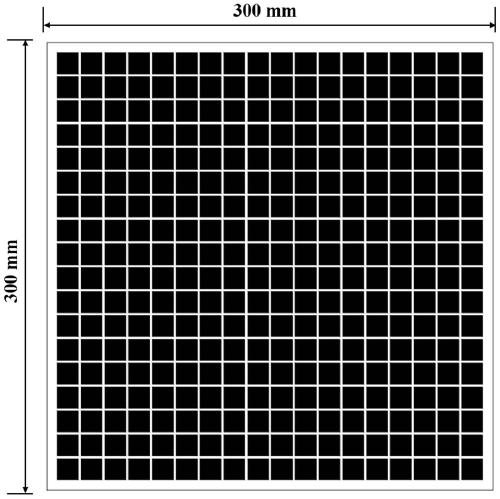

[0076] for preparation image 3 Frequency-selective surface patterning of the flexible resistive film of the pattern shown. The length of the pattern multiplied by the width is 300mm*300mm. The preparation method of this embodiment comprises the following steps:

[0077] S1: Cropped slightly larger than figure 2 For FR4 with a thickness of 0.15mm in the size shown, a layer of photosensitive blue film is pasted on the surface through a laminating machine; the thickness of the photosensitive blue film is 0.15mm.

[0078] S2: processed by AutoCAD and Photoshop to get figure 2 In the printing pattern of FSS, the FSS pattern is printed on the film slightly larger than the size of the FSS pattern through a large inkjet printer;

[0079] S3: Transfer the designed FSS pattern to FR4 coated with blue film through a large-scale printing machine;

[0080] S4: exposing the flexible FR4 with the frequency selective surface pattern transferred;

[0081] S5: Configure a sodium bicarb...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com