Patents

Literature

88results about How to "Preparation fit" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Water-soluble drug sustained-release tablet and preparation method thereof

InactiveCN101288652ASimple preparation processSimple processPill deliveryPharmaceutical non-active ingredientsProlonged-release tabletWater soluble drug

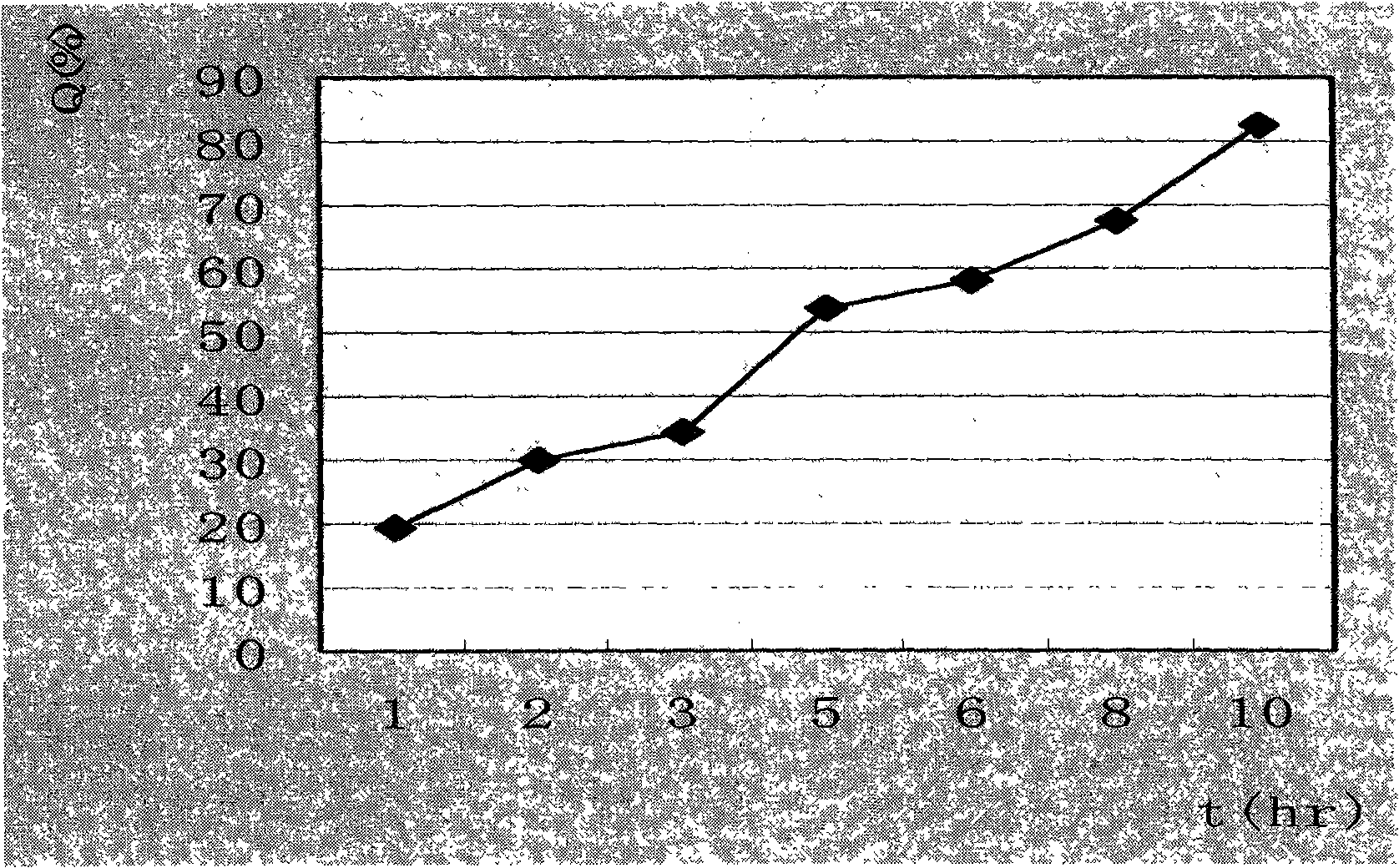

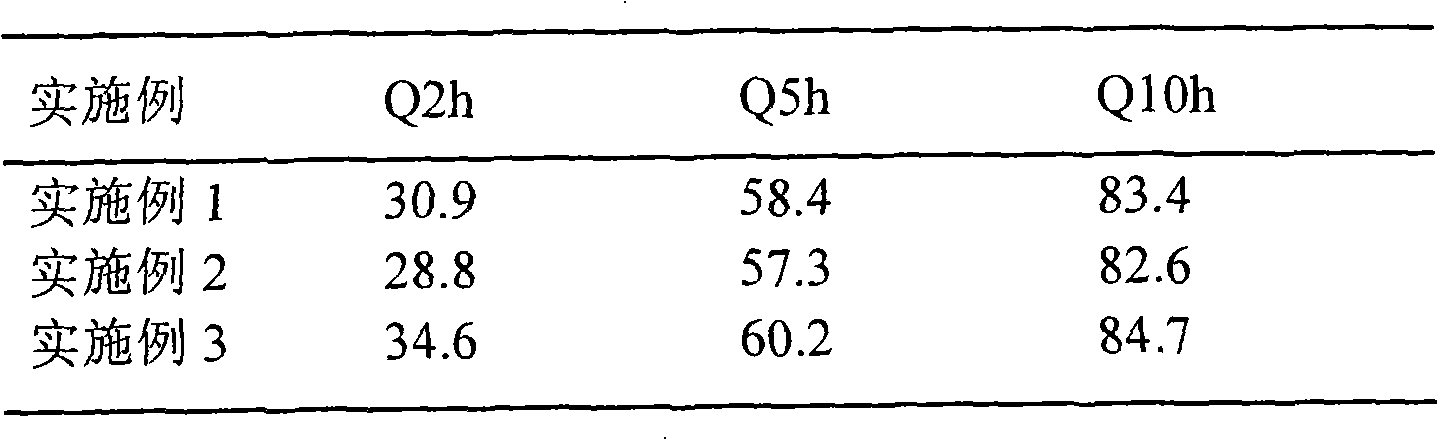

The invention relates to a water-soluble drug sustained-release tablet and a preparation method thereof, the technology is characterized in that: the components and the weight percentages are as follows: 1 to 20 percent of water-soluble drug, 20 to 70 percent of hydrophilic gel, 30 to 50 of percent waxy material and the rest of filler, lubricant and other excipients that are commonly used for ordinary tablets. The method takes the hydrophilic gel sustained-release material and the waxy sustained-release material as a mixed matrix, the water-soluble drug is added to change the features of fast dissolution and short half life of the drug release, thus achieving the purpose of slow and smooth release. The drug of the invention has good stability, the needed equipment is simple, the manufacturing process is simple and easy, the operatability is strong, the in vitro dissolution test shows that the release rate is 25 to 35 percent in 2 hours, 55 to 65 percent in 5 hours and more than 80 percent in 10 hours, thus having good sustained-release effect. In addition, the sustained-release tablet is less affected by the gastrointestinal tract environment, the absorption is stable, and the individual difference is small, thus being the ideal sustained-release tablet.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

Method for preparing graphene/polymer composite material based on infrared irradiation

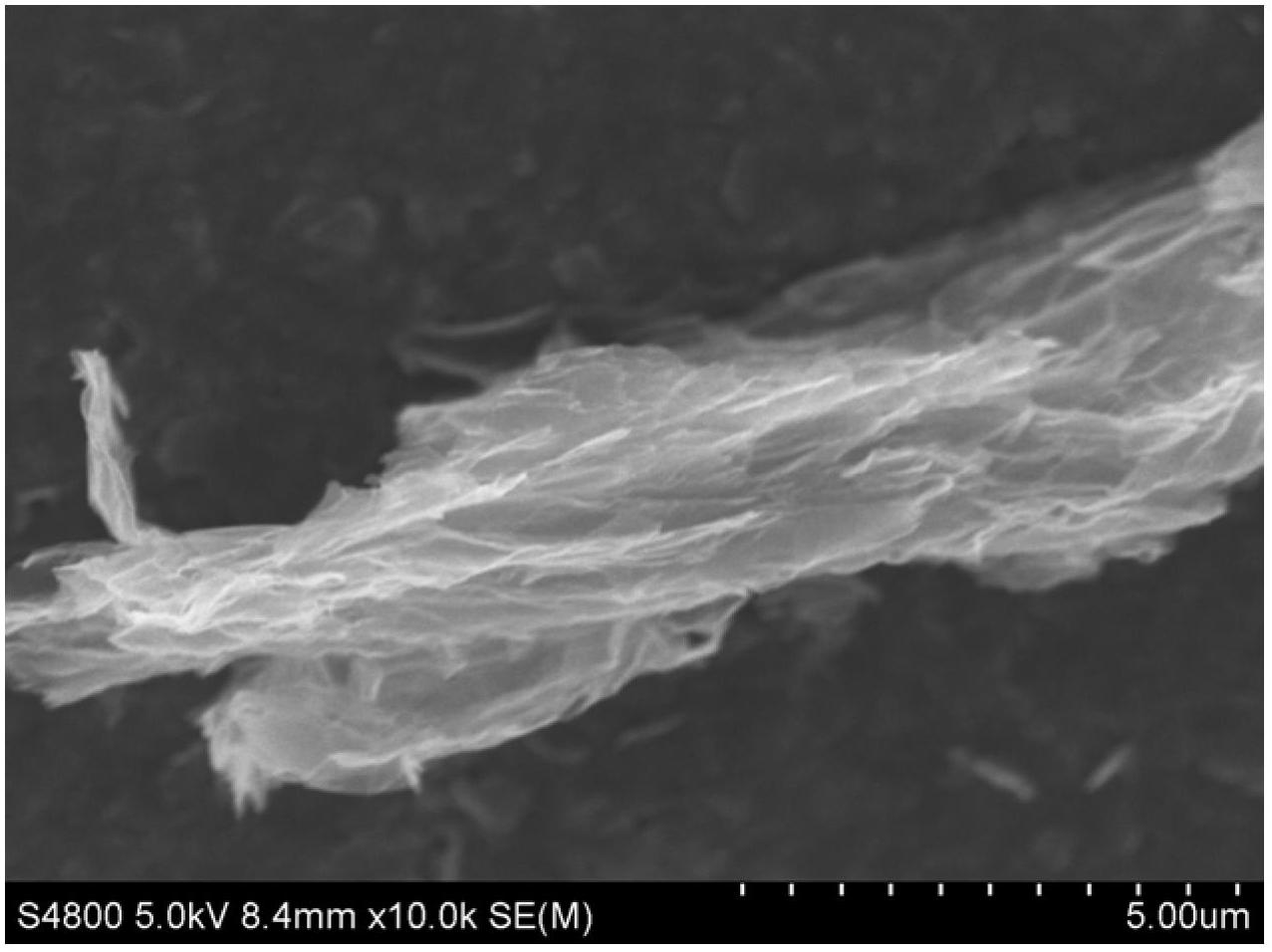

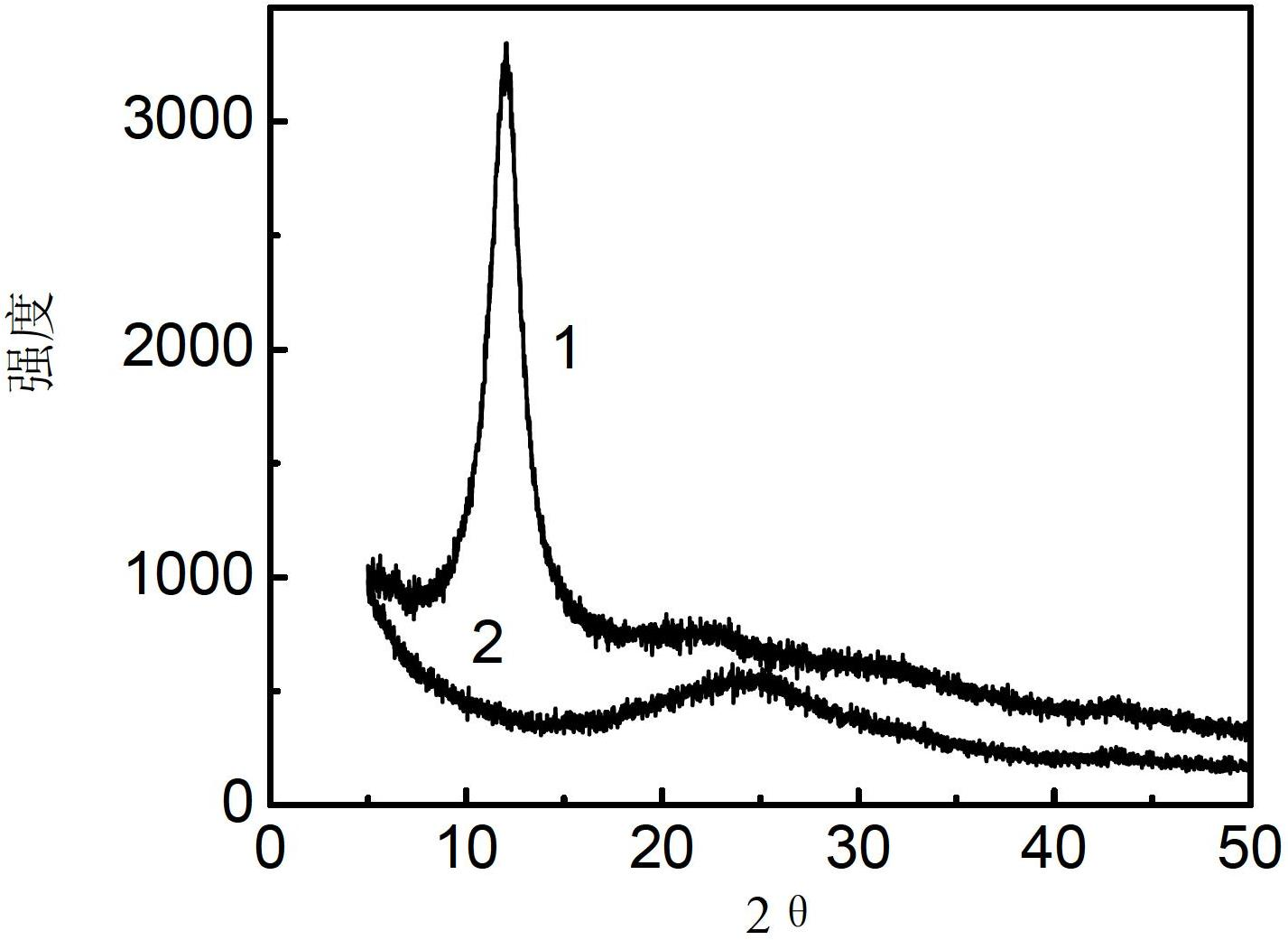

The invention discloses a method for preparing a graphene / polymer composite material based on infrared irradiation. The method comprises the following steps: 1) mixing a graphite oxide solution with a polymer solution or polymer emulsion to obtain a mixed solution, casting or spinning, and drying until the weight percentage of the total solvent is less than or equal to 50 percent so as to obtain a composite product; and 2) removing the solvent from the composite product under the irradiation of an infrared heating lamp, and performing reduction reaction of graphite oxide to obtain the graphene / polymer composite material. By the preparation method, the graphene / polymer composite material is prepared under the irradiation of the infrared heating lamp, the process is simple and convenient, the production cost is low, the method is suitable for large-scale industrial production, different polymers can be selected for preparing different graphene / polymer composite materials so as to meet the production and use requirements, and the graphene / polymer composite material has a wide application prospect in the fields such as conductive polymer composite materials, films and fibers.

Owner:ZHEJIANG UNIV

Freeze dried polyene lecithin powder for injection and its prepn

ActiveCN1771914AImprove solubilityImprove drug activityPowder deliveryOrganic active ingredientsPolyene phosphatidylcholineSodium dehydrocholate

The present invention discloses one kind of freeze dried polyene phosphatidylcholine powder for injection and its preparation process. It features that the preparation contains polyene phosphatidylcholine and solubilizer sodium deoxycholate, sodium dehydrocholate or sodium cholate in the weight ratio of 0.5-1.5.

Owner:CHIA TAI TIANQING PHARMA GRP CO LTD

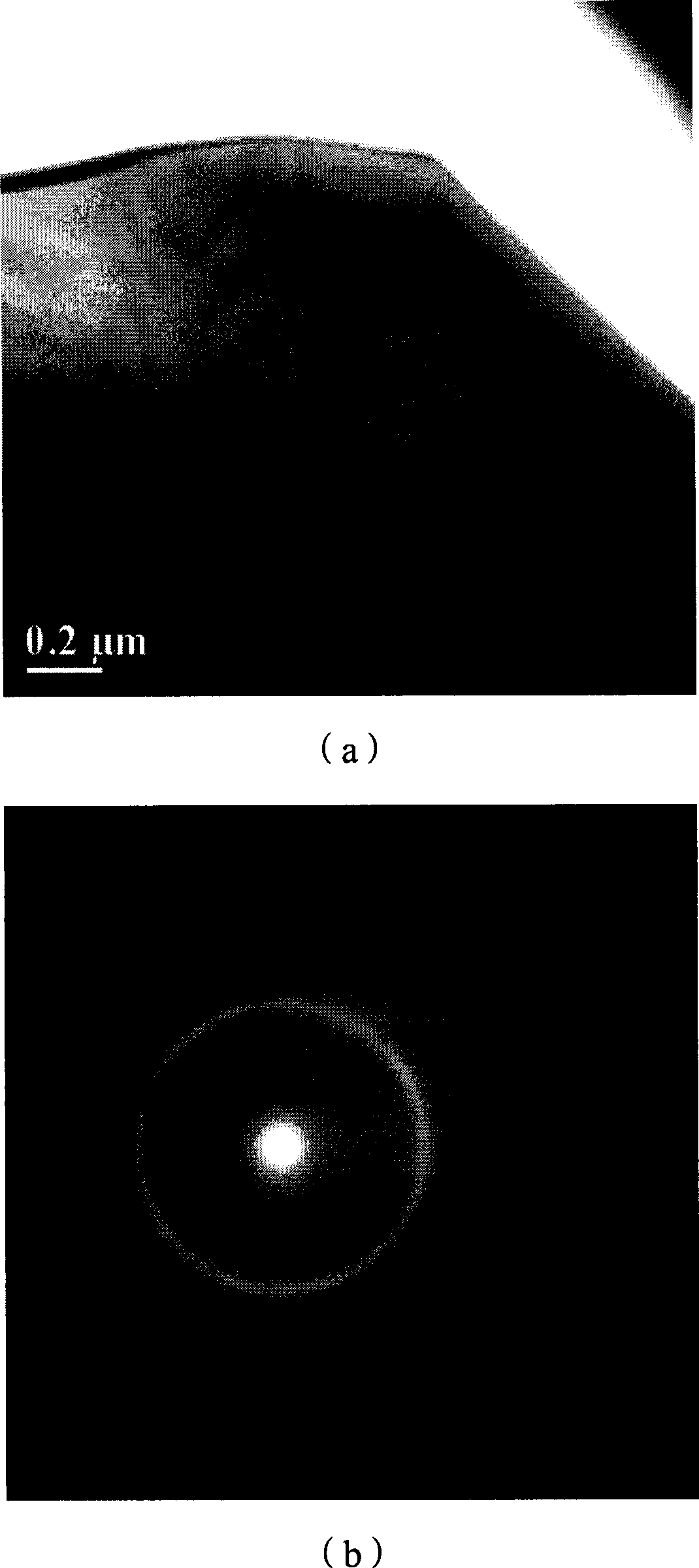

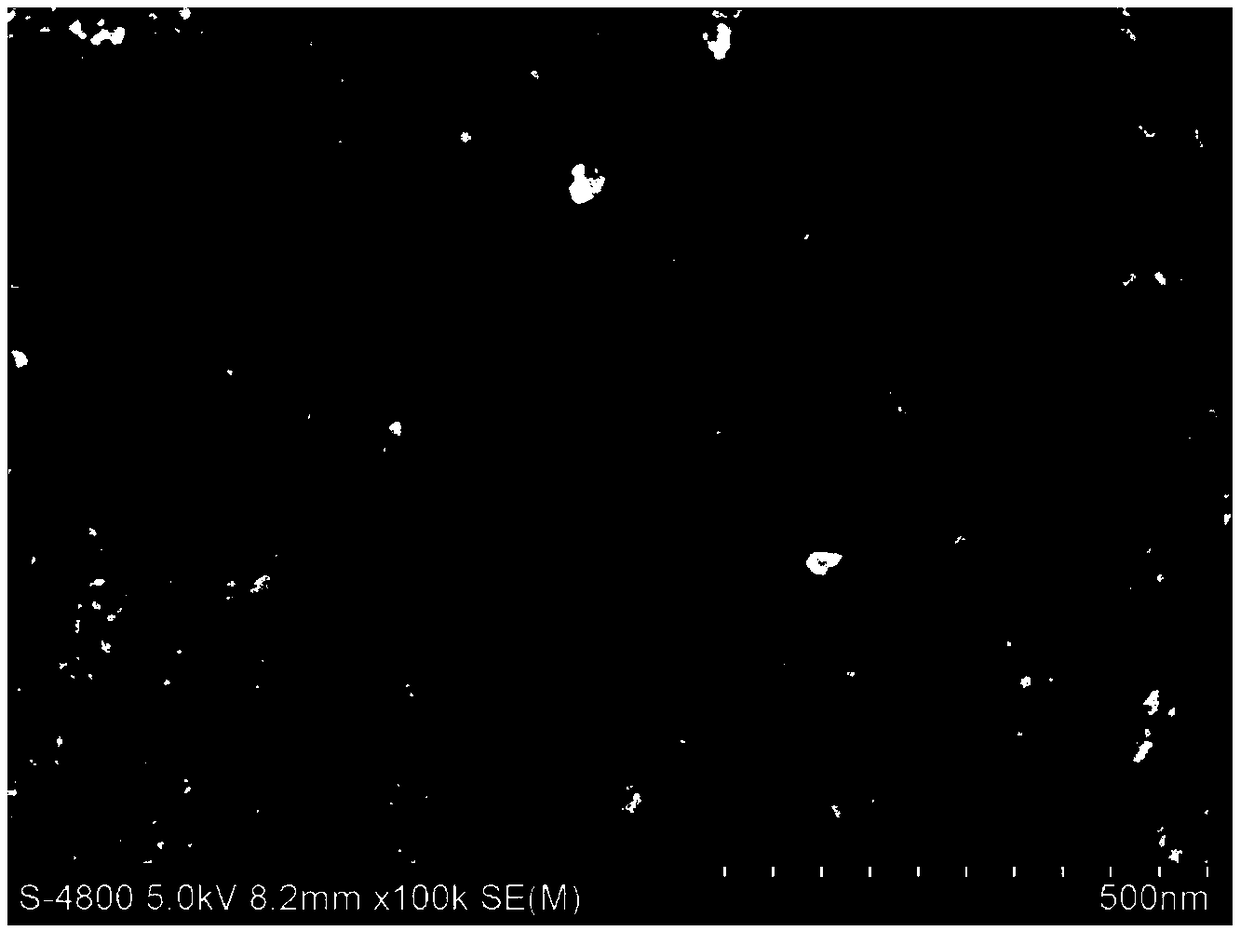

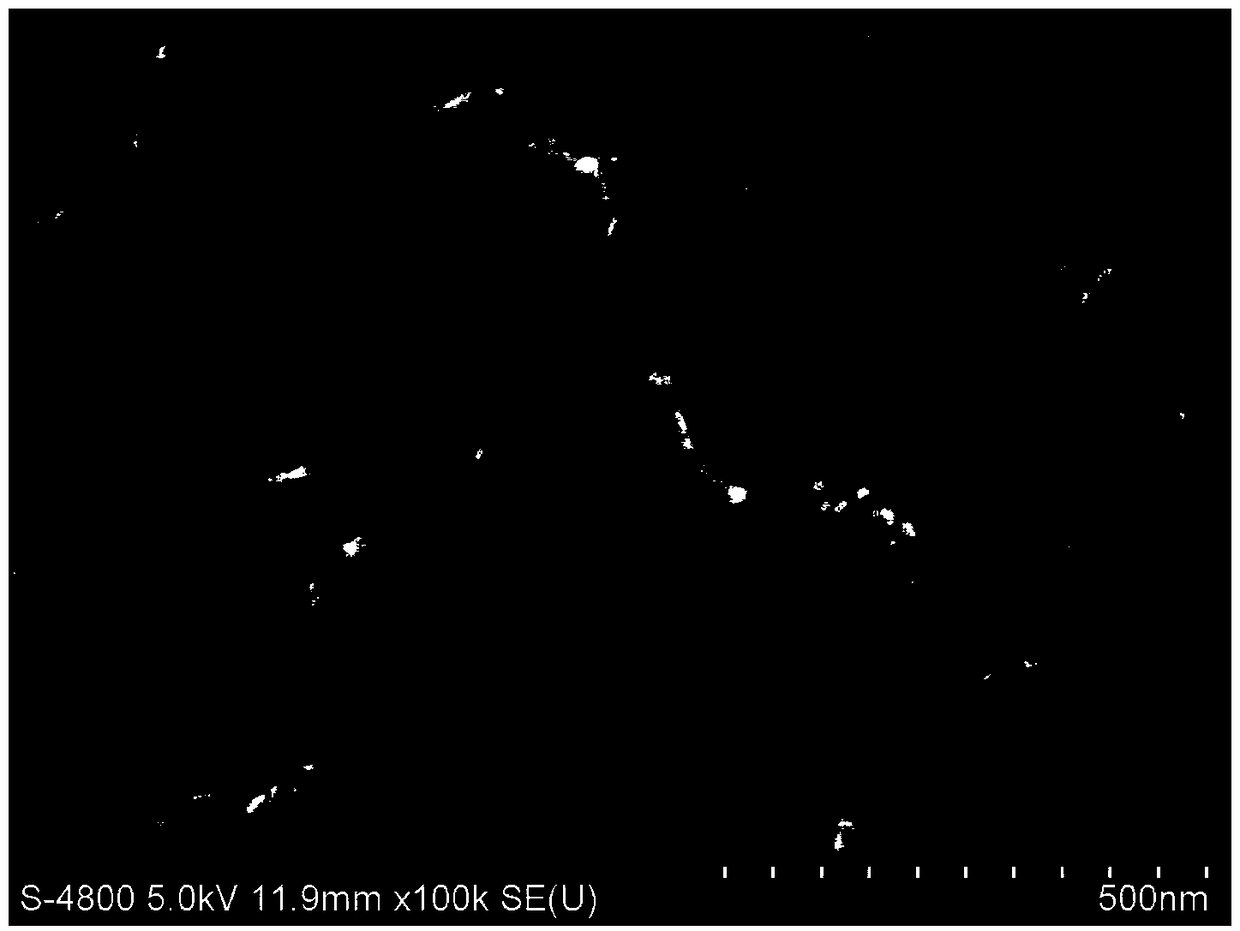

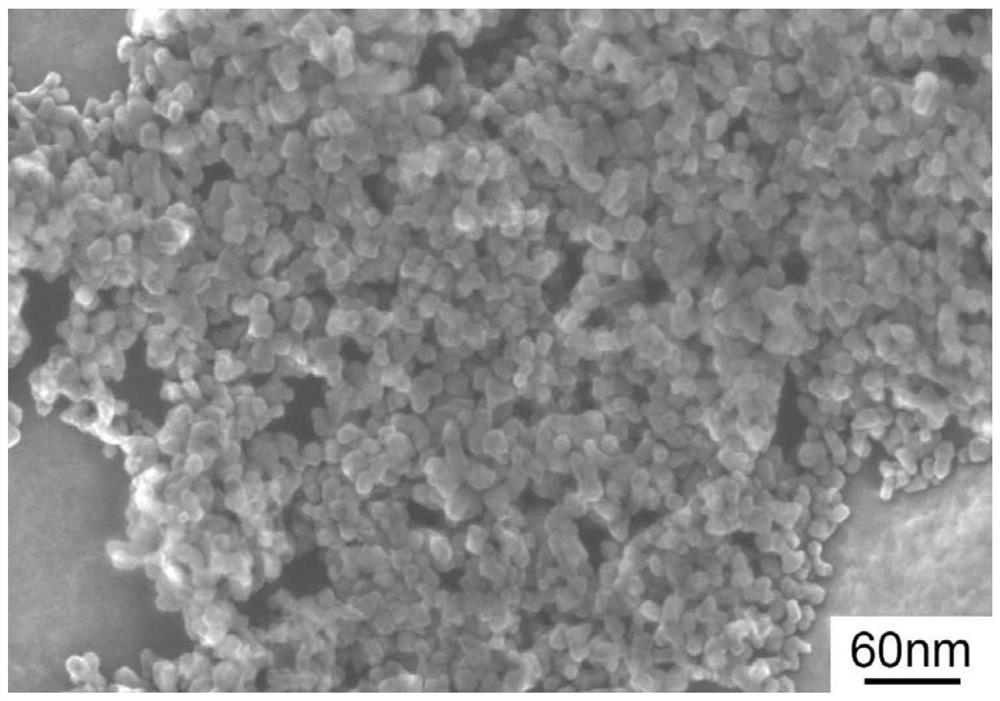

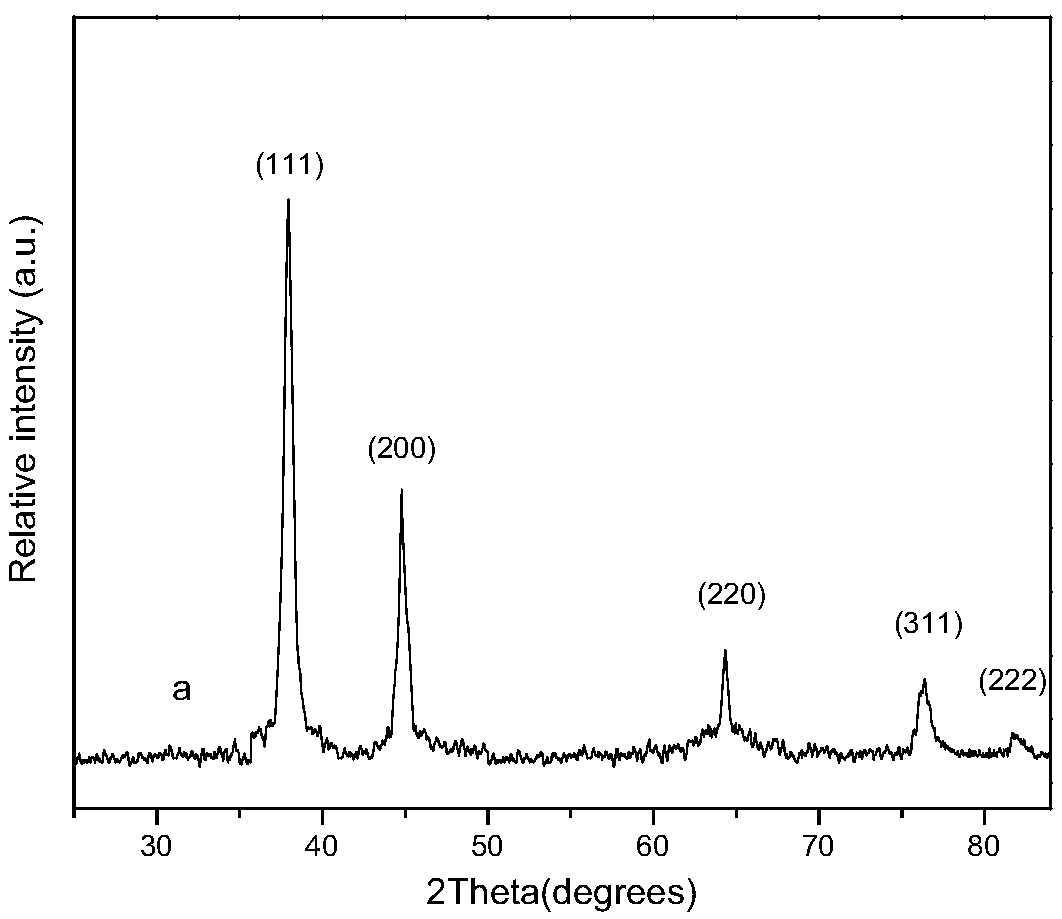

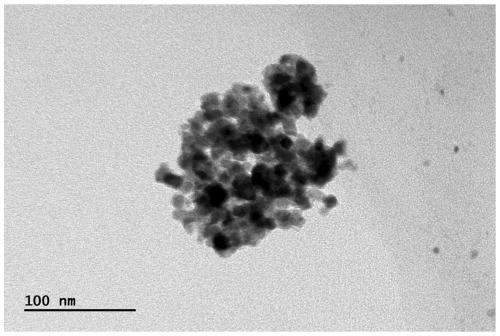

Nanometer silver particle and synthetic method thereof

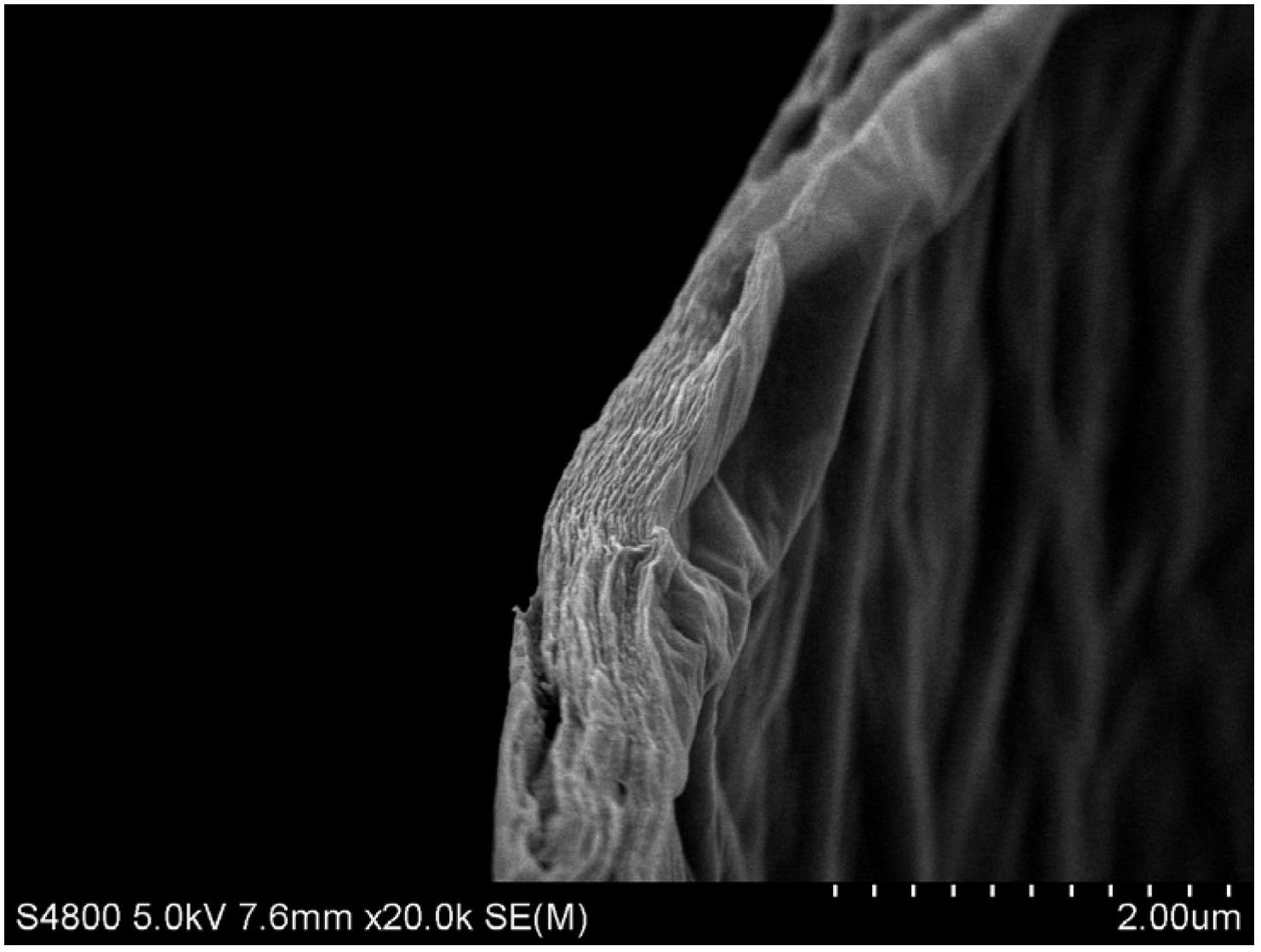

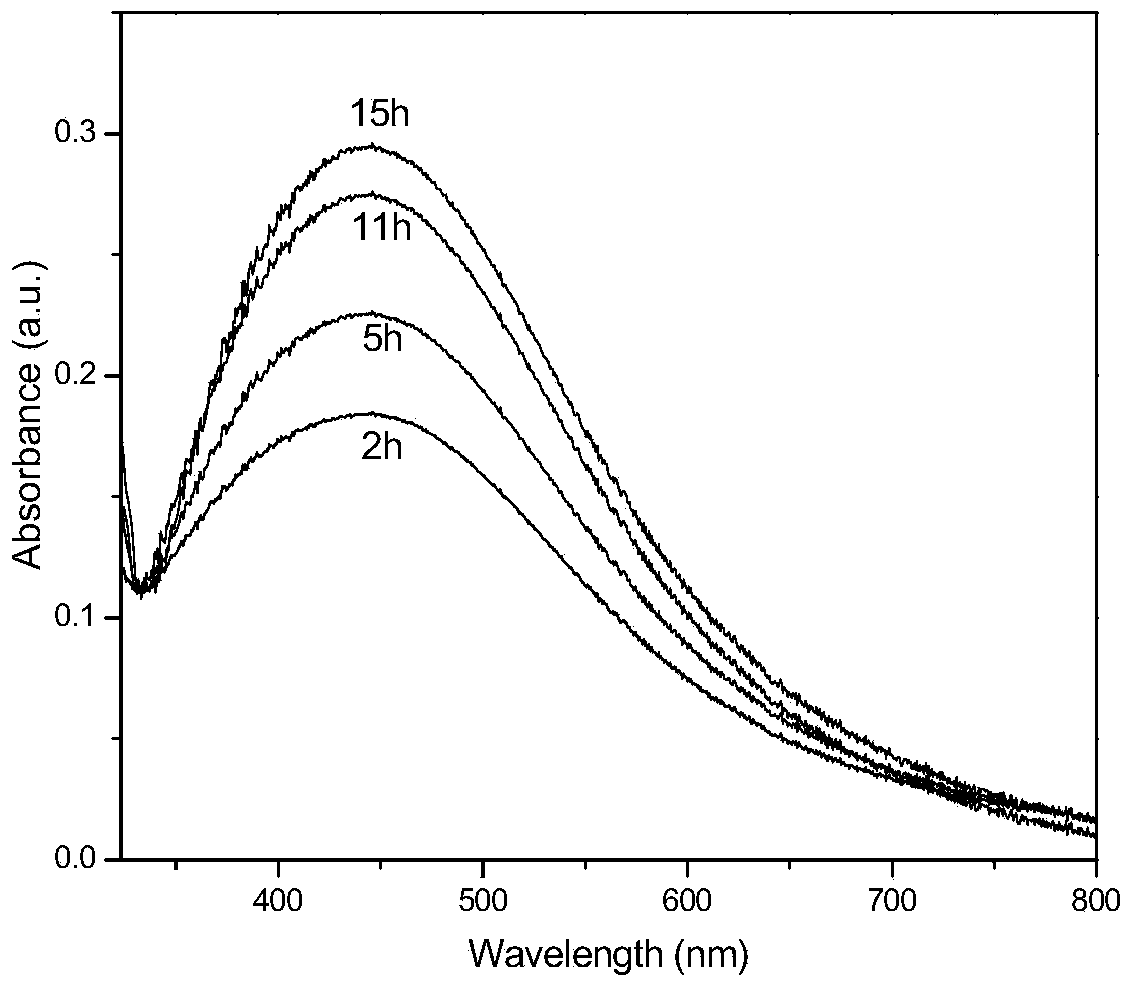

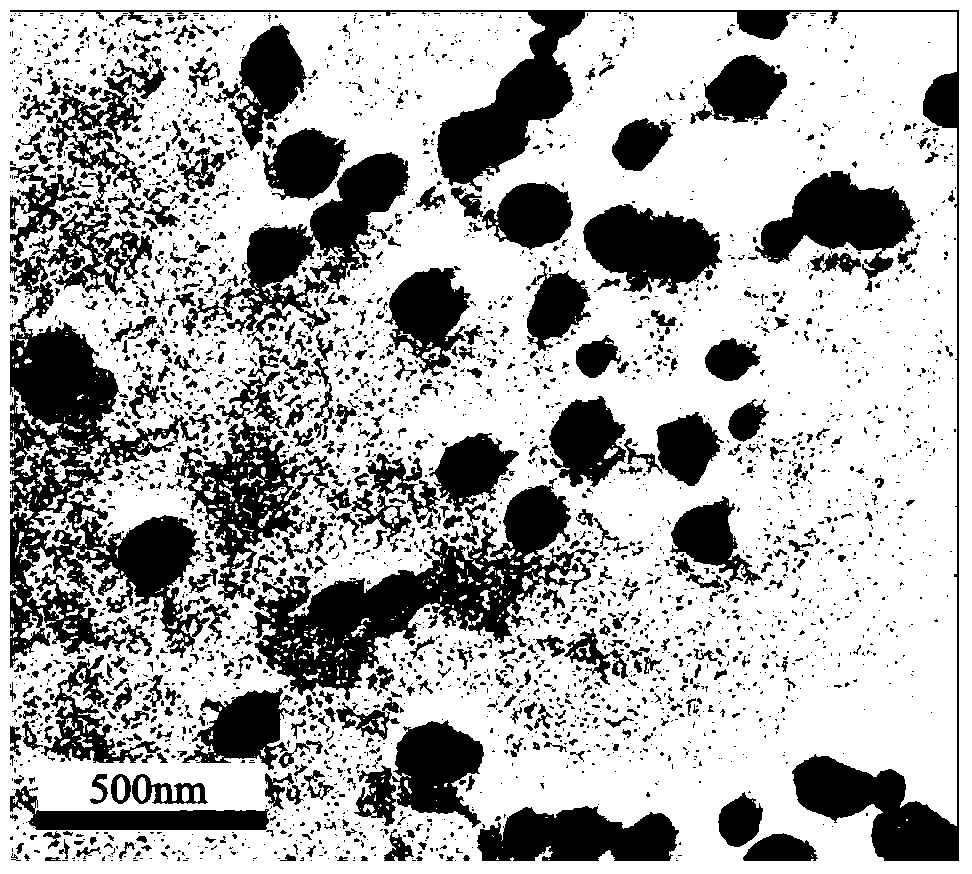

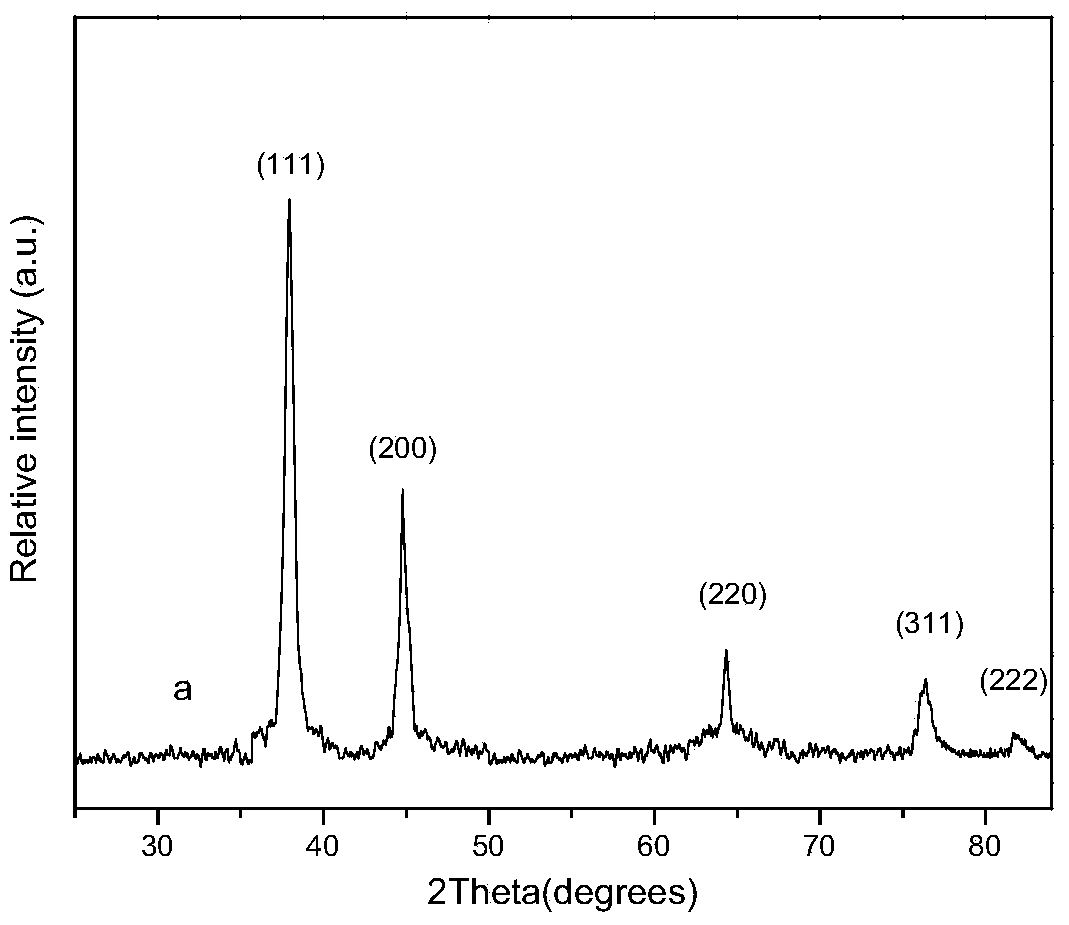

ActiveCN103769603AInduce and regulate productionIncrease concentrationCoatingsSpherical shapedOxygen

The invention belongs to the technical field of nanometer material synthesis, and particularly relates to a nanometer silver particle and a synthetic method thereof. The nanometer silver particle is in a spherical shape or a similar spherical shape, the surface of the nanometer silver particle is provided with a biomolecule wrapping layer, and biomolecules contain carboxyl groups with negative charge oxygen atoms. The nanometer silver particle is of a cubic crystal structure, and the particle diameter of the nanometer silver particle is 50 to 150nm. The nanometer silver particle is prepared by a biological material reduction method, orange juice and Ag<+> solution are uniformly mixed, the stirring is carried out at 26 to 34 DEG C, the centrifugal separation is carried out after the reaction completion, precipitates are washed and dried, and the nanometer silver particle is obtained. The biomolecules in the orange juice are used as templates, AgNO3 solution is utilized for providing silver ions, and the nanometer silver particle with the spherical appearance is synthesized through regulation and control. In fruit and vegetable juice such as orange juice, oxygen atoms on the groups such as carboxyl contained in biomolecules such as amino acid and vitamin mostly carry residual negative charges, the residual negative charges generate mutual effects with Ag<+>, nucleation sites are provided, and the generation of the nanometer silver particle is induced, regulated and controlled.

Owner:永新股份(黄山)包装有限公司

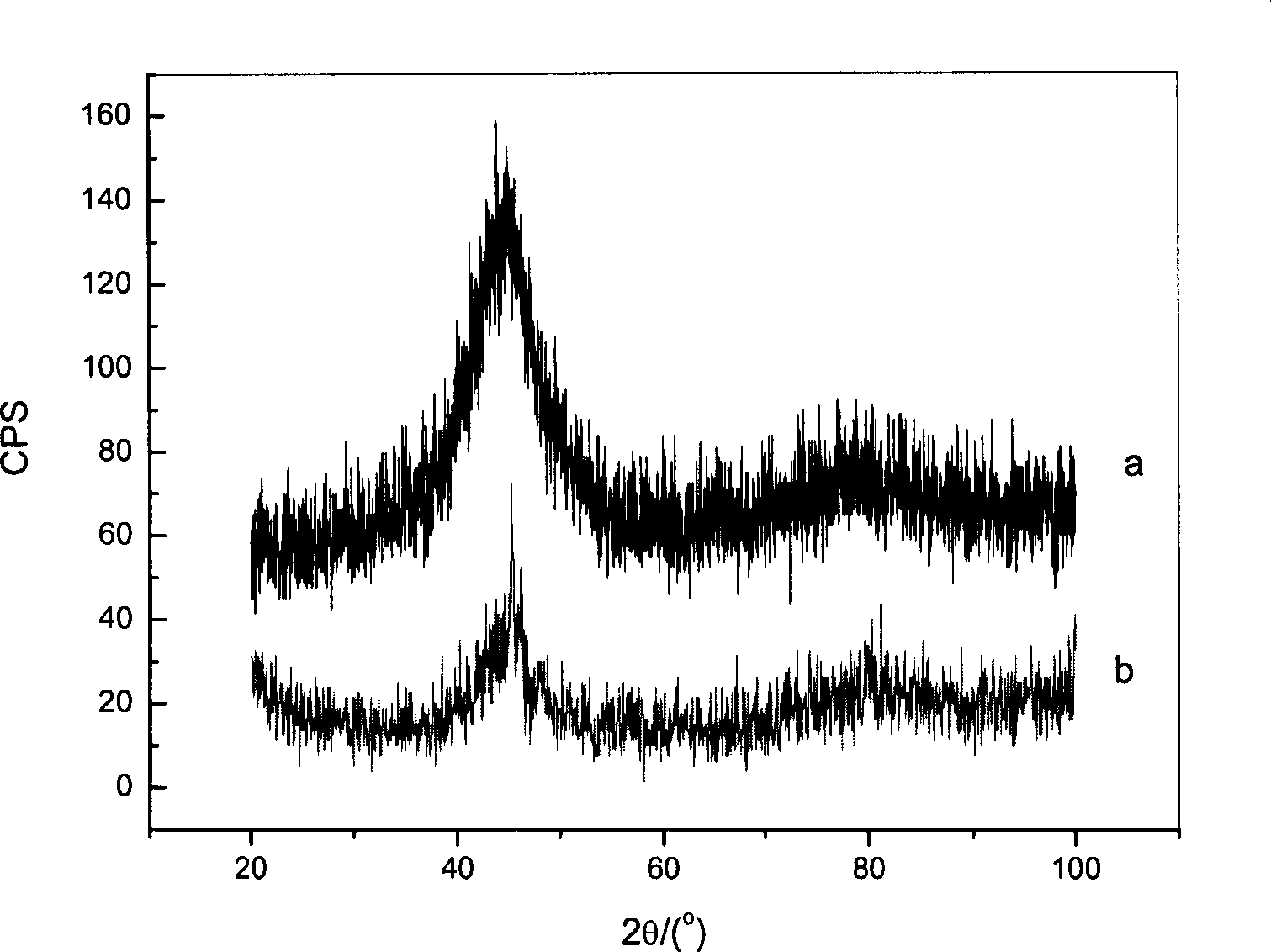

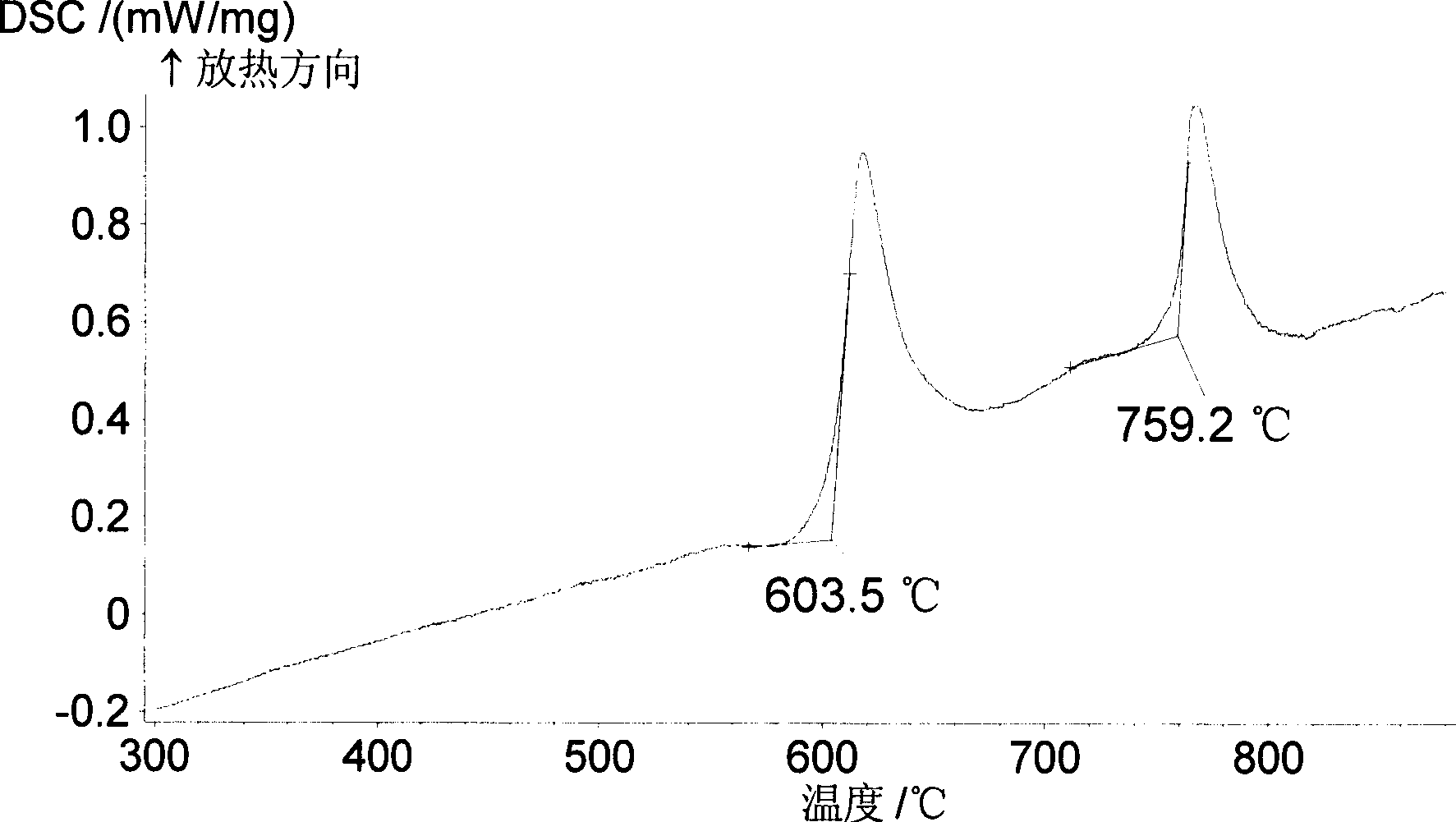

Amorphous soft magnetic alloy coatings and preparation method thereof

ActiveCN101441915ASimple processLess stress sensitiveMolten spray coatingMagnetic/electric field screeningMetallurgyMaterials science

The present invention relates to an amorphous soft magnetic alloy coating and the preparation method thereof, particularly relates to Fe-Co base amorphous soft magnetic alloy coating, characterized in that: (1) the sum of atom percentage content of Fe and Co is no less than 70&; (2) basically the coating is in amorphous structure. The invention also relates to the usage of the coating and the preparation method thereof.

Owner:ADVANCED TECHNOLOGY & MATERIALS CO LTD

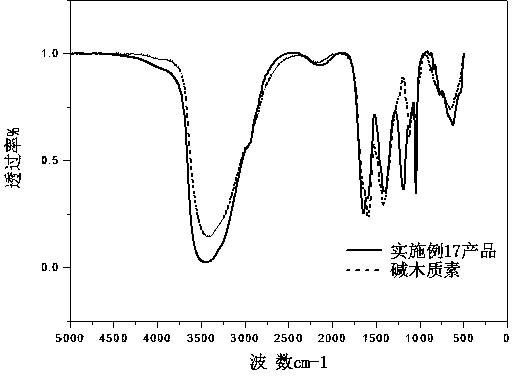

Alkali lignin gasification coal-water slurry dispersing agent and preparation method thereof

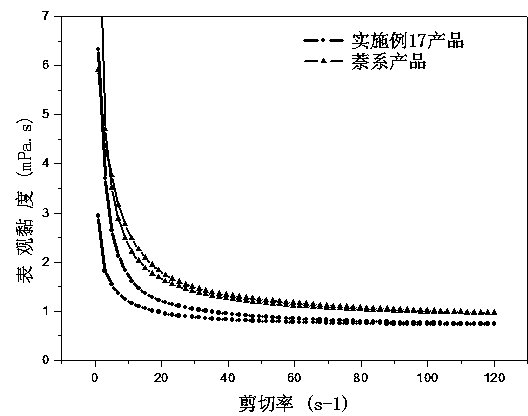

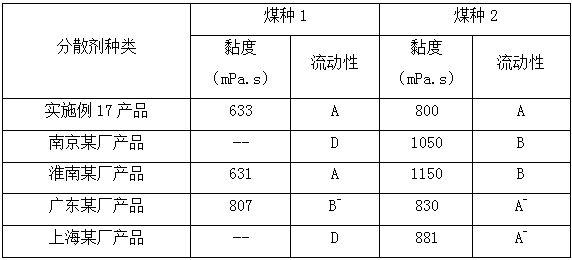

InactiveCN103666608AImprove stabilityGood dispersionLiquid carbonaceous fuelsSulfite saltEngineering

The invention relates to an alkali lignin gasification coal-water slurry dispersing agent and a preparation method thereof, belonging to the field of gasification coal-water-slurry production technology. The alkali lignin gasification coal-water slurry dispersing agent comprises the following raw materials in parts by weight: 100 parts of alkali lignin, 30-50 parts of carbonyl compounds, 150-250 parts of aldehydes, 25-90 parts of sulfonating agent and 200-400 parts of water. According to the alkali lignin gasification coal-water-slurry dispersing agent, alkali lignin is used as a main raw material and urea, acetone, sulfite and the like are used as modifiers, the raw materials are low in cost and easily available. The addition of the alkali lignin gasification coal-water slurry dispersing agent is small when the alkali lignin gasification coal-water slurry dispersing agent is used for preparing gasification coal-water slurry. The alkali lignin gasification coal-water-slurry dispersing agent has no sharp aroma, is dry and powdered, and convenient to store; the high stability advantage of lignin serving as the coal-water slurry dispersing agent is retained, but also the dispersion property can be greatly improved, the liquidity of the coal-water slurry prepared by using the product is obviously better than that of other lignin products, and the alkali lignin gasification coal-water-slurry dispersing agent is especially suitable for the preparation of the gasification coal-water slurry.

Owner:中国东方电气集团有限公司

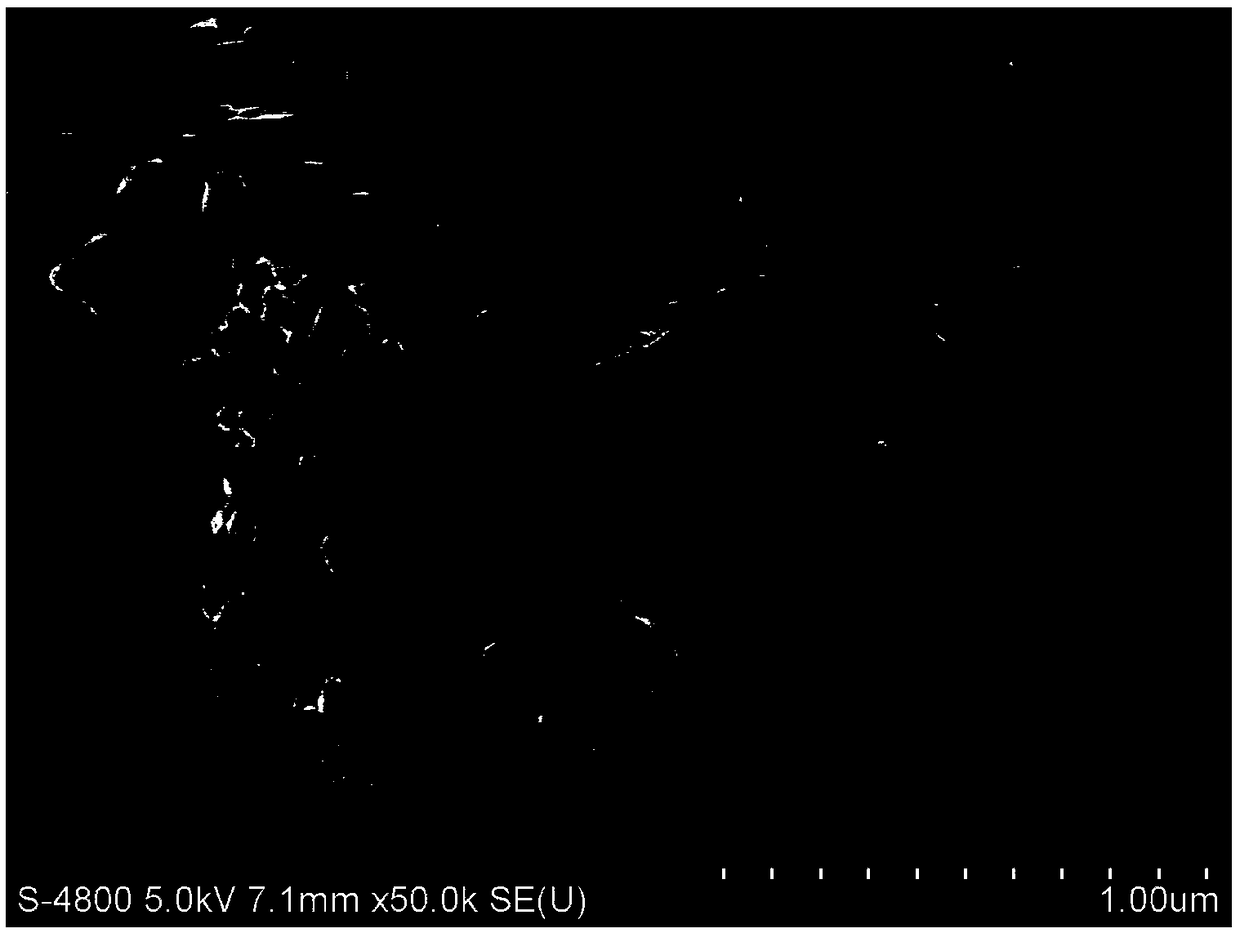

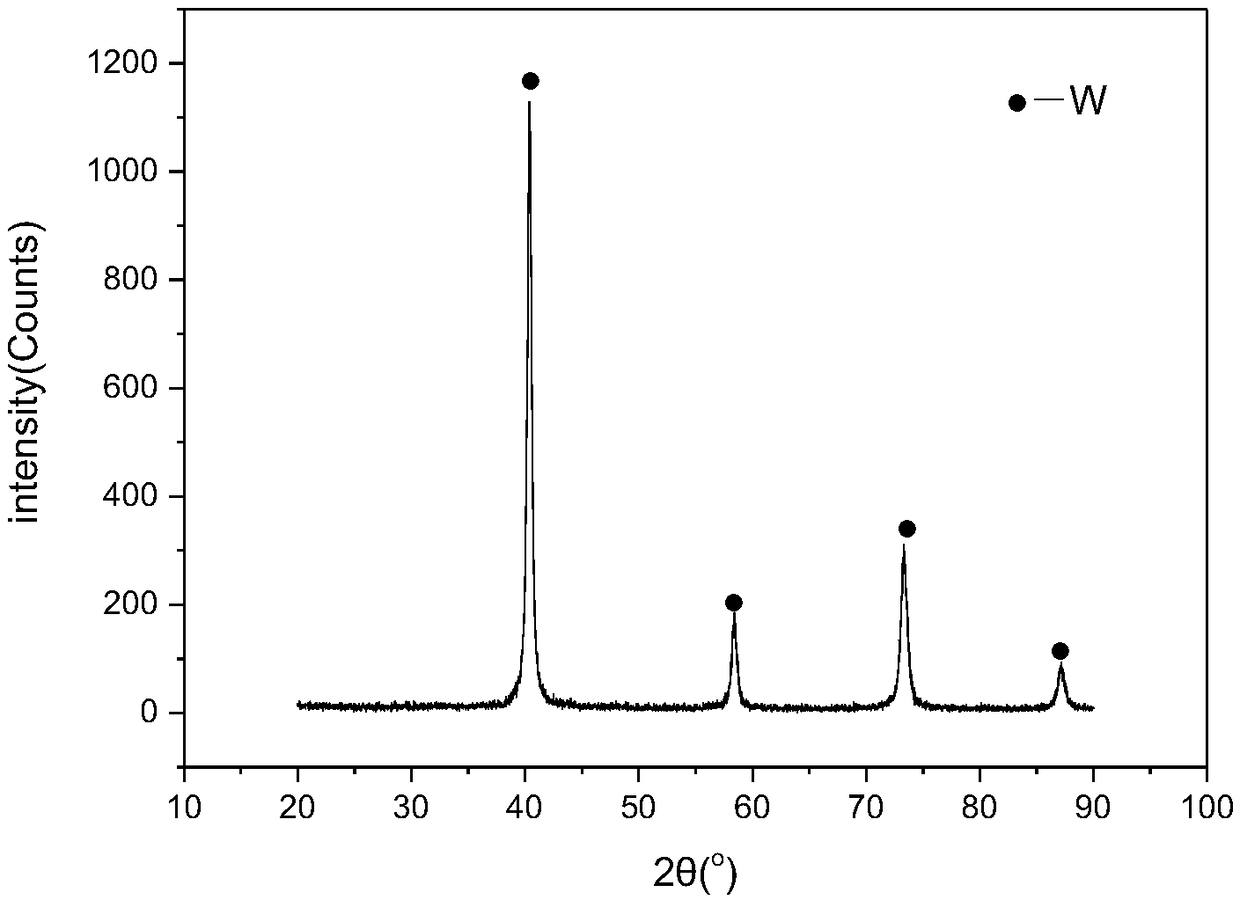

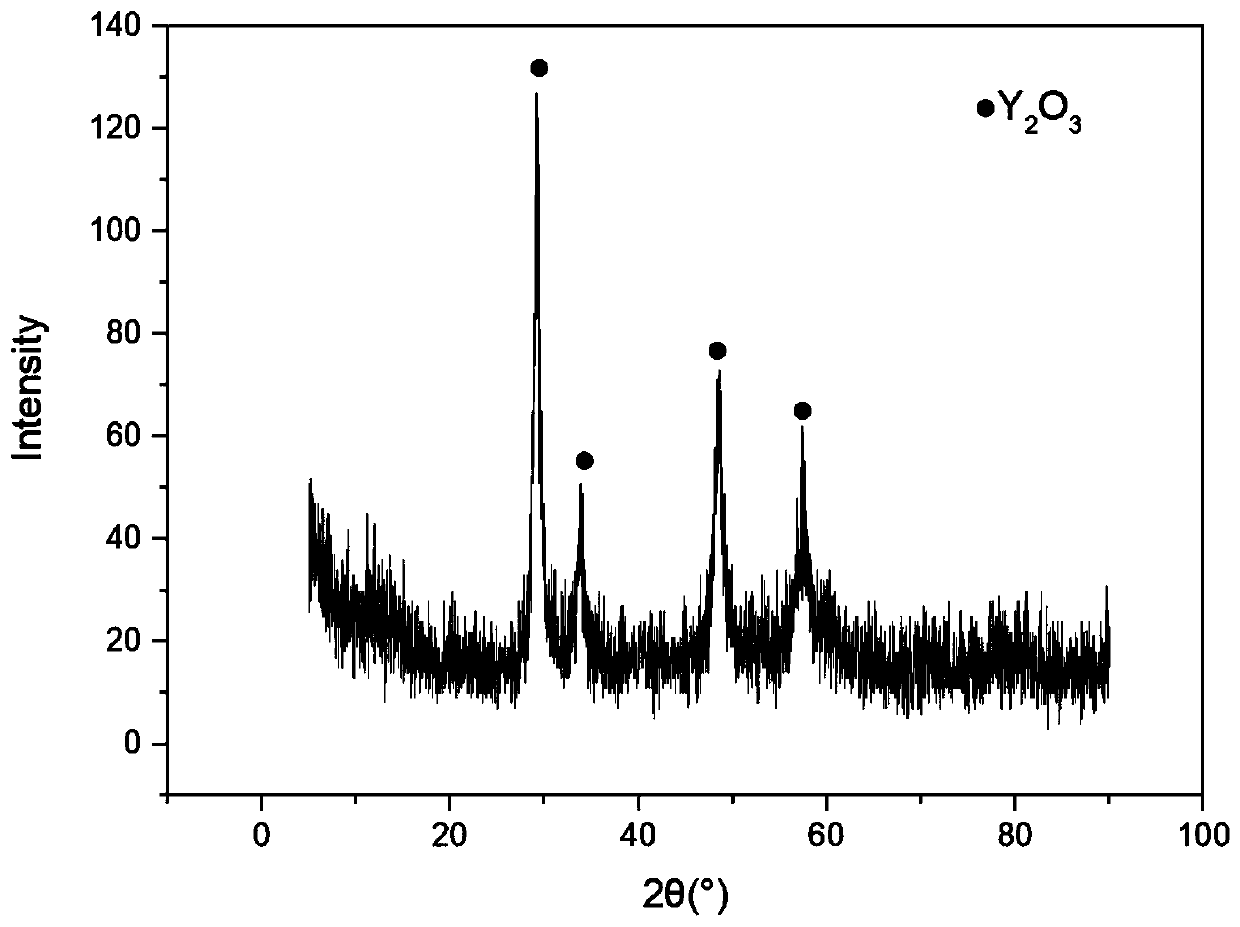

Freeze drying preparation method for ultra-fine tungsten-doped yttrium oxide composite powder

The invention provides a freeze drying preparation method for ultra-fine tungsten-doped yttrium oxide composite powder. According to the freeze drying preparation method, a surface-active agent polyethylene glycol (PEG), polyvinylpyrrolidone (PVP) or polyoxyethylene lauryl ether are added on the basis of freeze drying for in-situ preparing of about 10 nm of ultra-fine nanometer W-Y2O3 composite powder. The freeze drying preparation method comprises the steps that ammonium meta-tungstate, yttrium nitrate hexahydrate and a surface-active agent are dissolved into water and are fully dispersed anddissolved through ultrasonic treatment; then a mixture is placed in a refrigerator to be pre-frozen for a period of time; after being pre-frozen, the mixture is put into a freeze dryer to be subjected to freeze drying; a freeze-dried loose structure is ground and calcined in air so as to remove the surface-active agent, and thus WO3-Y2O3 composite powder is obtained; and finally, two-step reduction is conducted through hydrogen, and thus the ultra-fine tungsten-doped yttrium oxide composite powder is obtained. The powder, with the surface-active agent being added, prepared through the freezedrying method is small in particle aggregation, the average grain size reaches about 10 nm, granularity distribution of grains is extremely narrow, and second-phase Y2O3 is distributed quite evenly.

Owner:TIANJIN UNIV

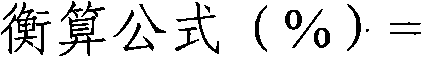

Preparation method for directly drained blow molded transfusion soft bag

The invention relates to a preparation method for a directly drained blow molded transfusion soft bag. The method comprises a bag blank injection molding step and a bag blowing step, wherein during bag blank injection molding, the temperature of a feed cylinder is 180-210 DEG C, the temperature of a main runner of a mould is 210 DEG C, the temperature of a sub-runner of the mould is 320 DEG C, the injection pressure is 25-50Kpa, and the injection speed is 45-55mm / s; pressure maintaining is performed in two sections; the pressure of a first pressure maintaining section is 30-35Kpa and the time is 2 seconds; the pressure of a second pressure maintaining section is 30Kpa and the time is 1 second; and during bag blowing, bag blowing pressure of a bag blowing machine is 1.6-2.2Mpa, pressure of cooling water is 0.2-0.5Mpa, and the temperature of the cooling water is 40-50 DGE C. When the method in the technical scheme is used for preparing a bag blank during injection molding, the bag blank can fill the mould; and the qualification rate of the prepared transfusion soft bag is also improved to over 96 percent.

Owner:ANHUI FENGYUAN PHARM CO LTD

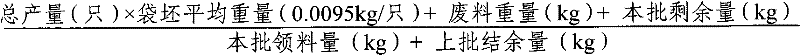

Assistant alloy for Nd-Fe-B permanent magnetic material and its preparation method

ActiveCN1805073AIncrease the solidification rateImprove efficiencyInductances/transformers/magnets manufactureMagnetic materialsRare-earth elementHeat flow

The invention relates to an auxiliary alloy of neodymium iron boron permanent magnetic material and relative one-way control heat flow preparation method. The invention is characterized in that: said auxiliary alloy comprises one or several rare-earth elements, whose total amount is between 30-60wt%, and the other is transition group and one or several kinds of other metallic elements. The producing method comprises: melting raw material to cast the rotational water cooling disc; the rotational water cooling disc forces the water cooling to control the one-way hot flow direction to form the auxiliary alloy with fine cylinder crystal solidified organism. Compared to traditional neodymium iron boron auxiliary alloy producing method, the invention has high producing efficiency, non-component error analysis, uniform solidified organism, easy breakage and high magnetic property without uniform heating process.

Owner:LESHAN YOUYAN RARE EARTH NEW MATERIAL CO LTD

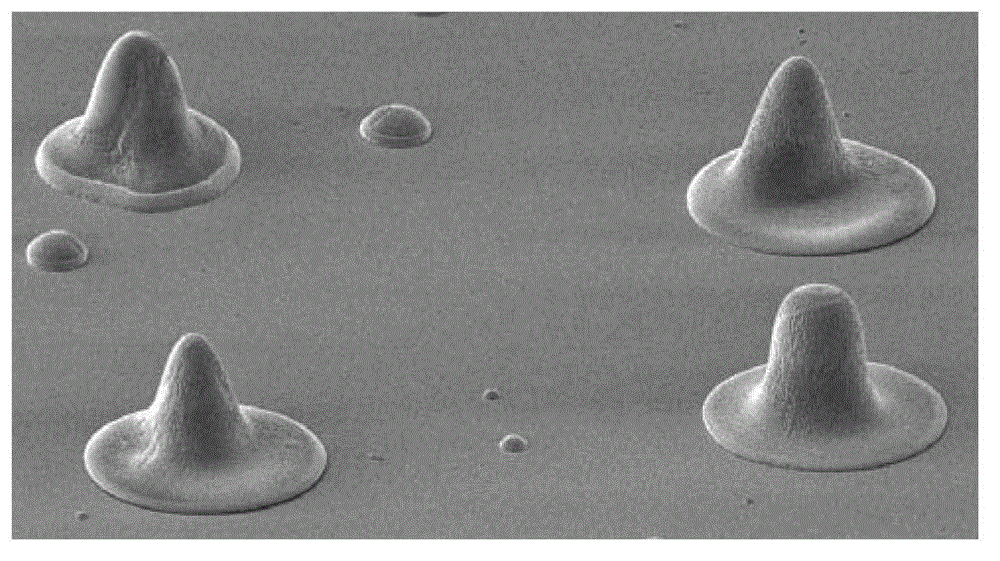

Method for batch preparation of anisotropic particles by ink-jet printing and anisotropic particles thereof

InactiveCN104059430APreparation fitEasy to operateDuplicating/marking methodsInksSolid baseNanometre

The invention relates to a method for batch preparation of anisotropic particles by ink-jet printing and anisotropic particles thereof. The method is characterized in that a polymer aqueous dispersion is taken as an ink-jet printing ink for injecting to a solid base material, the formed ink droplet can form annular semispherical particles with different length diameter according to different wellability of solid base materials; or a response functional material is dispersed in the polymer aqueous dispersion, then is injected to the solid base material, and is deformed under the effect of outfield stimulation, so that taper shape or hat shape particles are formed; or the metal nanoparticles or inorganic oxide nanoparticles are dispersed in the polymer aqueous dispersion, then is injected to the solid base material, because that the metal nanoparticles or inorganic oxide nanoparticles are separated with a phase between the polymers, the anisotropic particles which are characterized in that one end of particle is metal nanoparticle or inorganic oxide nanoparticle, and the other end is the polymer. The method has the advantages of simple operation and low cost, and is suitable for large scale preparation of the anisotropic particles.

Owner:INST OF CHEM CHINESE ACAD OF SCI

Preparation method of electrode for CO2 electrochemical reduction and electrode and application thereof

ActiveCN108118363AAdjustable diameterAdjustable lengthNanotechnologyElectrodesBond energyChemical treatment

The invention relates to a preparation method of an electrode for CO2 electrochemical reduction and the electrode and application thereof. The preparation method comprises the steps that firstly, impurity removal treatment is conducted to a substrate material; secondly, the substrate material is soaked in oxidizing chemical treatment liquid to obtain an electrode precursor with the surface being of a nanometer wire structure; and thirdly, the electrode precursor is subjected to electrochemical reduction treatment to obtain the electrode with a nanometer wire structure layer being attached to the surface of the electrode. According to the preparation method of the electrode for CO2 electrochemical reduction and the electrode and application thereof, compared with an existing bulk phase metal electrode preparation technology, the electrode can provide more active sites for an electrochemical reduction reaction of CO2, and the yield of a target product is improved; and the surface roughness of the nanometer wire structure layer attached to the surface of the electrode is high and changes the bonding energy between the intermediate product CO* and the electrode surface of key steps ofan ERC reaction, the subsequent reaction course of CO* is adjusted and changed, and selectivity of the target product is changed accordingly.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

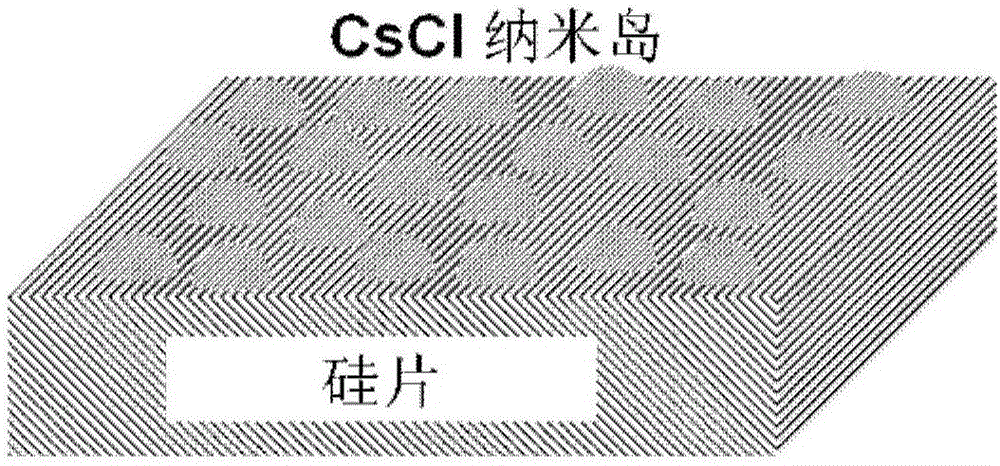

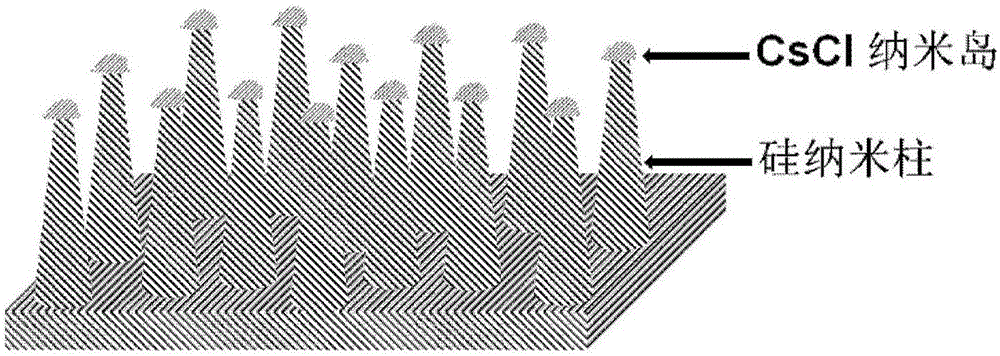

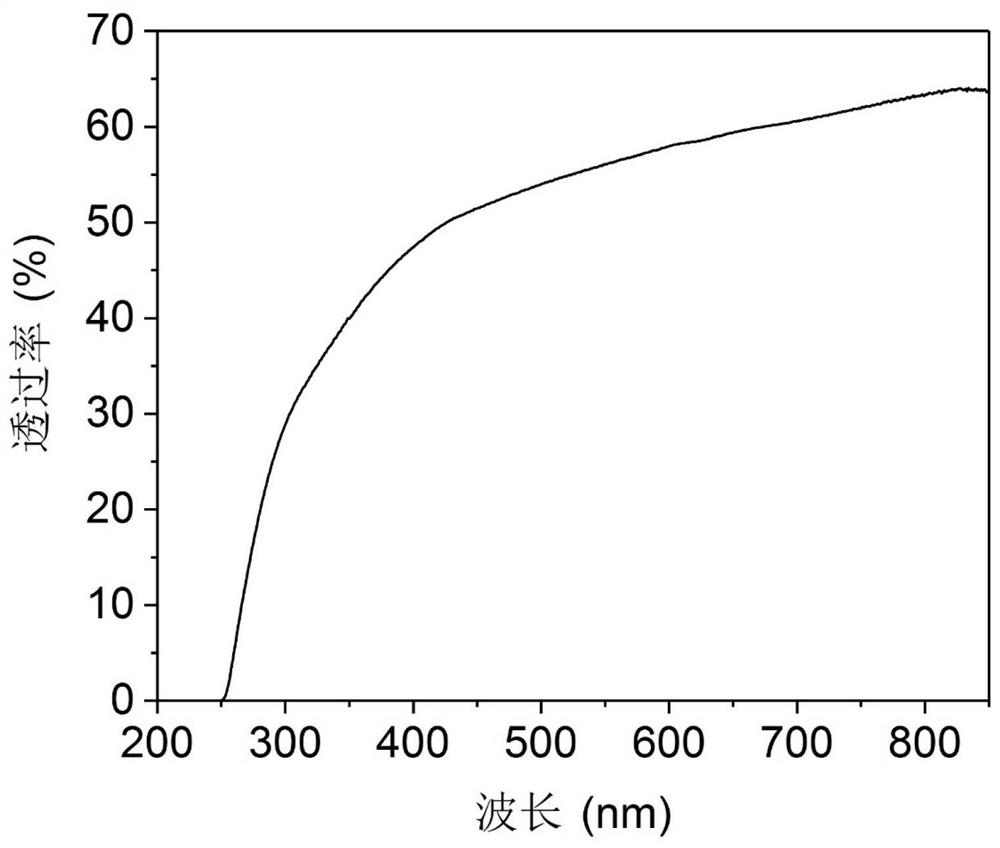

Heterojunction solar cell taking silicon nanorod array as substrate and fabrication method of heterojunction solar cell

InactiveCN106206779AImprove trapping effectIncrease surface ratioFinal product manufacturePhotovoltaic energy generationHeterojunctionTrapping

The invention discloses a heterojunction solar cell taking a silicon nanorod array as a substrate and a fabrication method of the heterojunction solar cell. The solar cell uses a silicon nanorod array with a large depth-width ratio as the substrate, and other thin film materials are wrapped by a magnetron sputtering method to form a heterojunction structure. The fabrication method comprises the following steps of fabricating the silicon nanorod array with the large depth-width ratio on a surface of a P-type silicon wafer by a self-assembly method of a cesium chloride nanometer island; fabricating an aluminum back filed on a back surface; wrapping a surface of the silicon nanorod array with an N-type material layer such as zinc oxide and cadmium sulfide by the magnetron sputtering method; covering a surface of the N-type material layer with an ITO transparent conductive layer; and fabricating a titanium-silver electrode on an upper surface. The solar cell taking the silicon nanorod array with the large depth-width ratio as the substrate has the advantages that 1, the surface ratio of the substrate can be effectively increased, the effective area of a heterojunction is expanded, and absorption to incident light is improved; and 2, by means of a favorable light trapping effect, reflection can be reduced, and the performance of the heterojunction cell is improved.

Owner:INST OF HIGH ENERGY PHYSICS CHINESE ACAD OF SCI

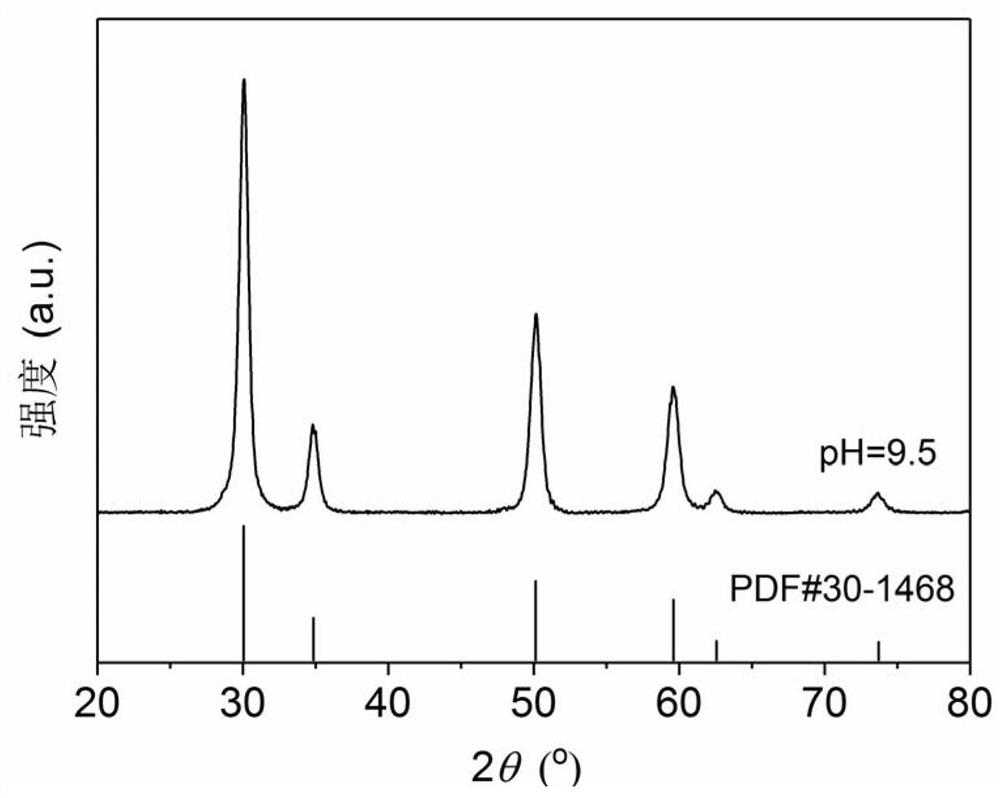

Yttrium-stabilized zirconia ceramic nano-powder as well as preparation method and application thereof

PendingCN112110485ASmall particle sizeImprove compactnessMaterial nanotechnologyRare earth metal compounds preparation/treatmentPhysical chemistryAmmonium carbonate

The invention relates to yttrium-stabilized zirconia ceramic nano-powder as well as a preparation method and application thereof; the yttrium-stabilized zirconia ceramic nano-powder is composed of Y2xZr1-2xO2-x, wherein x is more than 0 and less than 0.15; and the preparation method is characterized by comprising the following steps: (1), respectively weighing a metal ion salt solution containingZr<4+> and a metal ion salt solution containing Y<3+> according to a stoichiometric ratio ofY2xZr1-2xO2-x, and performing mixing to obtain a metal ion mixed solution; (2), adding the obtained metal ion mixed solution into a precipitant solution containing a dispersing agent, and fully performing stirring to obtain a precipitation solution, the precipitant being at least one of ammonia water, ammonium carbonate, ammonium bicarbonate and urea; and (3), aging, washing, drying and sieving the obtained precipitation solution, and performing calcining at 500-1500 DEG C for 1-10 hours to obtain the yttrium-stabilized zirconia ceramic nano-powder.

Owner:SHANGHAI INST OF CERAMIC CHEM & TECH CHINESE ACAD OF SCI +1

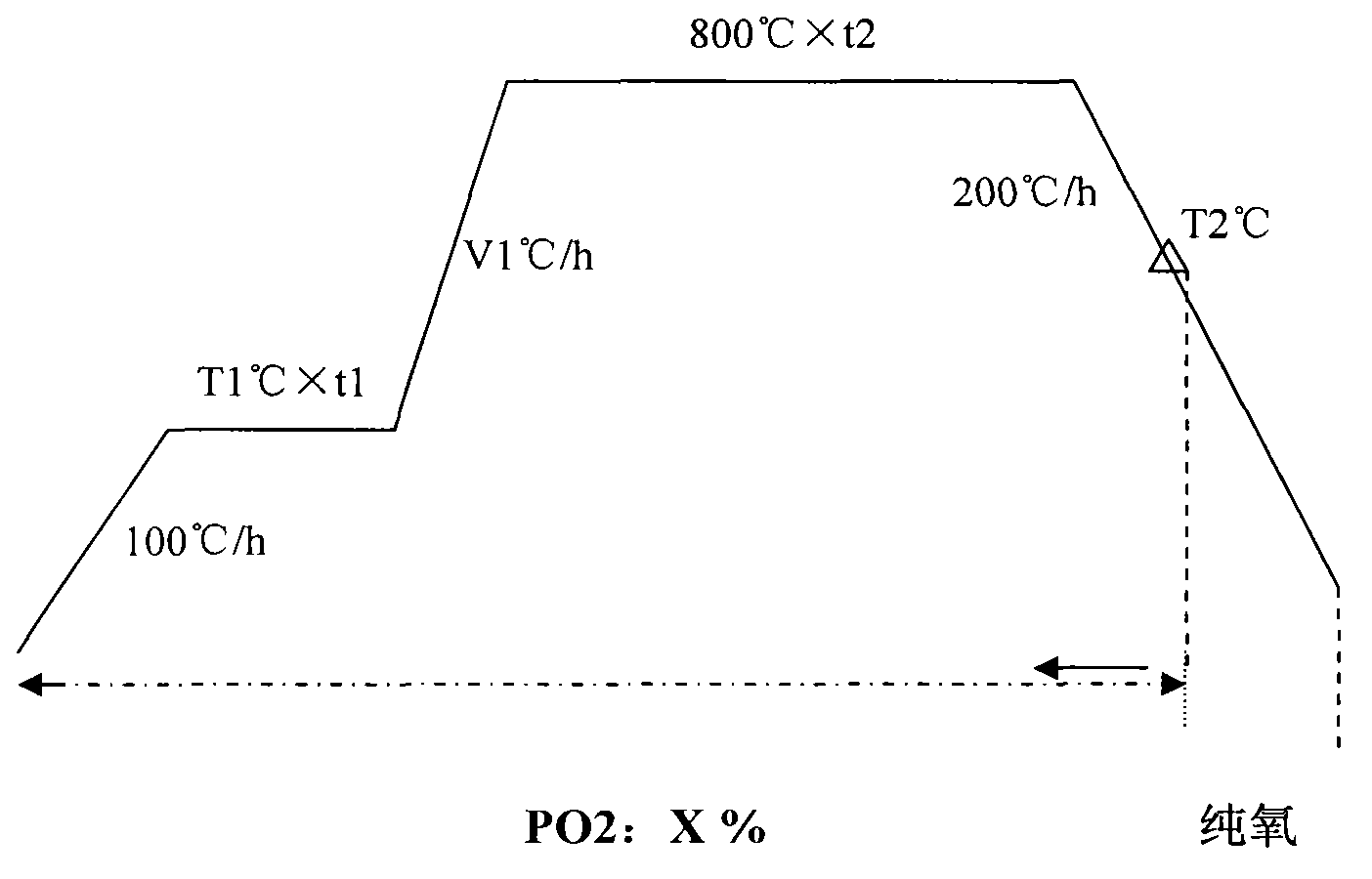

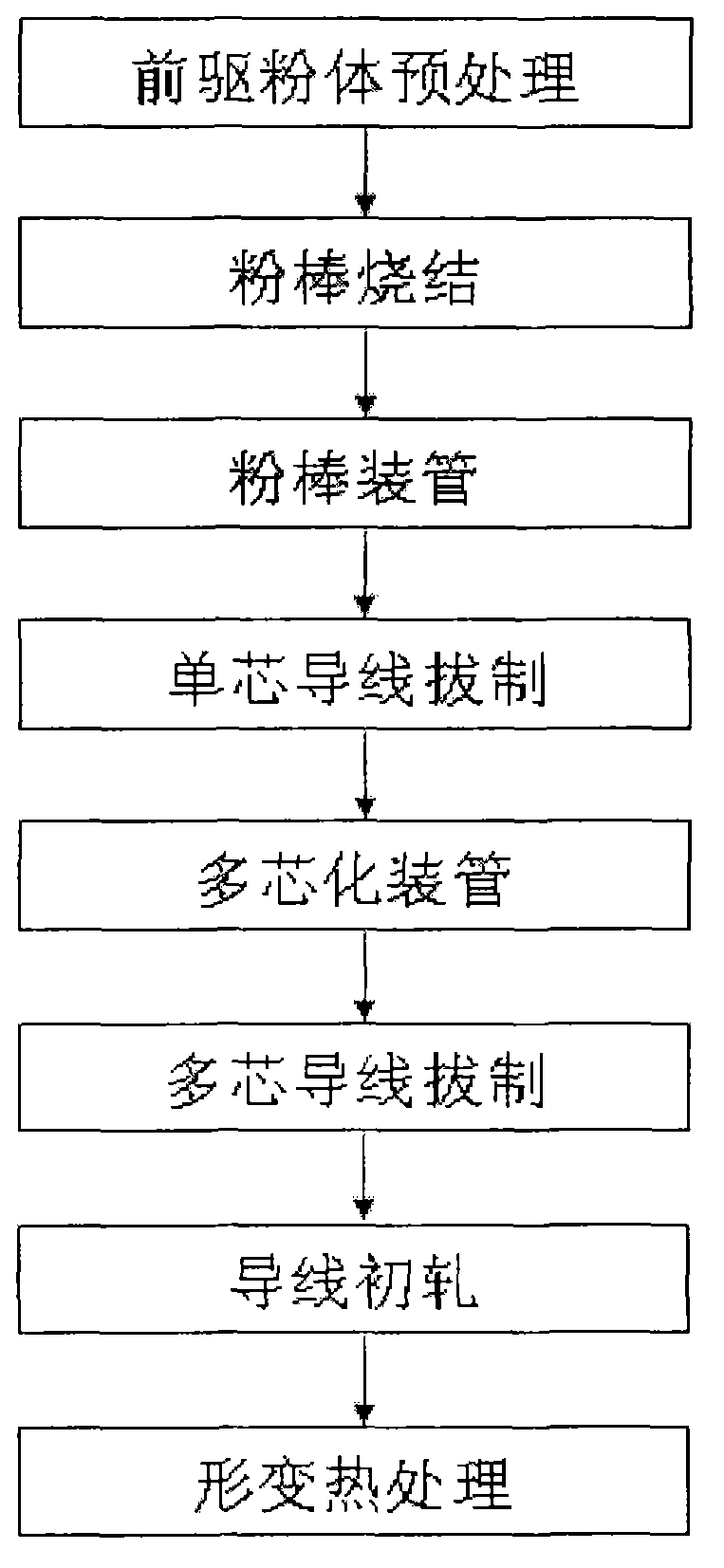

A sintering method for an oxide superconducting powder rod and a method for preparing a superconducting wire rod by using the powder rod sintered by using the sintering method

ActiveCN103058668AImprove fill factorIncrease the critical current densityCable/conductor manufactureWire rodVolumetric Mass Density

The invention relates to a sintering method for an oxide superconducting powder rod, and the concrete method comprises performing sintering treatment at variable rate and variable temperature to the powder rod before tube loading under controlled atmosphere. The invention also relates to a method of preparing a superconducting wire rod, the method comprises treatment steps used for preparing superconducting powder before the tube loading, and the superconducting powder before the tube loading comprises: performing pretreatment to precursor powder, and specifically, performing a step of high temperature sintering, a step of grinding and drying, and a step of pressing into powder rods to the precursor powder, and then performing the step of sintering treatment at variable rate and variable temperature to the powder rod before tube loading under controlled atmosphere. The method for preparing a superconducting wire rod of the present invention enables the superconducting wire rod to have a relatively high filling factor, a high critical current density, uniform performance, and a low defect rate, and the method is particularly suitable for preparation of industrial long superconducting wire rods.

Owner:INNOVA SUPERCONDUCTOR TECH

Hydrothermal preparation method of ultrafine yttrium oxide doped tungsten composite powder

The invention provides a hydrothermal preparation method of ultrafine yttrium oxide doped tungsten composite powder. The hydrothermal preparation method comprises the steps of dissolving one of polyvinylpyrrolidone (PVP), sodium dodecyl sulfate (SDS) or cetyl trimethyl ammonium bromide (CTAB) as dispersant in water together with ammonium metatungstate and yttrium nitrate hexahydrate, regulating pHwith nitric acid or hydrochloric acid, and fully dispersing and dissolving by ultrasonic treatment so as to prepare a solution or a suspension; putting the solution or the suspension in a reaction kettle for hydrothermal reaction; filtering, washing and drying the suspension after the reaction is completed; and calcining composite powder in air flow so as to remove residual dispersant, and performing two-step reduction with hydrogen so as to prepare the ultrafine yttrium oxide doped tungsten composite powder. Compared with a mechanical alloying method, a vacuum drying method, a sol-gel method, a wet chemical precipitation method, a spray drying method and the like, the powder prepared by adopting the hydrothermal preparation method adding the dispersant has the advantages of small grainsand less aggregation, the average grain size can reach about 10 nm, and the grain size distribution is narrow. The method has obvious advantages.

Owner:TIANJIN UNIV

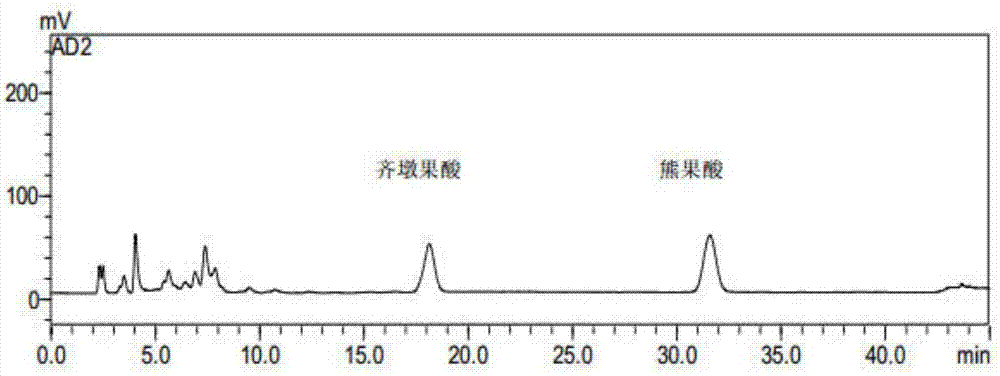

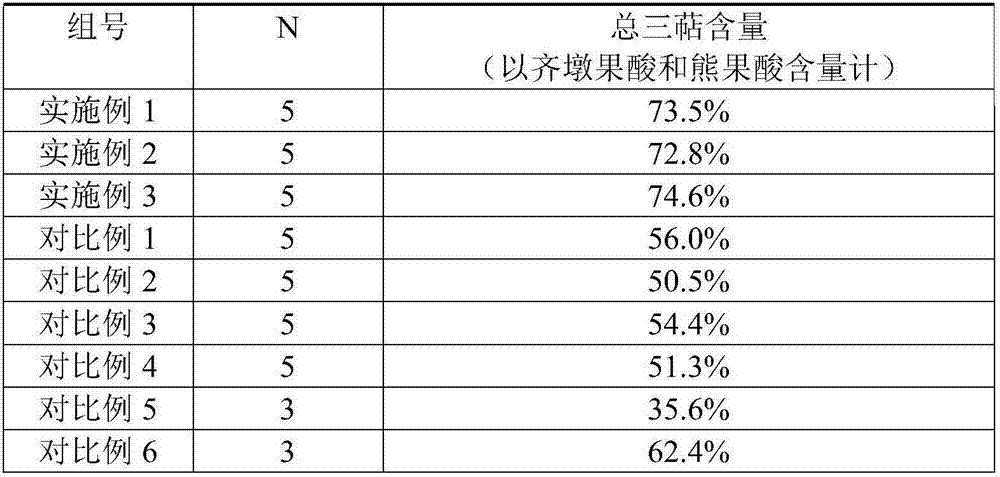

Preparation method and application of ligustrum lucidum ait total triterpene acid extract

ActiveCN107468761AThe preparation process is stable and controllableSuitable for large-scale industrial productionMetabolism disorderPlant ingredientsTriterpeneAlcohol ethyl

The invention discloses a preparation method of a ligustrum lucidum ait total triterpene acid extract. The method comprises the following steps: (1) performing ultrasonic extraction on an ethyl alcohol solution of NaOH; (2) performing heat reflux extraction on ethyl alcohol; (3) performing adsorption by using macroporous resin; (4) performing elution by using a mixed solution of the ethyl alcohol, acetone and water; (5) performing extraction by using petroleum ether and the ethyl alcohol. The prepared ligustrum lucidum ait total triterpene acid extract has high total triterpene acid content (based on oleanolic acid and ursolic acid), namely the purity is high and is up to 70 percent or above; furthermore, the prepared ligustrum lucidum ait total triterpene acid extract contains definite chemical components; a blood fat-reducing medicine prepared from the ligustrum lucidum ait total triterpene acid extract is good in blood fat reducing effect and little in side effect. The preparation method disclosed by the invention is stable, controllable and suitable for large-scale industrial production.

Owner:SHANDONG PROVINCIAL INST OF DERMATOLOGY & VENEREOLOGY

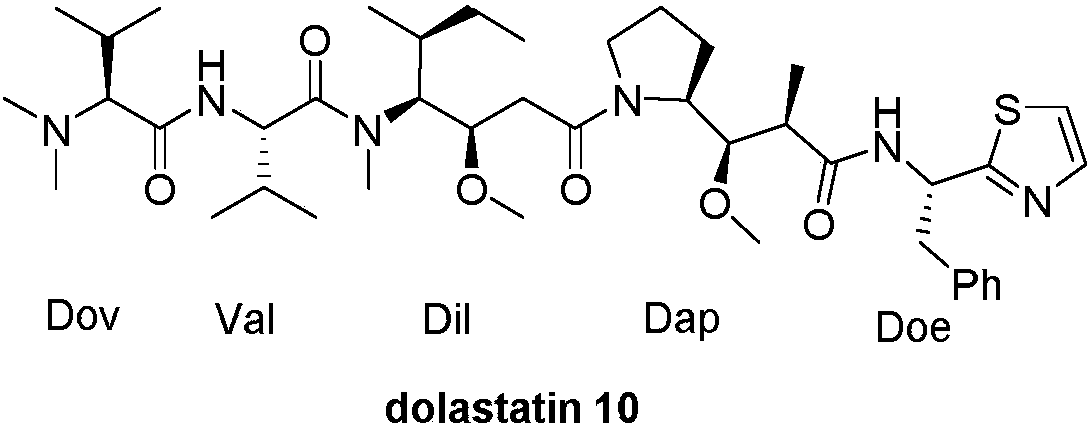

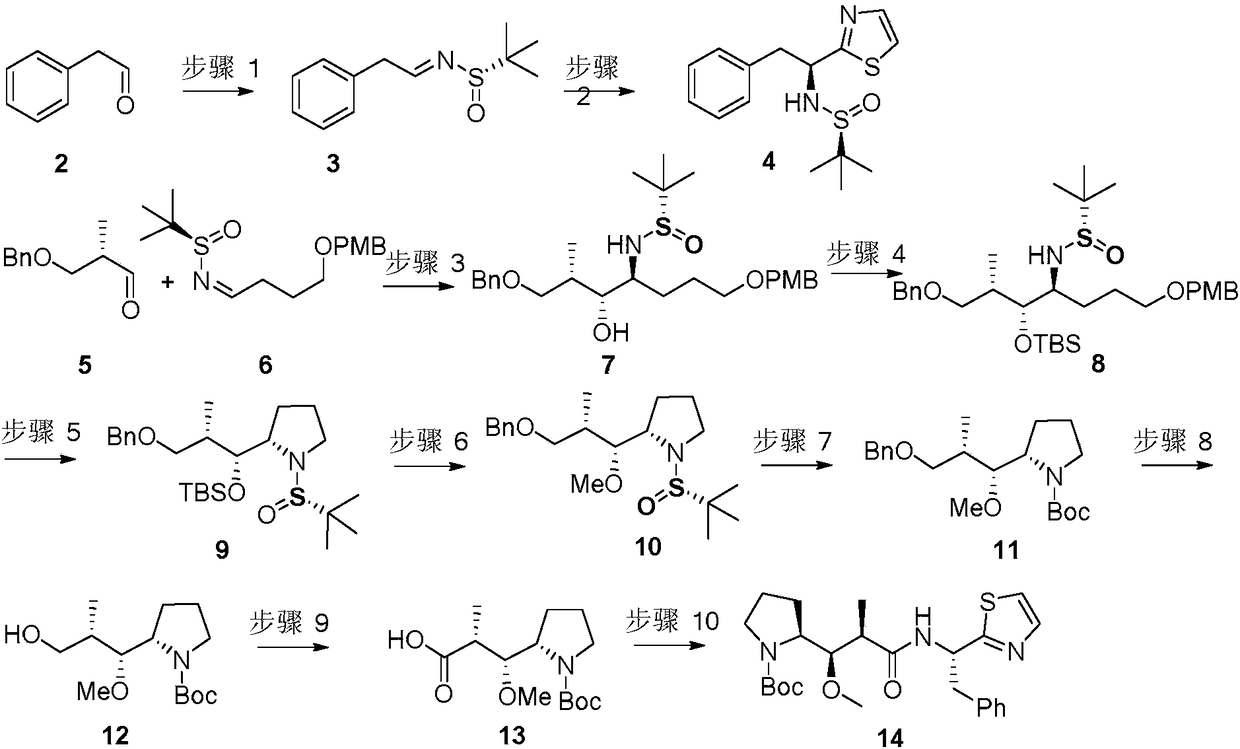

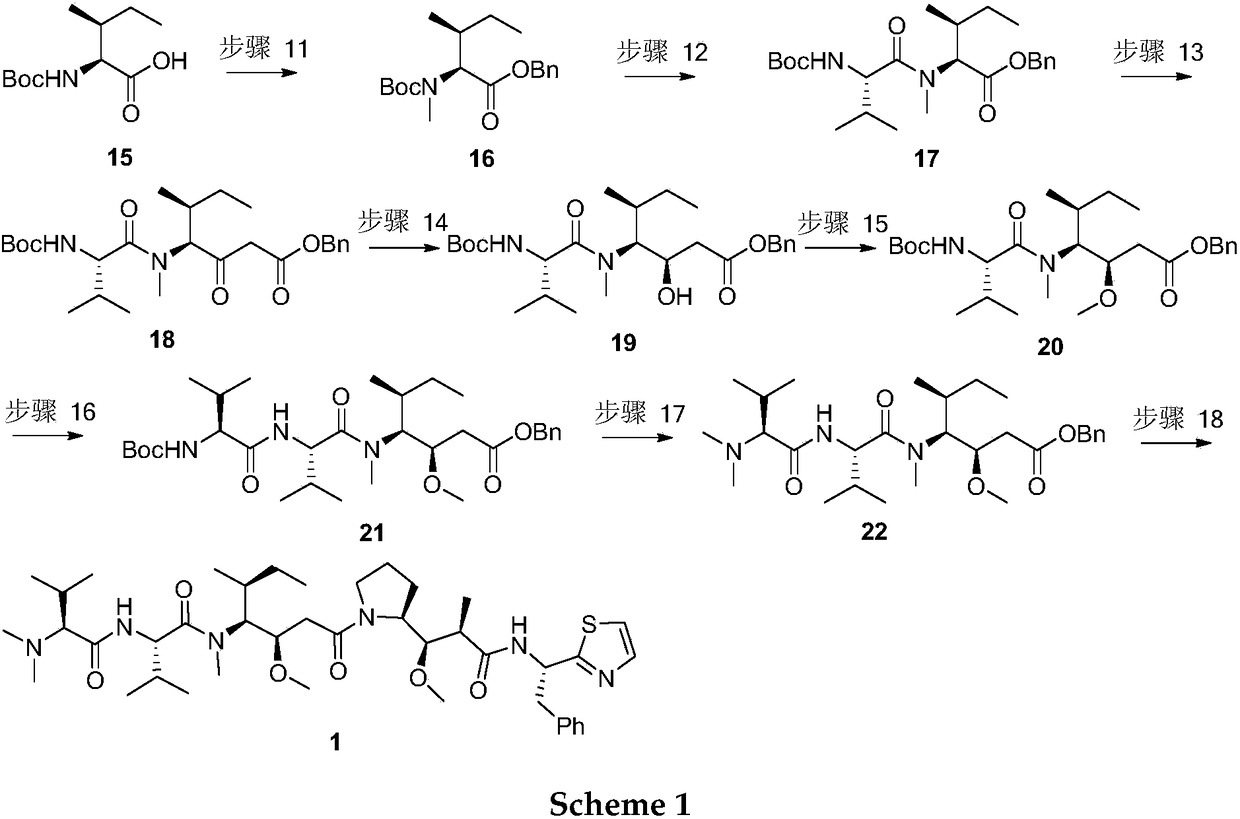

Method for preparing Dolastatin 10 having high anticancer activity

The invention belongs to the technical field of chemical synthesis, and relates to a preparation method of Dolastatin 10 having anticancer activity and represented by the following formula. Accordingto the present invention, in the technical route for preparing the dolastatin 10, the used reagents are all commonly used reagents; the method has advantages of simple operation, high yield, low cost,convenient enlargement production and the like; and the experiment results confirm that the cost of the Dolastatin 10 preparation technical route is significantly reduced, the preparation of the 1-10g Dolastatin 10 can be conveniently achieved in the laboratory, and the method is suitable for large-scale preparation. The formula is defined in the specification.

Owner:FUDAN UNIV

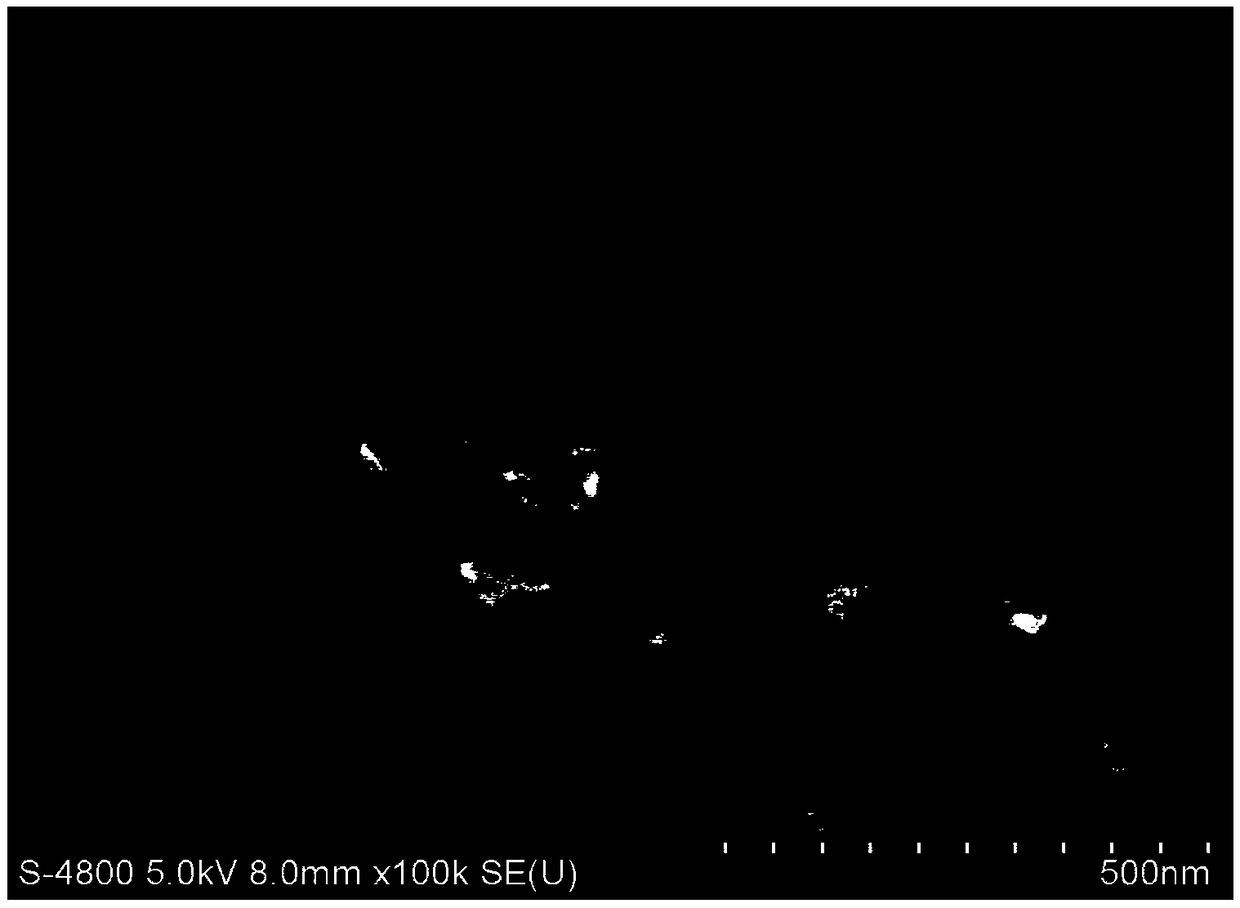

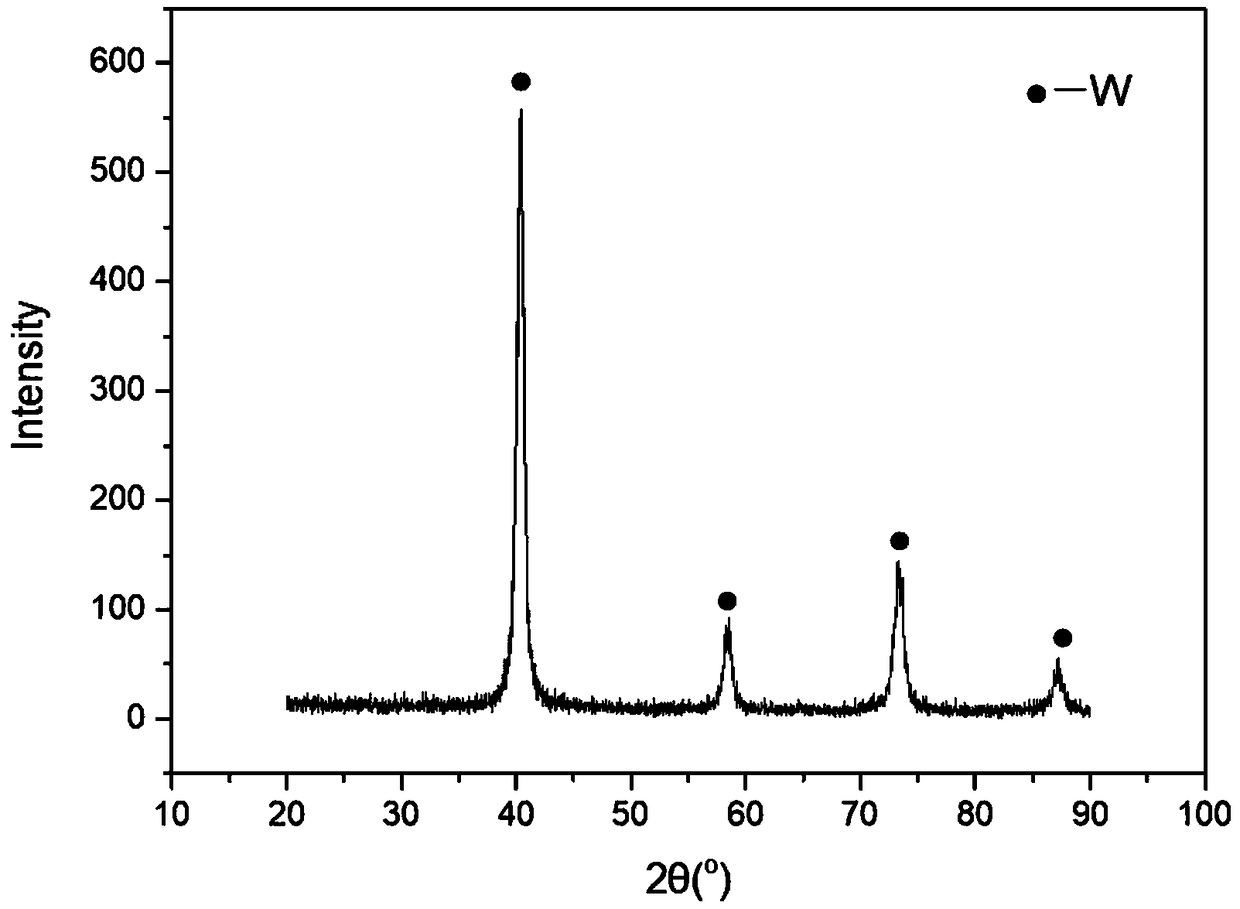

Nano tungsten powder preparing method through adding of surface active agent via freezing drying

ActiveCN108705097AEasy to operateLow costTransportation and packagingMetal-working apparatusFreeze-dryingAmmonium metatungstate

The invention provides a nano tungsten powder preparing method through adding of a surface active agent via freezing drying. According to the method, on the basis of freezing drying, one of surface active agents including polyethylene glycol PEG, fatty alcohol-polyoxyethylene ether AE and polyvinylpyrrolidone PVP is added for in-situ preparing of ultra-fine nano tungsten powder. The surface activeagent and ammonium metatungstate are dissolved in water, and ultrasonic treatment is conducted for sufficient dispersing and dissolving; then pre-freezing is conducted in a refrigerator and other low-temperature environments; after pre-freezing, the mixture is placed in a freezing drying machine to be frozen dry; after freezing dry, grinding is conducted, the surface active agent is removed through roasting in air, and the ultrafine WO3 powder is obtained; and finally, hydrogen is subjected to two-step reduction, and the ultrafine nano tungsten powder is obtained. The powder prepared throughthe freezing drying method after the surface active agent which is PEG, or AE or PVP is small in particle aggregation, the average grain size reaches 10-30 nm, and grain granularity distribution is extremely narrow. The ultrafine nano tungsten powder prepared through the method has obvious advantages.

Owner:TIANJIN UNIV

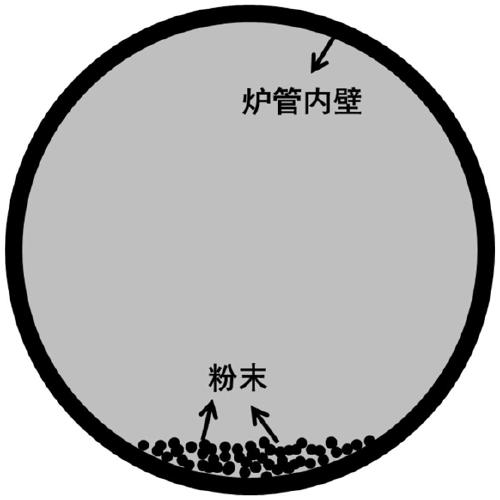

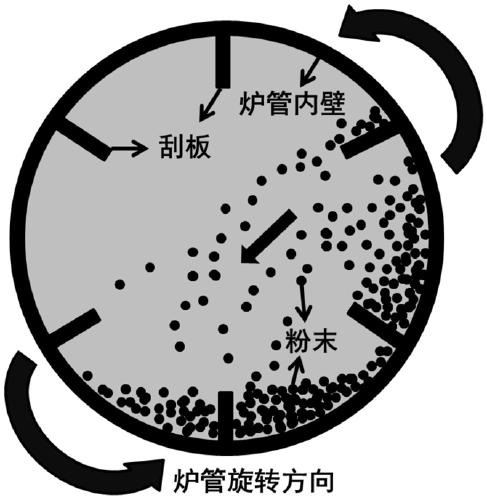

Preparation method for rotary roasting and reduction of yttrium oxide doped tungsten composite powder

InactiveCN109894626AImprove reduction efficiencyReduce throughputRoom temperatureReducing atmosphere

The invention provides a preparation method for rotary roasting and reduction of yttrium oxide doped tungsten composite powder. Precursor powder obtained through various chemical methods is put in a rotary furnace, and the rotating speed of a furnace pipe is adjusted; the precursor powder is roasted in the furnace; and then two-step reduction is carried out in the reducing atmosphere, cooling is carried out in the reducing atmosphere to room temperature, and finally the ultrafine yttrium oxide doped tungsten composite powder is obtained. The preparation method for rotary roasting and reductionis suitable for precursor powder prepared by all chemical methods; and meanwhile, compared with traditional roasting and reduction of precursor powder, the reduction efficiency of the preparation method for rotary roasting and reduction can be improved by 10 times or above. Meanwhile, resources are saved, cost is reduced, and time is saved.

Owner:TIANJIN UNIV

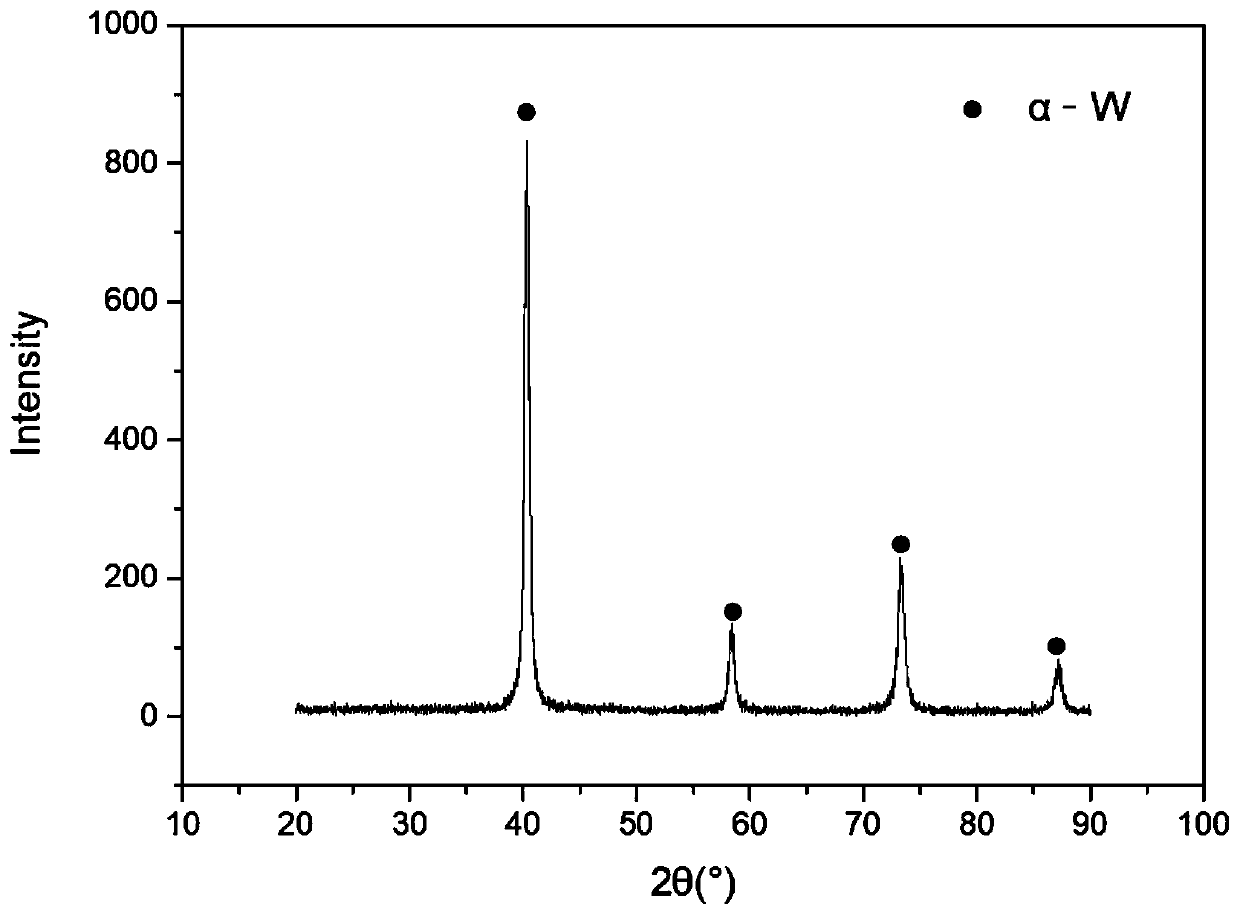

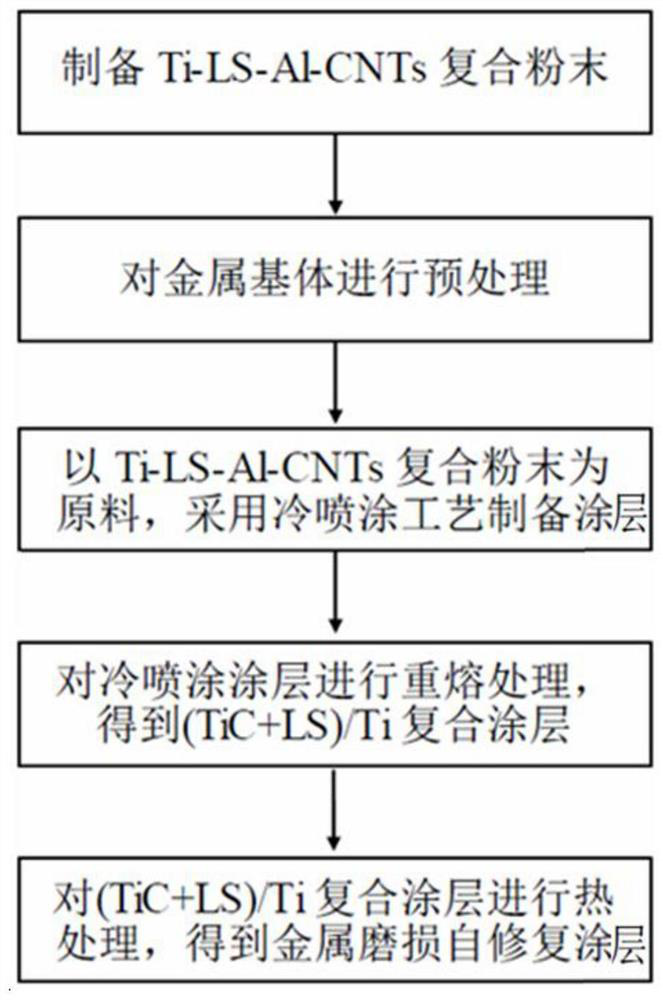

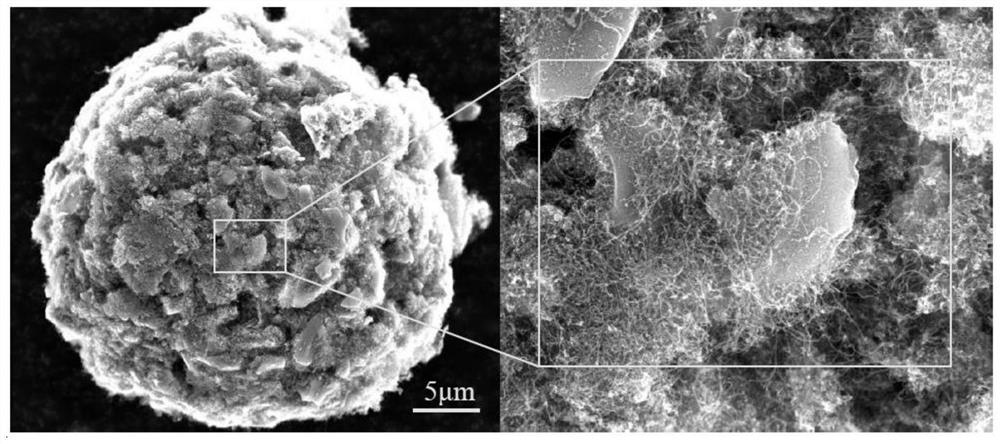

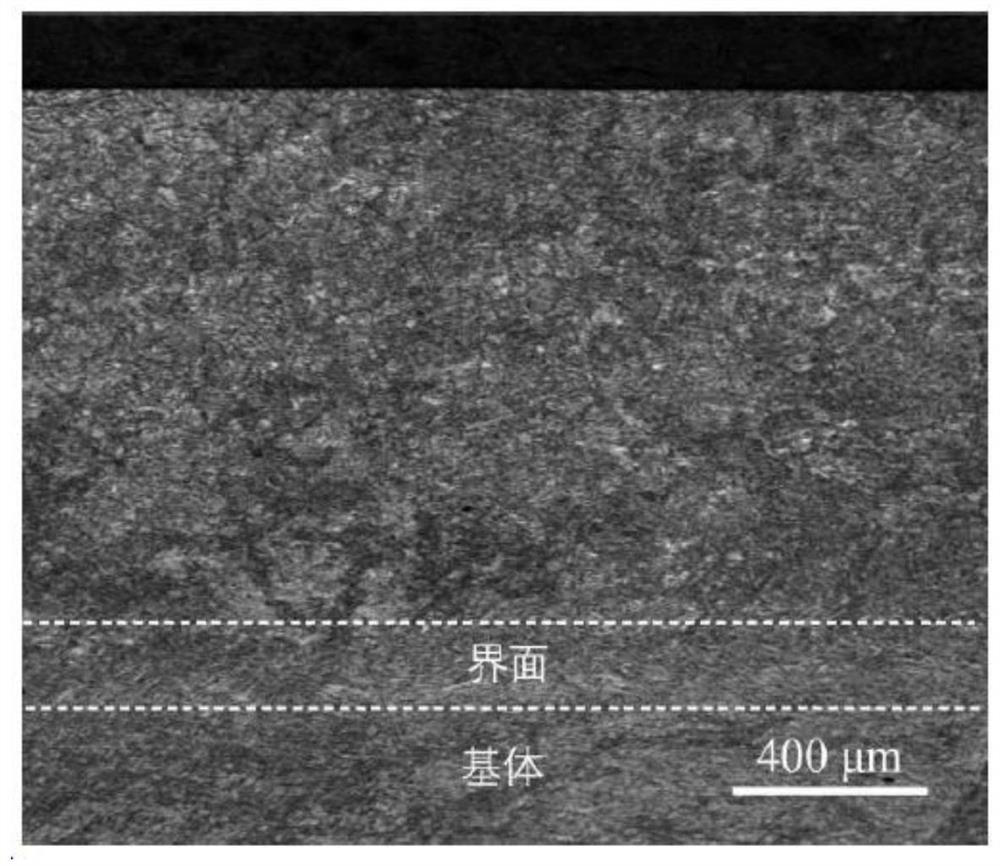

Composite powder for preparing self-repairing coating, preparation method of composite powder, titanium-based wear-resistant self-repairing coating and preparation method of titanium-based wear-resistant self-repairing coating

ActiveCN112974799AEvenly distributedHigh hardnessMaterial nanotechnologyTransportation and packagingAl powderCarbon nanotube

The invention provides composite powder for preparing a self-repairing coating, a preparation method of the composite powder, a titanium-based wear-resistant self-repairing coating and a preparation method of the titanium-based wear-resistant self-repairing coating. The preparation method of the composite powder comprises the following steps: firstly, mixing powder materials (layer silicate mineral powder, Al powder and Ti powder), a nitrate solution, a dispersing agent and a binder, and performing ball milling to obtain slurry; secondly, carrying out spray drying to obtain spherical composite powder particles; and finally, performing chemical vapor deposition treatment in an environment containing carbon source gas to form a carbon nanotube coating layer on the surface of the spherical composite powder, thereby obtaining spherical composite powder coated with carbon nanotubes (namely CNT). The composite powder is used as a raw material, and the wear-resistant self-repairing coating is prepared on the surface of a metal matrix through the steps of matrix surface pretreatment, cold spraying, re-melting treatment, heat treatment and the like. The titanium-based wear-resistant self-repairing coating provided by the invention has high hardness and good wear resistance, and has a wear self-repairing function in oil lubrication, dry friction and vacuum environments.

Owner:ARMOR ACADEMY OF CHINESE PEOPLES LIBERATION ARMY +1

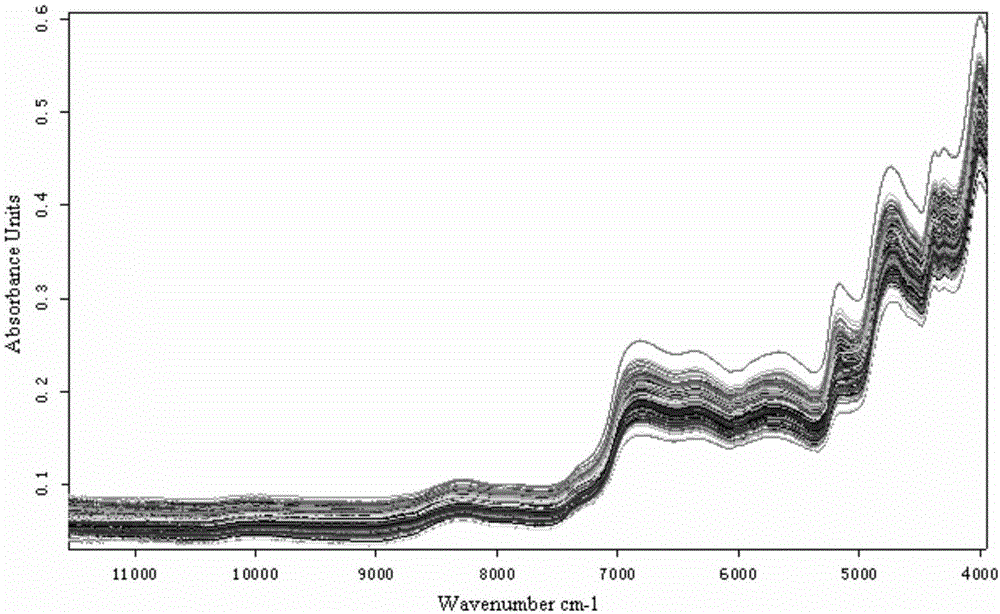

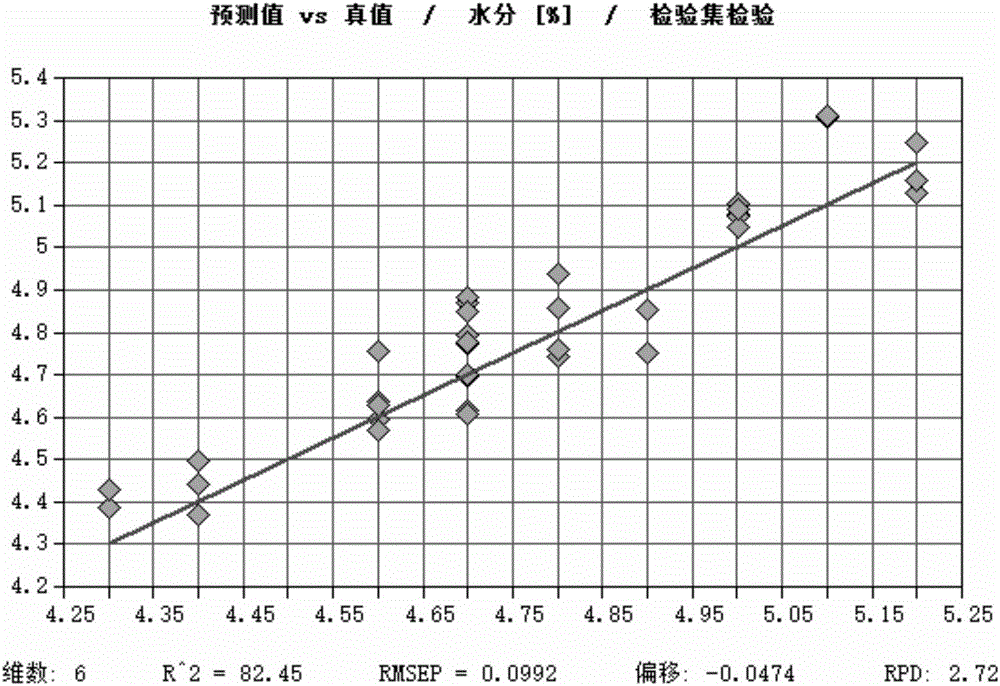

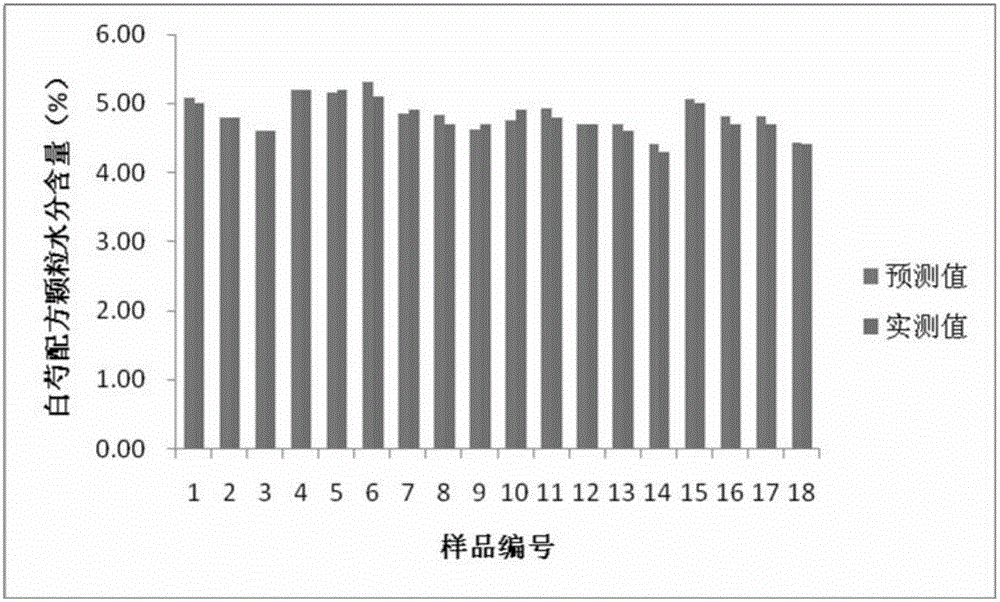

Radix paeoniae alba particles and traditional Chinese medicine preparation

ActiveCN106074742AAdapt quicklyAdapt to needsAntipyreticDigestive systemTraditional medicineChinese herbology

The invention discloses radix paeoniae alba particles. The radix paeoniae alba particles are prepared through a method including the following steps that radix paeoniae alba medicinal slices are taken, water is added into the medicinal slices to decoct the medicinal slices for 1-3 times, water with the volume being 5-10 times that of the medicinal slices is added each time, and heating decocting is carried out for 1-2 h each time; the decoction is collected, the filter liquor is concentrated to obtain clear paste with the relative density of 1.02-1.12, and the clear paste is filtered through a 250-350-mesh screen while the clear paste is hot; spray drying is carried out on the clear paste to obtain spray powder; dry granulation is carried out on the spray powder to obtain the radix paeoniae alba particles with the particle size of 16-40 mesh. The preparation process of the radix paeoniae alba particles is simple, process parameters are easy to control, and a detection method is scientific, fast and high in operability.

Owner:GUANGDONG YIFANG PHARMA

Method for preparing a sintering-resistant metal catalyst

ActiveCN110152676APreparation fitRealize large-scale productionOrganic compound preparationHydroxy compound preparationPorous carbonMetal catalyst

The invention discloses a method for preparing a sintering-resistant metal catalyst, and belongs to the field of catalyst preparation. The problem of sintering is common in the field of catalysis, andis especially common for fixed bed reactions, and migration, agglomeration and growth of active components are caused by sintering of catalysts so that the catalysts are deactivated. The method for preparing the sintering-resistant catalyst has the characteristic of comprising the steps: performing heat treatment on a precursor in an organic liquid phase firstly, then performing Soxhlet extraction and natural airing so as to form solid powder, and finally performing calcination in an inert atmosphere. The surface of the metal catalyst prepared using by the method is covered with a layer of porous carbon films, and the metal catalyst particles can be isolated through the porous carbon films, so that the catalyst is prevented from being sintered; and the method for preparing the catalyst issuitable for preparation of sintering-resistant catalysts which adopt elemental metal as a main body, and the use environment of the metal catalyst is a reaction system which contains no oxidizing gas.

Owner:TAIYUAN UNIV OF TECH

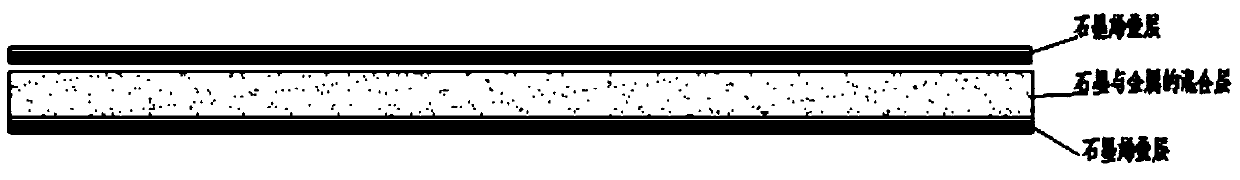

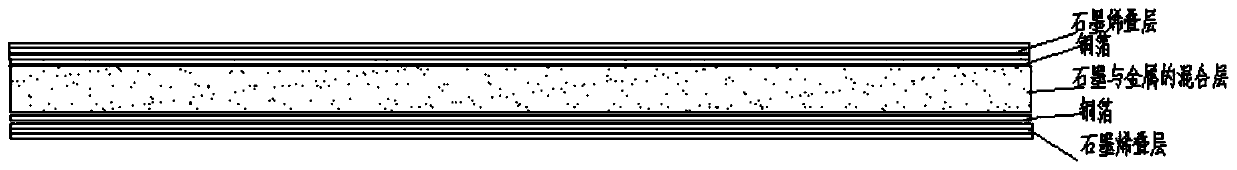

Graphite-graphene-metal composite material preparation method

ActiveCN111069611AImprove conductivityImprove performanceNon-insulated conductorsConductive materialCopper foilGraphene

The invention discloses a graphite-graphene-metal composite material preparation method which comprises the steps of (1) depositing graphene on a coper foil, superimposing multiple layers of copper foils deposited with graphene layers together, and forming a copper-graphene composite layer, wherein the thickness of the copper-graphene composite layer ranges from 1mm to 8mm; (2) preparing a copper-graphite composite layer: uniformly mixing a copper-plated graphite sheet and copper powder, and spreading out to form the copper-graphite composite layer, wherein the thickness ranges from 1mm to 10mm; and (3) alternately stacking the copper-graphene composite layer and the copper-graphite composite layer, and hot-pressed sintering to form a graphite-graphene-metal composite material provided bythe invention. According to the graphite-graphene-metal composite material preparation method provided by the invention, through superimposing and compounding the structure layers with excellent heat-conducting property and electricity-conducting property, a structured anisotropic material with a heat-conducting channel and an electricity-conducting channel which do not influence each other is formed; and meanwhile, due to the same metal matrix, the structure layers are combined tightly, the overall mechanical property and the processability are favorable, and the composite material as a whole shows excellent heat-conducting property and electricity-conducting property and can meet the demand of modern electronic industrialization.

Owner:SICHUAN LEFEI OPTOELECTRONICS TECH CO LTD

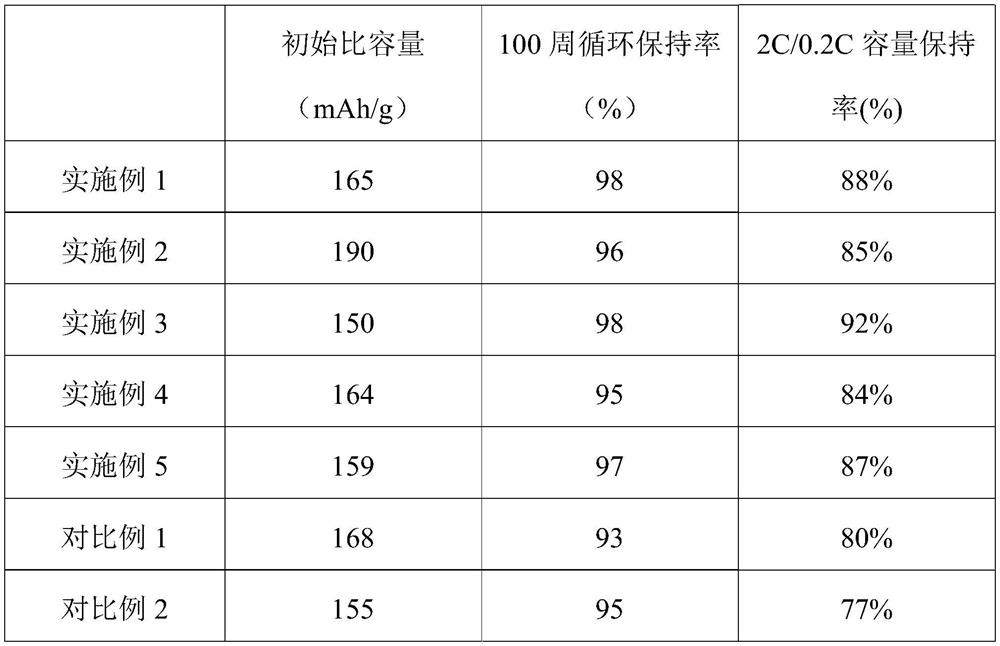

Anode material and preparation method thereof, and lithium ion battery

InactiveCN112421010AImprove electrochemical performanceReduce the mixing degree of lithium and nickelSecondary cellsPositive electrodesComposite materialLithium electrode

The invention discloses an anode material and a preparation method thereof, and a lithium ion battery. The anode material comprises a core and a coating layer coating the core, and the coating layer is made of a material capable of conducting electrons and ions. The preparation method comprises the following steps: 1) mixing a lithium source with a hydroxide precursor, and calcining a mixed product to obtain the core; and 2) mixing the core with the coating layer material, and calcining the mixed product to obtain the anode material, wherein the coating layer material is the material capable of conducting both electrons and ions. According to the anode material provided by the invention, the material capable of conducting electrons and ions is coated so that the electrochemical performanceof the material is improved, and a rate capability and safety performance can be improved while good cycle performance is maintained.

Owner:EVE ENERGY CO LTD

Preparation method of PbMo6S8 superconducting wire

ActiveCN111554505AIncrease the critical current densityGuaranteed uniformityInorganic material magnetismInductances/transformers/magnets manufactureWire rodCopper wire

The invention discloses a preparation method of a PbMo6S8 superconducting wire. The method comprises the steps that: precursor powder is prepared through adoption of a high-energy ball milling method;then, the PbMo6S8 precursor powder is put into a Mo pipe; the Mo pipe is processed into a PMS single-core wire / bar; and then a plurality of PMS single-core wires / rods and a central copper wire / rod are loaded into a stainless steel pipe or a Monel 400 jacketed pipe for secondary assembly, a multi-core PMS precursor wire rod is manufactured through stretching, and the wire rod is subjected to high-temperature melting quenching treatment and phase-forming heat treatment to obtain the PMS superconducting wire rod. MRHQ and phase-forming heat treatment are adopted to replace traditional diffusionphase-forming heat treatment, intergranular impurities in the superconductor are remarkably reduced, grain connectivity is improved, and therefore the critical current density of the wire is remarkably improved. The method is simple, is suitable for preparing the superconducting long wire, is beneficial to large-scale popularization and application, and has huge commercial value.

Owner:合肥夸夫超导科技有限公司

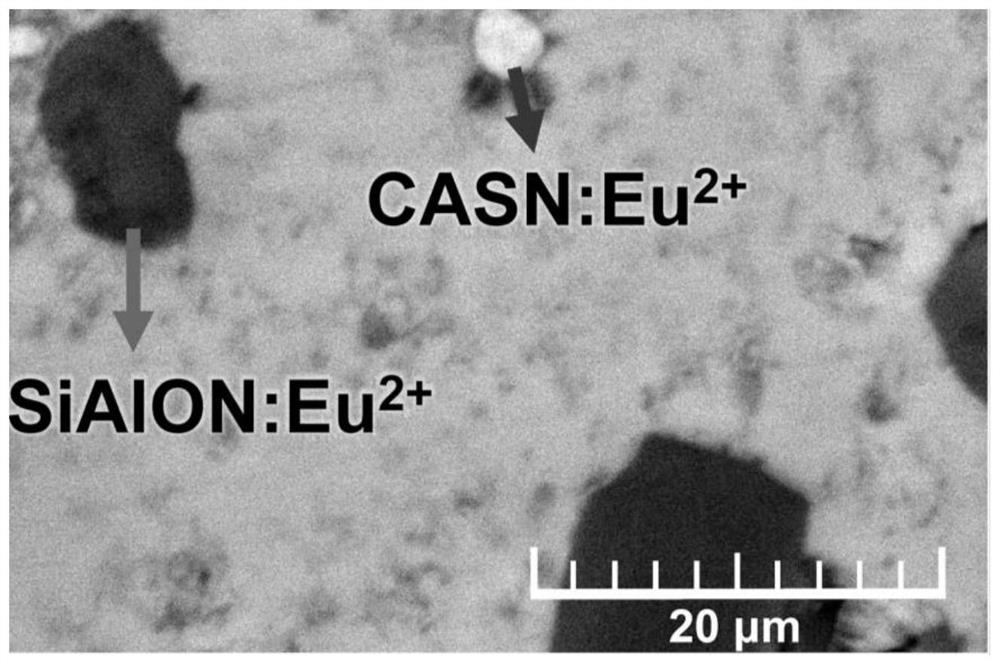

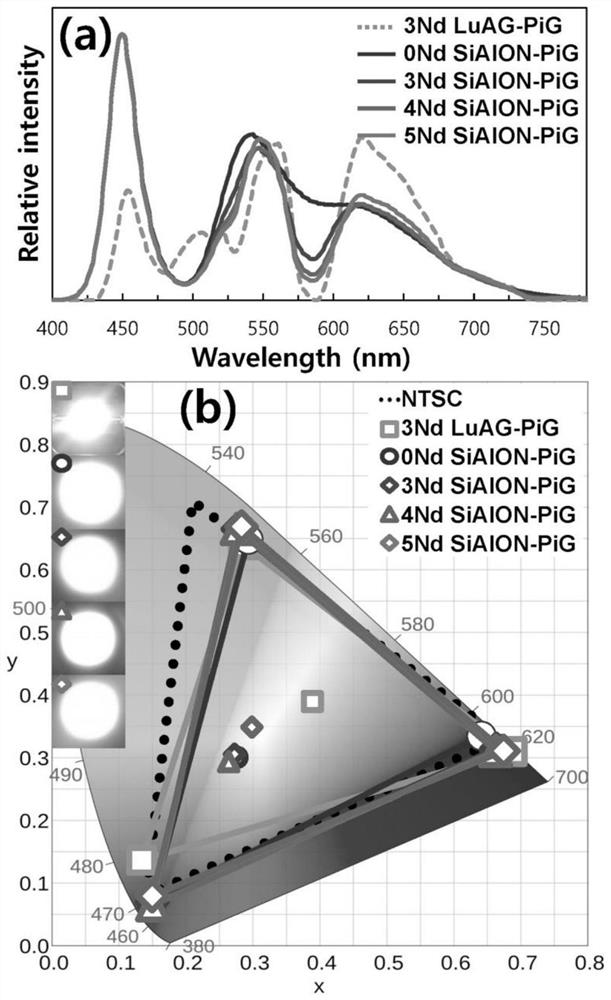

Wide-color-gamut glass for LED display and preparation method thereof

ActiveCN112551892APreparation fitIncrease productionGlass shaping apparatusLuminescent compositionsPhysicsSilicate glass

The invention discloses wide-color-gamut glass for LED display and a preparation method thereof, and belongs to the technical field of preparation and application of photoelectric display materials. The chemical component of the wide-color-gamut glass is 65SiO2-25Na2O-5BaO-5ZnO-xNd2O3, x is larger than or equal to 3 mol% and smaller than or equal to 5 mol%, and 0.3 wt% (beta-SiAlON: Eu < 2 + >) fluorescent powder and yCaAlSiN3: Eu < 2 + > fluorescent powder are doped, wherein y is larger than or equal to 1 wt% and smaller than or equal to 3 wt%. The wide-color-gamut glass is prepared by usingthe melt quenching method, and the Nd2O3 is doped into the silicate glass so that the emission bandwidths of the green fluorescent powder and the red fluorescent powder are effectively reduced, the color gamut is further improved, and the NTSC color gamut of the prepared glass is 87-88%; the preparation method is simple in process, stable in product performance and suitable for industrial production.

Owner:XINYI XIYI ADVANCED MATERIALS RES INST OF IND TECH CO LTD

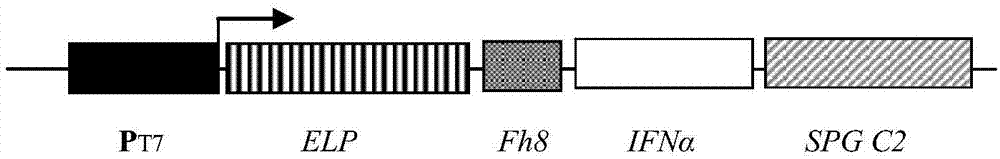

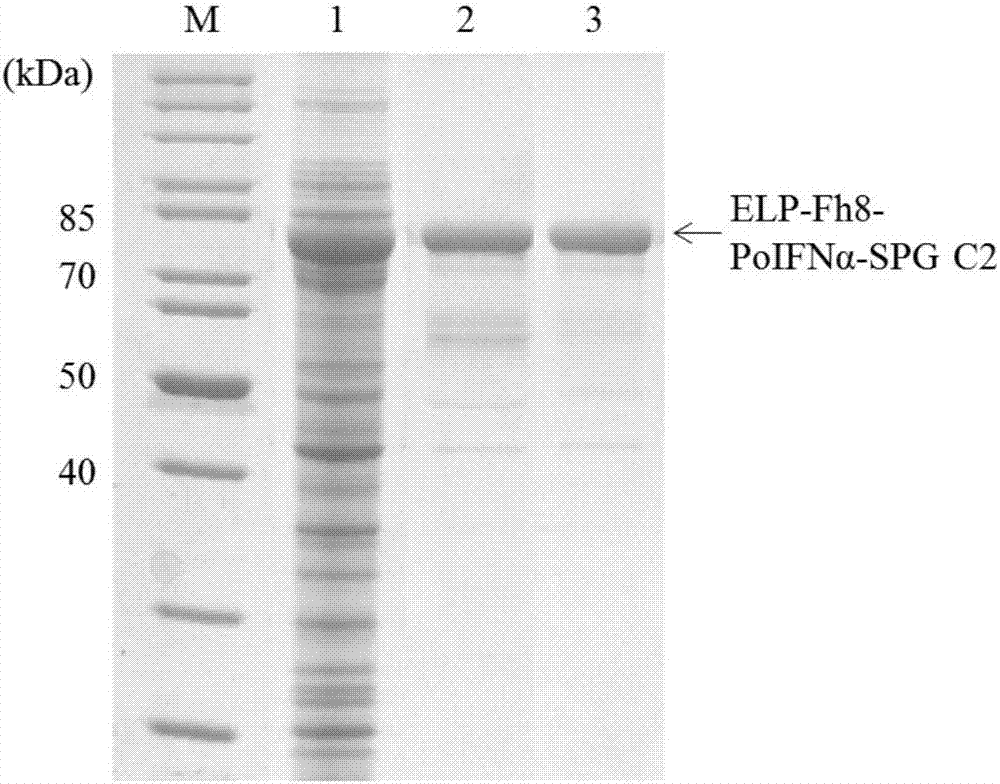

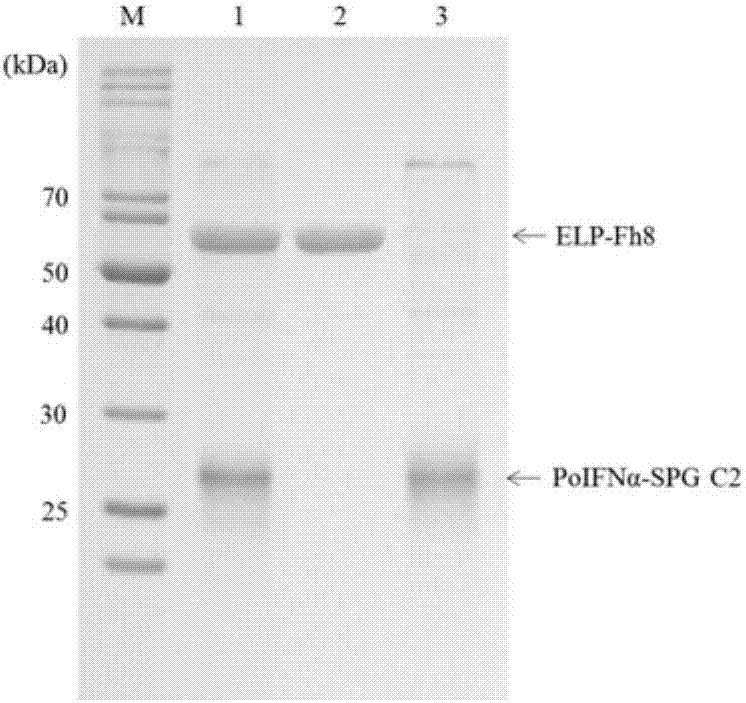

Long-acting interferon and preparation method thereof

InactiveCN107082814AExtended half-lifeEasy to prepareNucleic acid vectorFusions for plasma life prolongingBiotechnology researchHalf-life

The invention belongs to the field of biotechnological research, and particularly relates to long-acting interferon and a preparation method thereof. The long-acting interferon is composed of interferon and streptococcal G protein C2 structural domain, and the preparation method includes the steps of fusion expression vector, fusion interferon expression and purification, purification tag removal and fusion interferon recovery. Compared with the existing recombinant interferon, the long-acting interferon has the advantages of being simple in preparation process, low in cost, long in half-life period and the like, and can be used for the preparation of long-acting interferon for human and animals.

Owner:YANGZHOU UNIV

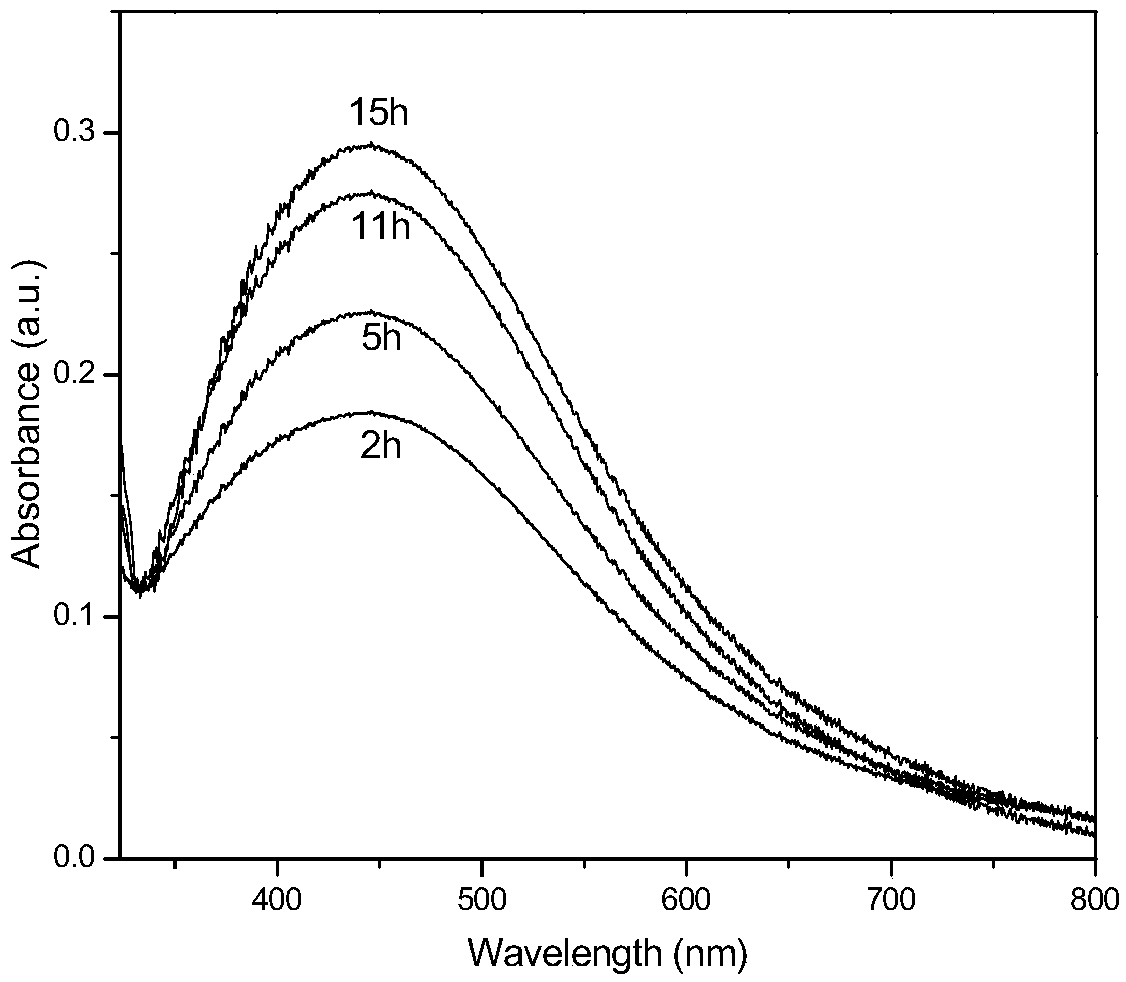

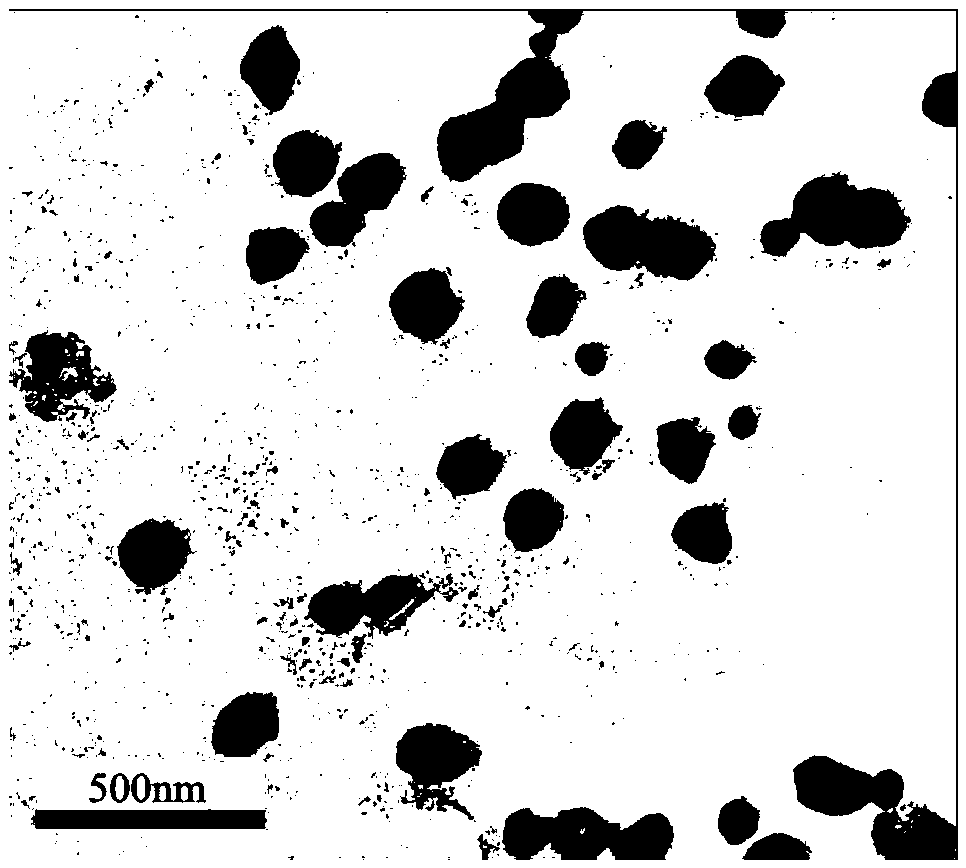

Nano silver particle and its synthesis method

ActiveCN103769603BInduce and regulate productionIncrease concentrationCoatingsSynthesis methodsSpherical shaped

The invention belongs to the technical field of nanometer material synthesis, and particularly relates to a nanometer silver particle and a synthetic method thereof. The nanometer silver particle is in a spherical shape or a similar spherical shape, the surface of the nanometer silver particle is provided with a biomolecule wrapping layer, and biomolecules contain carboxyl groups with negative charge oxygen atoms. The nanometer silver particle is of a cubic crystal structure, and the particle diameter of the nanometer silver particle is 50 to 150nm. The nanometer silver particle is prepared by a biological material reduction method, orange juice and Ag<+> solution are uniformly mixed, the stirring is carried out at 26 to 34 DEG C, the centrifugal separation is carried out after the reaction completion, precipitates are washed and dried, and the nanometer silver particle is obtained. The biomolecules in the orange juice are used as templates, AgNO3 solution is utilized for providing silver ions, and the nanometer silver particle with the spherical appearance is synthesized through regulation and control. In fruit and vegetable juice such as orange juice, oxygen atoms on the groups such as carboxyl contained in biomolecules such as amino acid and vitamin mostly carry residual negative charges, the residual negative charges generate mutual effects with Ag<+>, nucleation sites are provided, and the generation of the nanometer silver particle is induced, regulated and controlled.

Owner:永新股份(黄山)包装有限公司

Freeze drying preparation method for nano-rare earth oxide powder

ActiveCN109942015ANo chemical reactions involvedReduce pollutionNanotechnologyRare earth metal compoundsChemical reactionFreeze-drying

The invention discloses a freeze drying preparation method for nano-rare earth oxide powder. The method comprises the following steps: dissolving one or two of dispersants, namely polyethylene glycoland fatty alcohol-polyoxyethylene ether, in water, dissolving soluble rare earth nitrate in water, and carrying out ultrasonic treatment so as to realize adequate dispersion and dissolving; atomizingthe solution into liquid nitrogen for pre-freezing or carrying out pre-freezing at -20 DEG C for over 4 hours; after the temperature of a freeze dryer is decreased to -50 DEG C, introducing the pre-frozen solution into the freezer dryer, starting a vacuum pump to maintain the vacuum degree to be below 20Pa, and carrying out freeze drying for 8-36 hours; and after the freeze drying, grinding composite powder, putting the composite powder into a furnace, and calcining the composite powder in air to remove the dispersing agent, so as to obtain the superfine nano-rare earth oxide powder. The preparation method is a physical method, does not relate to chemical reaction and is low in pollution, and the process is simple and convenient.

Owner:TIANJIN UNIV

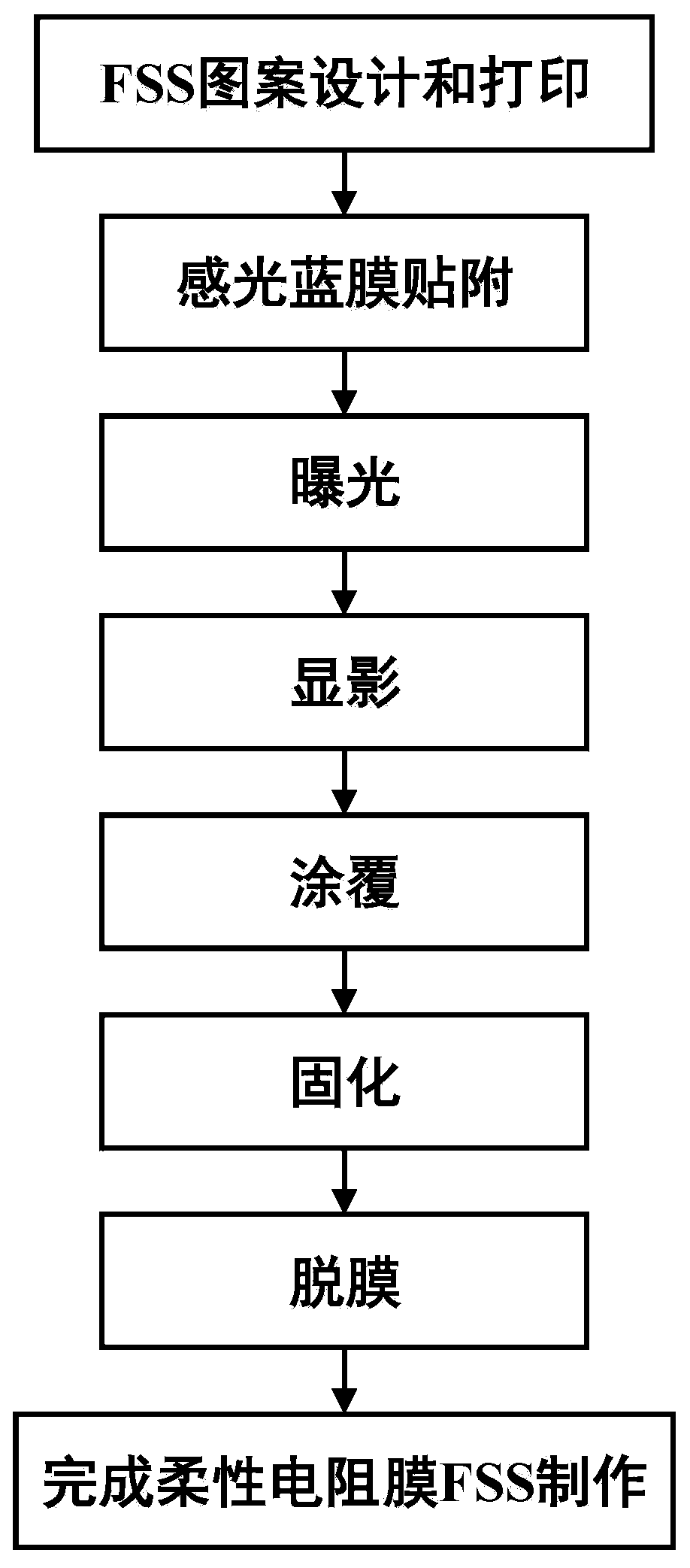

Preparation method and application of a flexible resistive film frequency selective surface

ActiveCN110247192BMature technologyEasy to operateMagnetic/electric field screeningResistor manufacture by lithographyRadarDielectric substrate

The invention belongs to the field of flexible FSS radar wave-absorbing structures, and more particularly to a flexible resistive film frequency selective surface, a preparation method and application thereof. The method comprises the steps of: printing a set frequency selective surface pattern on a photosensitive film, and attaching the photosensitive film to the surface of a flexible dielectric substrate; successively exposing and developing the photosensitive film on which the frequency selective surface pattern is printed in order to expose the frequency selective surface pattern on the surface of the flexible dielectric substrate; coating the surface of the developed flexible dielectric substrate with resistive conductive carbon paste, and sintering and curing the flexible dielectric substrate coated with the conductive carbon paste, wherein the cured conductive carbon paste is a resistive film; demolding the cured flexible dielectric substrate, removing the photosensitive film and the resistive film on the surface of the flexible dielectric substrate to obtain the flexible resistive film frequency selective surface. The FSS surface preparation method of the invention is simple, and can produce a large-area flexible passive resistive film frequency selective surface applied to a curved surface.

Owner:HUAZHONG UNIV OF SCI & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com