Composite powder for preparing self-repairing coating, preparation method of composite powder, titanium-based wear-resistant self-repairing coating and preparation method of titanium-based wear-resistant self-repairing coating

A composite powder, self-healing technology, applied in nanotechnology, coating, metal material coating technology for materials and surface science, etc., can solve problems such as the inability to effectively improve the tribological properties of titanium-based composite materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

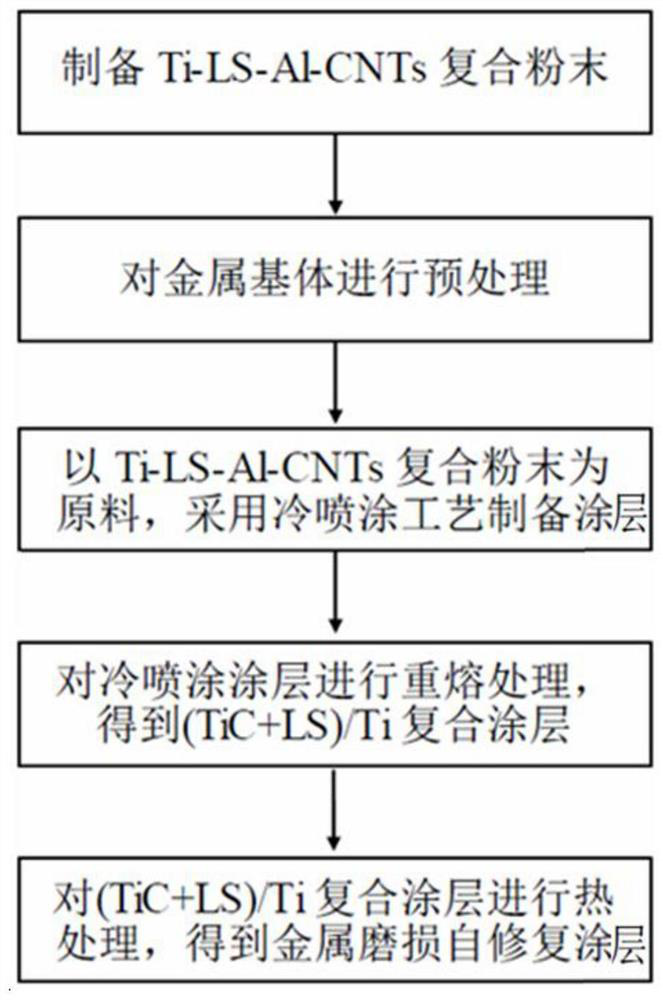

[0070] The present invention provides a kind of preparation method for the composite powder that is used for preparing self-healing coating, comprises the following steps:

[0071] a) mixing and ball milling powder, dispersant, nitrate solution and binder to obtain slurry;

[0072] b) spray drying the slurry to obtain Ti-LS-Al spherical composite powder;

[0073] c) performing chemical vapor deposition on the Ti-LS-Al spherical composite powder in a mixed gas environment of hydrocarbon gas, hydrogen and inert gas to obtain a carbon nanotube-coated Ti-LS-Al spherical composite powder;

[0074] Described powder comprises the component of following mass ratio:

[0075] Layered silicate mineral powder 1% to 6%;

[0076] Al powder 3% ~ 9%;

[0077] Ti powder balance;

[0078] The nitrates in the nitrate solution are iron nitrate, nickel nitrate and magnesium nitrate.

[0079] In the present invention, powder (layered silicate mineral powder, Al powder and Ti powder), nitrate s...

Embodiment 1

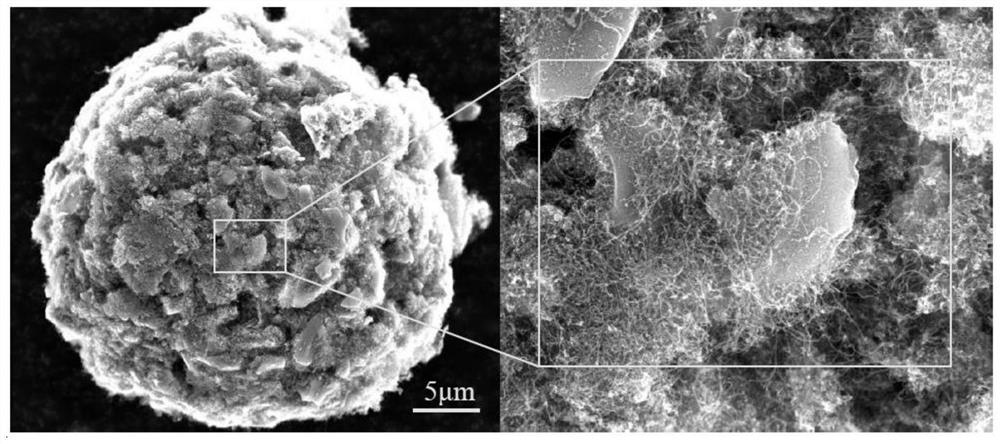

[0134] 1.1 Preparation of carbon nanotube-coated Ti-LS-Al spherical composite powder

[0135] S1, put the powder, absolute ethanol and nitrate solution into the ball milling jar of the planetary ball mill, add polyvinyl alcohol after ball milling for 2 hours and continue ball milling for 4 hours (using the ball milling jar and grinding balls of agate material, the ball-to-material ratio is 25: 1), obtain slurry.

[0136] in:

[0137] The powder includes: 1% attapulgite, 6% Al powder, and the balance of Ti powder.

[0138] Dehydrated alcohol is 100% of powder quality.

[0139] The nitrate solution is 80% of the powder mass, and the concentrations of iron nitrate, nickel nitrate and magnesium nitrate in the solution are all 0.7mol / L.

[0140] Polyvinyl alcohol is 15% of powder mass.

[0141] S2. Take out the slurry in the ball mill tank, spray dry and granulate with spray drying equipment. The conditions of the equipment are: inlet temperature 280°C, outlet temperature 110°C...

Embodiment 2

[0150] 1.1 Preparation of carbon nanotube-coated Ti-LS-Al spherical composite powder

[0151] Carry out as in Example 1, the difference is that the content of attapulgite is adjusted to 2%.

[0152] 1.2 Preparation of titanium-based wear-resistant self-healing coating: same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com