Patents

Literature

112results about How to "Adjustable diameter" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

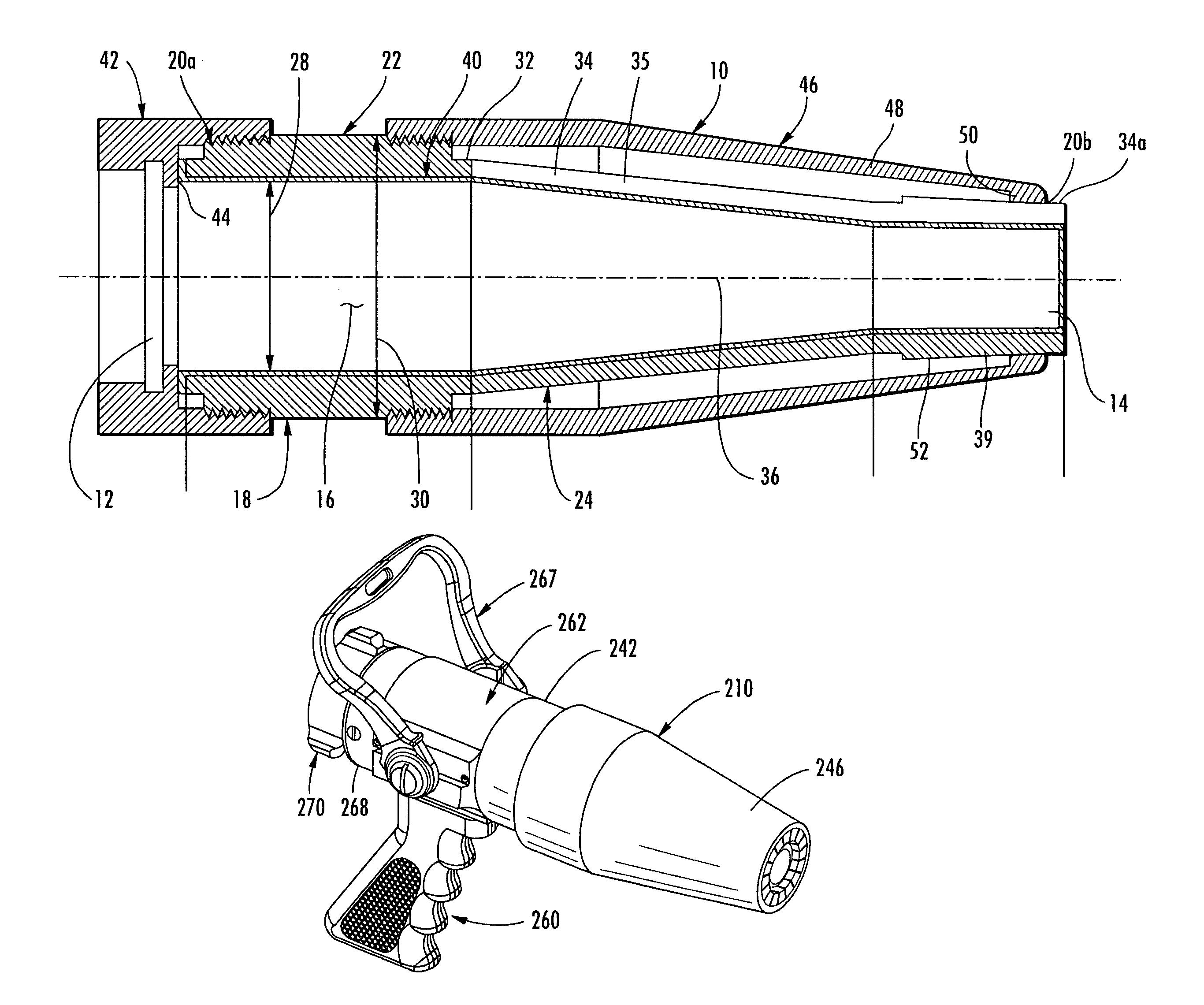

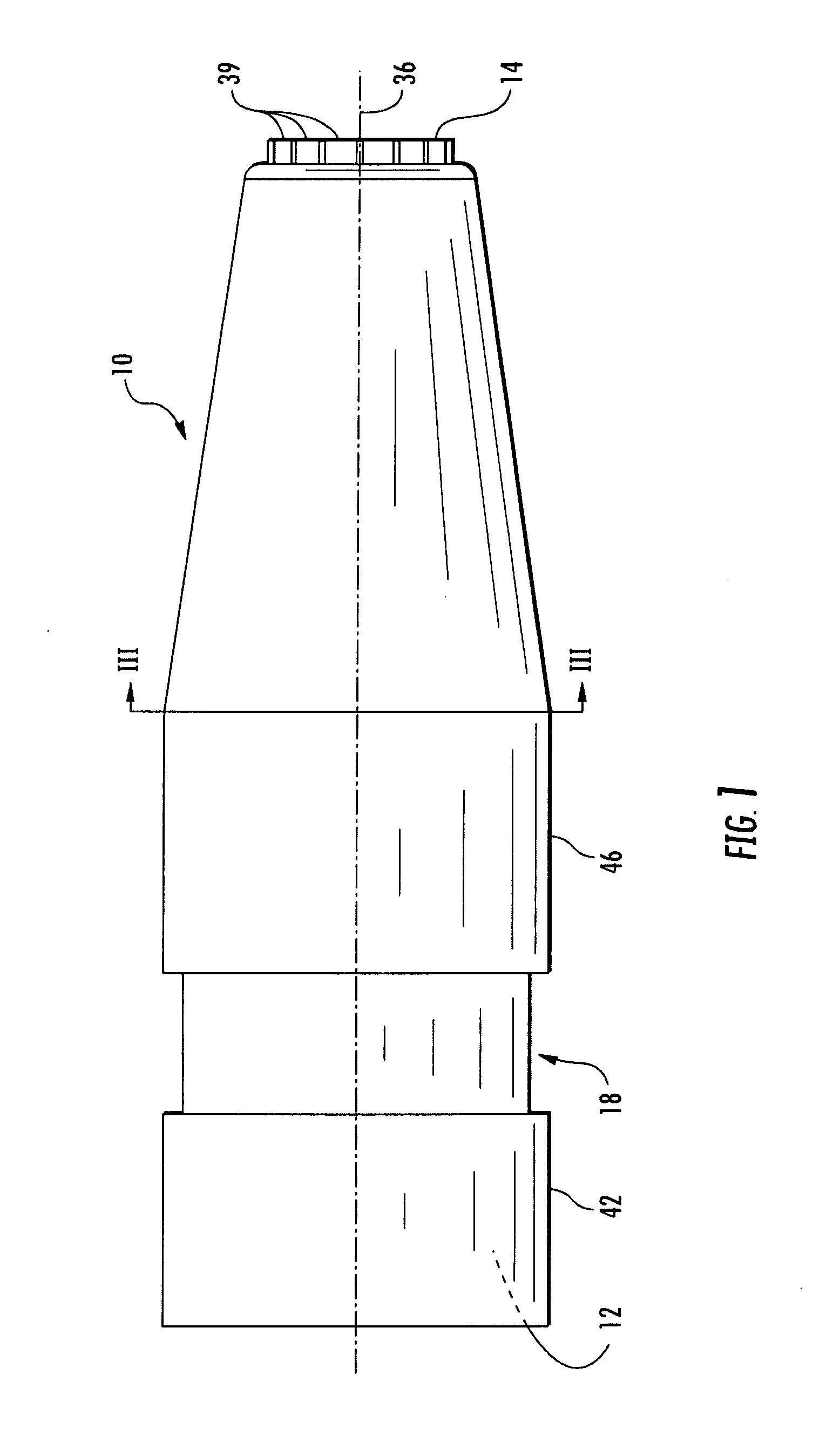

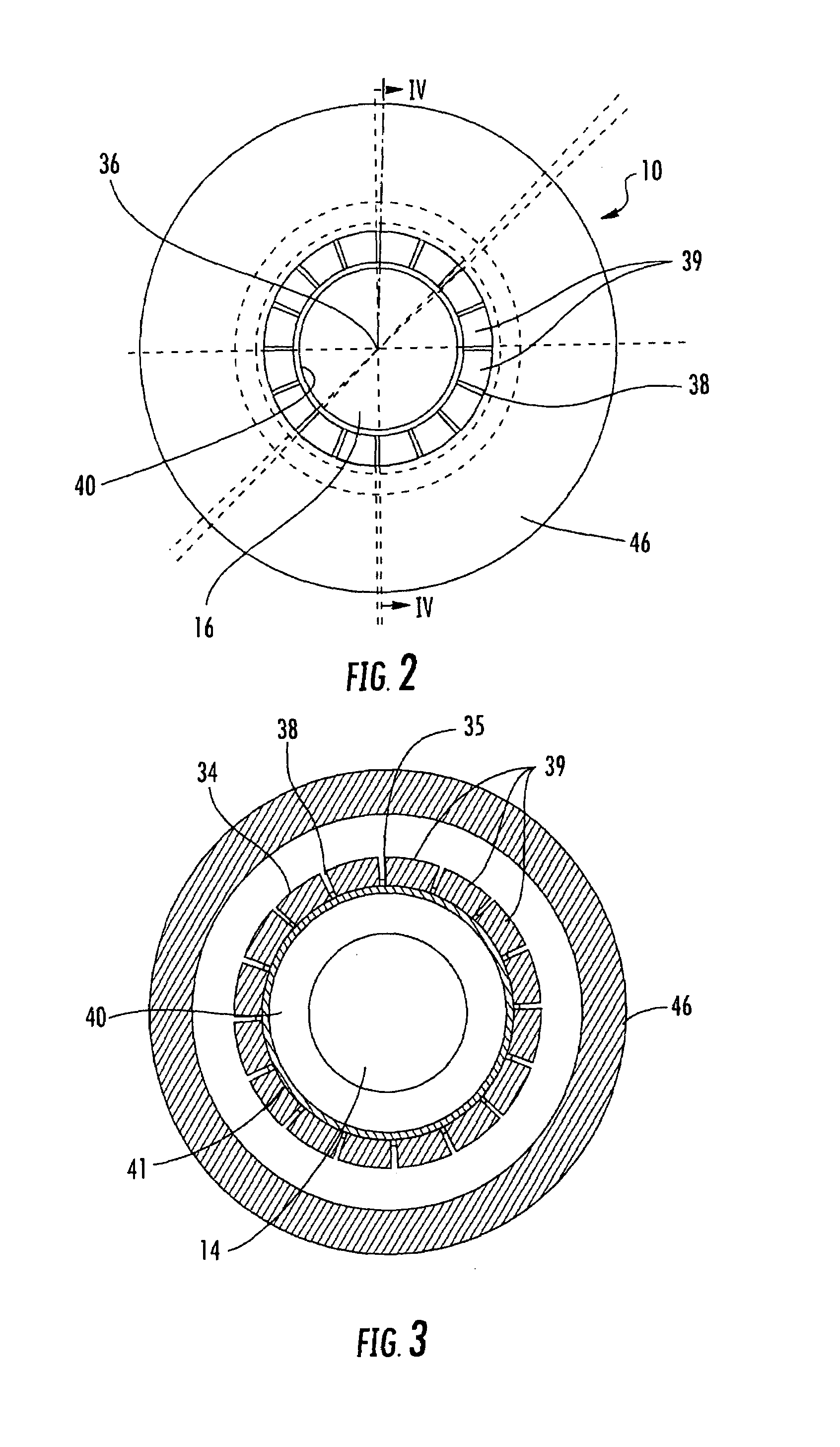

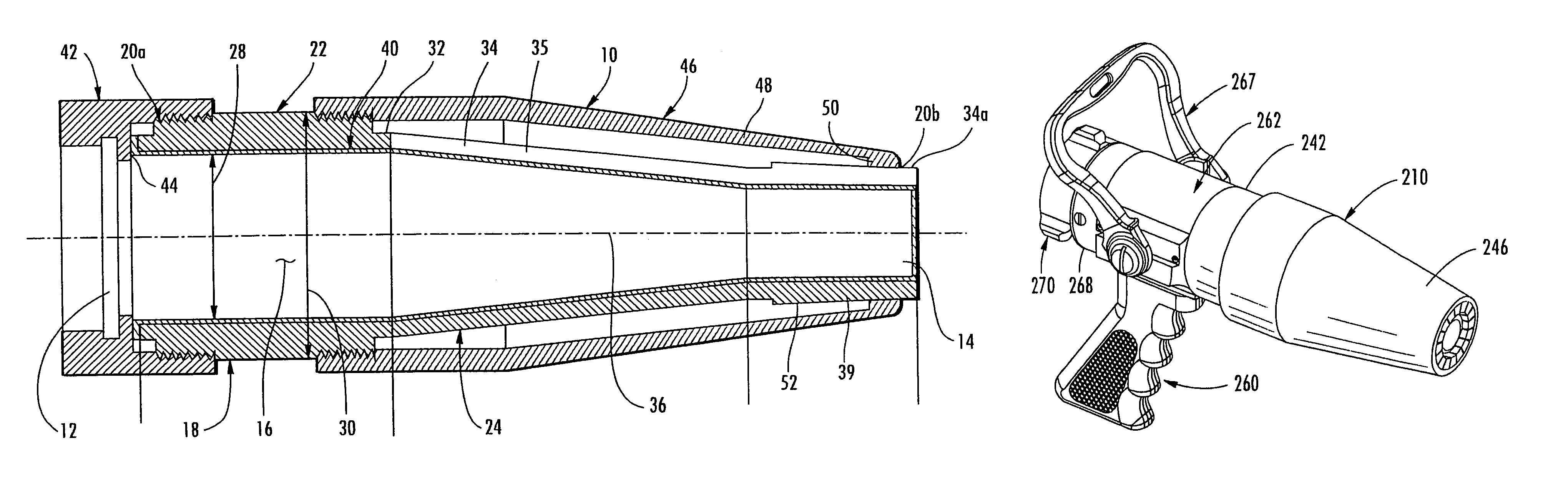

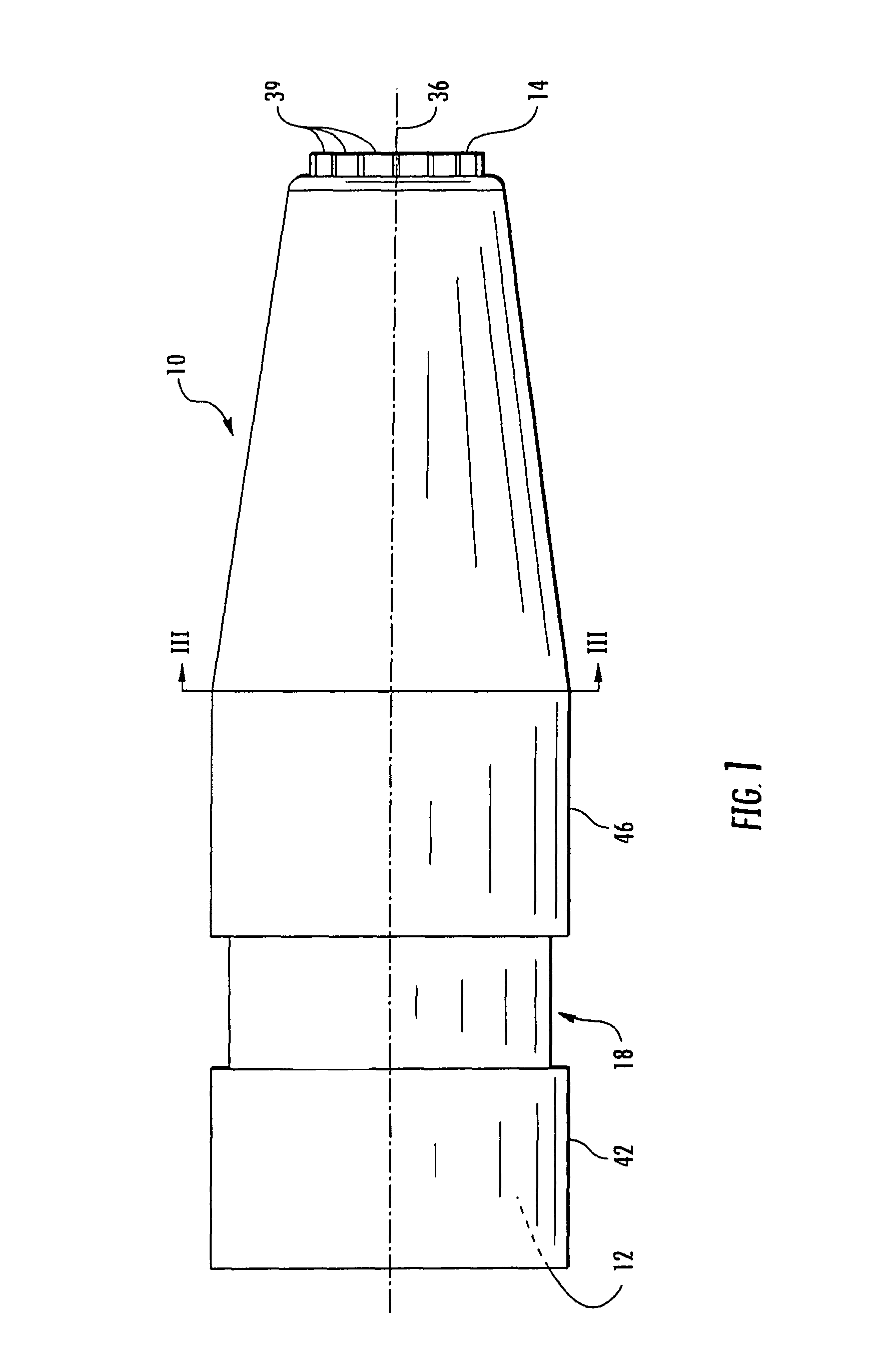

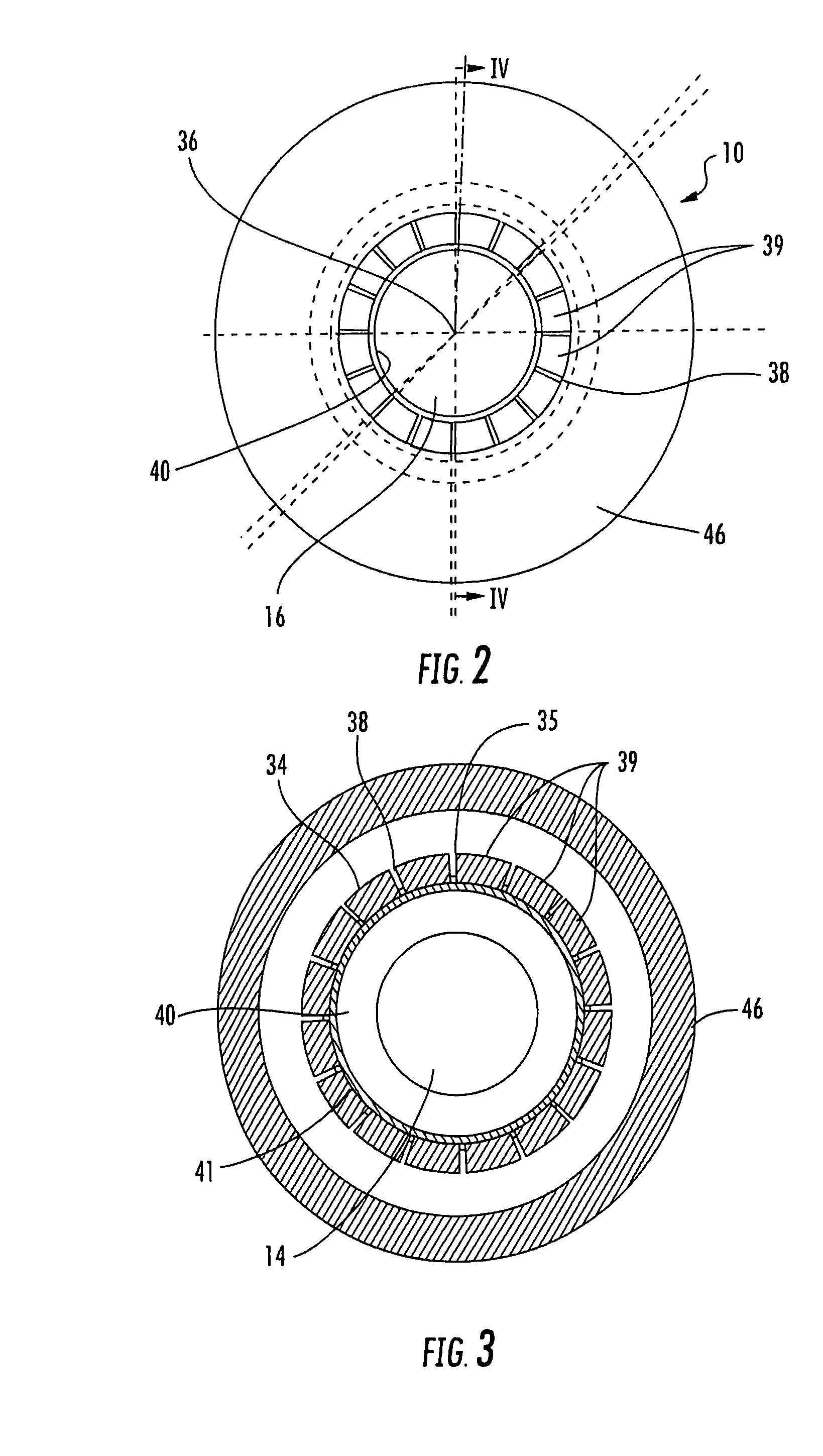

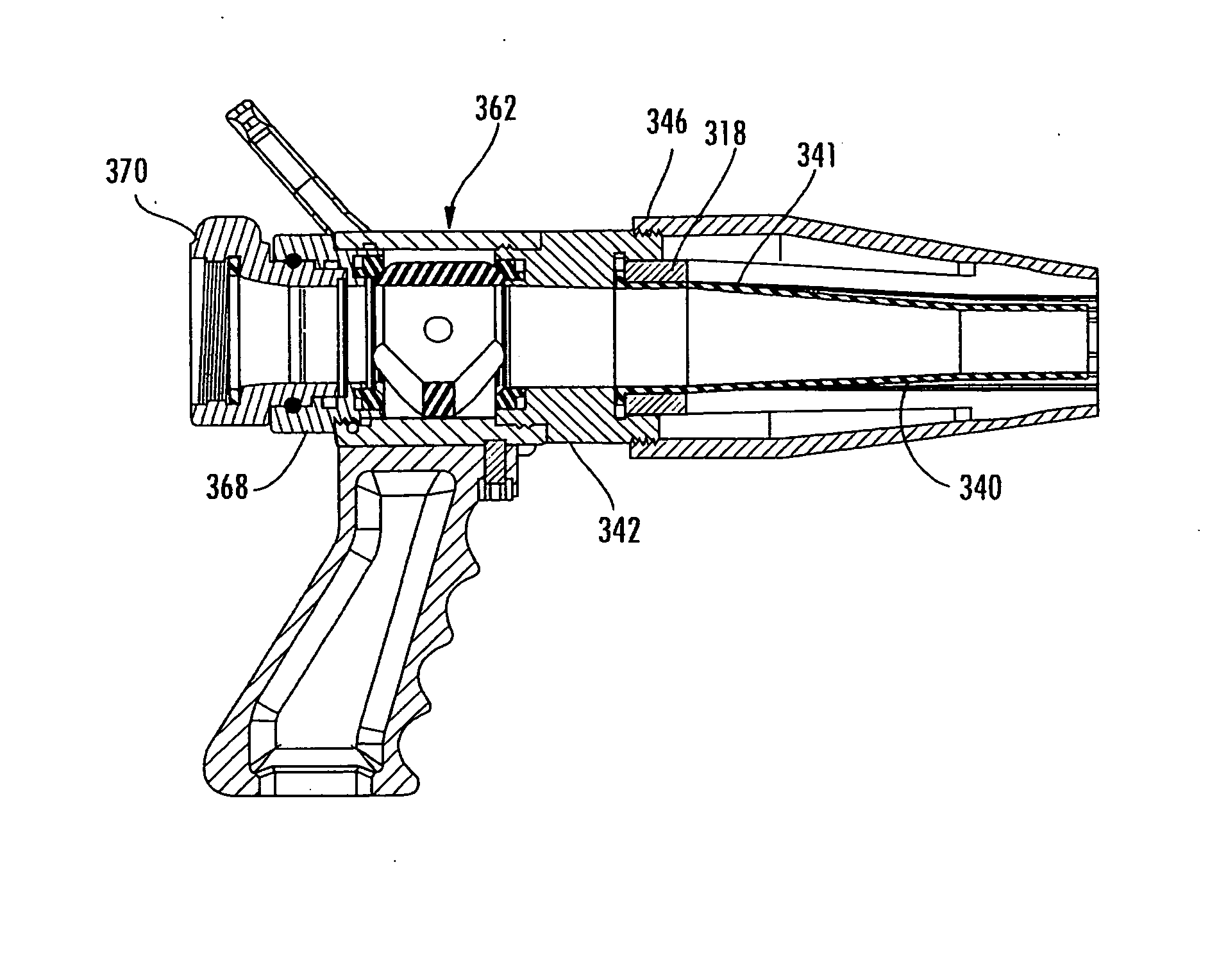

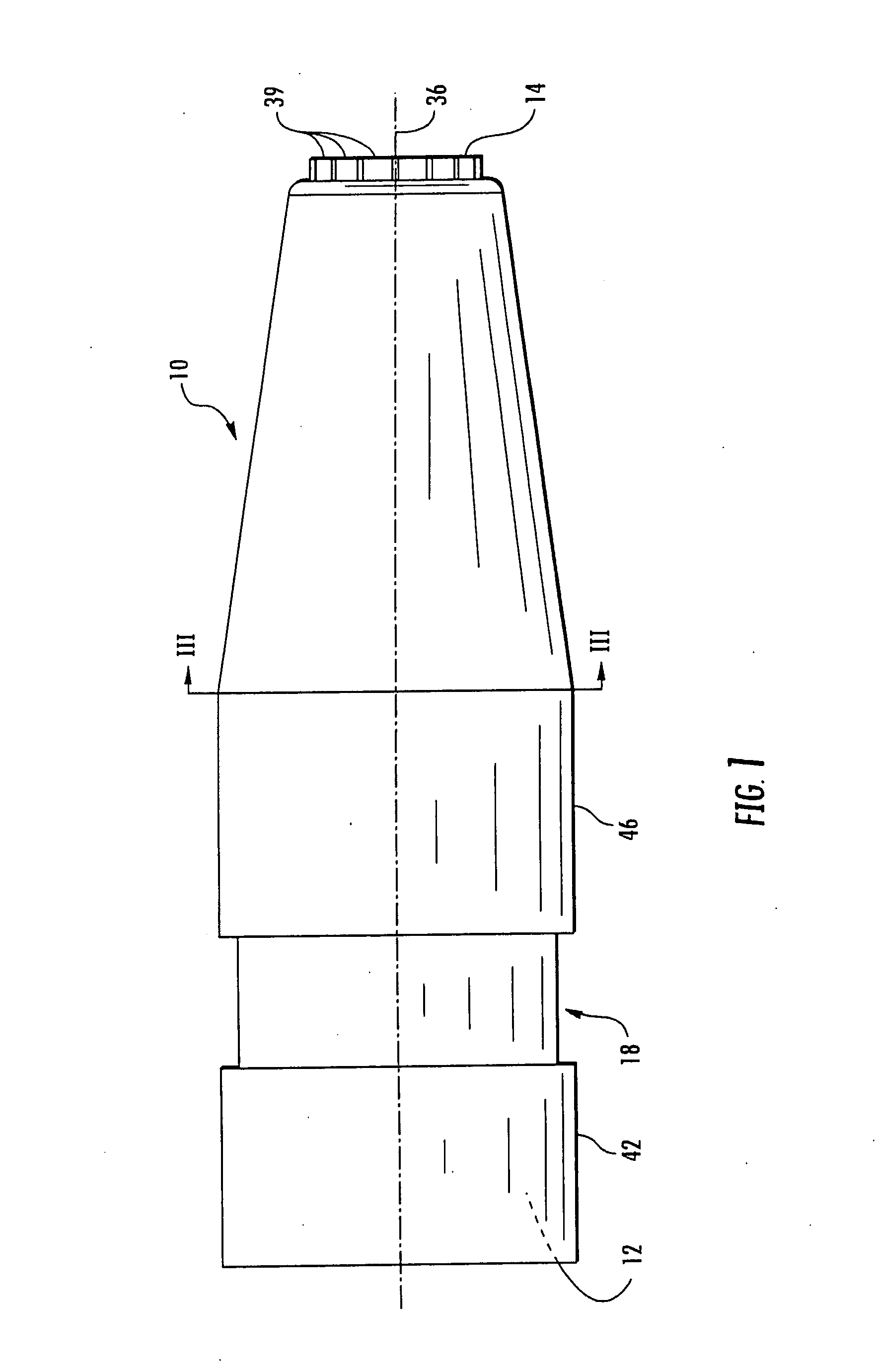

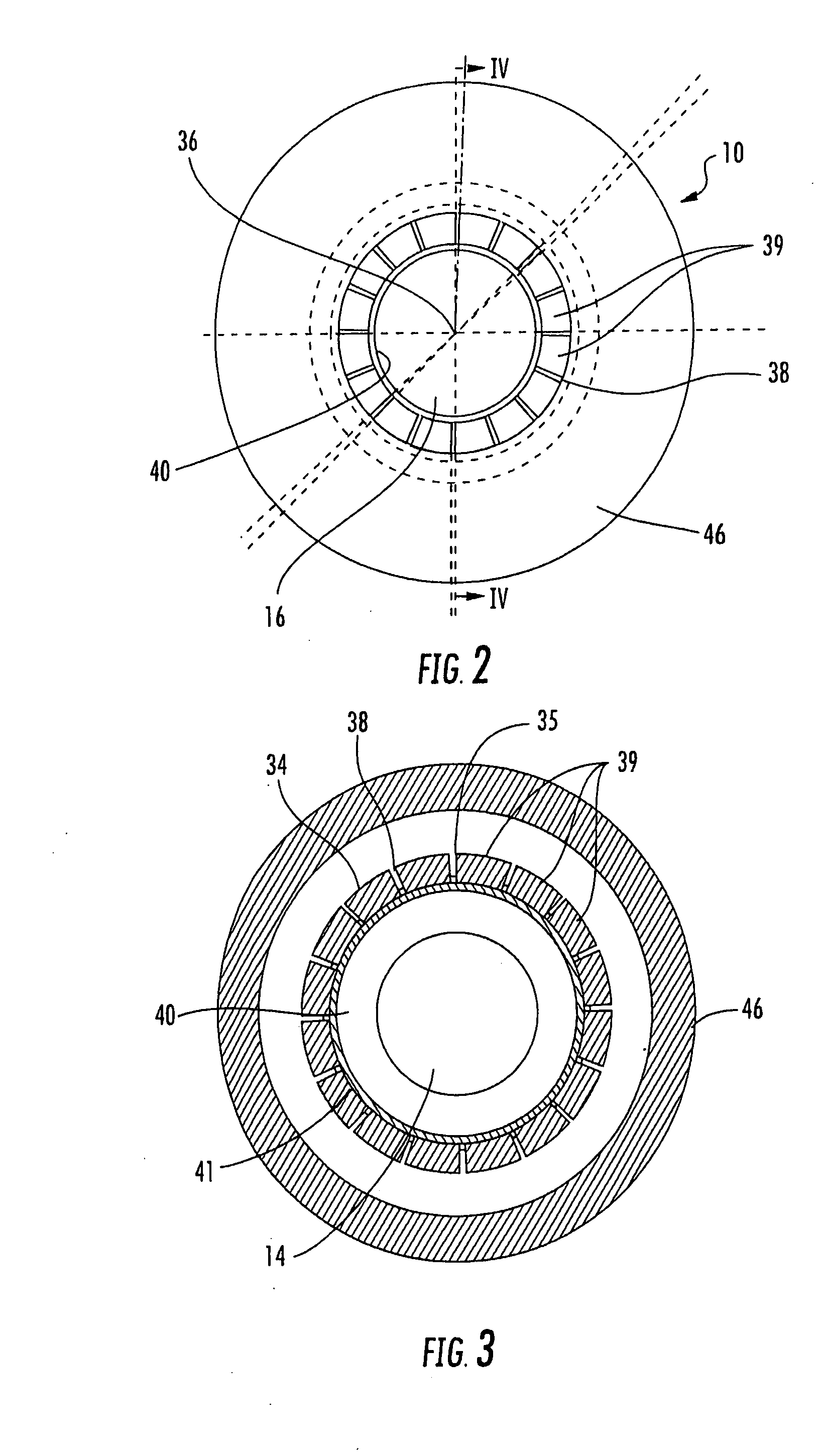

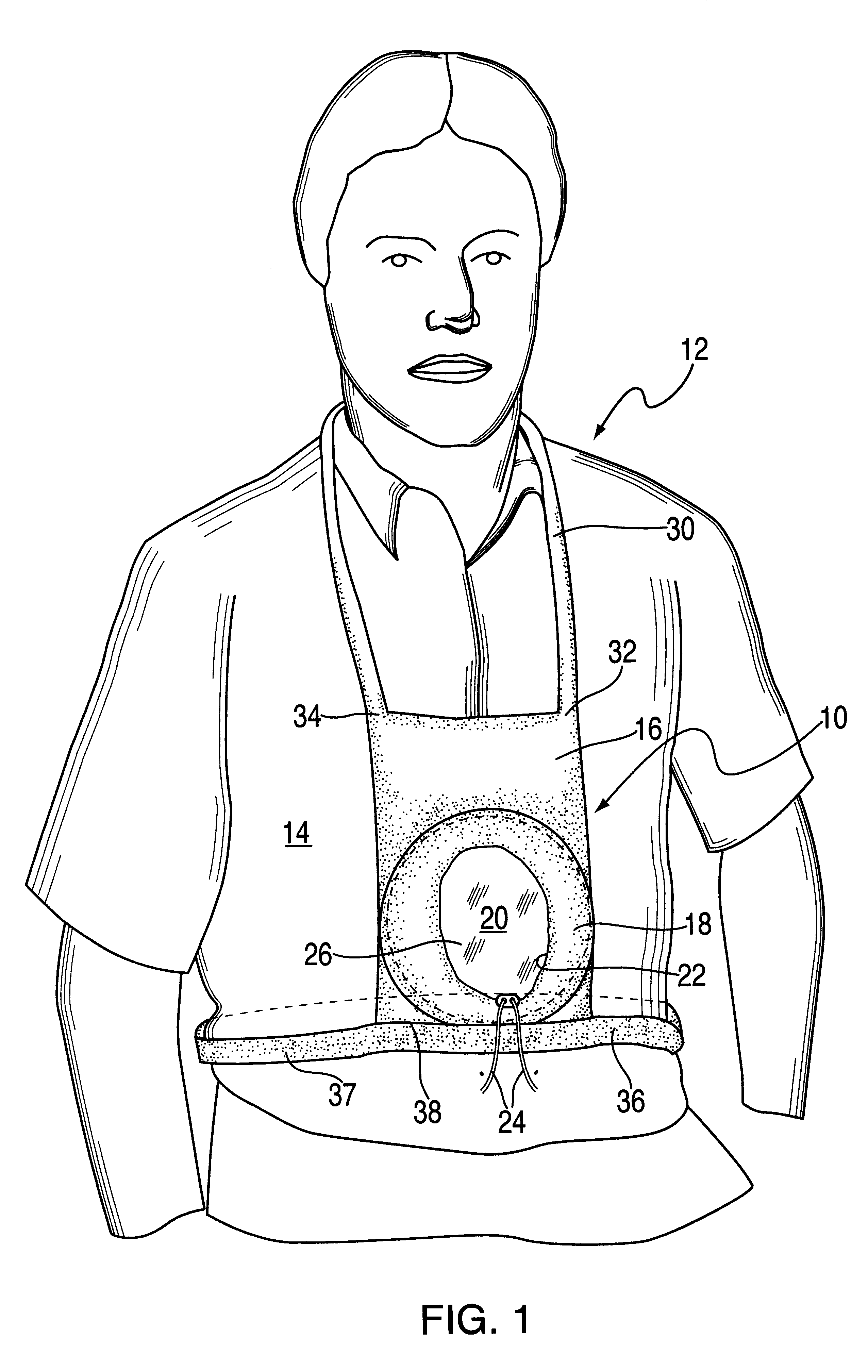

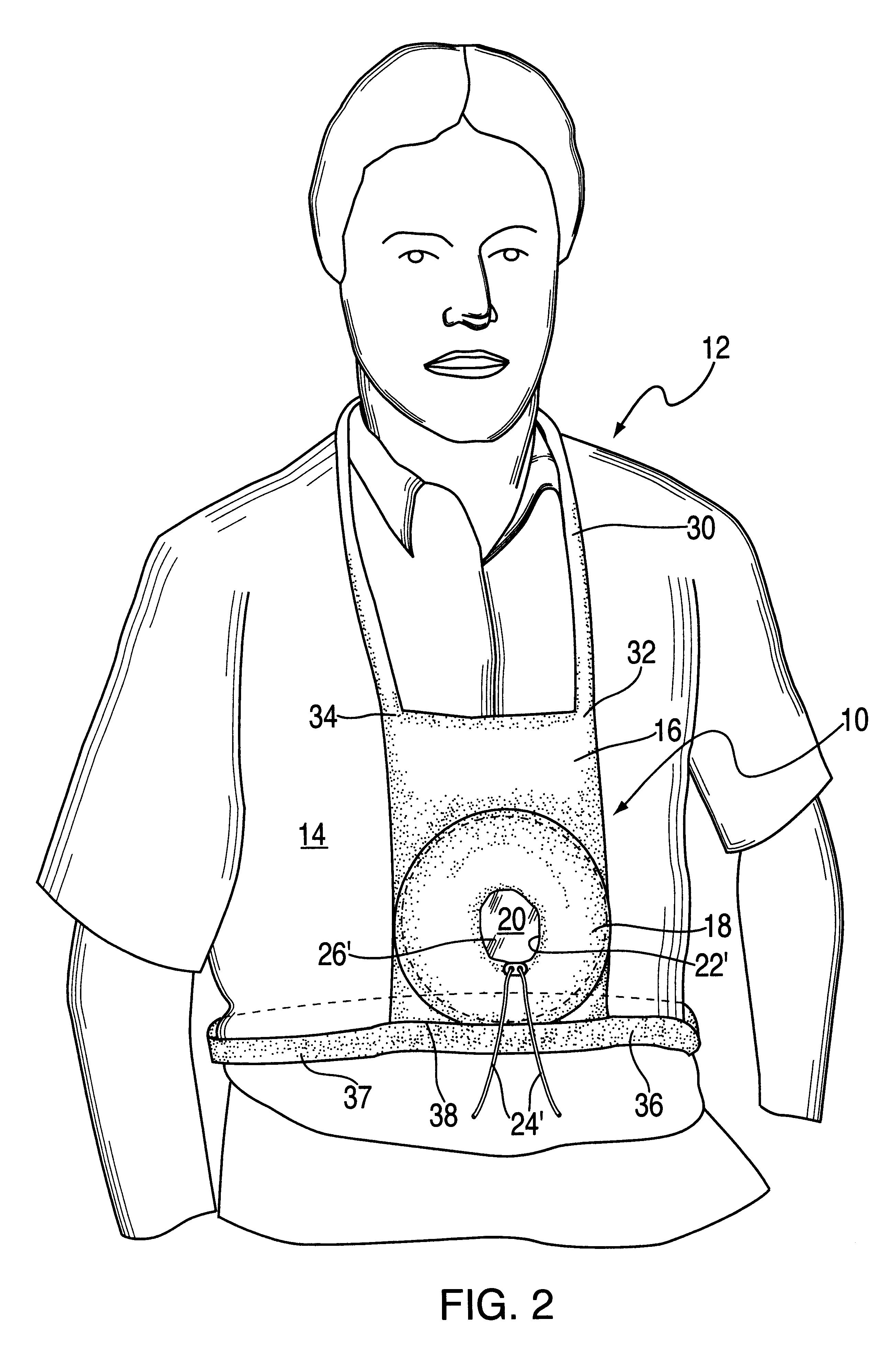

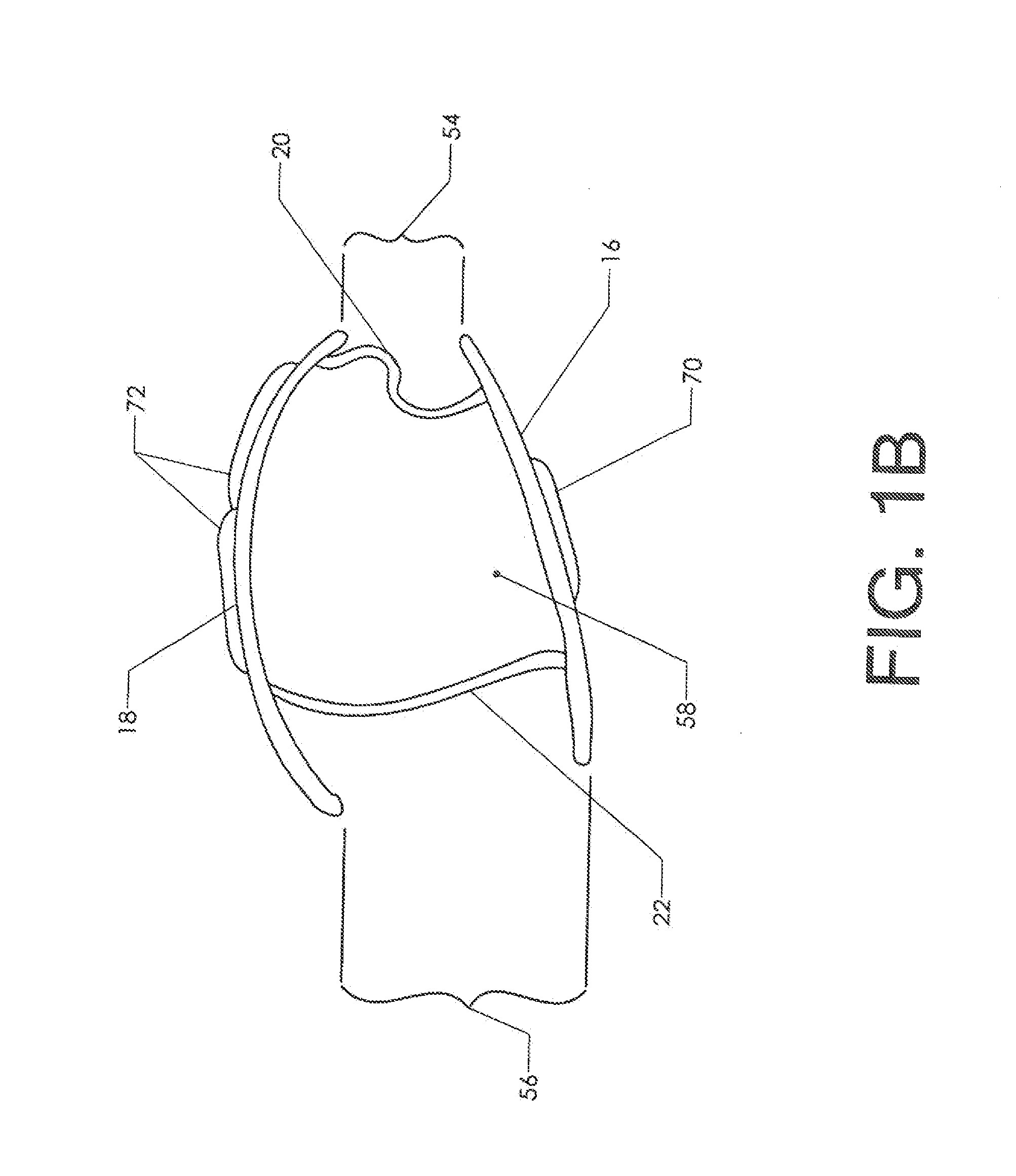

Adjustable smooth bore nozzle

InactiveUS7258285B1Increase pressureIncrease flow rateDiaphragm valvesEngine diaphragmsEngineeringNozzle

An adjustable nozzle comprising a nozzle body with an inlet, an outlet, and a passageway having a smooth bore extending between the inlet and the outlet. The passageway has an inner dimension transverse to the central axis of the nozzle and a compressible wall wherein the inner dimension is adjustable to adjust the flow rate through the nozzle.

Owner:ELKHART BRASS MFG

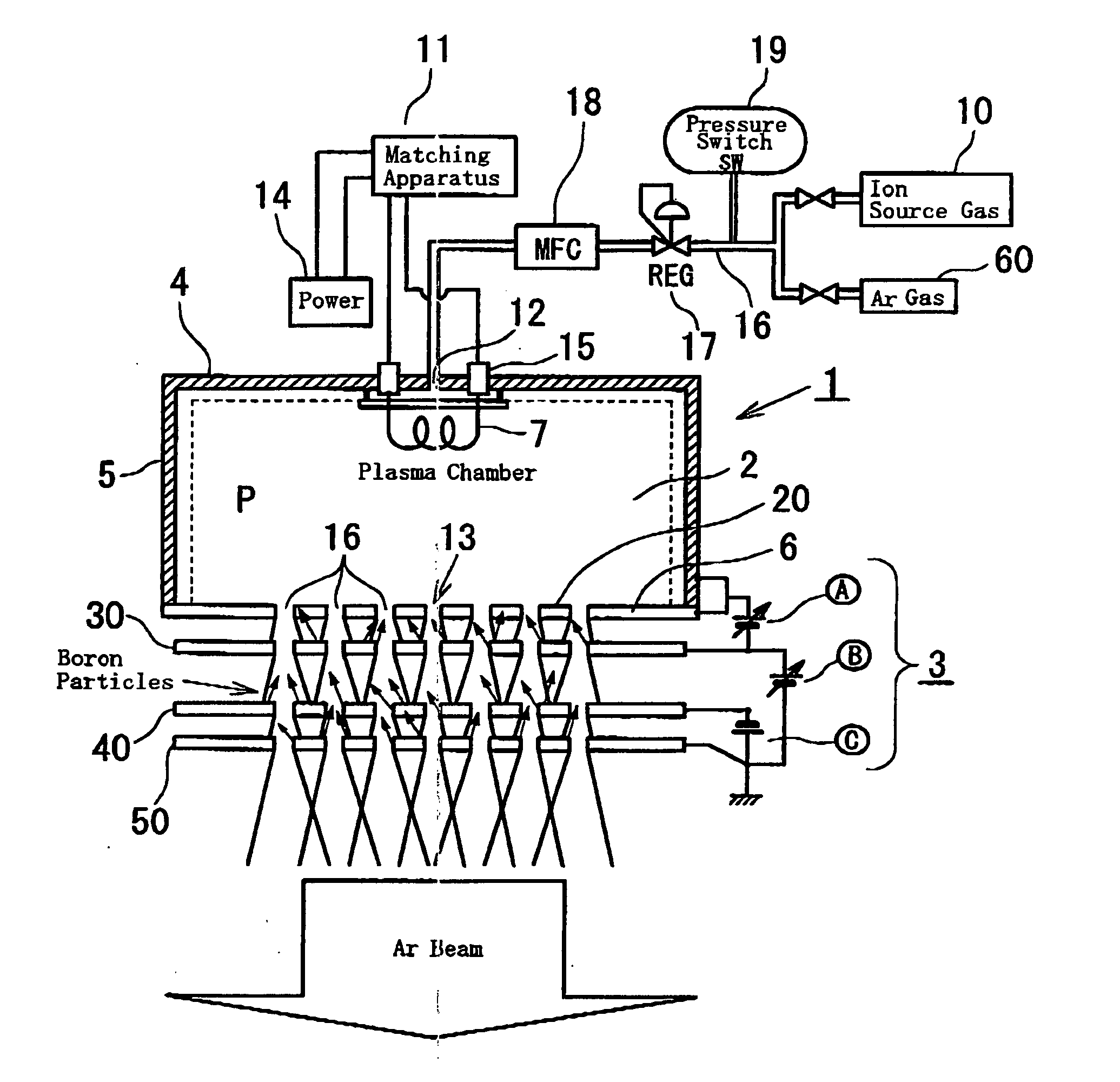

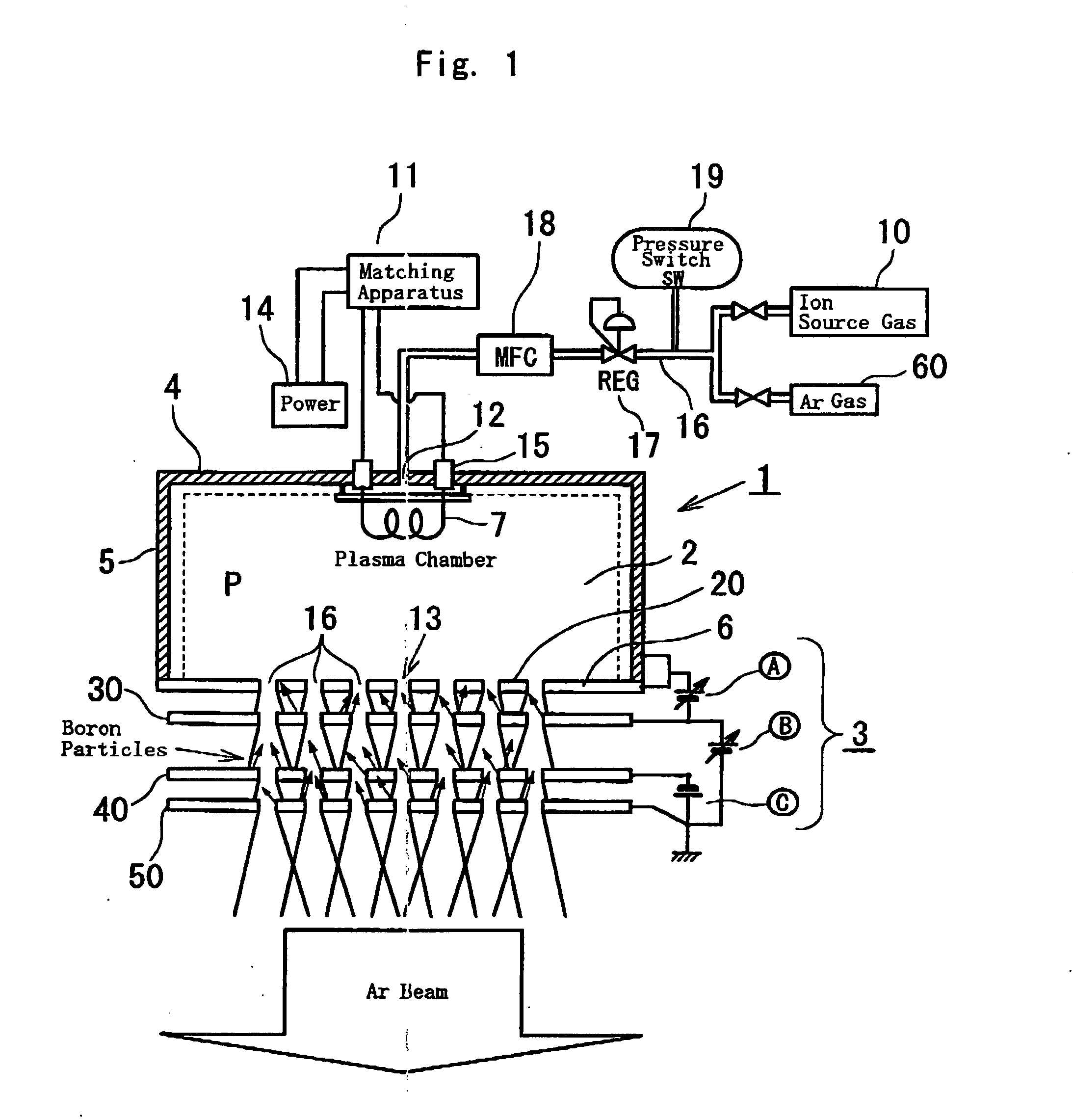

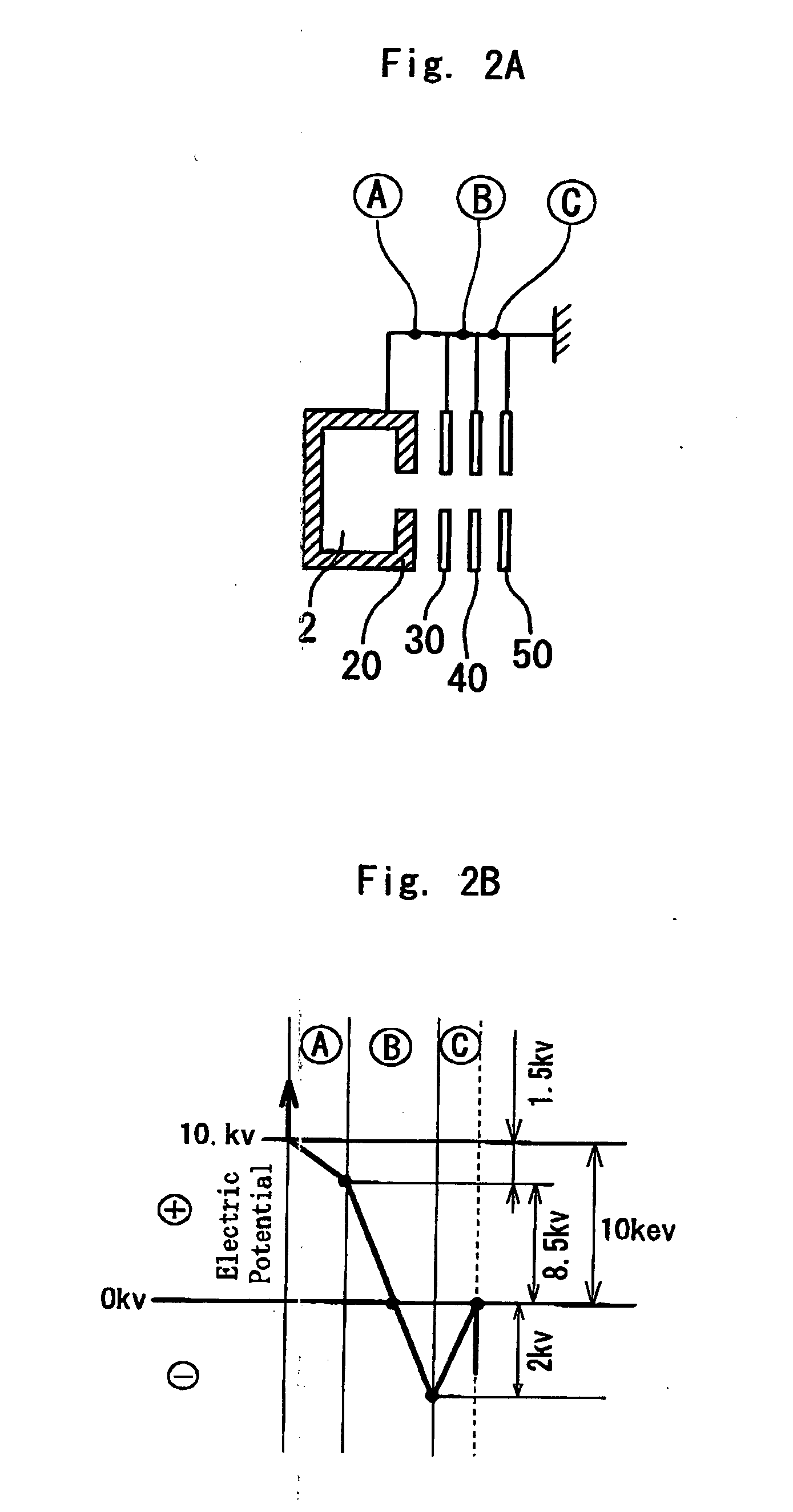

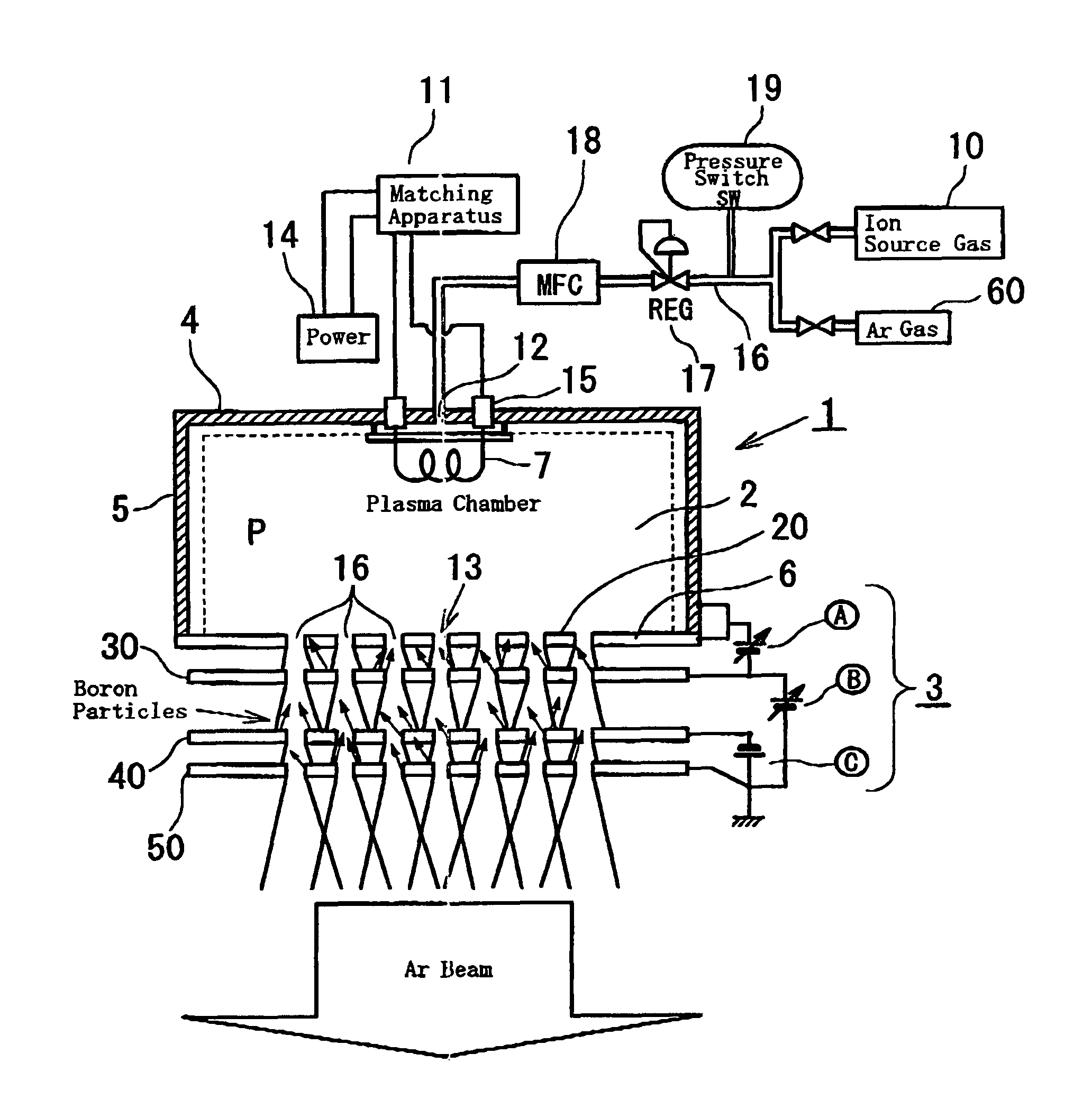

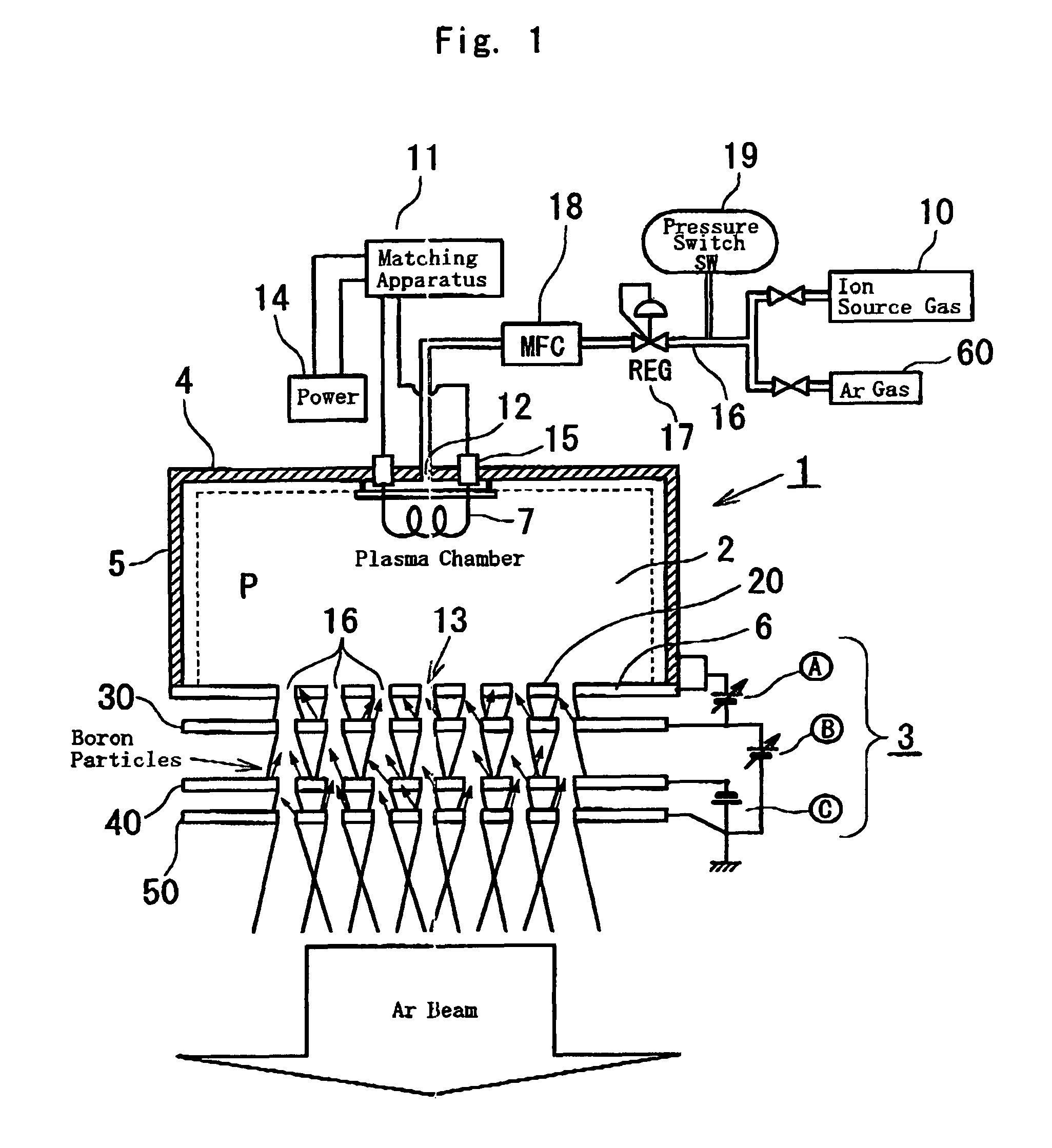

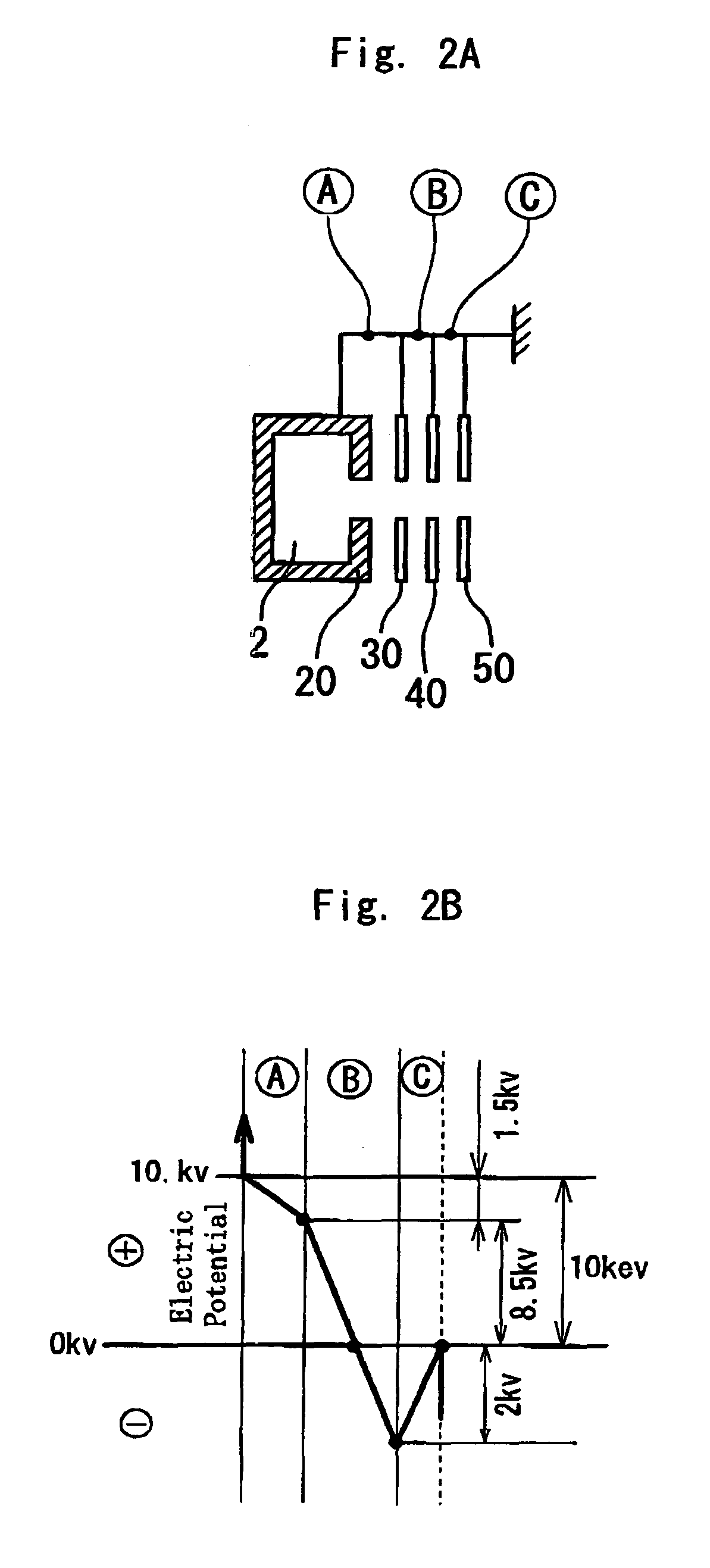

Ion source apparatus and cleaning optimized method thereof

InactiveUS20050016838A1Optimized diameterIncreased durabilityCellsVacuum evaporation coatingNoble gasInsulation layer

An ion source apparatus includes a rare gas supply source supplying rare gas instead of ion source gas to a plasma chamber, means to determine time and timing for cleaning electrodes in consideration of a collecting amount of insulation layers accreting to the electrodes of an extraction electrode system. Based on the above, the ion source apparatus removes the insulation layers by sputtering with ion beam of the rare gas while adjusting extraction or accelerate voltage and supply amount of the rare gas as a setting parameter. Moreover, by adjusting the setting parameter which changes a diameter of ion beam based on the rare gas when the ion beam collides onto each electrode surface of the extraction electrode system, the beam diameter is focused within an effective range in which intension of the sputtering of the insulation layers is maximized thus evenly removing the insulation layers.

Owner:SEN CORP AN SHI & AXCELIS

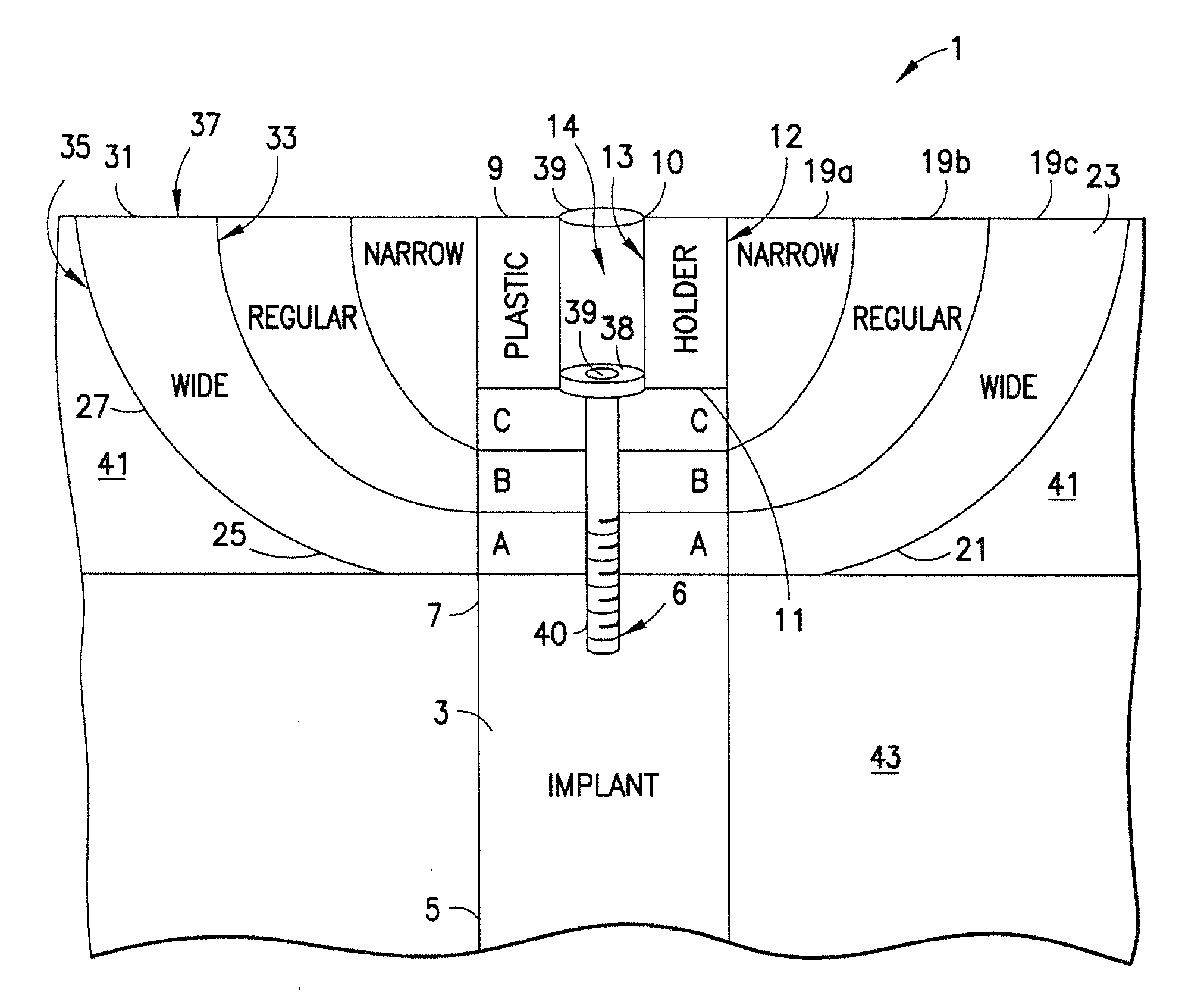

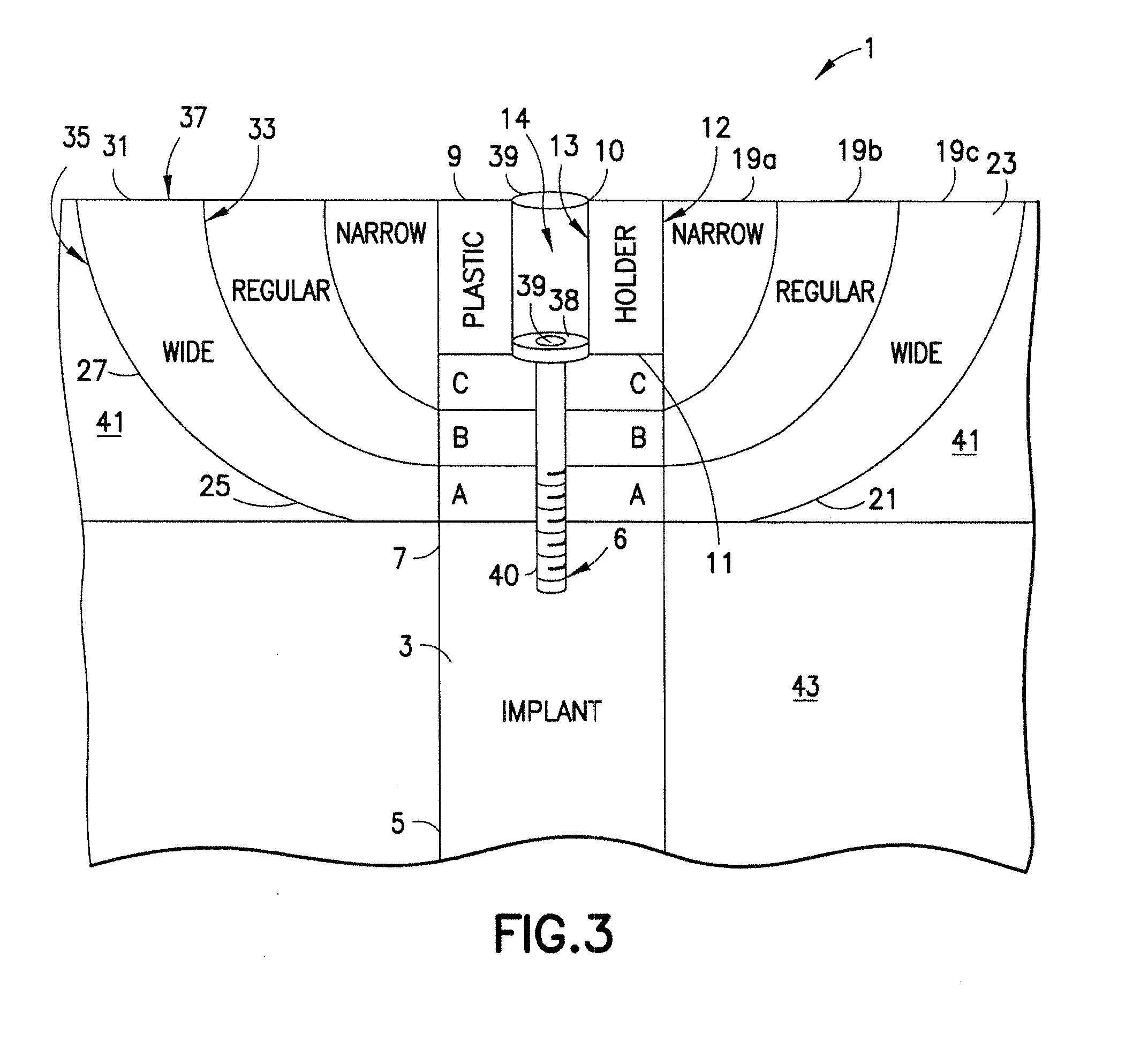

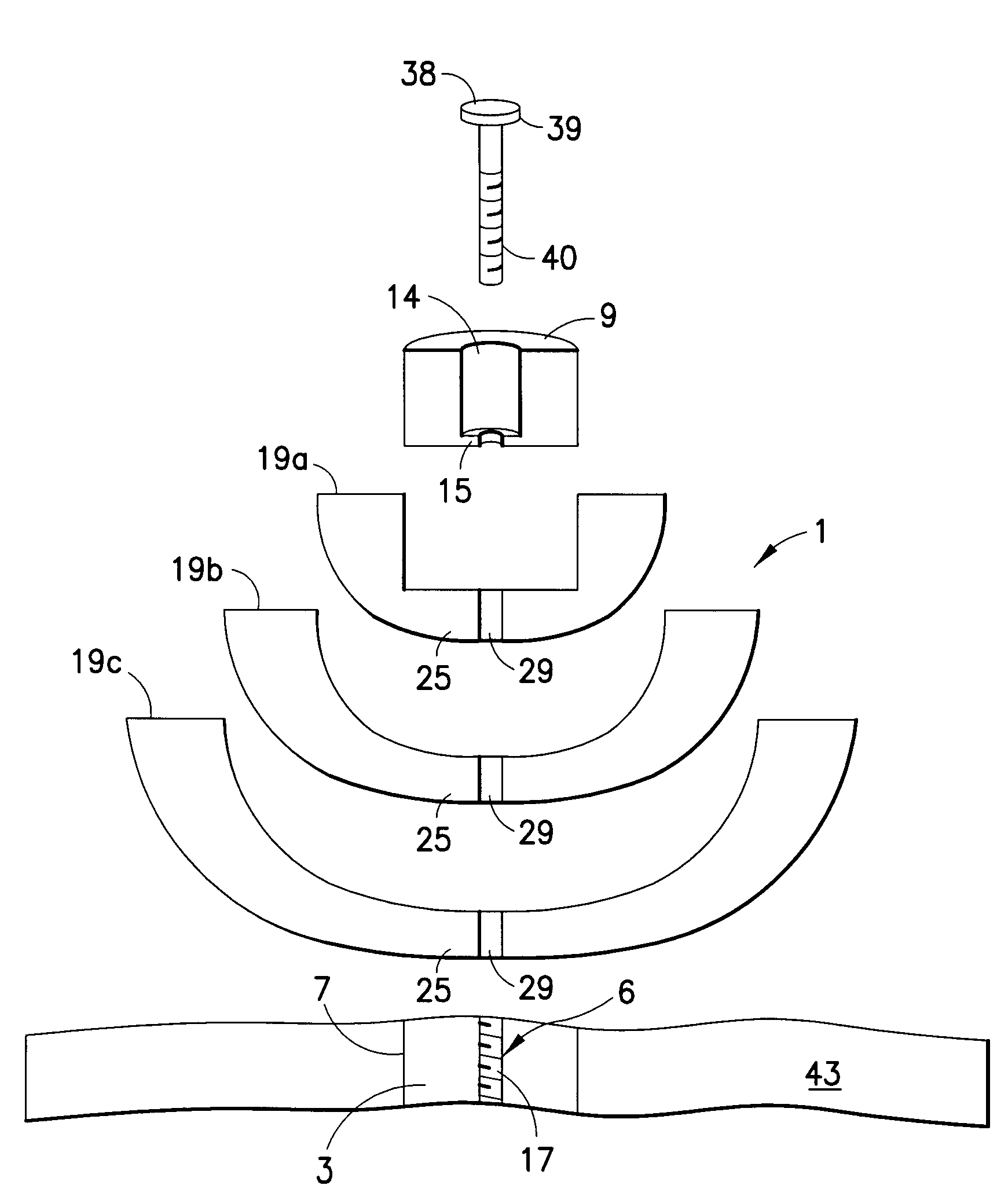

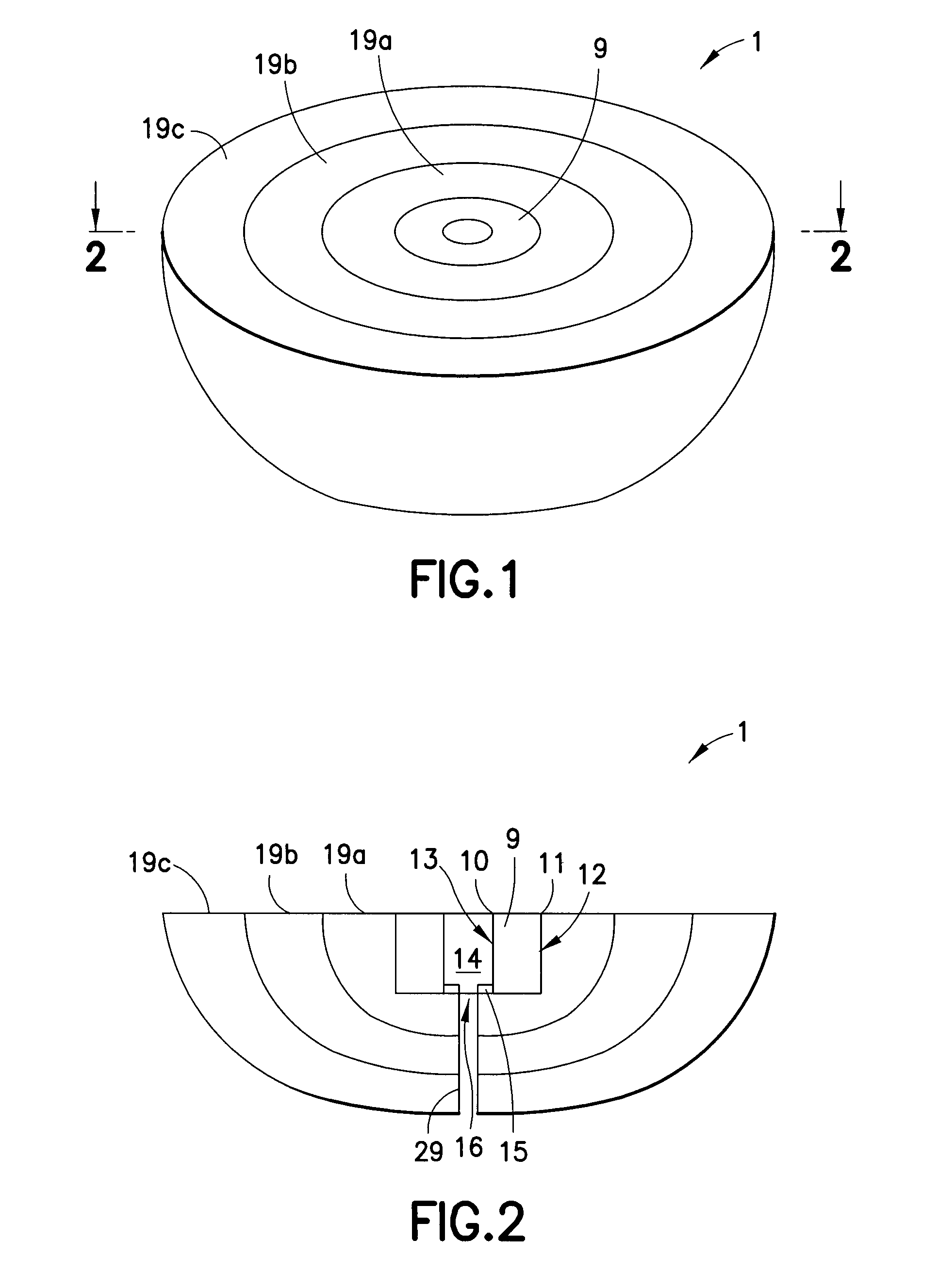

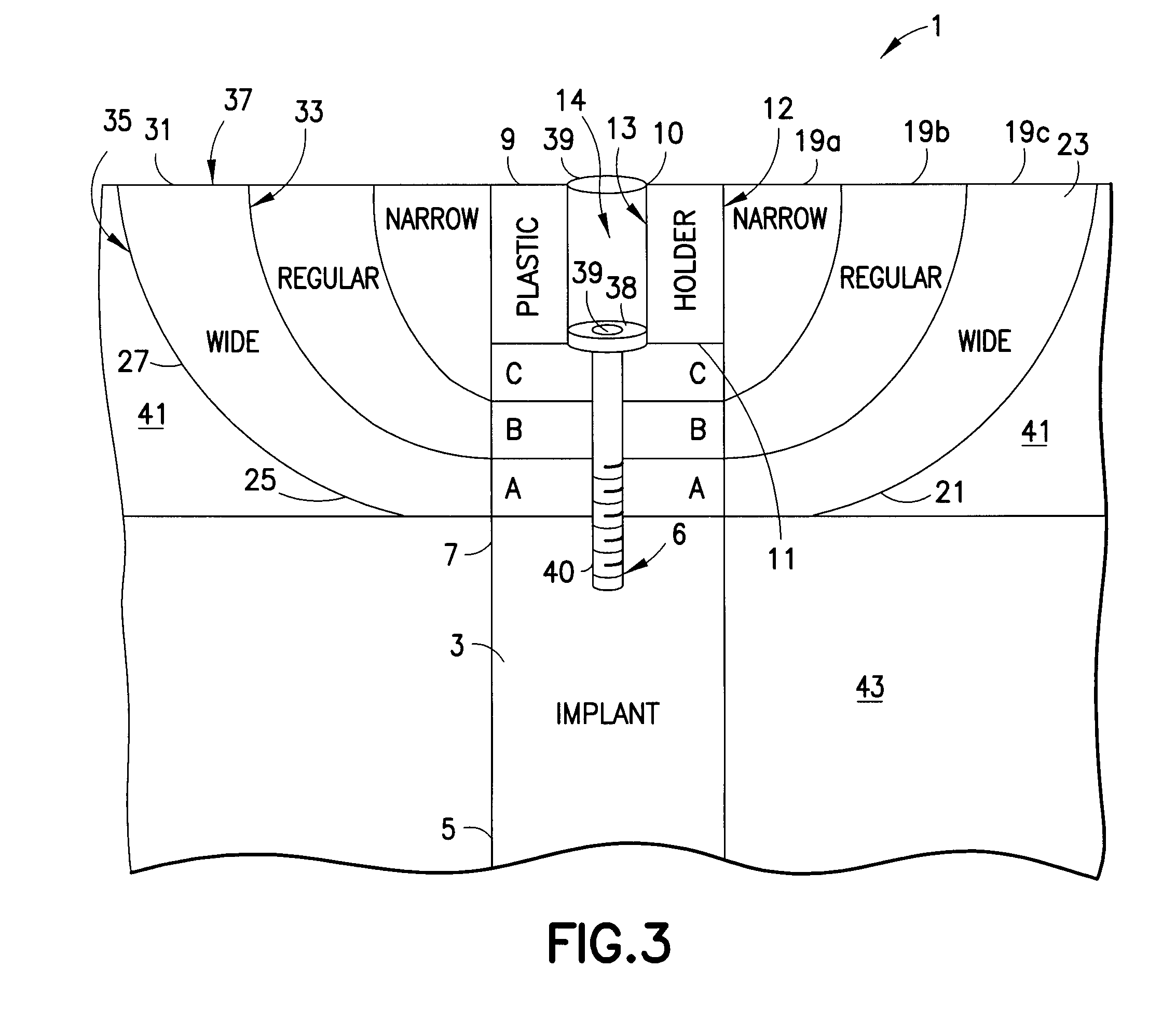

System and method for fabricating a dental healing abutment

InactiveUS20110200968A1Facilitate removalAdjustable diameterDental implantsHealing abutmentEngineering

A dental healing abutment assembly having a tubular holder and a plurality of removable nestable shells. Each nestable shell has a proximal end and a distal end open to permit the nesting of the shell with the holder or other nestable shells. The proximal end of each nestable shell is defined by a base plate. The tubular holder and the nestable shells each have a pass through hole for accommodating a mounting member. The healing abutment assembly is attached to a dental implant impacted in a patient's jawbone by way of the mounting member. Furthermore, a system and method are provided for fabricating a permanent abutment by decoding an identifier disposed on the healing abutment.

Owner:PROCEREX DENTAL LAB

Ion source apparatus and cleaning optimized method thereof

InactiveUS7947129B2Adjustable diameterMaximize the effectVacuum evaporation coatingElectrostatic cleaningInsulation layerNoble gas

An ion source apparatus includes a rare gas supply source supplying rare gas instead of ion source gas to a plasma chamber, means to determine time and timing for cleaning electrodes in consideration of a collecting amount of insulation layers accreting to the electrodes of an extraction electrode system. Based on the above, the ion source apparatus removes the insulation layers by sputtering with ion beam of the rare gas while adjusting extraction or accelerate voltage and supply amount of the rare gas as a setting parameter. Moreover, by adjusting the setting parameter which changes a diameter of ion beam based on the rare gas when the ion beam collides onto each electrode surface of the extraction electrode system, the beam diameter is focused within an effective range in which intension of the sputtering of the insulation layers is maximized thus evenly removing the insulation layers.

Owner:SEN CORP AN SHI & AXCELIS

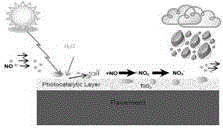

Graphene modified composite mesoporous carbon microsphere air purifying preparation

ActiveCN107174919ABroaden the photoresponse rangeUnique photocatalytic activityGas treatmentPhysical/chemical process catalystsMicrosphereNitric oxide

The invention provides a graphene modified composite mesoporous carbon microsphere air purifying preparation. A certain amount of beta-cyclodextrin is added to thin-layered nano-SiO2 particles covering the surfaces of obtained micro-SiO2 particles, a certain quantity of obtained RGO / TiO2 nanoparticles is added simultaneously, -OH, -COOH, C-O-C and C=O oxygen-containing functional groups rich on the surface of graphene are adsorbed by and bonded with the RGO / TiO2 nanoparticles on the basis of the molecular recognition characteristic of beta-cyclodextrin, then a certain amount of CTAB (cetyltrimethylammonium bromide) surfactant is added, CTAB serving as a micelle stabilizer can stop the RGO / TiO2 nanoparticles from further hydrolysis and growth, and finally, the novel air purifying preparation adopting RGO / TiO2 supported by carbon microspheres with a mesoporous shell structure is obtained. With adoption of the scheme, the purity is high, RGO / TiO2 supported by the carbon microspheres with the mesoporous shell structure in powder is better in bonding performance, uniform in distribution and controllable in dimension at mesopores, and the air purifying preparation can be used for purifying polluted air and removing dust in a haze environment as well as photo-catalytically degrading and separating nitric oxide, sulfide or other organic pollutants in the polluted air.

Owner:AVIC BEIJING INST OF AERONAUTICAL MATERIALS

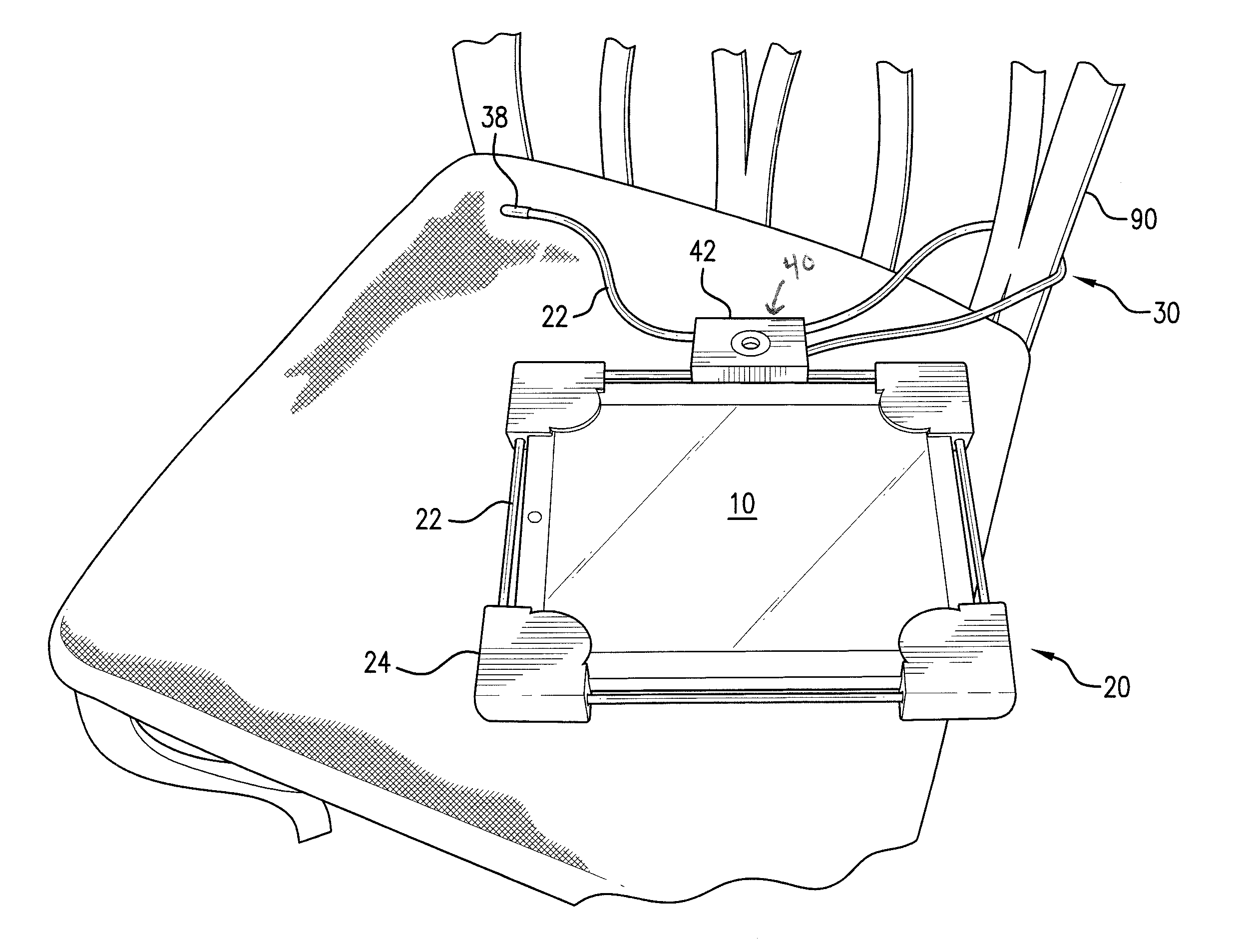

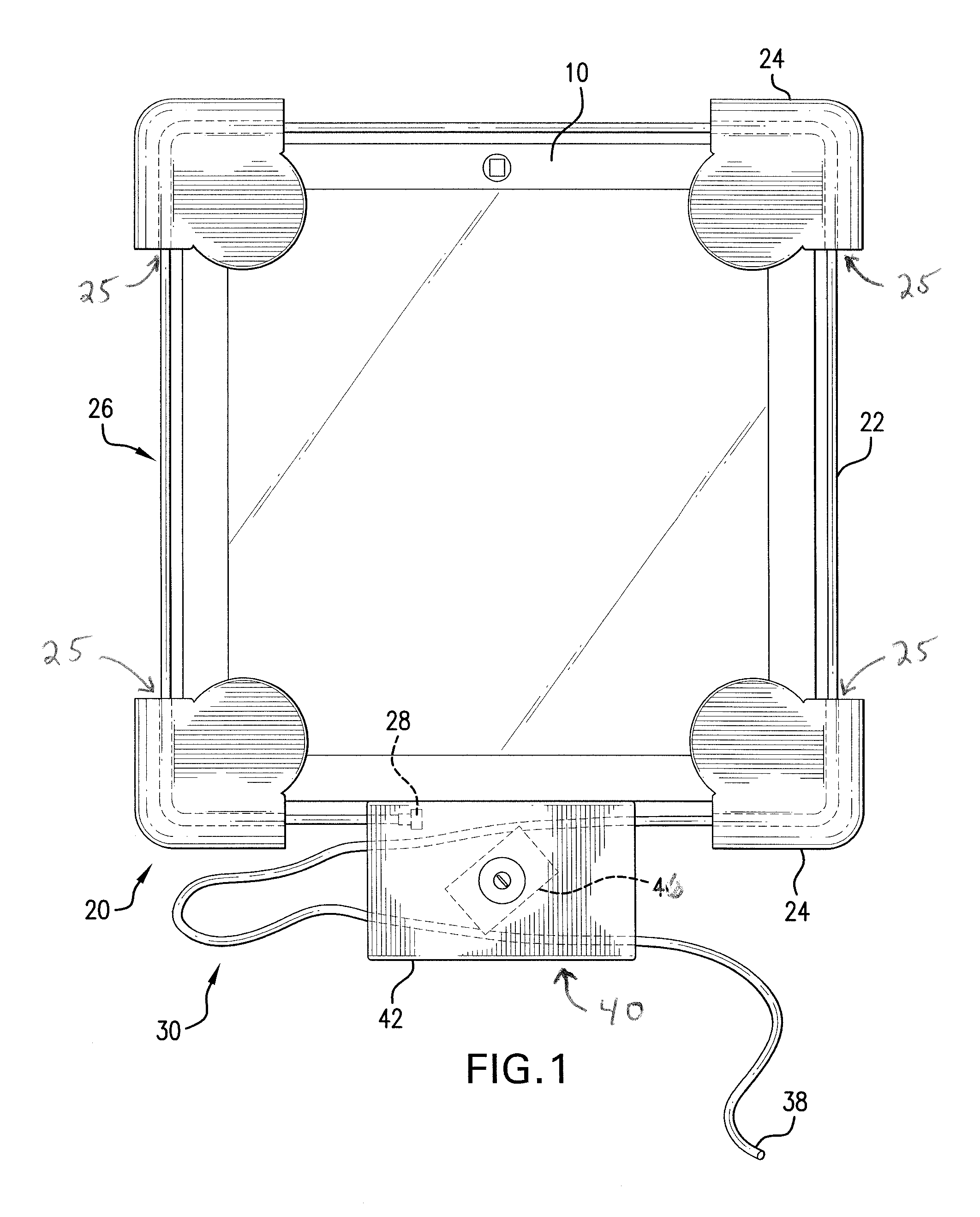

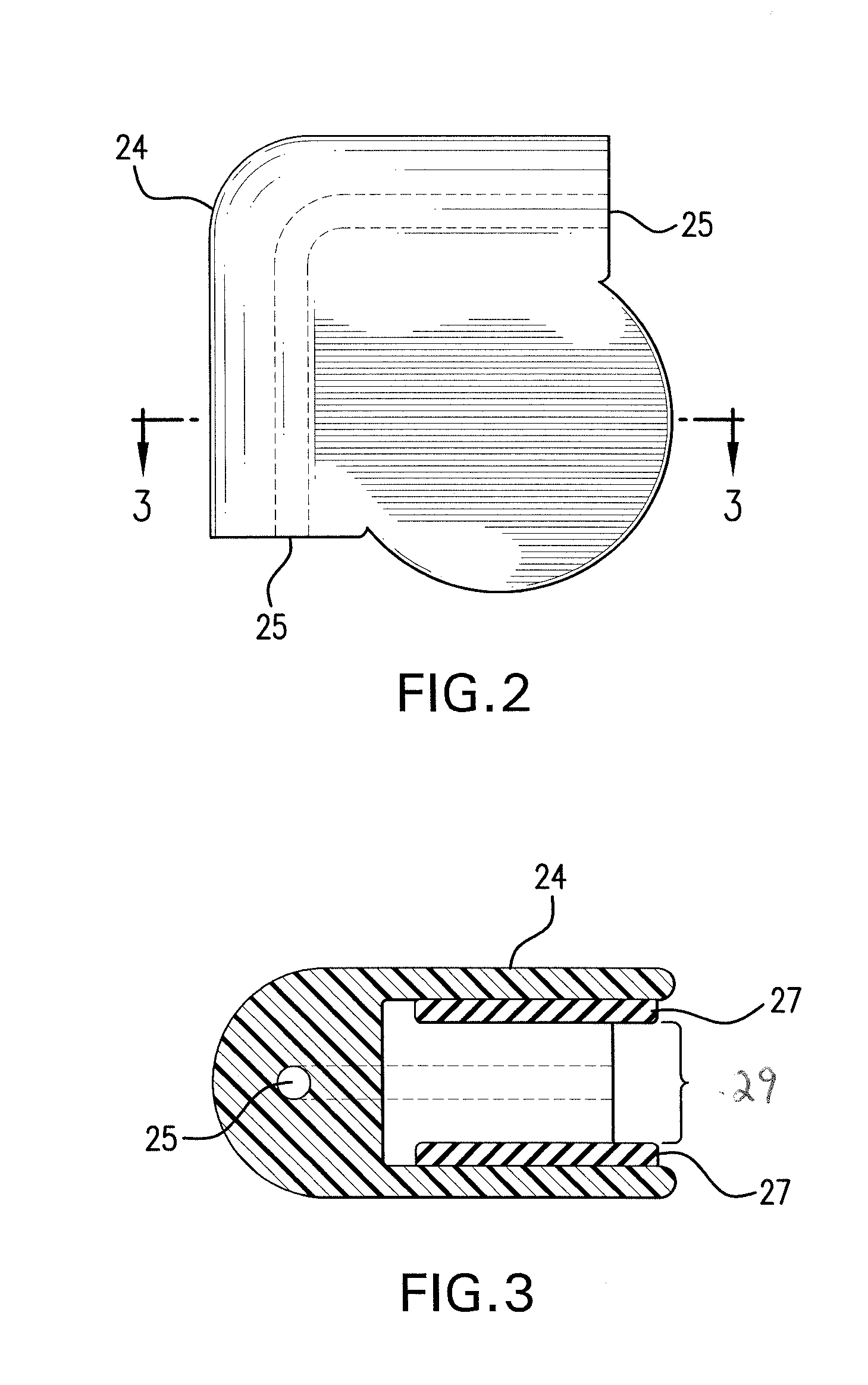

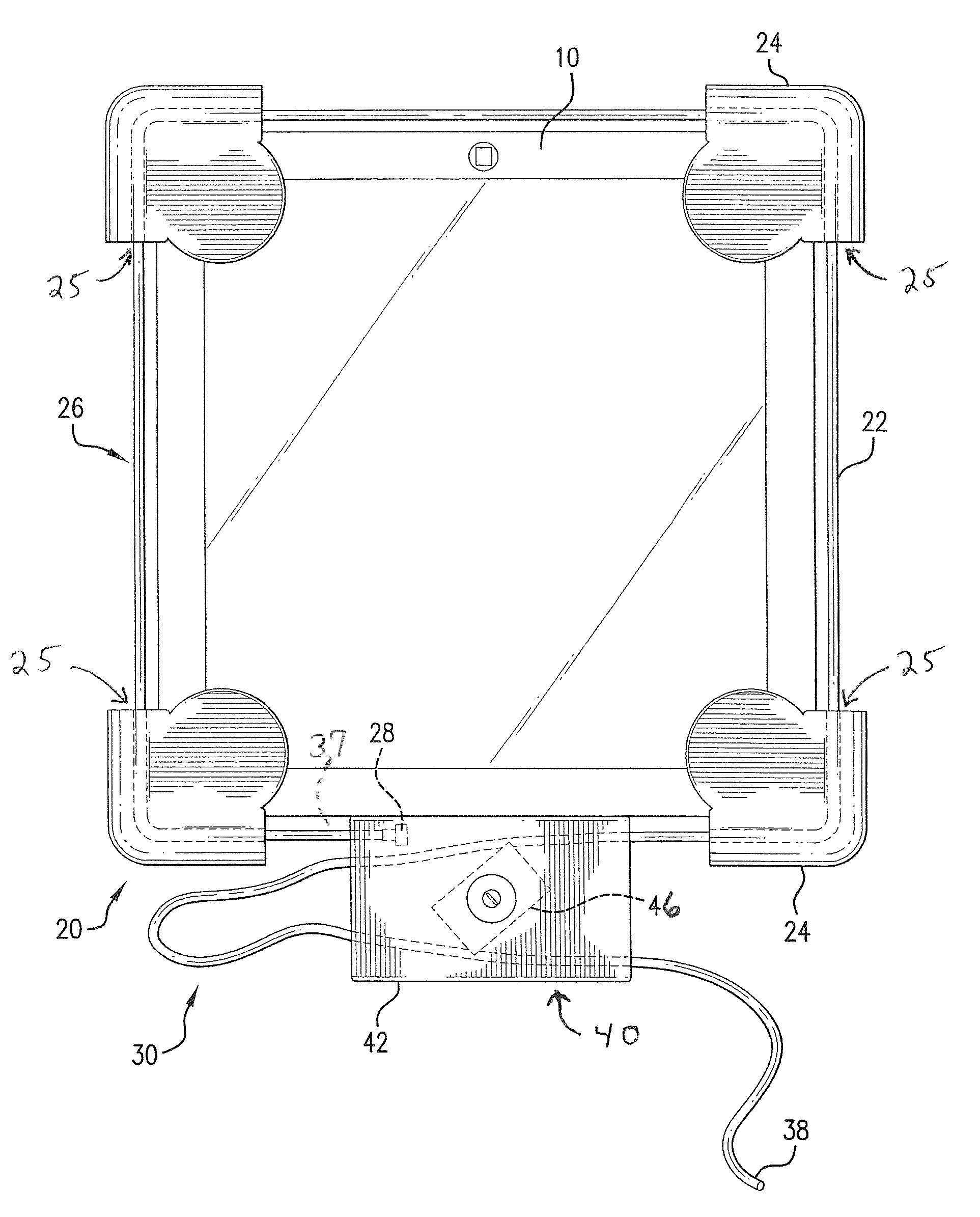

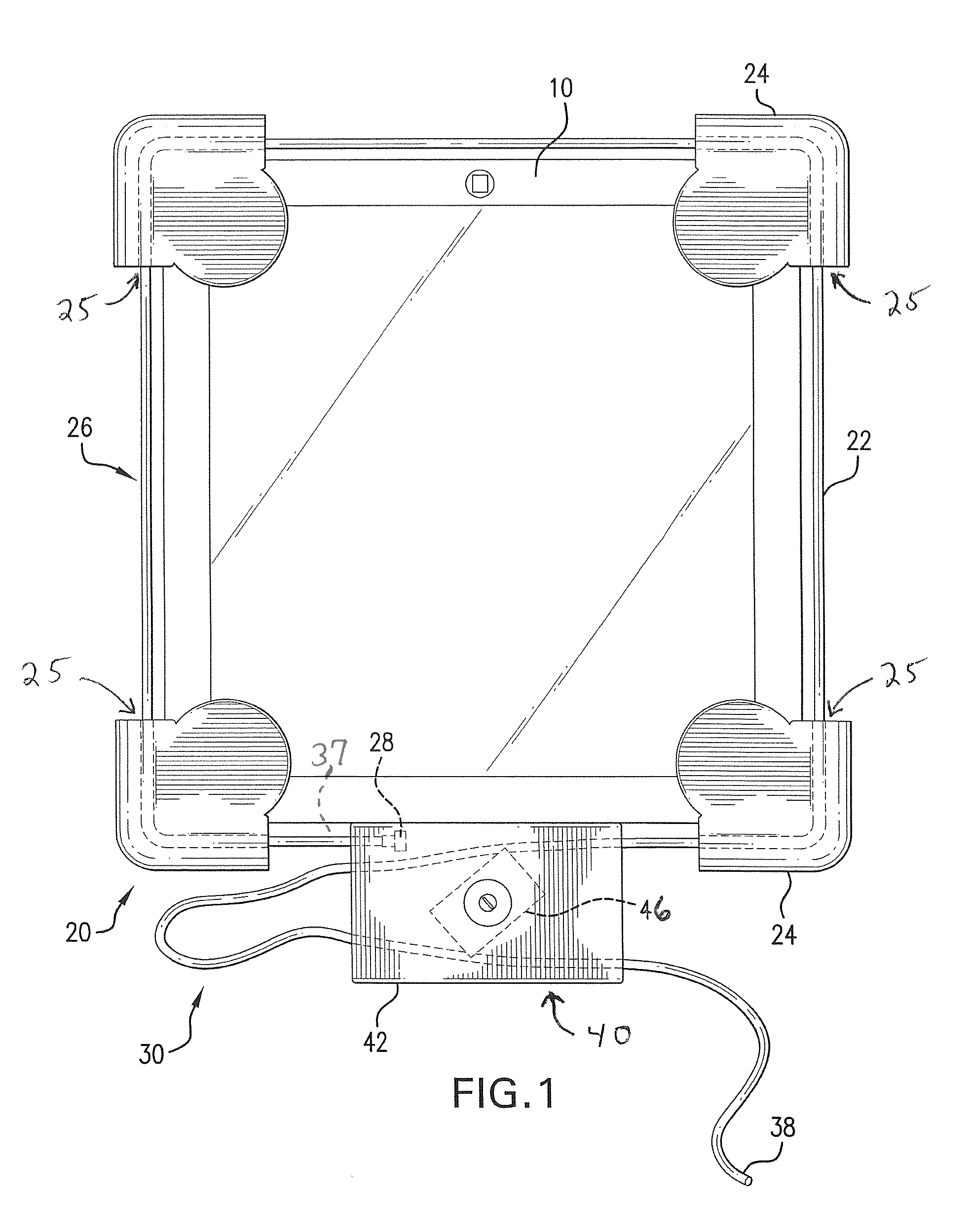

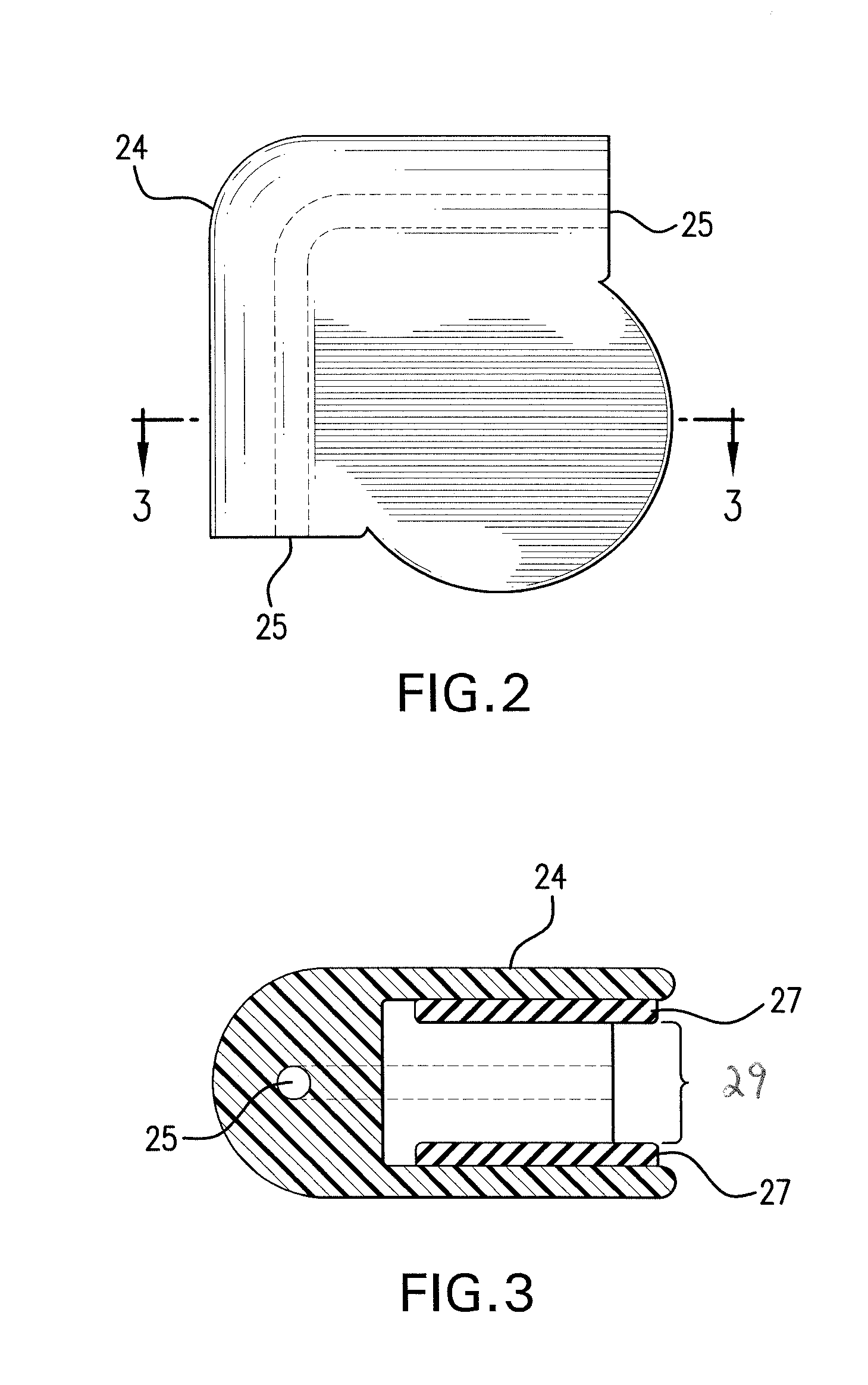

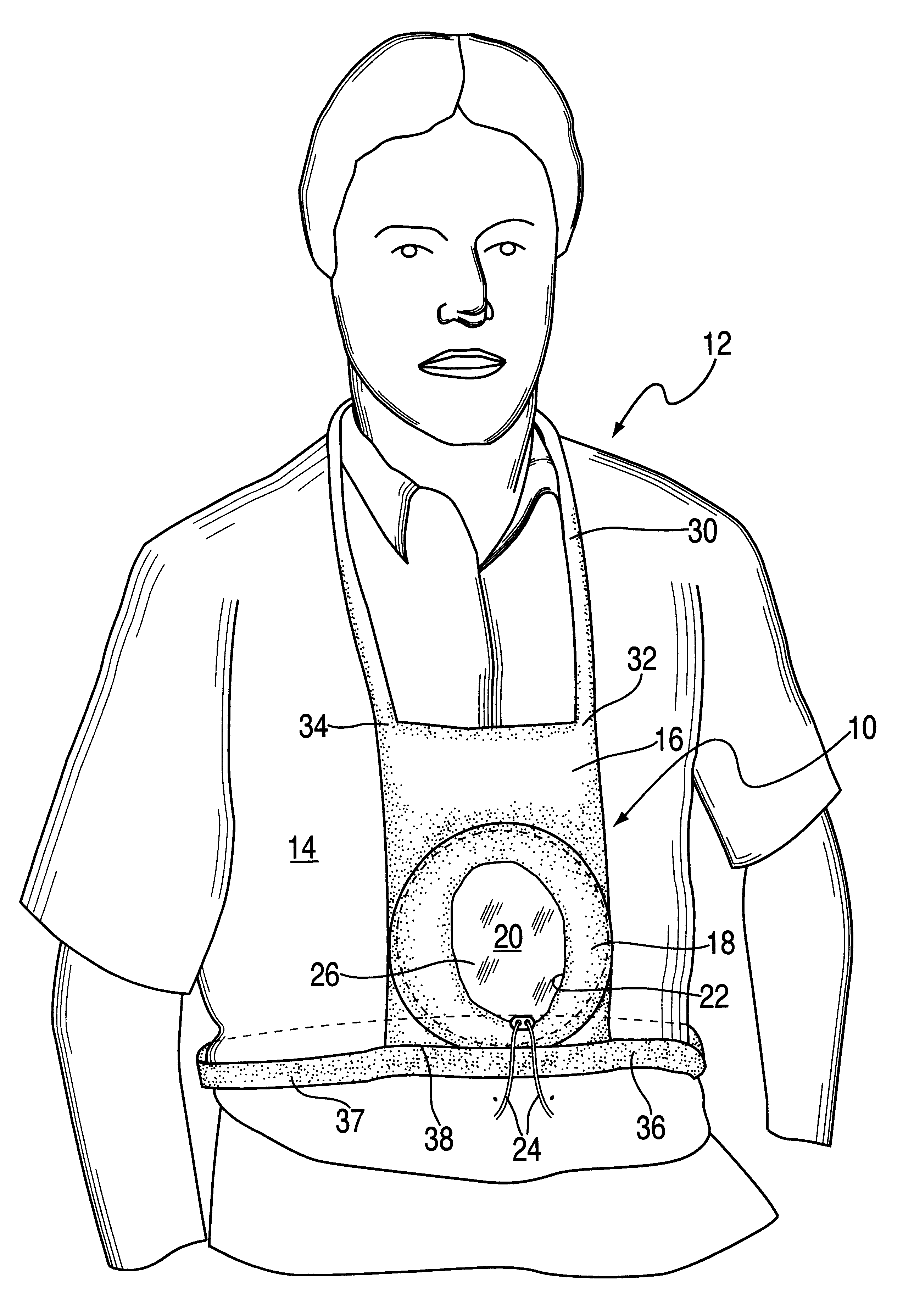

Theft prevention apparatus for a personal electronic device

InactiveUS20130067967A1Prevent theftAvoid damageLocks for portable objectsLocking mechanismHand held

An apparatus for securing a personal electronic or hand held device (PED), includes a housing for a “pull-tight” lock mechanism attached to an elongated, flexible cable looped through a plurality of corner pieces, and a lock for releasable attachment proximate the distal end of the cable for looping the cable around a secure stationary work object and back through a cable accepting means on said “pull-tight” lock housing. A releasable locking mechanism is disposed within said housing to allow movement of said cable in the first direction, but not in the direction opposite from the first direction when the cable is slidably engaged or “cinched” tight through the corner pieces and secured around the PED by the user.

Owner:OLEAR JORDAN A +1

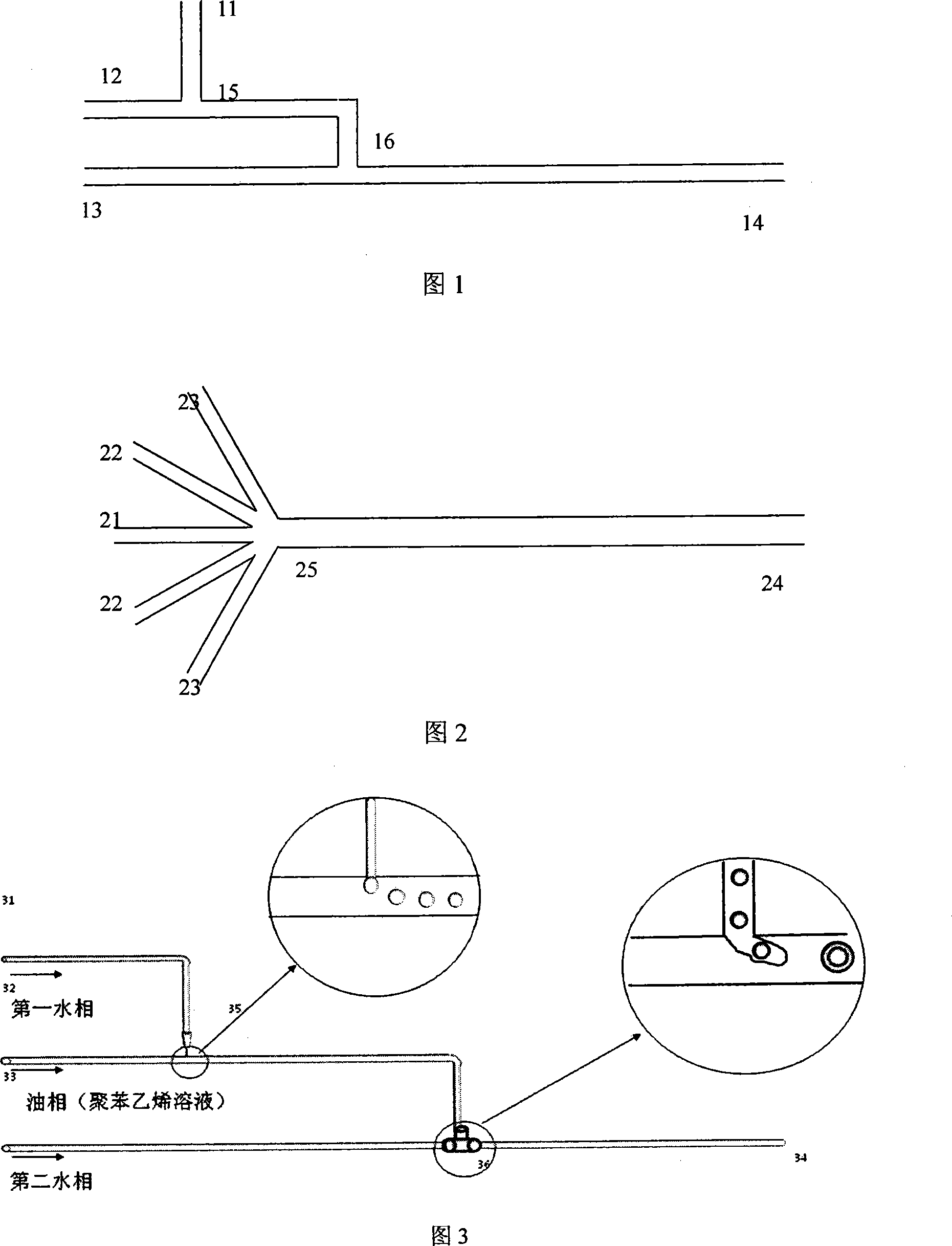

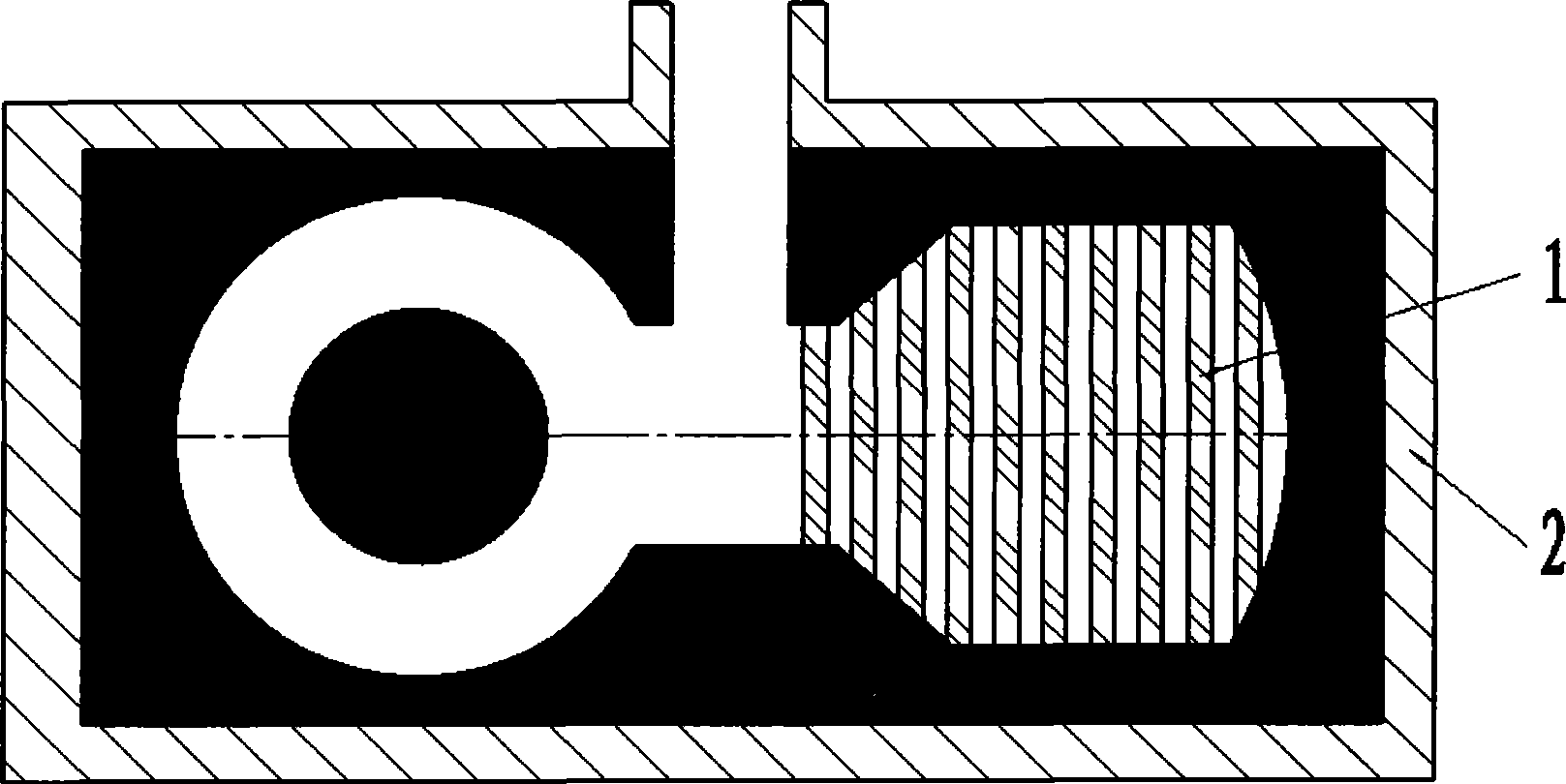

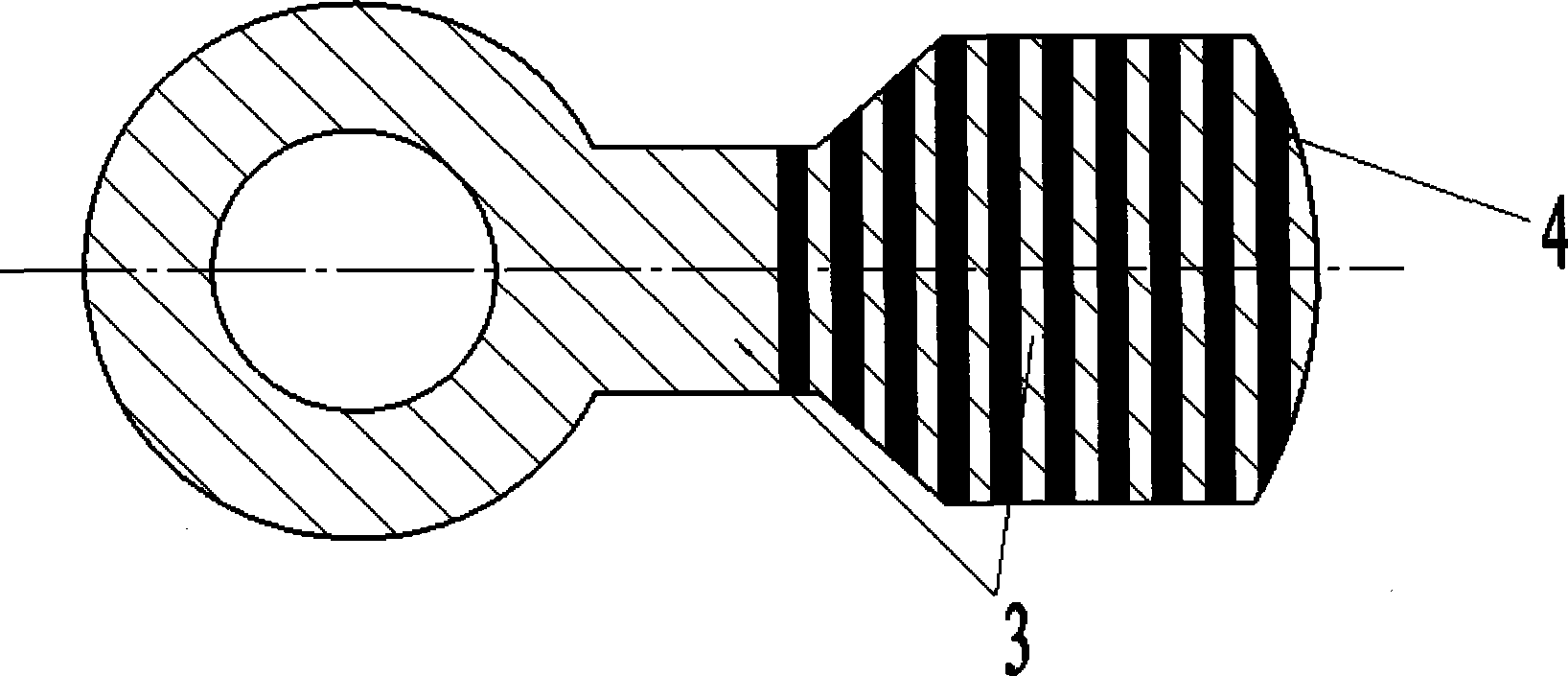

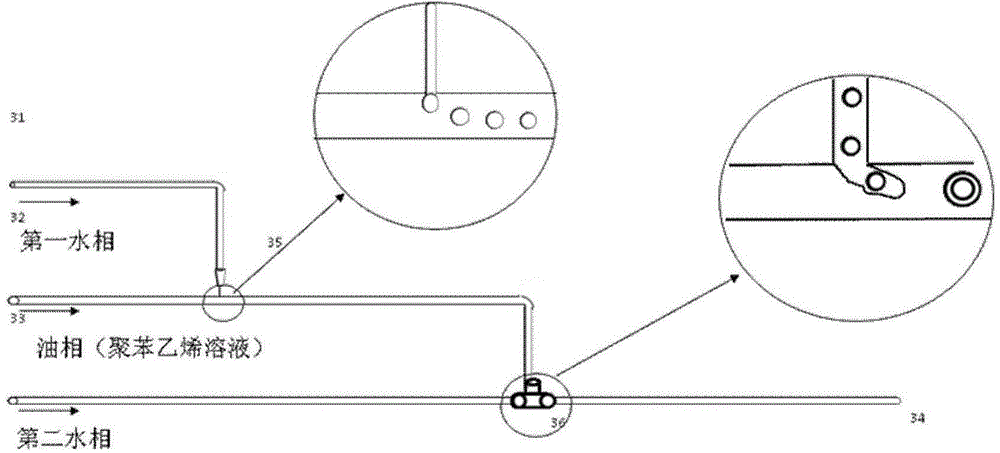

Method for preparing fusion pallet based on micro-fluid

InactiveCN101110278AAdjustable diameterAdjustable wall thicknessSemi-permeable membranesNuclear energy generationMicrofluidic channelEngineering

A preparation method for a fusion targeting pill based on microfluid control passage is provided, which is related in particular to a preparation method for an inertial restraint fusion targeting pill based on microfluid passage technology. The method adopts microfluid passage network to ensure the targeting pill solution or a pre-agglomerated body form double microemulsion fluid in flowing phase, form a hollow targeting pill that complies with the fusion requirements while basing on a liquid drop template and the diameter and wall thickness of the hollow targeting pill can be controlled. This preparation method ensures the solution or the pre-agglomerated body of the targeting pill material form double microemulsion via the microfluid passage, then forms a hollow microsphere that complies with ICF target requirement via solidification and drying. This preparation method is able to prepare hollow microsphere with even size and controllable sac wall and in compliance with ICF target requirement. The specific preparation method comprises: 1) preparation of microfluid passage; 2) preparation of microemulsion; 3) preparation of fusion targeting pill.

Owner:SOUTHEAST UNIV

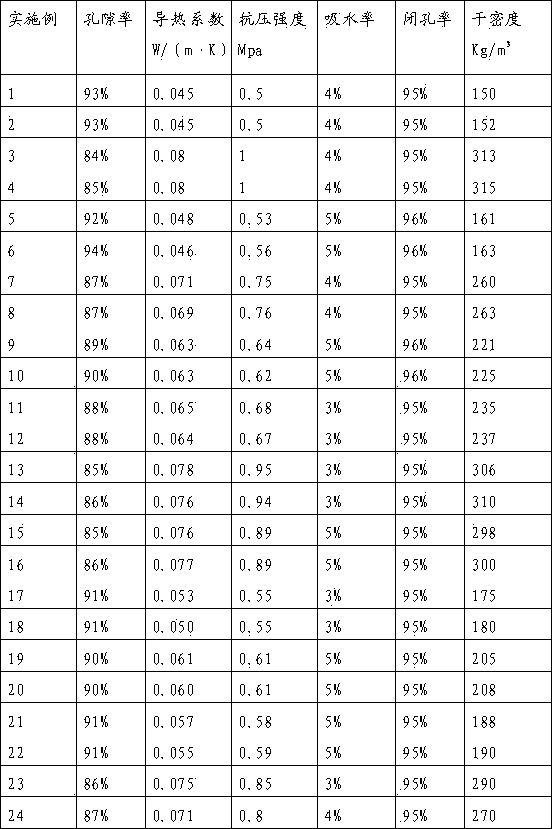

Material used for manufacturing foam cement, method for preparing foam cement from same, and foam cement

ActiveCN103420654ALow thermal conductivityImprove thermal conductivitySolid waste managementCeramicwareFoaming agentThermal insulation

The invention relates to a foamed cement material and a production and a preparation method thereof. The foamed cement material comprises the following components in parts by weight: 32 to 58 parts of cement, 10 to 34 parts of solid waste materials, 2 to 7 parts of foamed hole conditioning agents, 0.2 to 0.5 part of foamed hole wall reinforcing agent, 2.5 to 7 parts of foaming agents, 0.1 to 0.5 part of foaming speed conditioning agent, 0.1 to 1 part of curing speed conditioning agent and the balance of water, wherein the content of all the components reaches 100% after proper amount of the water is added. The foamed cement is an inorganic heat preservation material with the integrated performance of fire prevention and energy conservation. The foaming ratio of the foamed cement material can be regulated by using the foamed hole conditioning agents, so that the heat conductivity coefficient of the foamed cement material is controlled in a definite range. Therefore, the foamed cement material can satisfy the heat preservation and thermal insulation requirements in cold areas and other areas hot in summer and warm in winter. The foamed hole wall conditioning agent, the foamed hole wall reinforcing agent, the foaming agents, the foaming speed conditioning agent and the curing speed conditioning agent are prepared into solutions, so that the transportation and the category of metering equipment are reduced, i.e. the equipment investment is lowered and the dust emission is reduced. As a result, the sanitary production is realized, and the environment-friendly requirement is satisfied.

Owner:CUBIC DIGITAL TECH CO LTD

Adjustable smooth bore nozzle

An adjustable nozzle comprising a nozzle body with an inlet, an outlet, and a passageway having a smooth bore extending between the inlet and the outlet. The passageway has an inner dimension transverse to the central axis of the nozzle and a compressible wall wherein the inner dimension is adjustable to adjust the flow rate through the nozzle.

Owner:ELKHART BRASS MFG

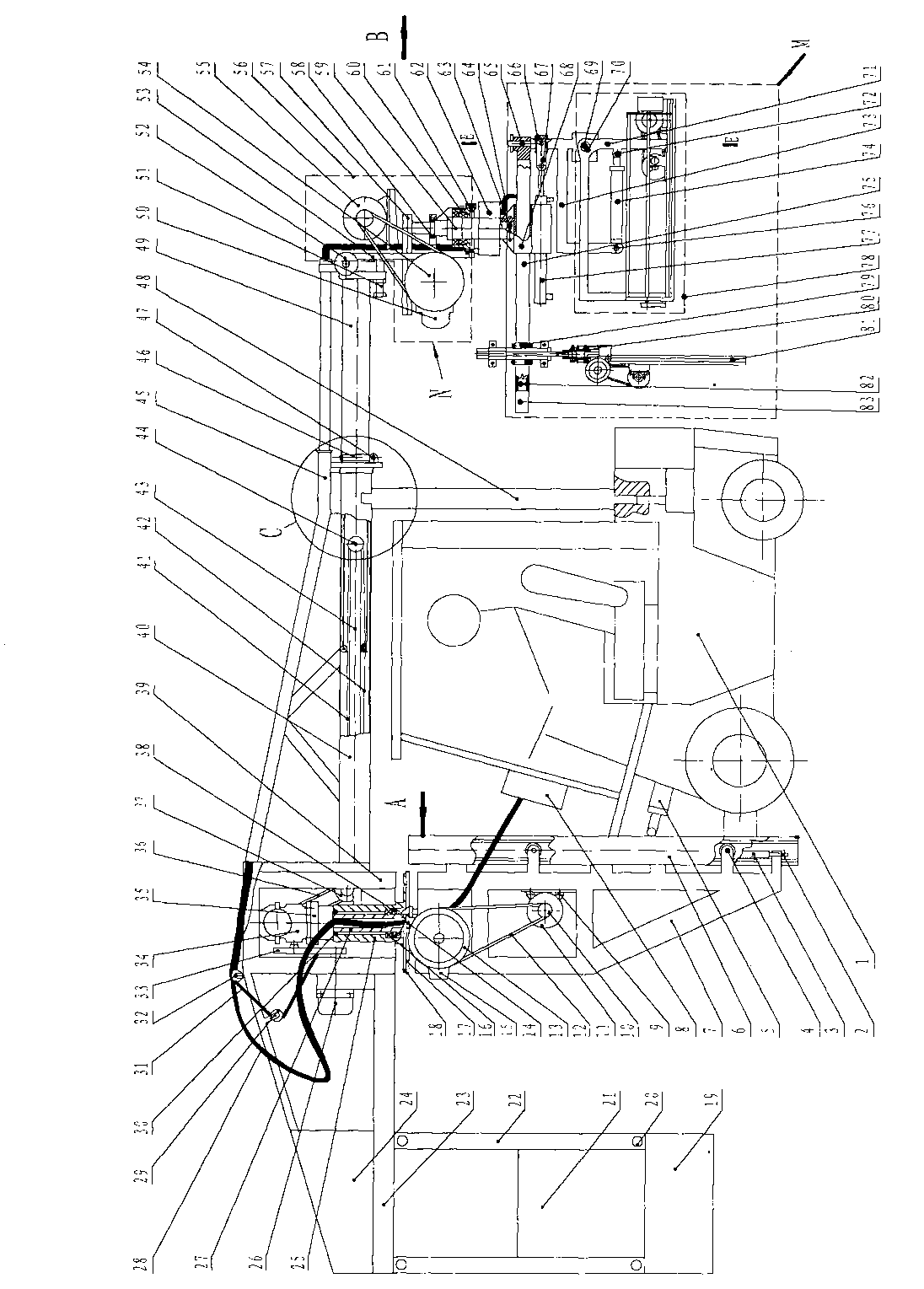

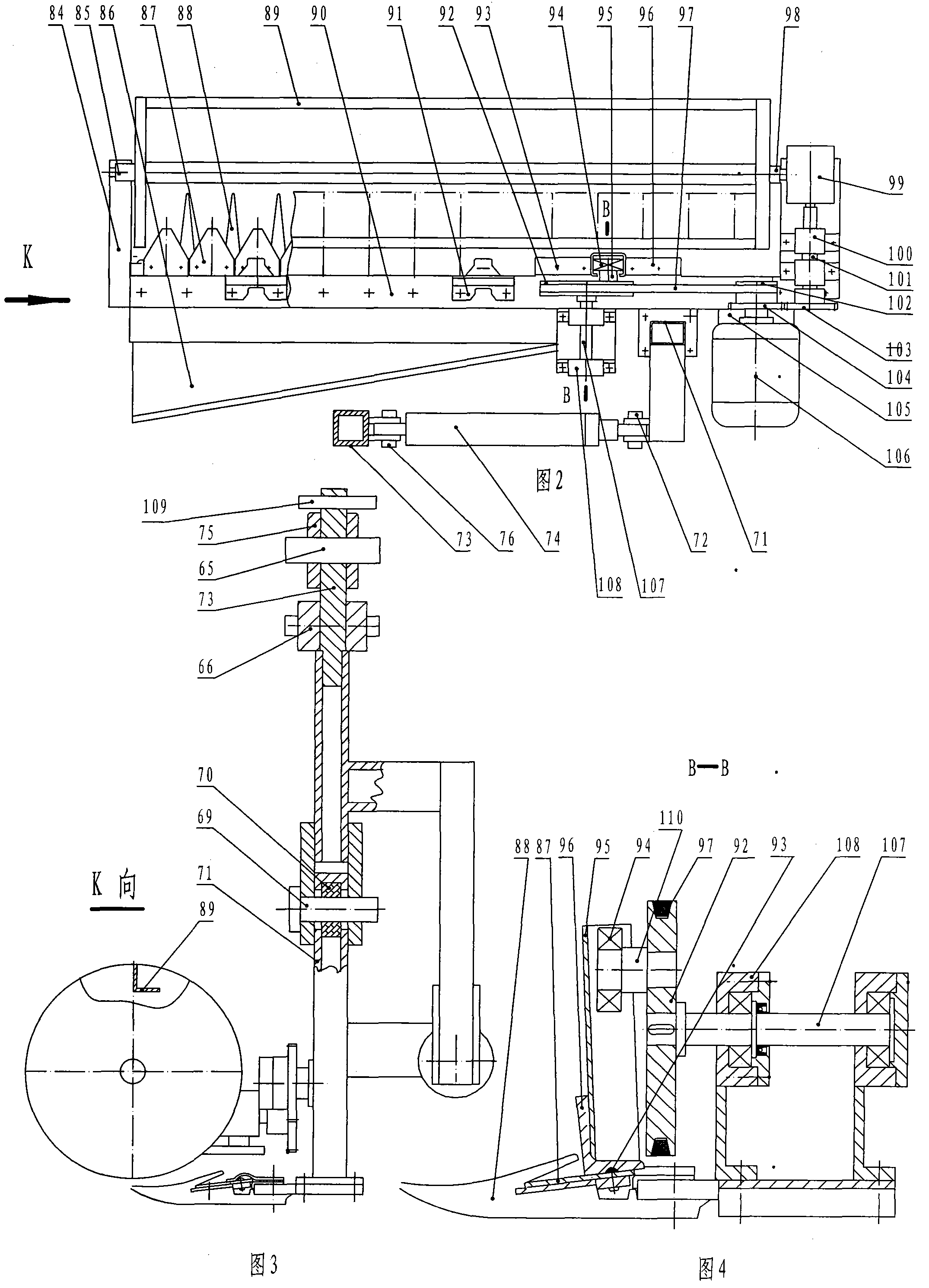

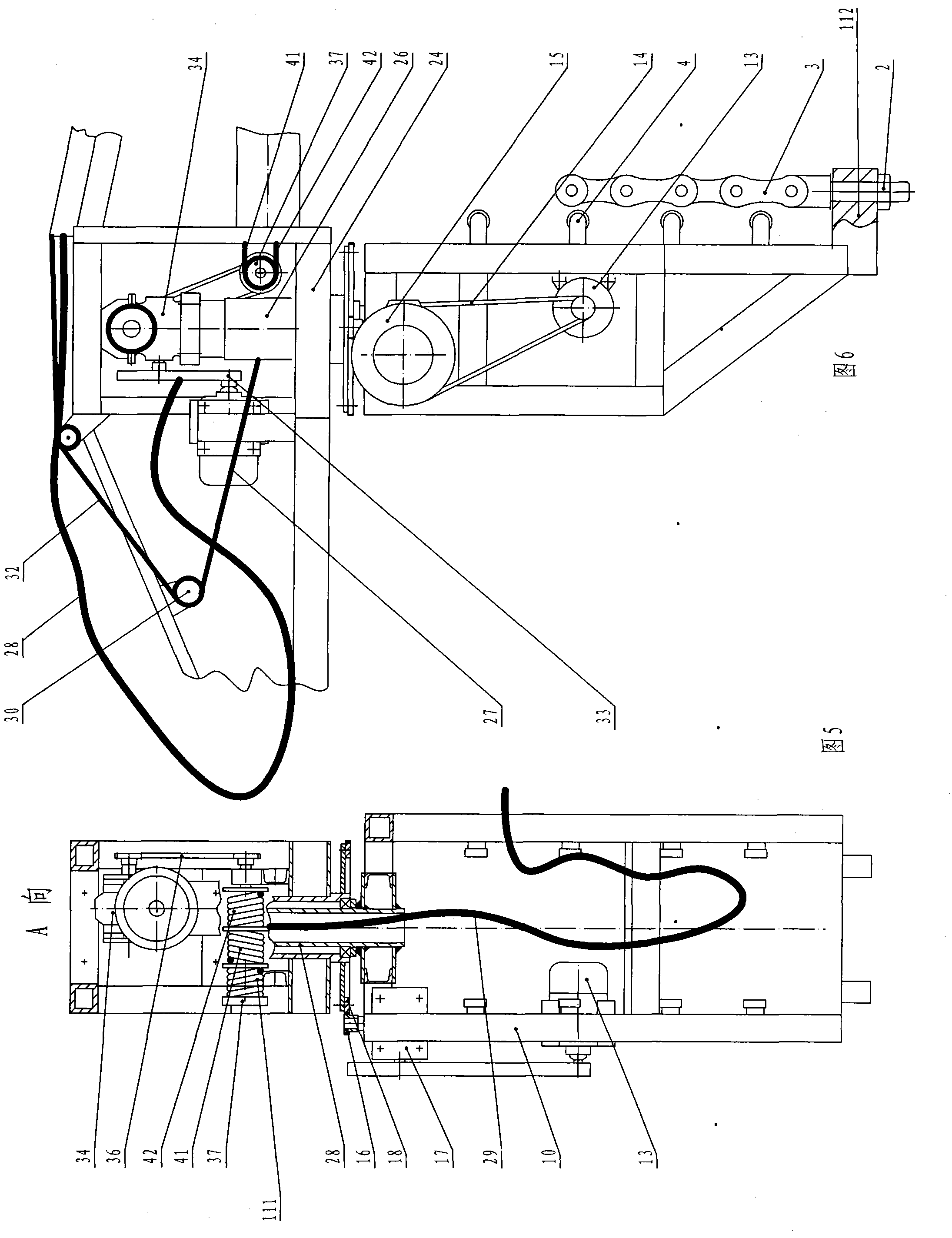

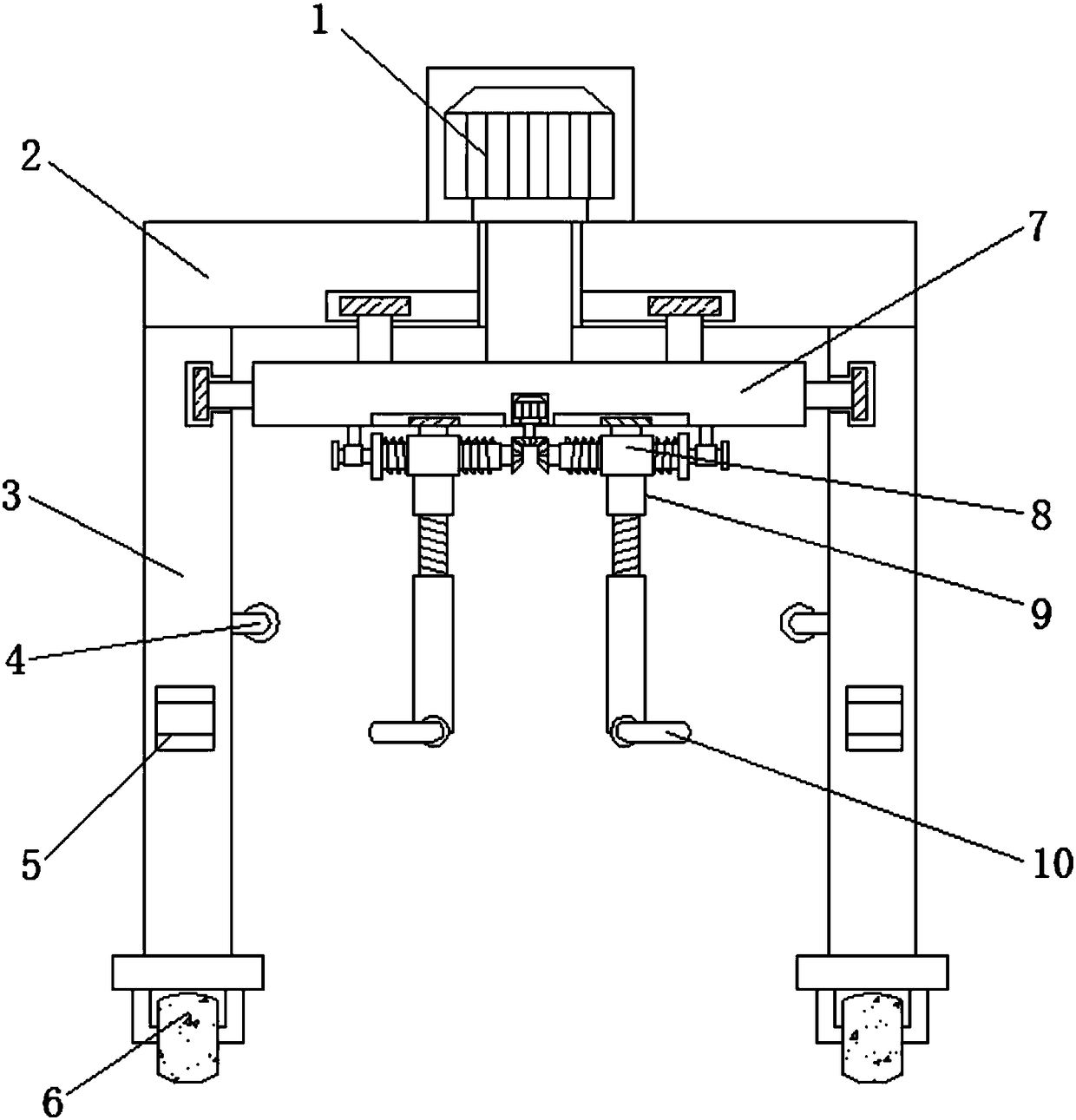

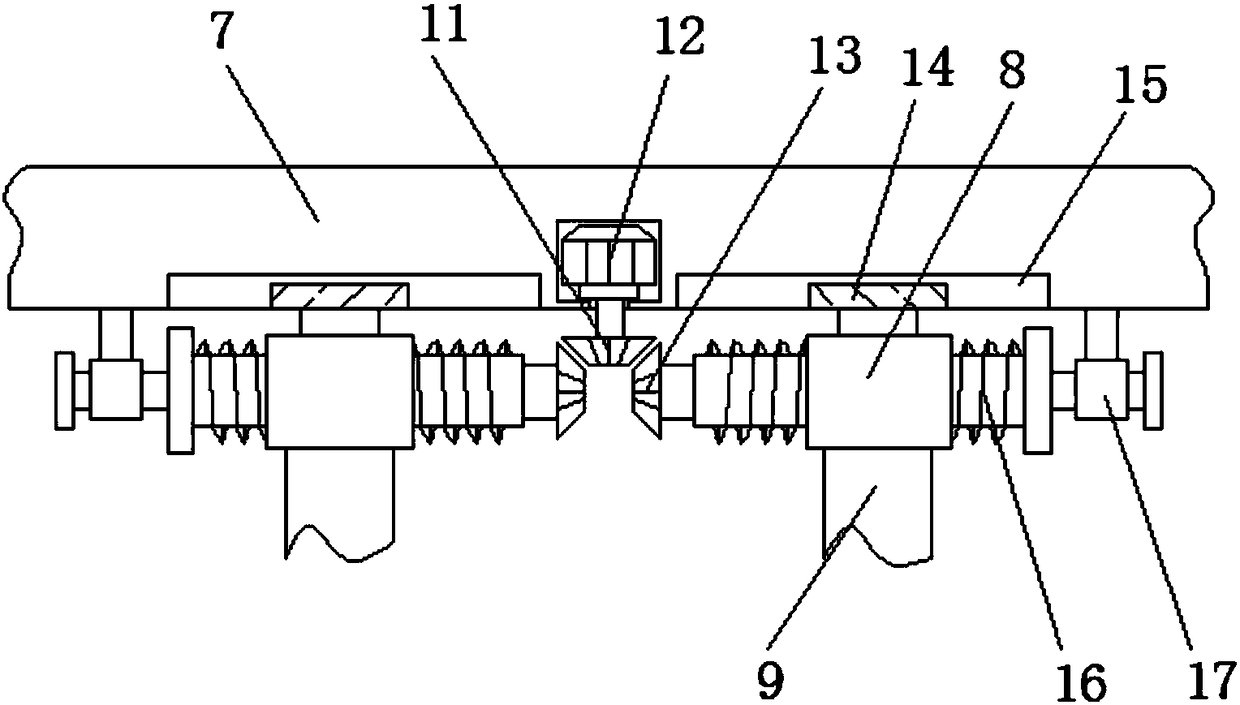

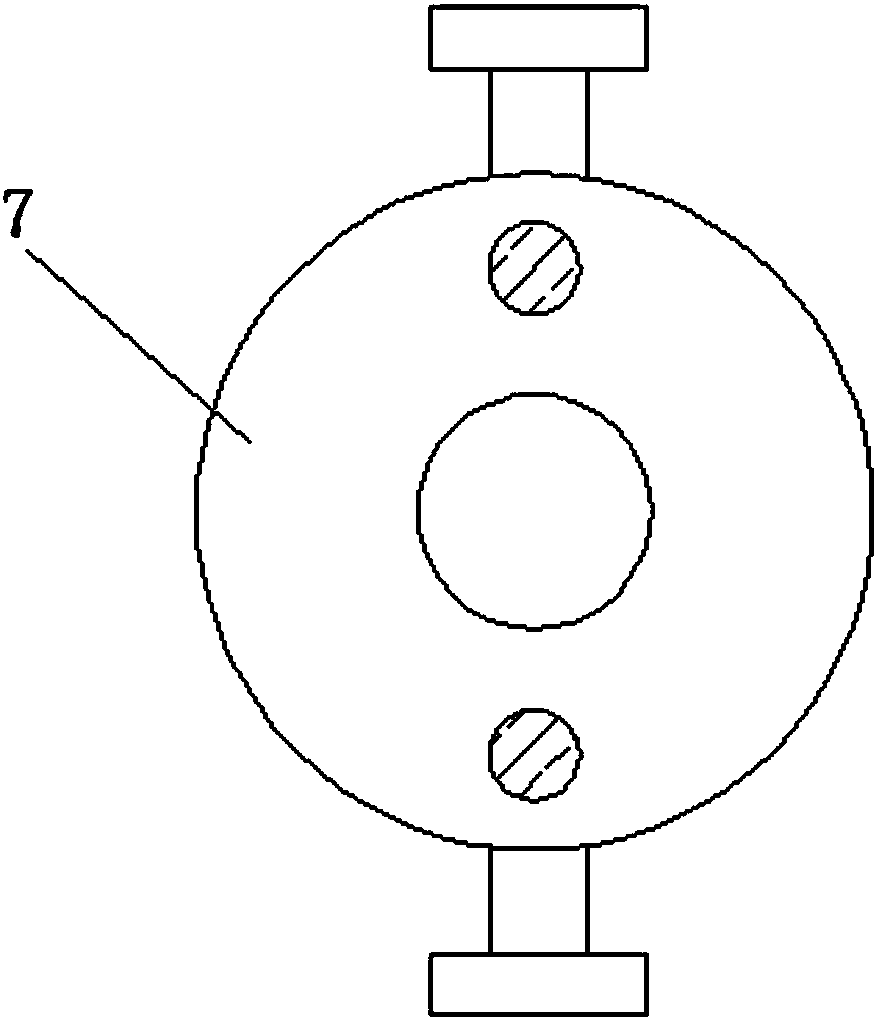

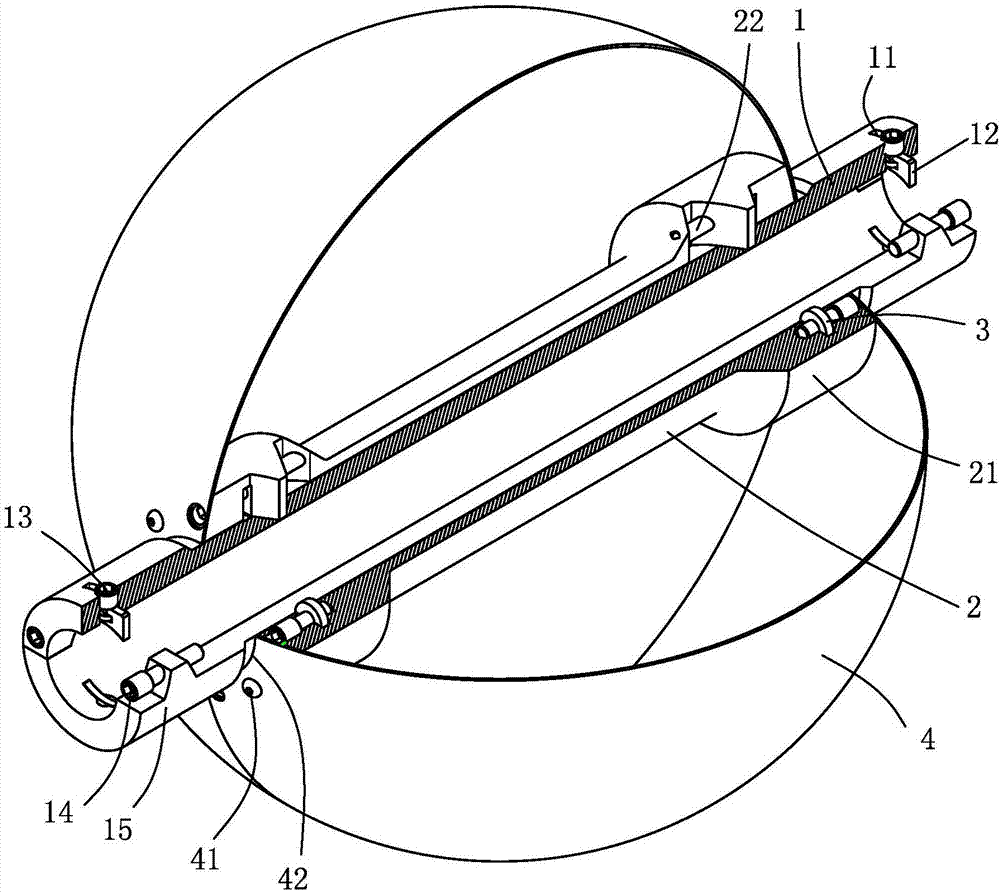

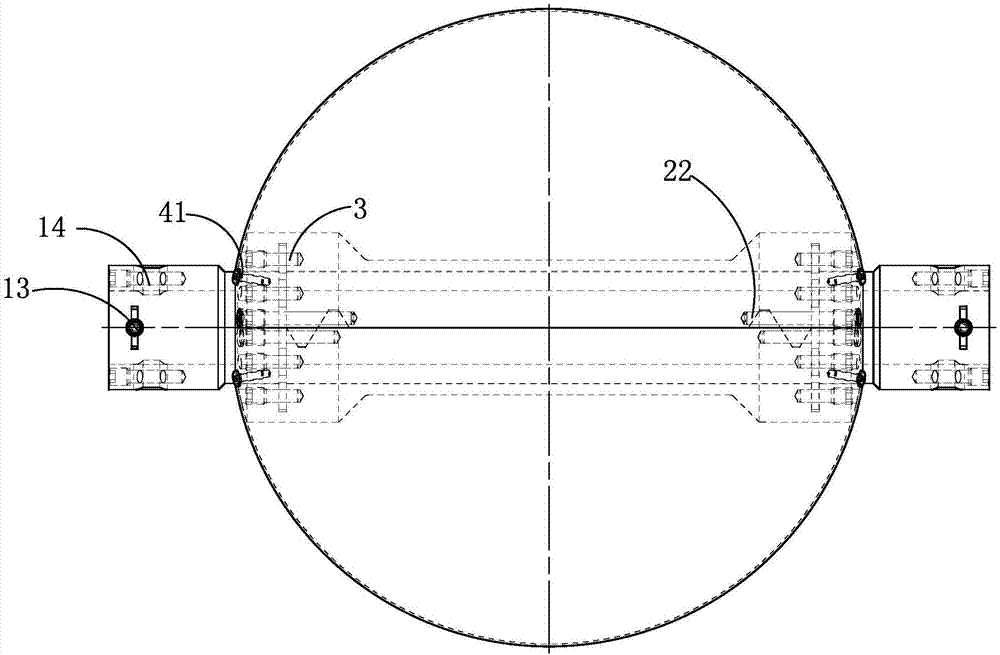

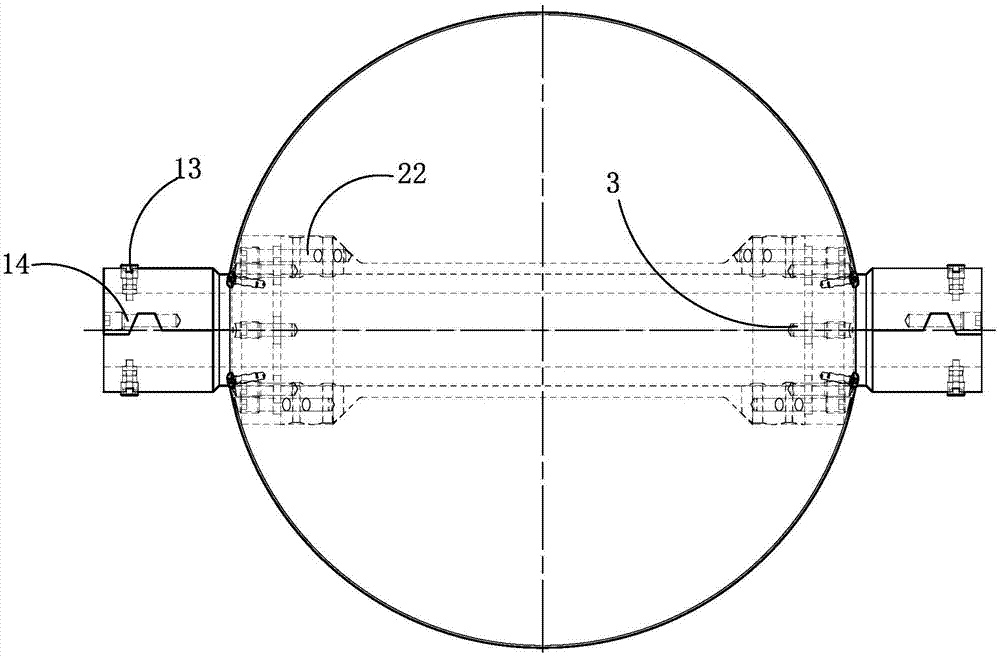

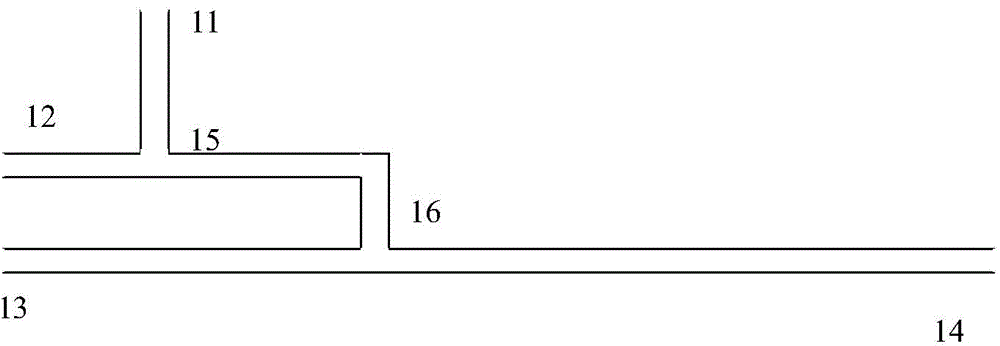

Automatic trimming machine for tree shapes

InactiveCN103518552AAdjustable lengthAdjustable diameterHedge trimming apparatusDriver/operatorEngineering

Disclosed is an automatic trimming machine for tree shapes. A machine frame of the trimming machine is installed inside a lifting track of a forklift. A rotating tower is inserted on a rotating shaft of the machine frame. A power source counterweight system, a large arm, a telescopic arm, a machine head and a trimming system M are sequentially installed on the two side faces of the rotating tower. The rotating tower can rotate to any position of the front side, the back side, the left side and the right side of the forklift around the rotating shaft to work. The whole work of the trimming machine is carried out by operating an electric appliance by a forklift driver. After the work of a header, swinging and lifting of the lifting track of the forklift are utilized for being matched with extension or retraction of the telescopic arm. Due to the addition of the rotation of a header hanging bracket and the swinging of the header, a landscape tree can be trimmed to be in the geometrical shapes such as a semi spherical body, a cylinder, a conical body and a circular truncated cone. After a vertical cutter is used in cooperation with the header, the top face and side faces of a green fence wall can be trimmed at the same time. When the whole trimming machine is parallel to the running center line of the forklift, the side direction of the trimming machine is the same as the forklift in width, non-working-state running can not affect other vehicle traffics.

Owner:孙宏志 +1

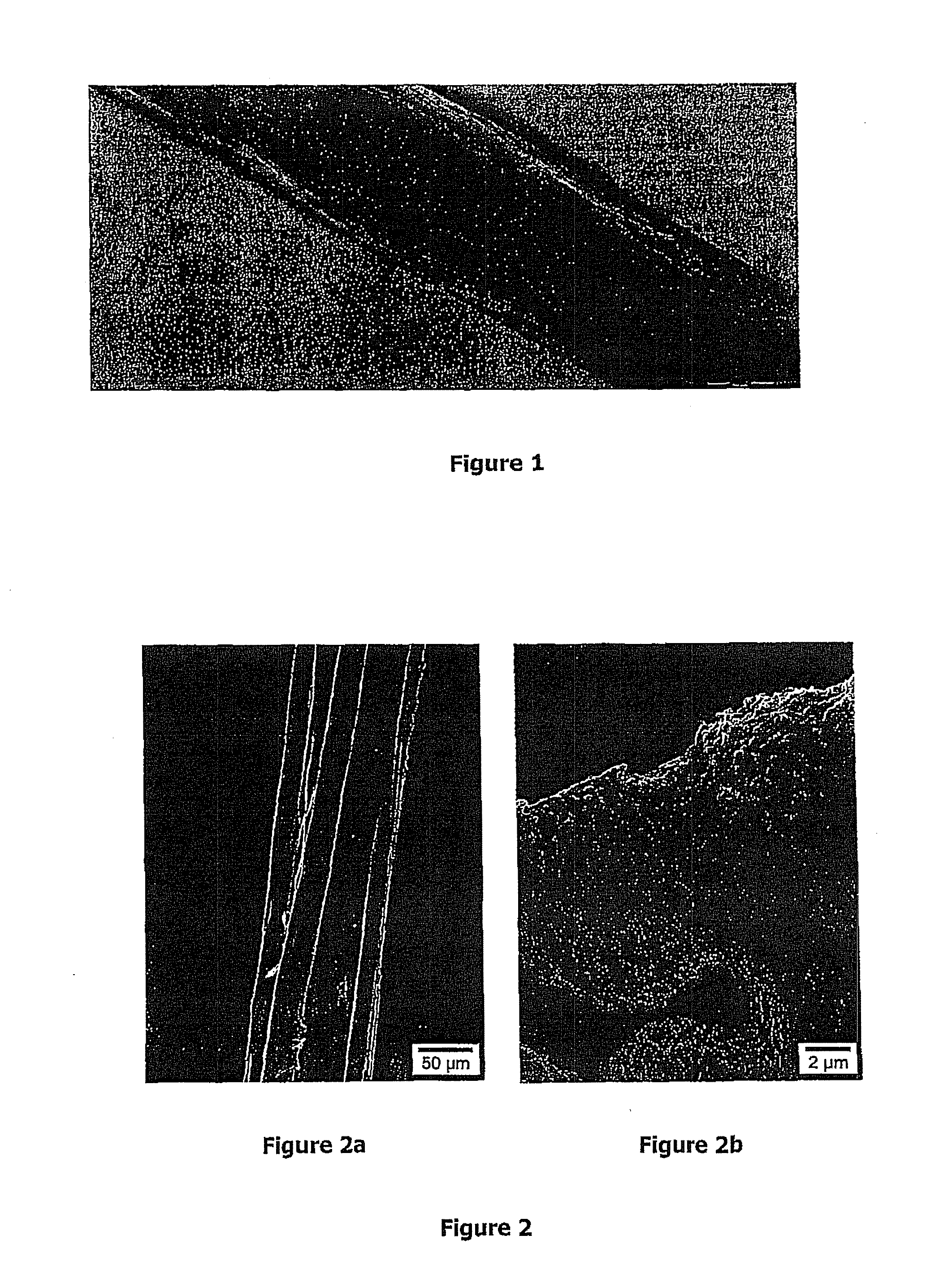

Filament based on hyaluronic acid in the form of free acid and method for obtaining it

InactiveUS20100310631A1Good biocompatibilityInduce inflammatory reactionAntibacterial agentsAntimycoticsAcetic acidAqueous solution

The present invention relates to a method for preparing by wet spinning a continuous filament based on hyaluronic acid in free acid form, notably soluble in water. The preparation method according to the invention comprises the following steps: a) preparing a spinnable aqueous solution of hyaluronic acid or of a hyaluronic acid salt, preferably a sodium hyaluronate solution; b) extruding said solution to an extrusion die; c) forming the filament by passing the extruded solution into a bath of acetic acid, concentrated to more than 80%, drawing and drying. The invention also relates to a filament based on hyaluronic acid in free acid form, said filament having swelling properties in water and physiological liquids and moreover being solubilizable in water under certain conditions.

Owner:UNIV CLAUDE BERNARD LYON 1 +1

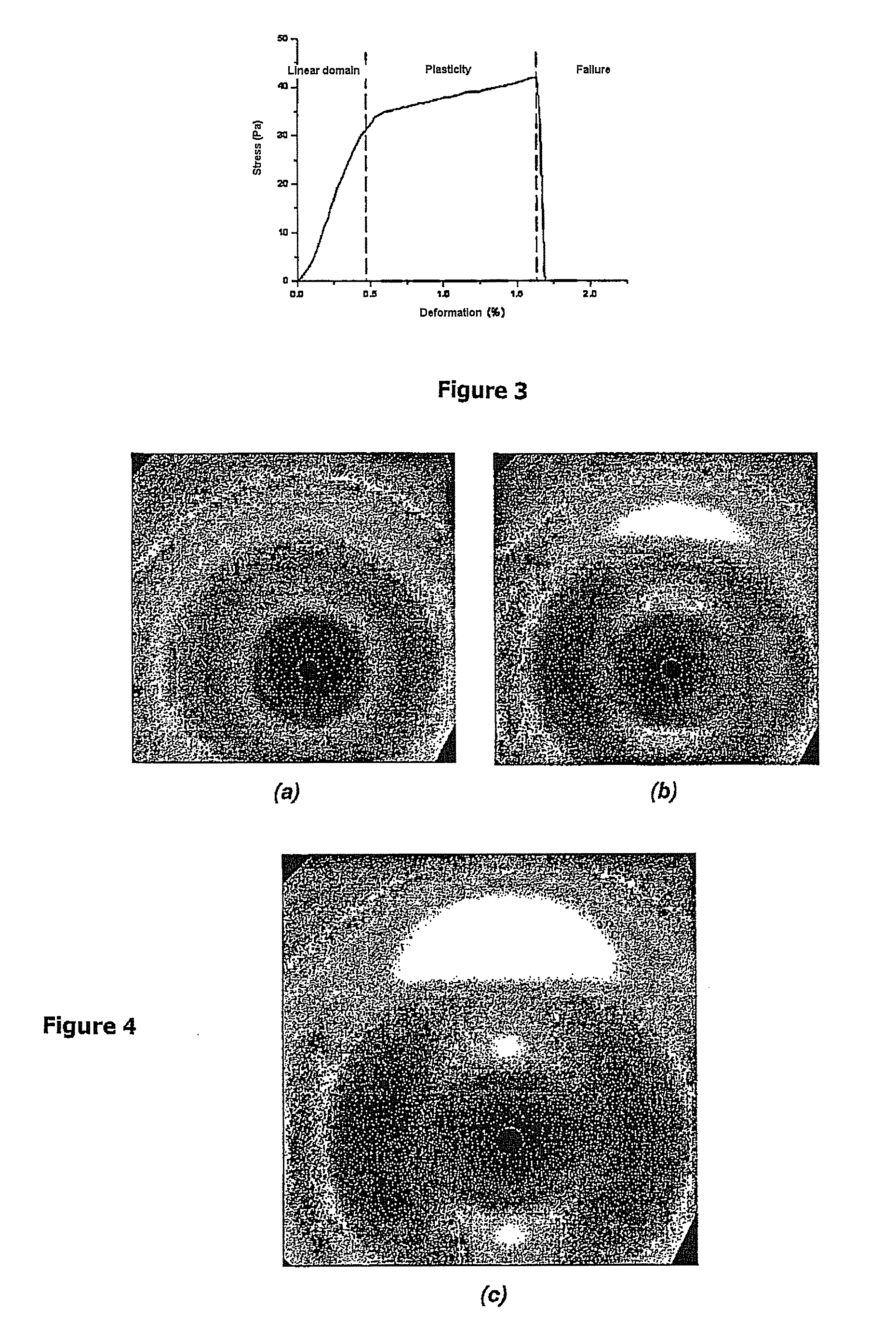

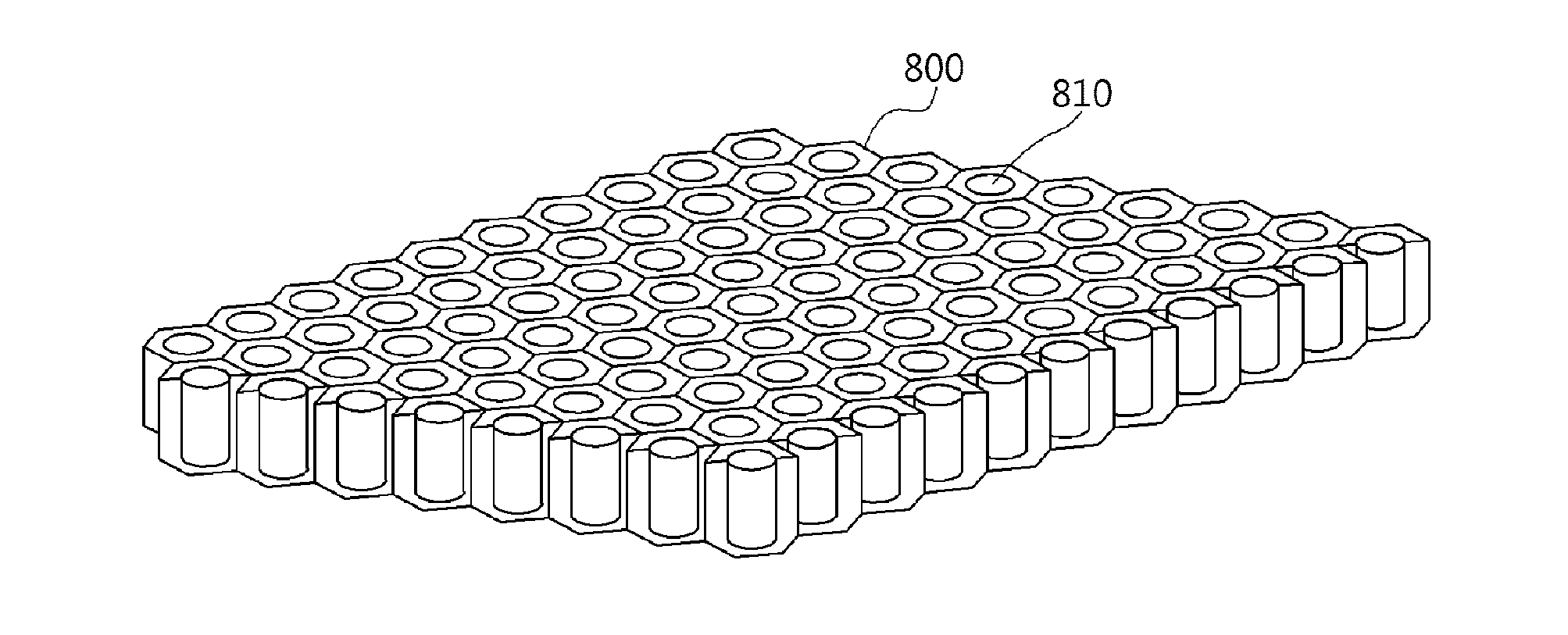

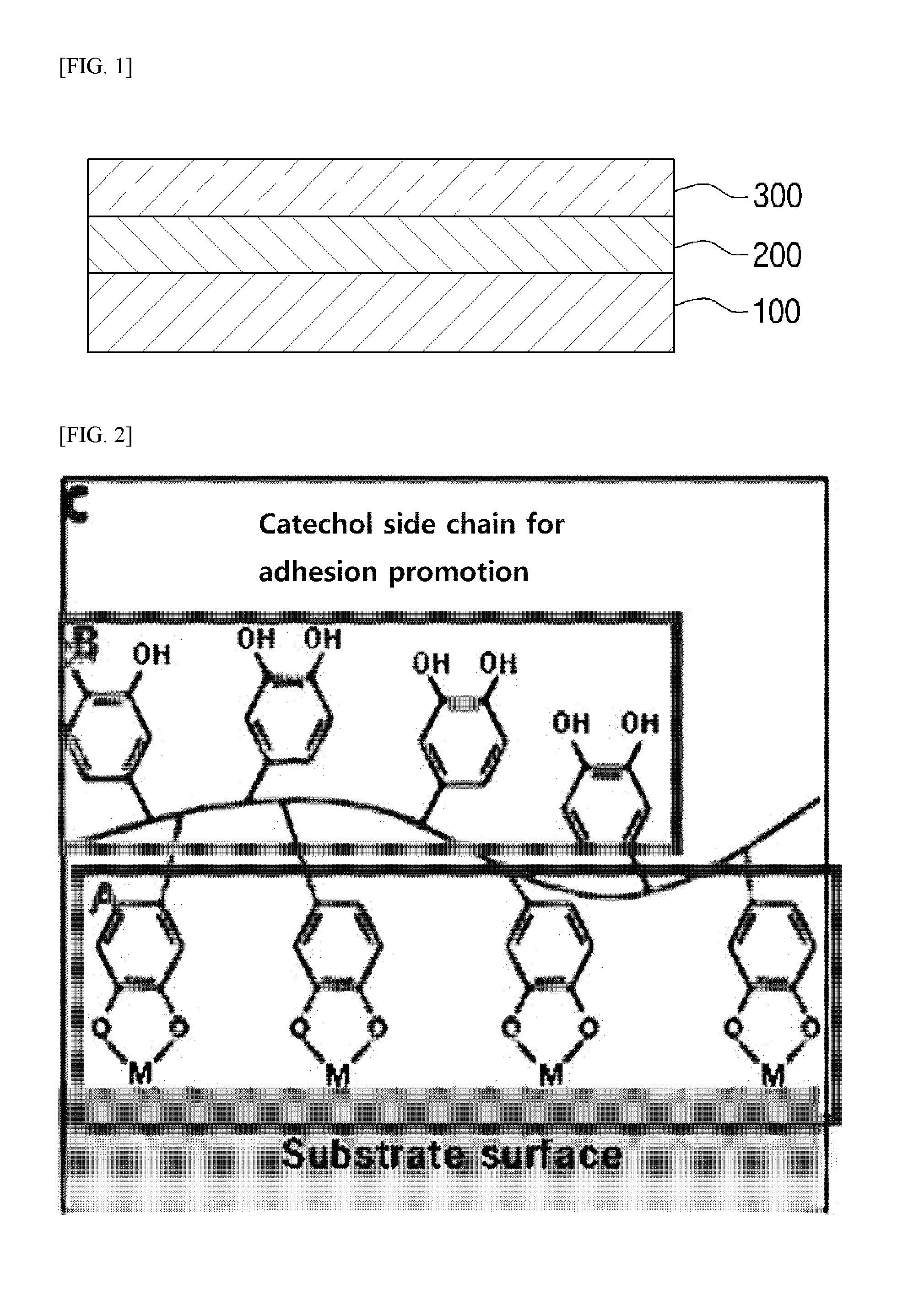

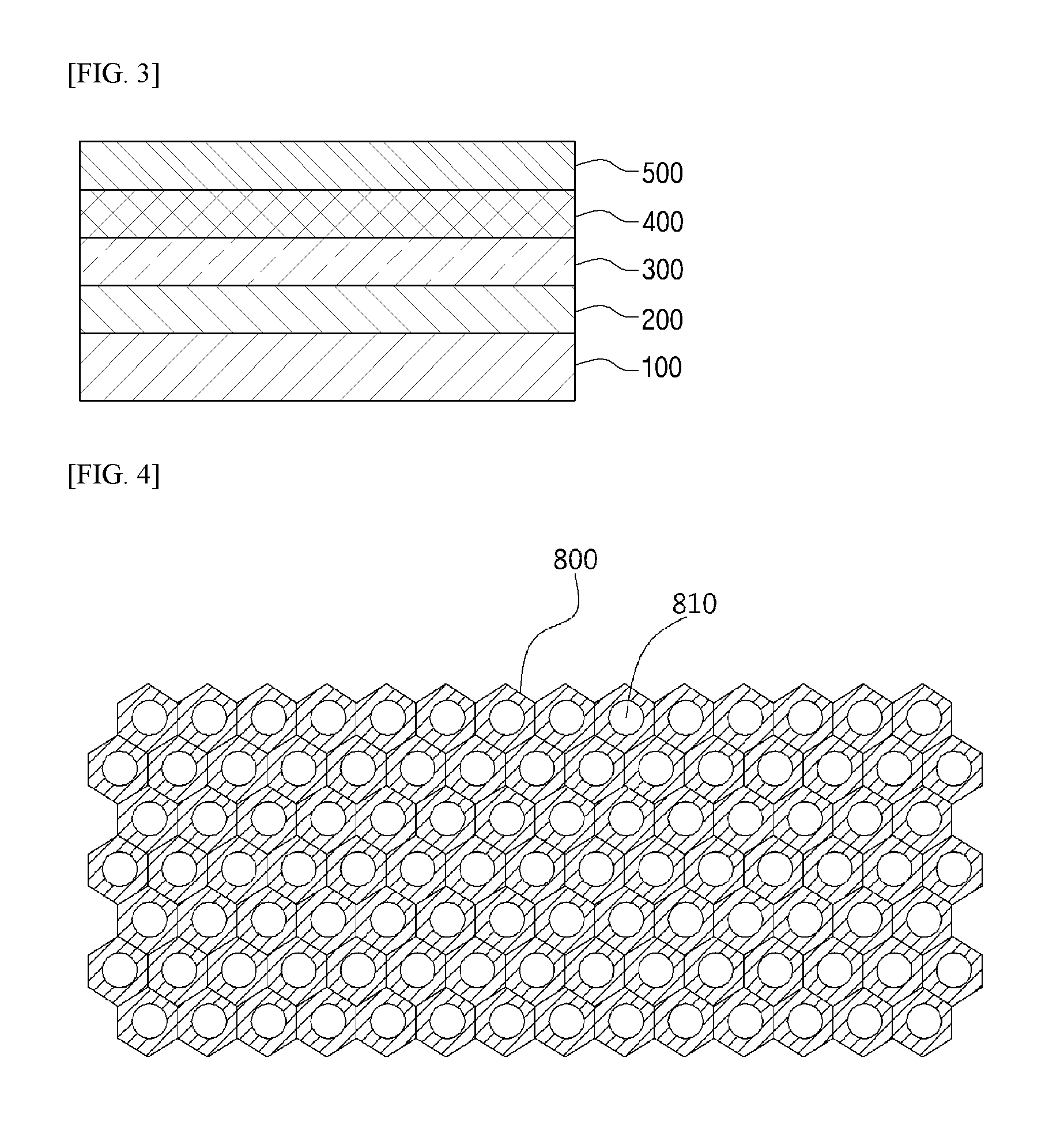

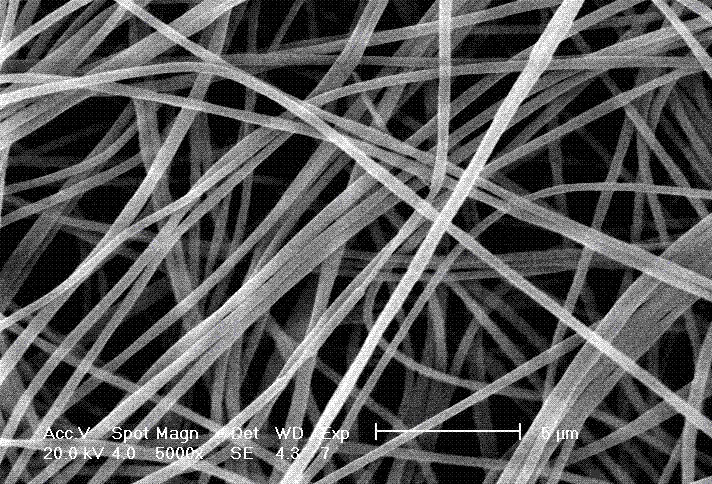

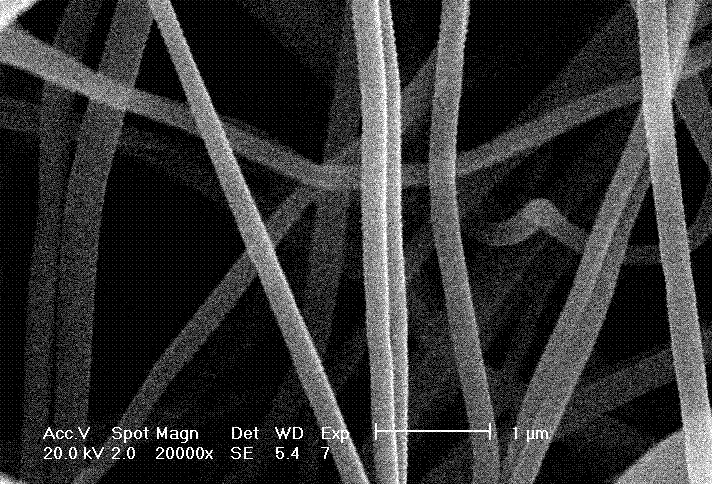

Pellicle for EUV lithography

ActiveUS20170038675A1High strengthCoupling strengthSemiconductor/solid-state device manufacturingPhotomechanical exposure apparatusLithographic artistUltimate tensile strength

A pellicle for EUV lithography is provided. The pellicle for EUV lithography may improve strength of a pellicle film by having a strength reinforcing layer including a first coupling layer and a carbon nanostructure disposed on a first inorganic layer, the first coupling layer here increase coupling strength between the first inorganic layer and the strength reinforcing layer, and a strength reinforcing layer including a carbon nanostructure. Also, a pellicle for EUV lithography according to another embodiment and a method of fabricating the same are provided. The pellicle for EUV lithography includes a plurality of holes and is a porous thin film made of a material with an extinction coefficient less than or equal to 0.02, and a diameter of the holes is less than or equal to 1 μm. Accordingly, improved strength is achievable because thickness may be made large with still having high EUV transmission.

Owner:IUCF HYU (IND UNIV COOP FOUND HANYANG UNIV)

Theft prevention apparatus for a personal electronic device

InactiveUS8813528B2Prevent theftAvoid damageClothing locksLocks for portable objectsLocking mechanismEngineering

An apparatus for securing a personal electronic or hand held device (PED), includes a housing for a “pull-tight” lock mechanism attached to an elongated, flexible cable looped through a plurality of corner pieces, and a lock for releasable attachment proximate the distal end of the cable for looping the cable around a secure stationary work object and back through a cable accepting means on said “pull-tight” lock housing. A releasable locking mechanism is disposed within said housing to allow movement of said cable in the first direction, but not in the direction opposite from the first direction when the cable is slidably engaged or “cinched” tight through the corner pieces and secured around the PED by the user.

Owner:OLEAR JORDAN A +1

Preparation method for water-resistant nano microcrystalline cellulose/polyvinyl alcohol/polyacrylic acid/silicon dioxide composite nanofiber membrane

ActiveCN103882624AGuarantee structureUniform diameterNon-woven fabricsSpinning solutions preparationSpinningPolyvinyl alcohol

The invention relates to a preparation method for a water-resistant nano microcrystalline cellulose / polyvinyl alcohol / polyacrylic acid / silicon dioxide composite nanofiber membrane. The preparation method includes the steps that (1), a polymer solution is prepared by polyvinyl alcohol and polyacrylic acid by the mass ratio of 1:1-1:5; (2), nano microcrystalline cellulose different in weight is added into the polymer solution in the step1, and therefore a 1wt-8wt% nano microcrystalline cellulose / polyvinyl alcohol / polyacrylic acid solution is prepared; (3), 1 g-2 g of tetraethyl orthosilicate, 2 g of alcohol, 1g of water and 0.8 mol / L hydrochloric acid are mixed to prepare a tetraethyl orthosilicate solution to be subjected to prehydrolysis; (4), the tetraethyl orthosilicate solution after prehydrolysis and a solution in the step2 after ultrasonic processing for 2 minutes-5 minutes are mixed according to the mass ratio of 1:3 to prepare a spinning solution, and a nanfiber membrane is prepared through a static spinning technology; (5), the prepared nanofiber membrane is dried for 12 h in a vacuum drying box at the temperature of 40 DEG C and then placed in a high-temperature vacuum drying box to be heated for 1 h. The defect that a polyvinyl alcohol nanofiber membrane is poor in water-resistant performance is overcome, and the preparation method has the advantages of being simple in preparation process, little in environment pollution, excellent in mechanical performance and the like. Three kinds of functional groups on the surface of the nanofiber surface greatly enable the application space of material to be expanded.

Owner:TONGJI UNIV

Adjustable smooth bore nozzle

InactiveUS20070290063A1Increase pressureIncrease flow rateDiaphragm valvesEngine diaphragmsEngineeringNozzle

An adjustable nozzle comprising a nozzle body with an inlet, an outlet, and a passageway having a smooth bore extending between the inlet and the outlet. The passageway has an inner dimension transverse to the central axis of the nozzle and a compressible wall wherein the inner dimension is adjustable to adjust the flow rate through the nozzle.

Owner:ELKHART BRASS MFG

Lamp body pouch

InactiveUS6554445B1Easily be turnedAdjustable diameterLighting support devicesElectric circuit arrangementsEngineeringDome shape

Owner:JACOBY JOSEPH

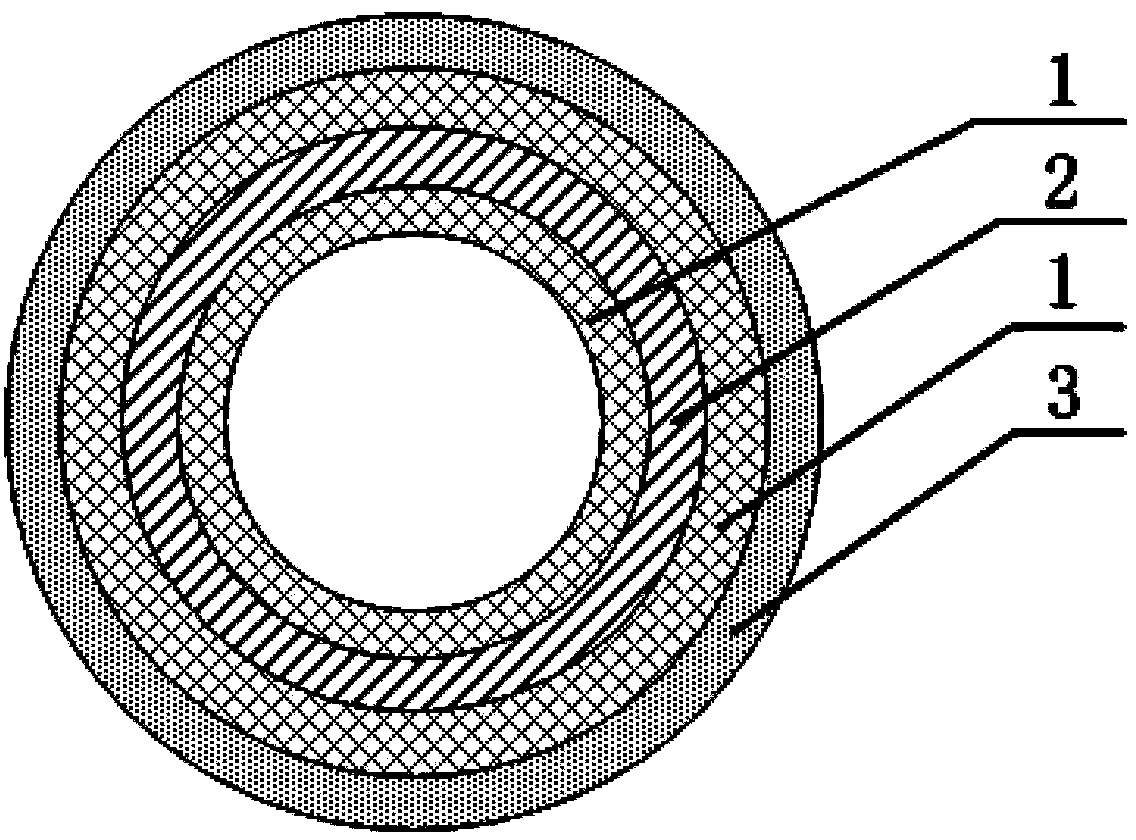

Preparation method of anti-coagulating composite tubular scaffold with good compliance

InactiveCN104524632AGood blood compatibilityImprove compliancePharmaceutical containersMedical packagingPoly(ethylene glycol) diglycidyl etherHaemodialysis machine

The invention provides a preparation method of an anti-coagulating composite tubular scaffold with good compliance. The tensile property of the tubular scaffold can be improved by the composite tubular scaffold by virtue of braided fabric; the tubular scaffold with sponge layers can be prepared by modification of silk fibroin and sulfated silk fibroin by polyethylene glycol diglycidyl ether; the compliance of the tubular scaffold is improved; the anti-permeability of the tubular scaffold can be improved by the silk fibroin and sulfated silk fibroin tubular scaffold with double sponge layers; meanwhile, the anti-coagulating property of the tubular scaffold can be improved by the sulfated silk fibroin; the composite tubular scaffold with good tensile property, compliance, anti-permeability and blood compatibility can be prepared by the combination; the pipe diameter is controllable; and the composite tubular scaffold can be applied to repair and reconstruction of a small-caliber blood vessel and building of hemodialysis vascular access. The preparation method is simple to operate and low in cost; and commercial production can be achieved.

Owner:BEIHANG UNIV

Method for preparing composite wear-resistant hammerhead

The invention discloses a method for preparing a high-ductility and high-abrasion composite hammerhead, which comprises the following steps: alloy dust core bars are bound into bundles and arranged in a hammerhead casting mould cavity, and the volume of the alloy dust core bars accounts for 20 to 60 percent of the total volume of the hammerhead; molten matrix metal is cast into the casting mould cavity, the alloy dust core bars are melted and dissolved under the heat effect of the matrix metal, a great number of alloy elements and the molten matrix metal generate metallurgical combination reaction so as to generate a highly dispersed alloy structure on the original position; and finally the alloy structure is cooled and solidified, and the bar-shaped hard phase is metallurgically and transitionally combined into a whole with the matrix metal, thereby preparing the composite hammerhead which takes the high-strength and high-ductility metal as the matrix and contains a certain number of metallurgically combined bar-shaped hard points. The composite hammerhead has high strength and high ductility of the matrix metal and high hardness and high wear resistance of the hard phase, can simultaneously bear high pressure and strong wear, and has the characteristics of long service life, low price and so on.

Owner:XI'AN UNIVERSITY OF ARCHITECTURE AND TECHNOLOGY

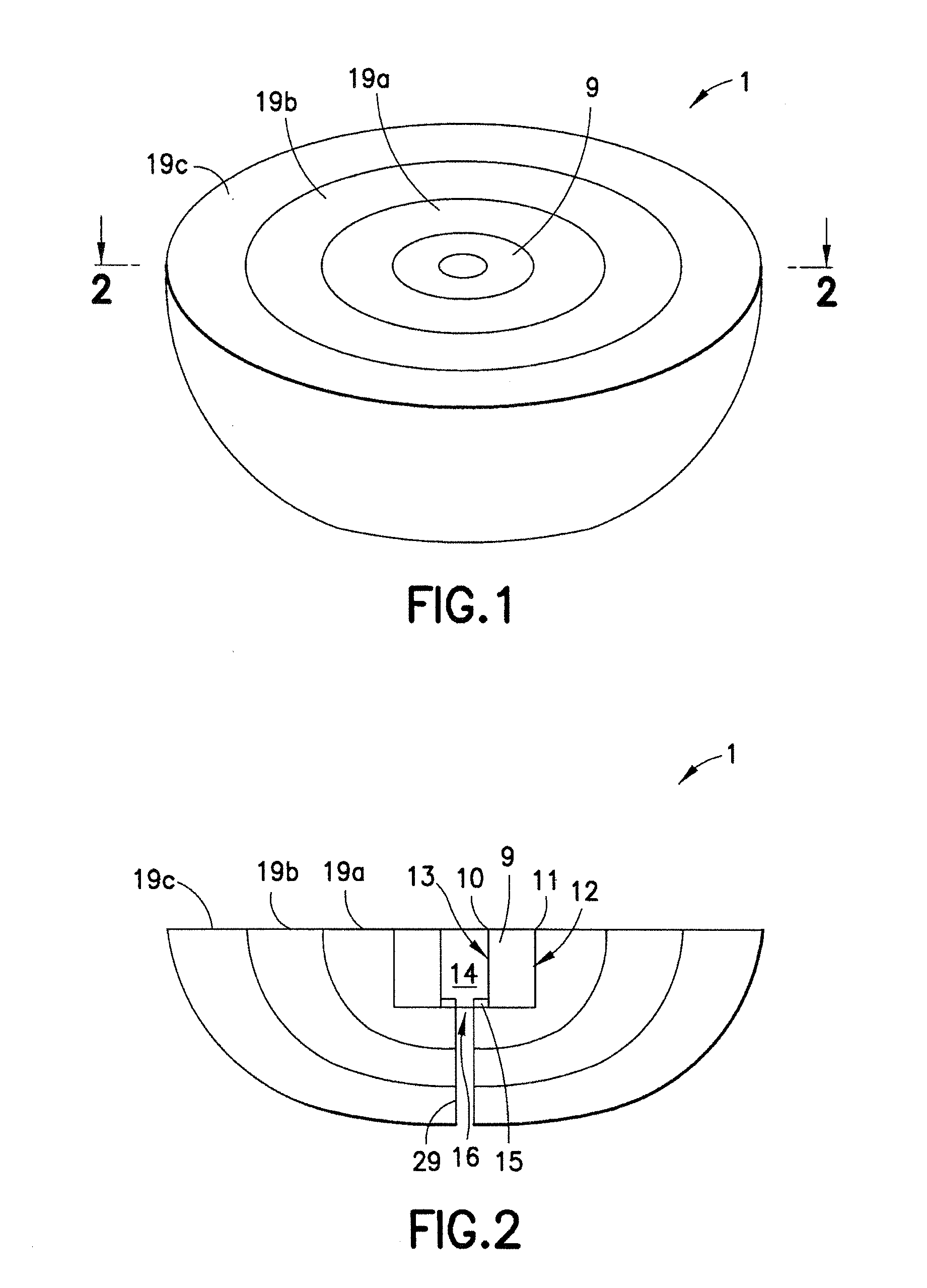

Dental healing abutment

InactiveUS20110200967A1Adjustable diameterDental implantsFastening prosthesisHealing abutmentAbutment

A dental healing abutment assembly having a tubular holder and a plurality of removable nestable shells. Each nestable shell has a proximal end and a distal end open to permit the nesting of the shell with the holder or other nestable shells. The proximal end of each nestable shell is defined by a base plate. The tubular holder and the nestable shells each have a pass through hole for accommodating a mounting member. The healing abutment assembly is attached to a dental implant impacted in a patient's jawbone by way of the mounting member.

Owner:PROCEREX DENTAL LAB

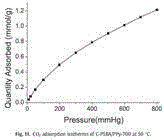

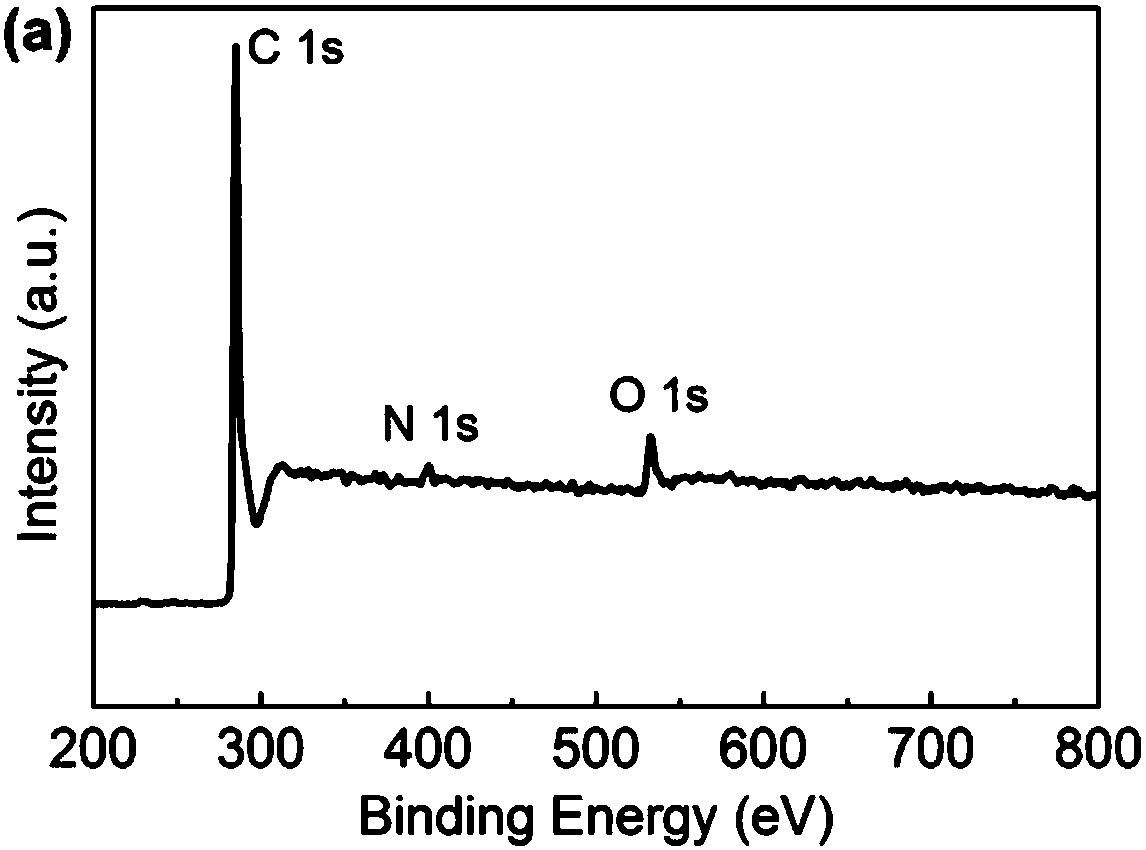

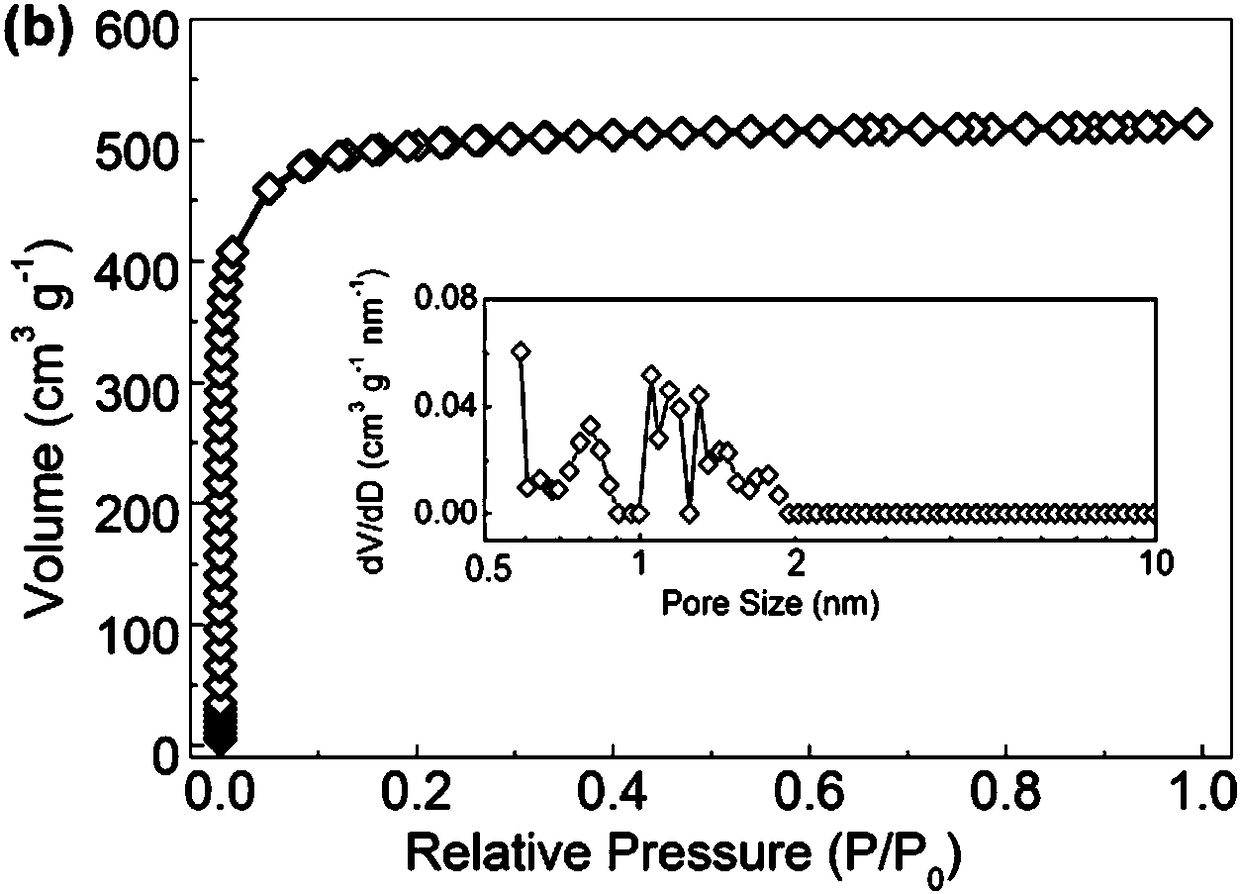

Nitrogen-doped micro-pore carbon spheres for super-capacitor electrode material and preparation method thereof

InactiveCN108569697APromote aggregationInhibition of agglomerationHybrid capacitor electrodesCarbon preparation/purificationDispersityCapacitance

The invention provides nitrogen-doped micro-pore carbon spheres for a super-capacitor electrode material and a preparation method thereof and relates to the field of polymers. The preparation method comprises the following steps: uniformly dispersing a template agent, phenol, formaldehyde and ammonia water in an alcohol solution to obtain a mixed base solution; putting the mixed base solution intoa sealed container and carrying out polymerization reaction to obtain phenolic resin spheres; after drying the phenolic resin spheres at 60 to 100 DEG C, carbonizing under an inert atmosphere to obtain a carbonized product; mixing the carbonized product and KOH; activating at 700 to 900 DEG C for 0.7 to 1.3h under the inert atmosphere, so as to obtain the nitrogen-doped micro-pore carbon spheres.The nitrogen-doped micro-pore carbon spheres prepared by the method have the advantages of high nitrogen doping amount, high sphericity degree, good dispersity and large specific surface area; the obtained nitrogen-doped micro-pore carbon spheres are used as the super-capacitor electrode material, have high specific capacitance and excellent circulation stability and have a wide application prospect.

Owner:夏辉

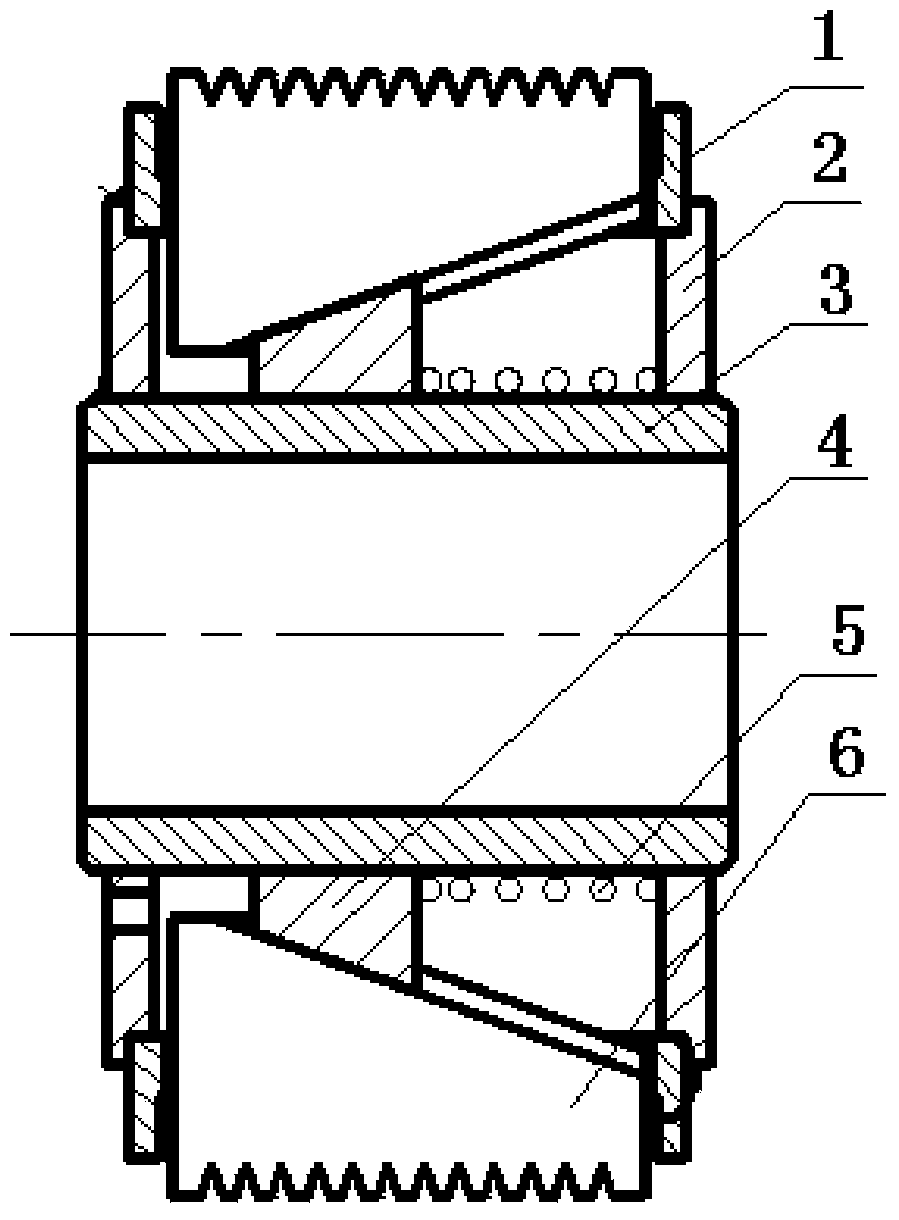

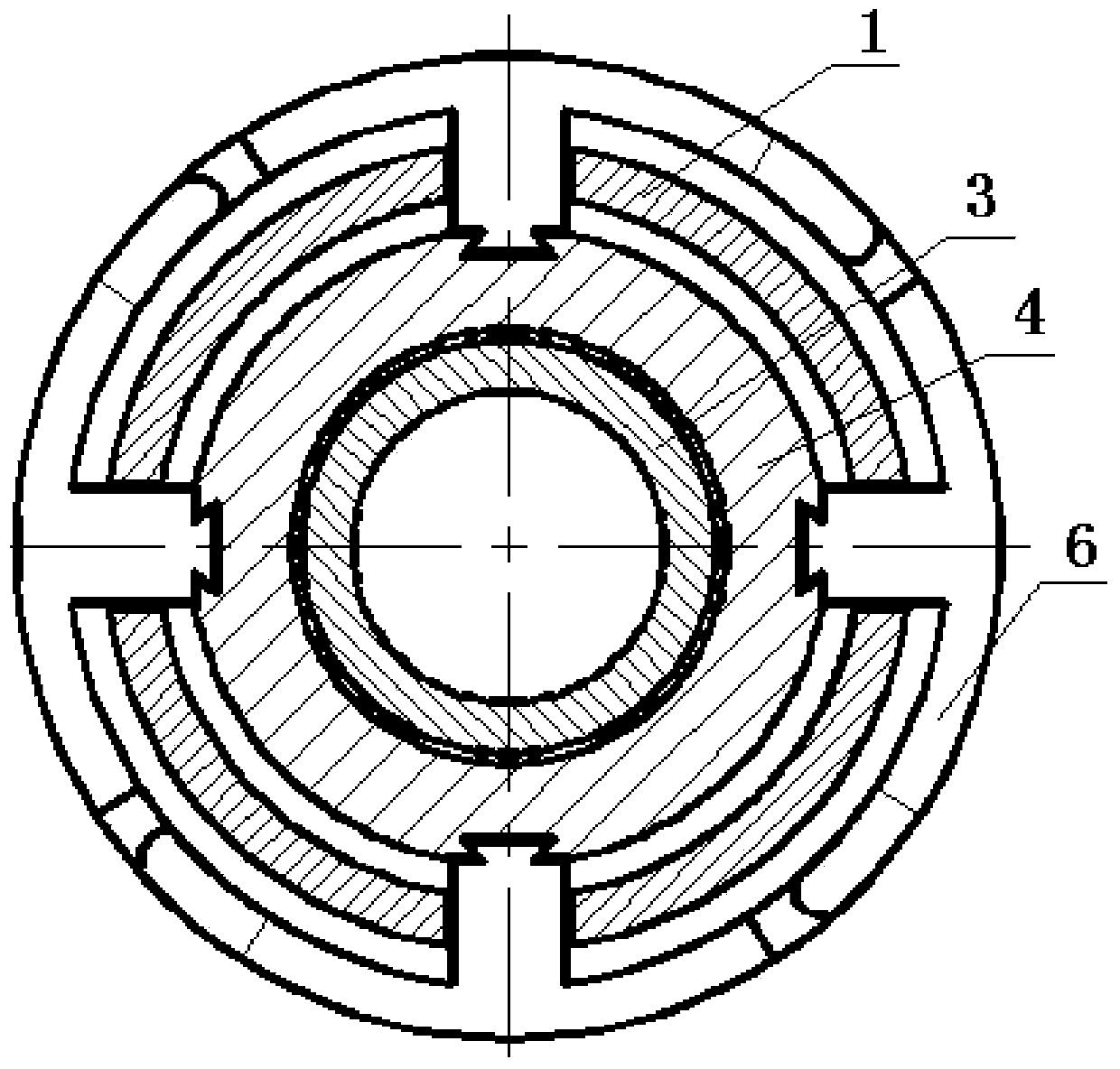

Diameter-variable belt pulley

ActiveCN103791062ASimple and reasonable structureGuaranteed normal operationPortable liftingGearing elementsEngineeringDiesel engine

The invention discloses a diameter-variable belt pulley. The diameter-variable belt pulley comprises a guiding ring, end caps, a mandrel, a slider, a plurality of arc rings and a compression spring. A plurality of square guiding holes extending axially are circumferentially formed in the peripheral surface of the guiding ring. Each end cap is shaped in a stepped round ring. The mandrel is shaped in a straight barrel. The peripheral surface of the slider is cone-shaped, the slider is provided with a plurality of inclined dovetail grooves corresponding to the square guiding hole of the guiding ring. The arc rings are spliced to form a circle. Each arc ring comprises an arc surface, an inclined dovetail tooth distributed on the inner circumferential face of the arc surface, an expanding diameter and a shrinking diameter. One end of the compression spring supports the larger end of the slider while the other end of the same supports the inner side of one of the end caps. The diameter-variable belt pulley has the advantage of simple and reasonable structure. Under an action of elastic force of the spring, the slider moves along the mandrel so as to push the arc rings to expand longitudinally, and a relative large approximate circle is obtained to enable the diameter of the belt pulley to be adjustable in size, belt pulley tensing of a belt pulley system can be achieved, and normal operation of the belt pulley system of a diesel engine can be guaranteed.

Owner:GUANGXI YUCHAI MASCH CO LTD

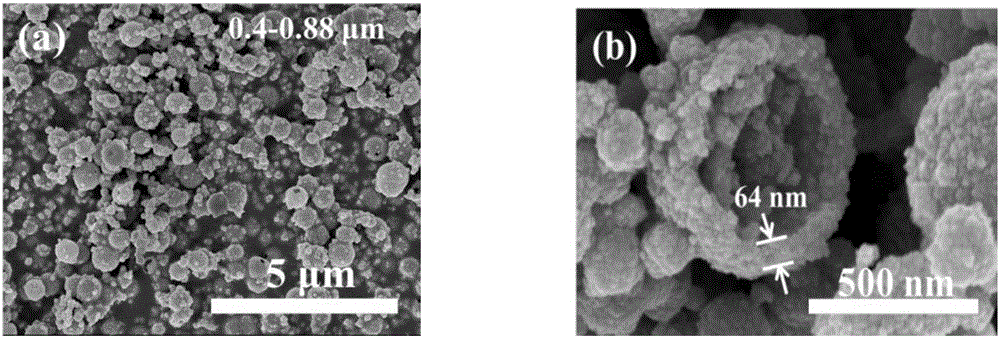

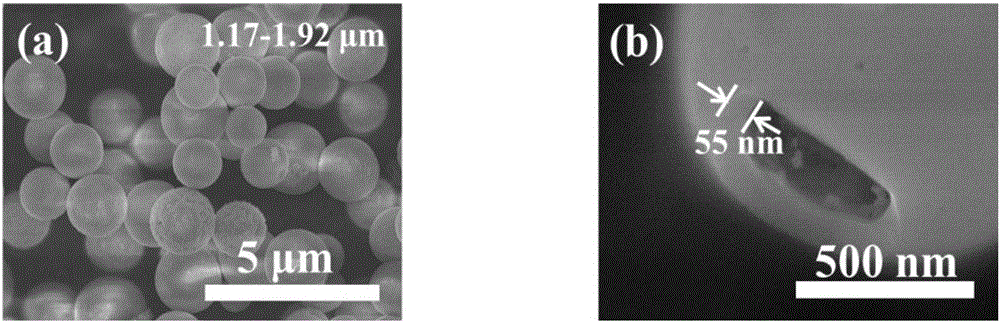

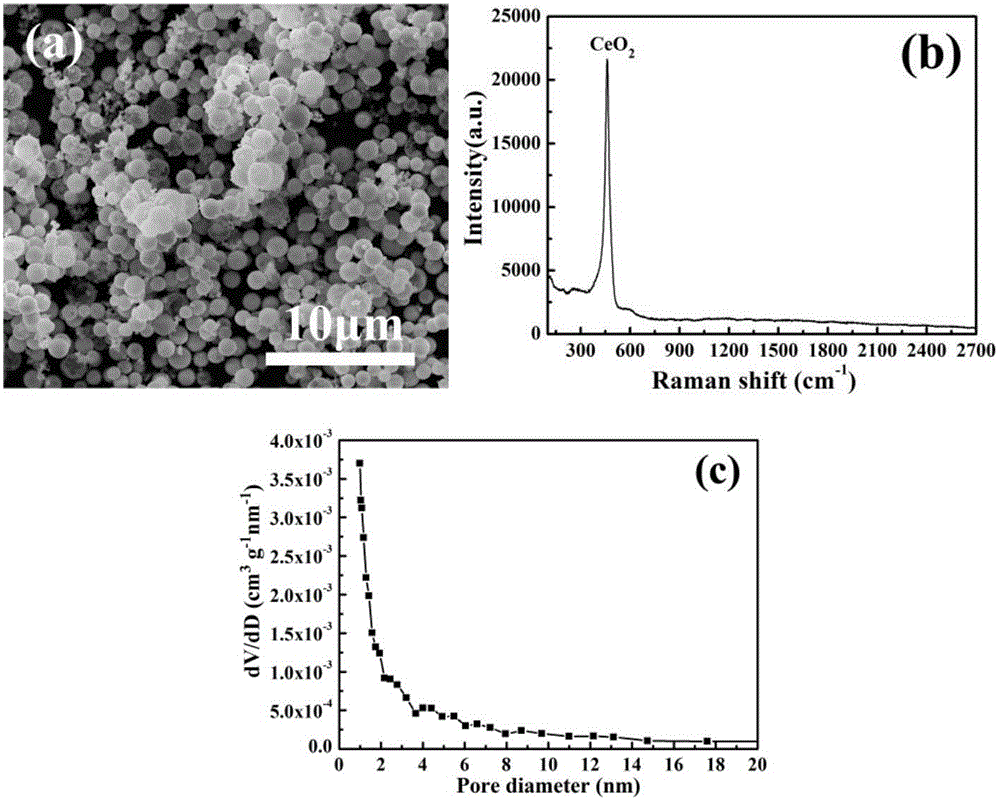

Mesoporous cerium dioxide hollow spheres or mesoporous cerium dioxide/carbon composite material hollow spheres and preparation method thereof

InactiveCN106622206ALow densityLarge specific surface areaRare earth metal oxides/hydroxidesMetal/metal-oxides/metal-hydroxide catalystsOrganic acidCarbon composites

The invention discloses mesoporous cerium dioxide hollow spheres or mesoporous cerium dioxide / carbon composite material hollow spheres and a preparation method thereof. The preparation method comprises the following steps: 1) dissolving one cerium salt and one organic acid into distilled water according to a certain ratio of amount of the substances, so as to prepare a mixed solution; 2) putting the mixed solution in a microwave hydrothermograph for reaction for a period of time at certain temperature; after finishing the reaction, performing suction filtration and washing; drying at 80 DEG C to obtain a hollow sphere type cerium dioxide precursor; 3) carrying out heat treatment on the dried precursor in an atmosphere at certain temperature and keeping heat for a period of time to obtain mesoporous cerium dioxide hollow sphere or cerium dioxide / carbon hollow sphere powder. The mesoporous cerium dioxide ( / carbon) hollow sphere powder prepared by the method has the characteristics of controllable phase composition, controllable sphere diameter and controllable wall thickness. Meanwhile, the method has the advantages of low cost, simple preparation process, high efficiency and easiness in control.

Owner:XI AN JIAOTONG UNIV

Preparation method of silk fibroin and sulfated silk fibroin composite tubular scaffold

InactiveCN103861158AGood cell compatibilityGood blood compatibilitySurgeryEngineeringHemodialysis access

The invention provides a preparation method of a silk fibroin and sulfated silk fibroin composite tubular scaffold. The composite tubular scaffold is characterized in that the composite tubular scaffold is composed of an elastic bonding layer, a fabric reinforcing layer and a compact coating layer, and the fabric reinforcing layer is embedded in the elastic bonding layer, and the outer surface of the compact coating layer is covered with the elastic bonding layer, wherein the compact coating layer and the fabric enhancing layer are made of silk fibroin, and the elastic bonding layer is made a silk fibroin and sulfated silk fibroin mixture. The elastic bonding layer can improve the compliance and the anticoagulation property of the tubular scaffold, the fabric reinforcing layer can improve the mechanical properties of the scaffold, and the compact coating layer can improve the impermeability of the scaffold. The tubular scaffold prepared in the invention has excellent mechanical properties, has good impermeability, cell compatibility and blood compatibility, has a controllable diameter, and can be used for restoring and reconstructing small caliber vessels and constructing a hemodialysis access. The preparation method has the advantages of simple operation, low cost, and commercial production realization.

Owner:BEIHANG UNIV

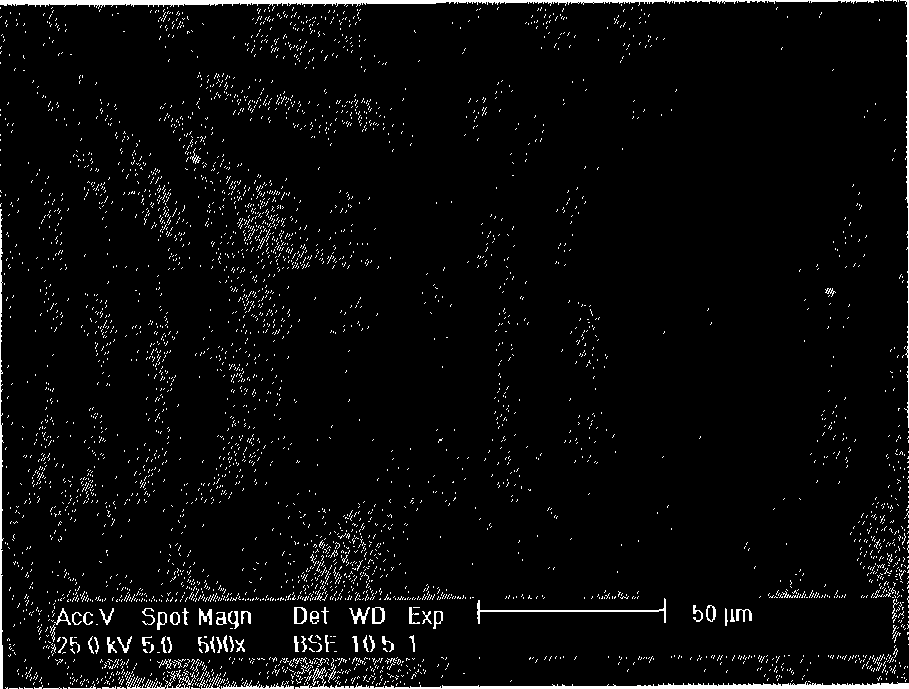

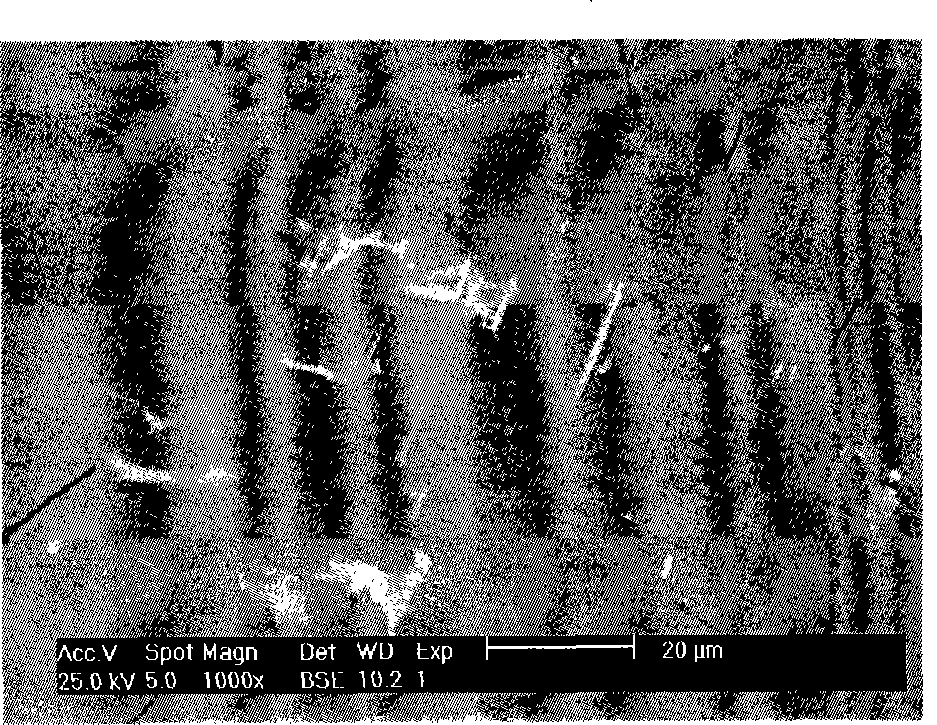

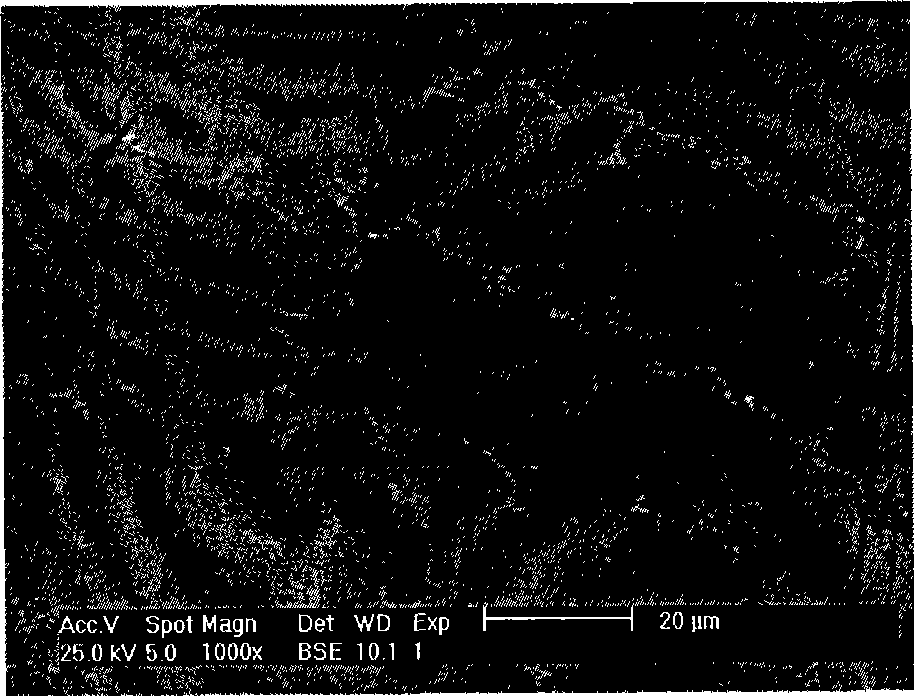

Production method for Sm(Co,M)7 type alloy thin strip magnet

InactiveCN101430958AOptimized grain size microstructureImprove intrinsic coercive forceInorganic material magnetismInductances/transformers/magnets manufactureMagnetic transitionsMicro structure

The invention provides a preparation method used for Sm(Co, M)7 typed alloy ligature magnet, belonging to the magnet technical field of hard magnetic material containing rare earth metal and magnetic transition metal. The preparation method comprises the steps as follows: the molecular formula of the fuse is SmCo<7-x>Mx(CNT)y; wherein, M is Hf, Ga or Si; CNT is carbon nano-tube; according to the atom percentage, the symbols which limits the composition meets the following formulas: x is not less 0.05 and not more than 1.6; y is not less than 0.01 and not more than 0.1; the fuse is rapidly quenched on a cooling molybdenum roller wheel or a copper roller wheel which rotates at a circumferential velocity of 10-60m / s, thus preparing the Sm(Co, M)7 typed alloy ligature magnet which has the mass magnetization intensity of 40.0-105.0Am<2> / kg, has the intrinsic coercivity of 480.0-1840.0kA / m after being magnetized in an external magnetic field of 4.8MA / m, has the intrinsic coercivity of 480.0-2,000.0kA / m after being magnetized in an external magnetic field of 7.2MA / m, has the thickness of 20-120 microns and has the average grain size of 10-200nm. The carbon nano-tube which is used as an ideal pinning phase stabilizes the phase structure of the Sm(Co, M)7 typed alloy ligature magnet when in a quick quenching state and a heat disposal state, optimizes the micro-structure of the grain size and leads the alloy to be practical permanent magnet with high coercivity.

Owner:HEBEI UNIV OF TECH

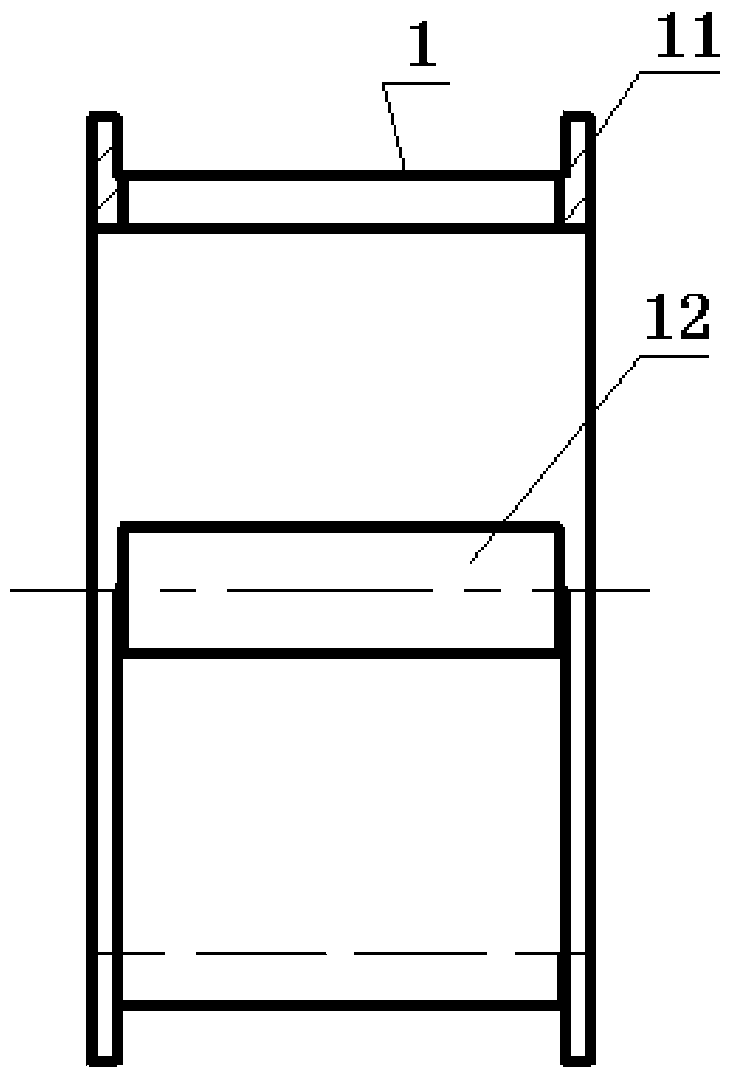

Coiling device for cable and wire

The invention discloses a coiling device for a cable and a wire. The device comprises a top plate and side plates, wherein a first motor is arranged in the middle of the top part of the top plate, andthe bottom part of the first motor is in transmission connection with a rotating plate at the bottom part of the top plate through a rotating shaft; a second motor is arranged in the rotating plate,and chutes are formed in two sides of the second motor in the rotating plate; and the bottom part of the second motor is in transmission connection with first tapered teeth through the rotating shaft.According to the device, the second motor is capable of driving the first tapered teeth and second tapered teeth to rotate so as to adjust the space between two coiling rods; when the cable coils thetwo coiling rods, the coiled cable can be simply removed by decreasing the space between the two coiling rods; with the adoption of the abovementioned mode, the cable can be coiled and removed at thesame time, so that the convenience of storing in later period is ensured.

Owner:郑州仟嘉安环保科技有限公司

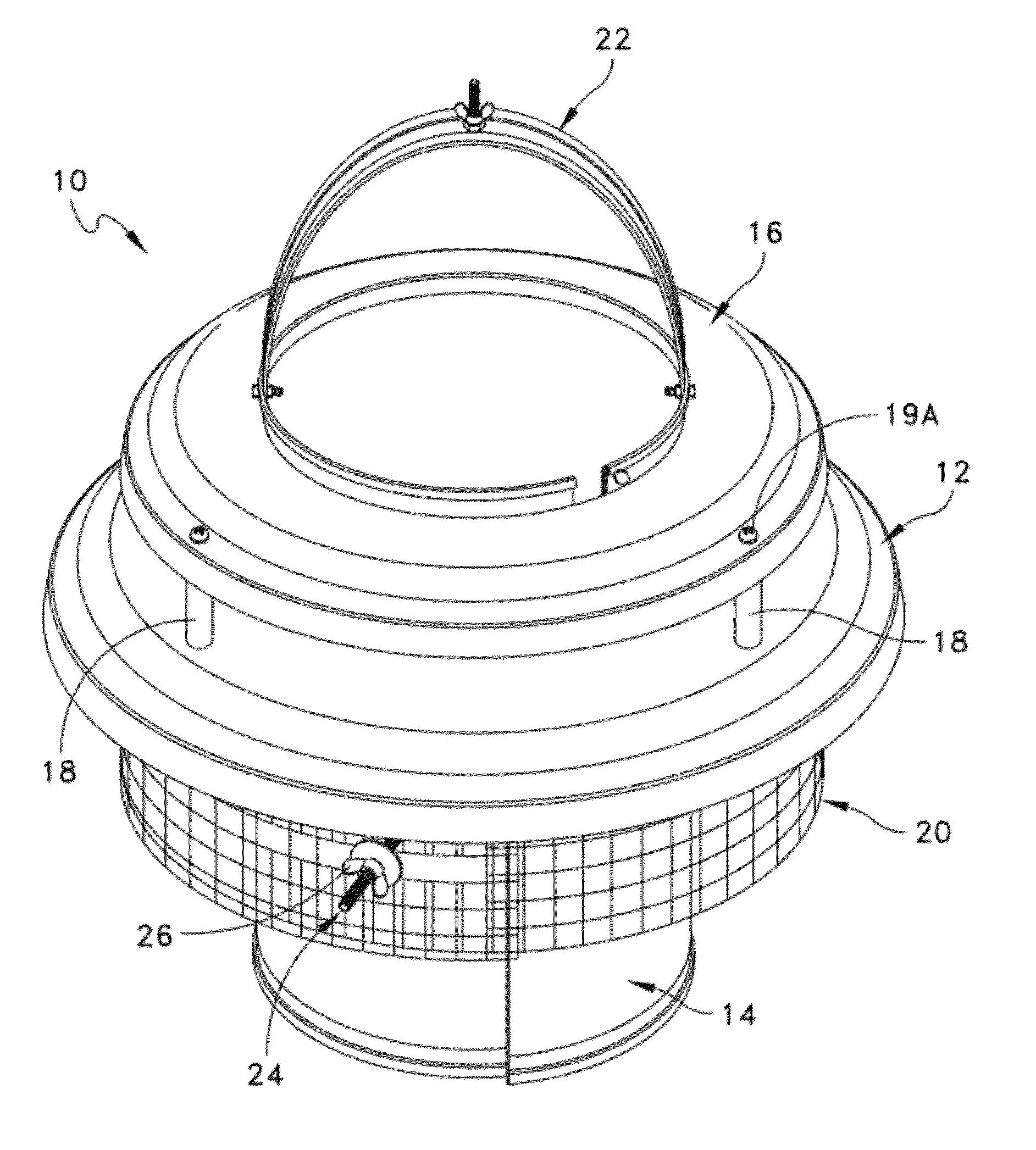

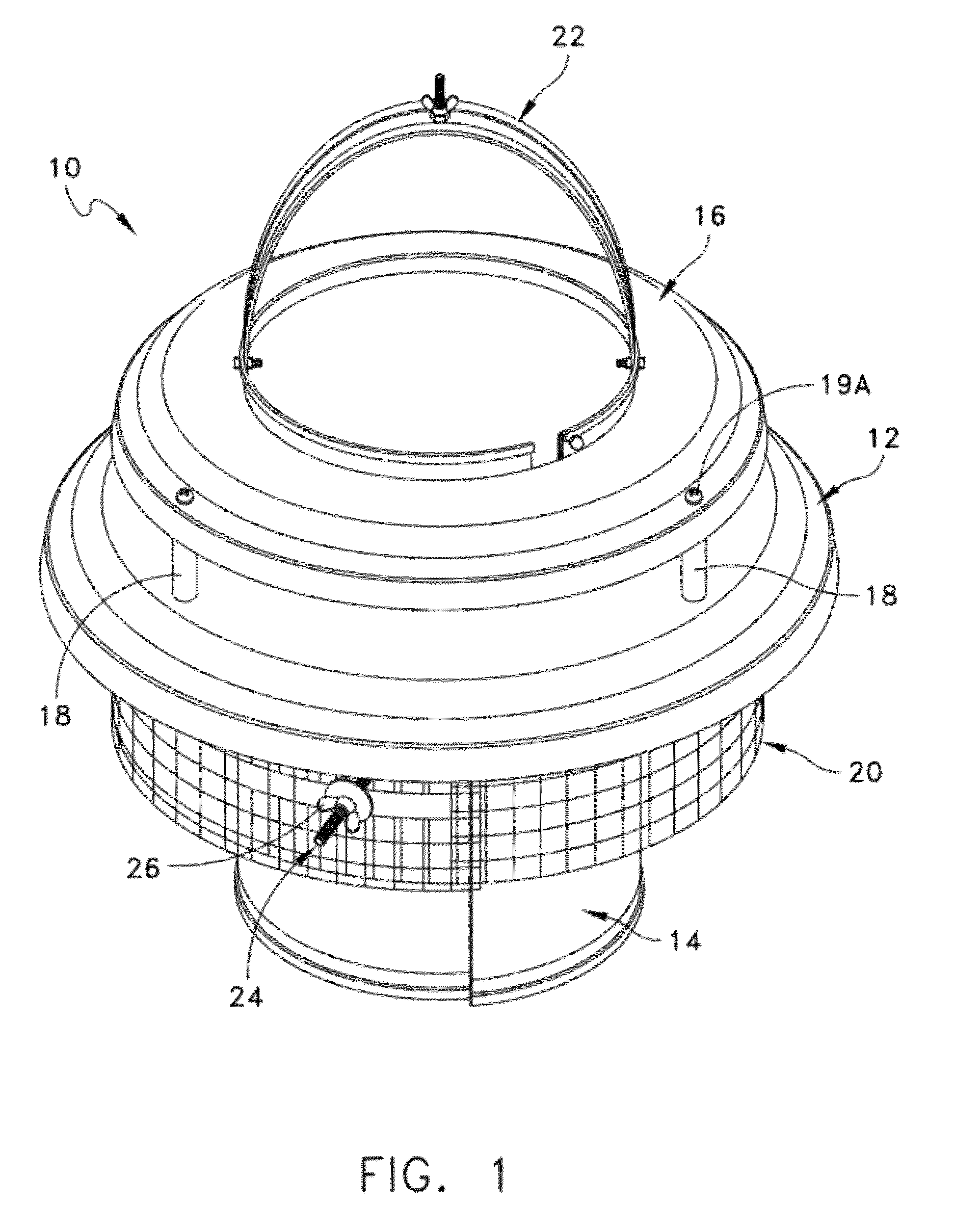

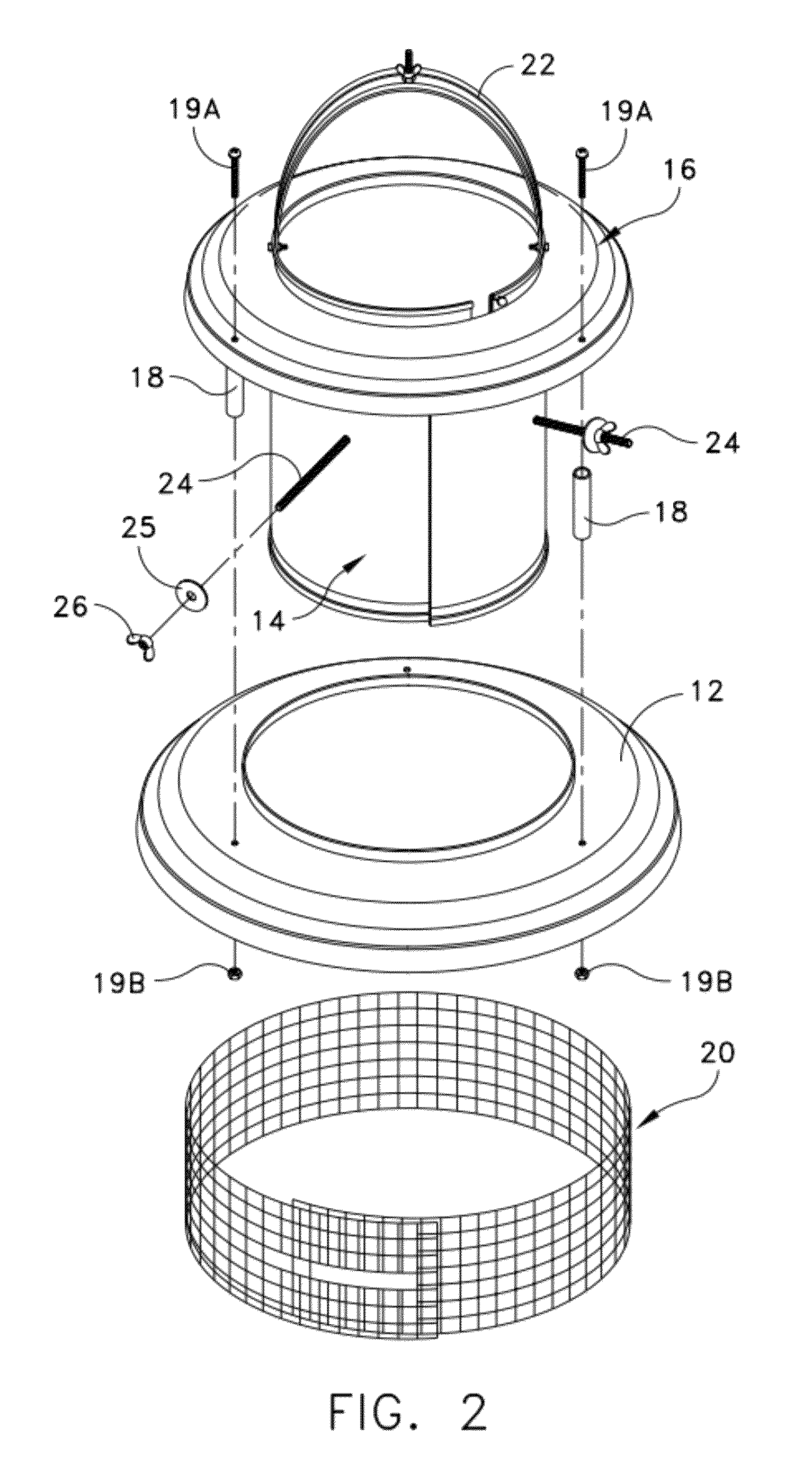

Chimney cap

InactiveUS8246430B1Easy to receiveAdjustable diameterChimneysDraught inductionEngineeringMechanical engineering

A chimney cap capable of being secured to a chimney and including a base; an annular collar member for insertion into a chimney, and having an outside circumference smaller than an opening of the chimney so as to be readily received therein; an annular shaped mesh member that is supported about the collar; a top supported over the base; and a plurality of support rods attached to the collar and for the purpose of supporting the annular shaped mesh member. The annular shaped mesh member has discharge openings for air flow and at least one elongated slot through which one of the support rods extends for securing the annular shaped mesh member. The elongated slot in combination with the one support rod enables adjustment of the diameter of the annular shaped mesh member.

Owner:IMPROVED CONSUMER PRODS

Preparation method of electrode for CO2 electrochemical reduction and electrode and application thereof

ActiveCN108118363AAdjustable diameterAdjustable lengthNanotechnologyElectrodesBond energyChemical treatment

The invention relates to a preparation method of an electrode for CO2 electrochemical reduction and the electrode and application thereof. The preparation method comprises the steps that firstly, impurity removal treatment is conducted to a substrate material; secondly, the substrate material is soaked in oxidizing chemical treatment liquid to obtain an electrode precursor with the surface being of a nanometer wire structure; and thirdly, the electrode precursor is subjected to electrochemical reduction treatment to obtain the electrode with a nanometer wire structure layer being attached to the surface of the electrode. According to the preparation method of the electrode for CO2 electrochemical reduction and the electrode and application thereof, compared with an existing bulk phase metal electrode preparation technology, the electrode can provide more active sites for an electrochemical reduction reaction of CO2, and the yield of a target product is improved; and the surface roughness of the nanometer wire structure layer attached to the surface of the electrode is high and changes the bonding energy between the intermediate product CO* and the electrode surface of key steps ofan ERC reaction, the subsequent reaction course of CO* is adjusted and changed, and selectivity of the target product is changed accordingly.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

Split rotary rat-proof sphere

The invention discloses a split rotary rat-proof sphere which comprises a fixed shaft sleeve, a rotary shaft sleeve, bearings and a sphere shell. The fixed shaft sleeve and the rotary shaft sleeve are in the shapes of hollow ring columns, a pair of circumferential clamp plate grooves which are symmetric with each other around the axis of the fixed shaft sleeve is formed in two ends of the fixed shaft sleeve, and clamp plates are connected into the clamp plate grooves by adjusting bolts; the fixed shaft sleeve and the rotary shaft sleeve are provided with two symmetric half fixed shaft sleeves and two symmetric half rotary shaft sleeves, and the axial end surfaces of the two half fixed shaft sleeves and the two half rotary shaft sleeves are butted to one another, are connected with one another by mortises and tenons and are fixed by the aid of bolts; the rotary shaft sleeve is connected to the outer surface of the fixed shaft sleeve by the bearings arranged in bearing blocks at two ends of the rotary shaft sleeve; the sphere shell is a spherical shell, circular through holes are symmetrically formed in two ends of the sphere shell along the axis of the sphere shell, the sphere shell comprises two symmetrical half sphere shells and sleeves the outer surface of the rotary shaft sleeve, the through holes sleeve the outer surface of the fixed shaft sleeve in a movable fit manner, and the two ends of the sphere shell are connected onto two end surfaces of the bearing blocks by mounting screws. The split rotary rat-proof sphere has the advantage that the purpose of preventing rats from passing through places between wharves and ship hulls can be achieved by the aid of the split rotary rat-proof sphere.

Owner:中国人民解放军62040部队

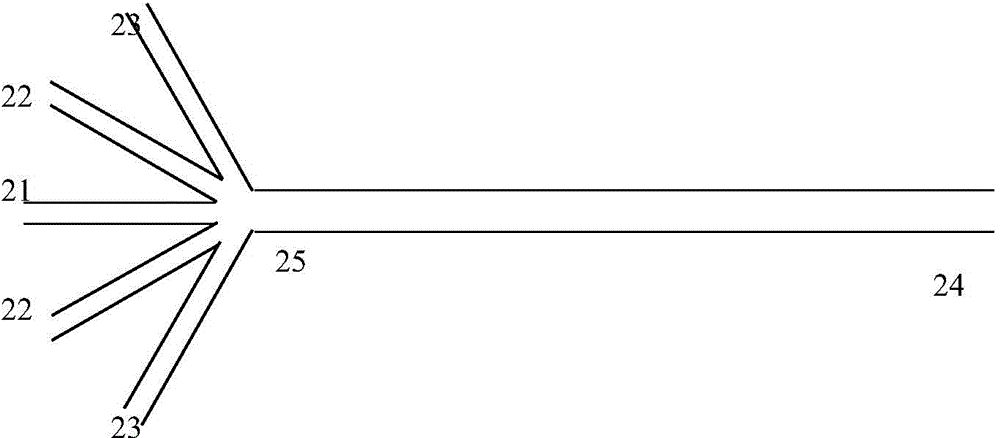

Method for manufacturing fusion pellet based on microfluid

InactiveCN104091620AAchieved diameterControllable diameterNuclear energy generationThermonuclear fusion reactorEmulsionChannel network

The invention relates to a method for manufacturing a fusion pellet based on a microfluid channel, in particular to a method for manufacturing an inertial confinement nuclear fusion pellet based on a microfluid channel technology. According to the method, dual microemulsion is formed by pellet solutions or a front fusion body in a flowing phase by adopting a microfluid channel network system, the inner diameter and the outer diameter of the dual microemulsion are adjusted in real time through an image collecting and analysis system and a flow control system, and finally a preset size is achieved. Then, hollow micro balls meeting the ICF target requirements are formed through curing and drying based on a liquid drop formwork. According to the manufacturing method, the hollow micro balls which are uniform in size and controllable in ball wall can be manufactured, and the ICF requirements are met. The manufacturing method particularly comprises the first step of manufacturing the microfluid channel, the second step of manufacturing the microemulsion, the third step of obtaining the size of the microemulsion, the fourth step of controlling the inner diameter and the outer diameter of the dual emulsion and the fifth step of manufacturing the fusion pellet.

Owner:SOUTHEAST UNIV

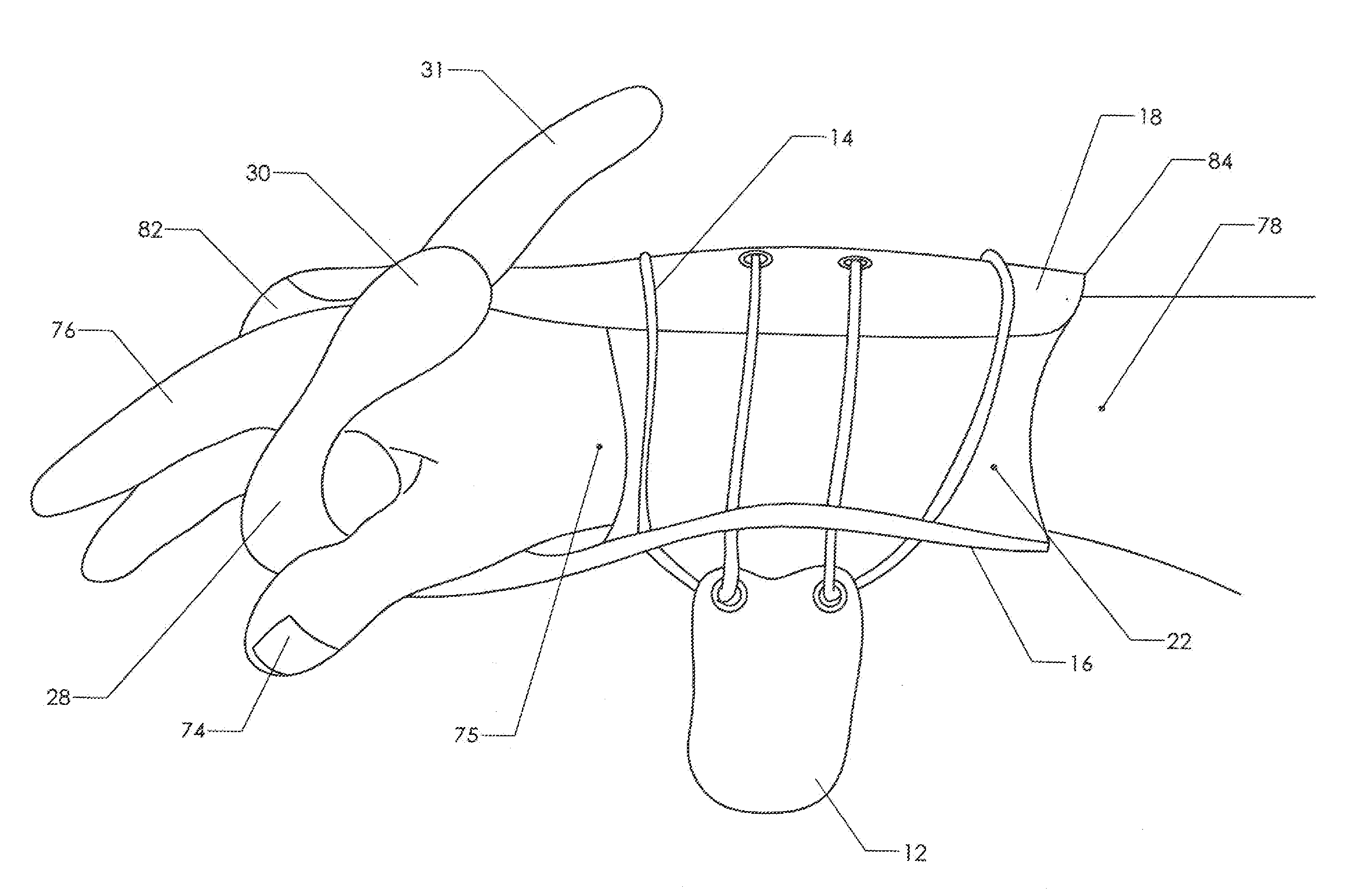

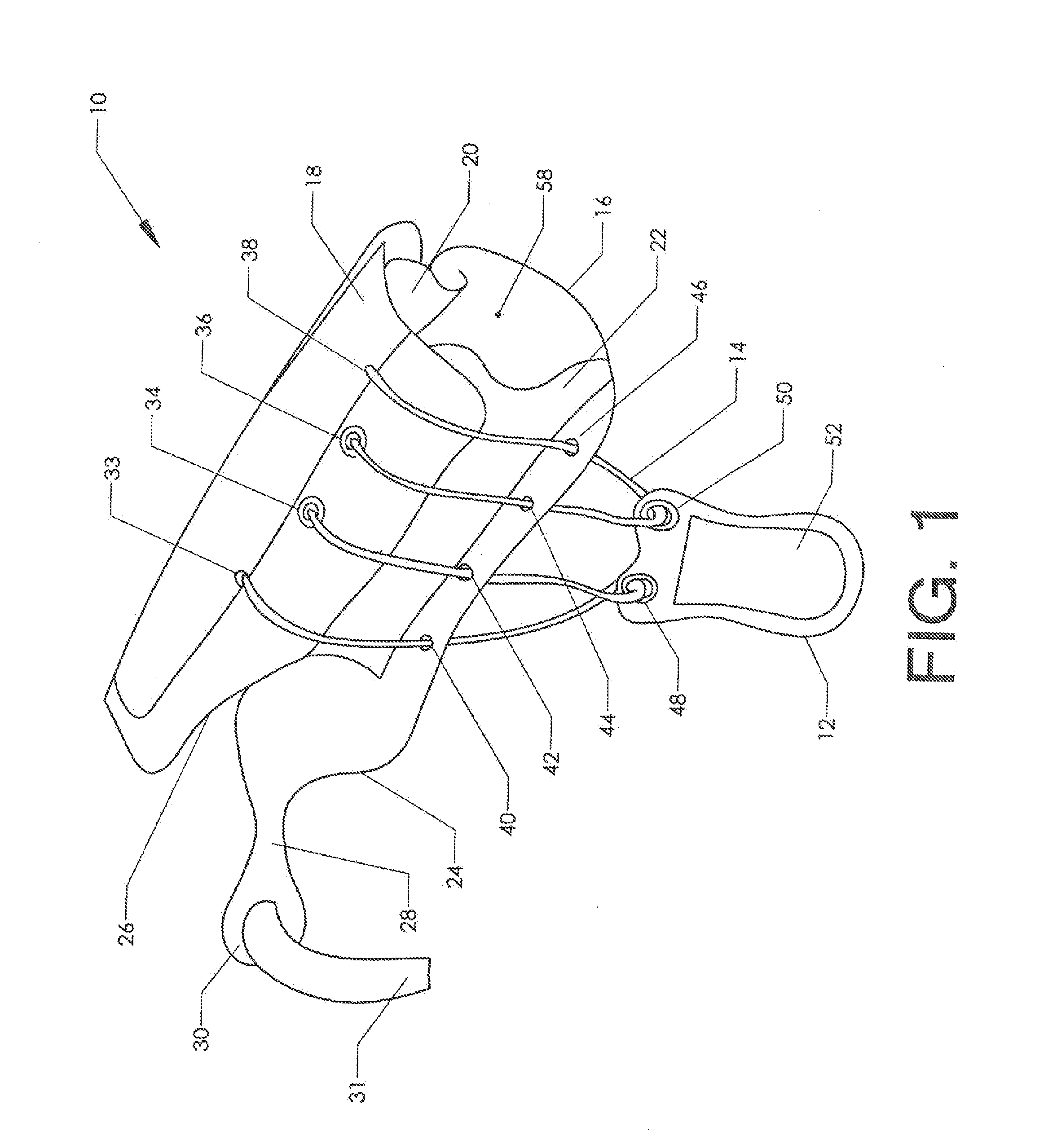

Wrist Orthotic Including Adjustable Ulna Gap

An adjustable wrist orthotic suitable for the treatment of wrist fractures and similar injuries. The orthotic preferably includes a top panel joined to a bottom panel. The top and bottom panels are preferably joined by a radius connector which spans a “radius gap” between the top and bottom panel. An “ulna gap” may optionally be provided between the top and bottom panels as well. If an ulna gap is present, then an ulna connector is preferably provided to span this gap. A radius lace assembly is provided for adjusting the closure of the radius gap. The radius lace assembly is secured by placing a radius tab attached to a radius lace in a desired position on the exterior of the orthotic. Varying the placement position of the radius tab varies the taper of the radius gap so that the orthotic can accommodate wide variations in forearm geometry.

Owner:KILBEY BRYAN E

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com