Preparation method of silk fibroin and sulfated silk fibroin composite tubular scaffold

A technology of silk fibroin and sulfation, applied in medical science, surgery, etc., can solve the problems of limited improvement of anticoagulant performance, unsatisfactory anticoagulant effect, and reduction of prothrombin activity, so as to avoid sticking The effect of the use of mixture and cross-linking agent, good cell compatibility and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

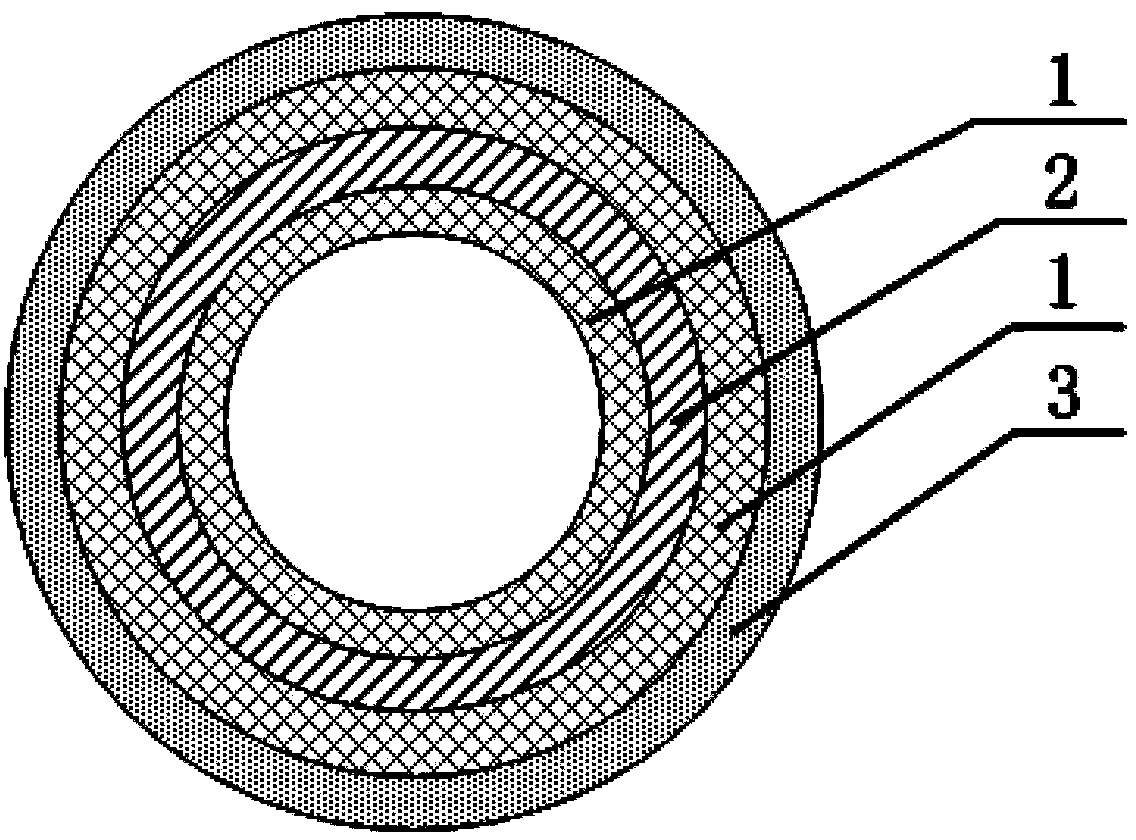

[0031] Such as figure 1 Shown is a schematic cross-sectional view of the composite tubular stent. The composite tubular stent includes an elastic bonding layer 1 , a fabric reinforcing layer 2 and a coating dense layer 3 composed of three layers. The fabric reinforcing layer 2 is embedded in the elastic bonding layer 1 , and the coated dense layer 3 is covered on the outer surface of the elastic bonding layer 2 . Wherein, the coated dense layer 3 and the fabric reinforcement layer 2 are silk fibroin, and the elastic adhesive layer 2 is a mixture of silk fibroin and sulfated silk fibroin. The inner diameter of the silk fibroin and sulfated silk fibroin composite tubular scaffold is 5mm. The wall thickness is 1 mm.

[0032] The preparation method of the above-mentioned silk fibroin and sulfated silk fibroin composite tubular scaffold is as follows:

[0033] a) Preparation of braid:

[0034] Use a braiding machine to weave silkworm silk into a tubular braid with an inner dia...

Embodiment 2

[0045] Such as figure 1 Shown is a schematic cross-sectional view of the composite tubular stent. The composite tubular stent includes an elastic bonding layer 1 , a fabric reinforcing layer 2 and a coating dense layer 3 composed of three layers. The fabric reinforcing layer 2 is embedded in the elastic bonding layer 1 , and the coated dense layer 3 is covered on the outer surface of the elastic bonding layer 2 . Wherein, the coated dense layer 3 and the fabric reinforcement layer 2 are silk fibroin, and the elastic adhesive layer 2 is a mixture of silk fibroin and sulfated silk fibroin. The inner diameter of the silk fibroin and sulfated silk fibroin composite tubular scaffold is 4 mm. The wall thickness is 0.9mm.

[0046] The preparation method of the above-mentioned silk fibroin and sulfated silk fibroin composite tubular scaffold is as follows:

[0047] a) Preparation of braid:

[0048] Use a braiding machine to weave silkworm silk into a tubular braid with an inner d...

Embodiment 3

[0058] Such as figure 1 Shown is a schematic cross-sectional view of the composite tubular stent. The composite tubular stent includes an elastic bonding layer 1 , a fabric reinforcing layer 2 and a coating dense layer 3 composed of three layers. The fabric reinforcing layer 2 is embedded in the elastic bonding layer 1 , and the coated dense layer 3 is covered on the outer surface of the elastic bonding layer 2 . Wherein, the coated dense layer 3 and the fabric reinforcement layer 2 are silk fibroin, and the elastic adhesive layer 2 is a mixture of silk fibroin and sulfated silk fibroin. The inner diameter of the silk fibroin and sulfated silk fibroin composite tubular scaffold is 3 mm. The wall thickness is 0.8mm.

[0059] The preparation method of the above-mentioned silk fibroin and sulfated silk fibroin composite tubular scaffold is as follows:

[0060] a) Preparation of braid:

[0061] Use a braiding machine to weave silkworm silk into a tubular braid with an inner d...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| The inside diameter of | aaaaa | aaaaa |

| Wall thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com