Composite nanometer fiber film and preparation method thereof

A composite nanofiber and gelatin technology, which is applied in the direction of animal fiber, fiber treatment, fiber type, etc., can solve the problems of non-complementary or simultaneous existence of functions, unsafe costs, and functional limitations, etc., to achieve broad-spectrum antibacterial activity compatibility, The effect of good liquid absorption rate and good cell compatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] In a 100ml three-necked flask with a vacuum interface, a thermometer and mechanical stirring, 40g of polycaprolactone glycol (molecular weight 4000g / mol) and 3.6g of 1,4-butanediol were added. The oil bath is heated to 100 degrees, and vacuum dehydration is carried out at 100 Pa for 1.5 hours. After that, the vacuum is released and the temperature is reduced to 80 degrees Celsius. 12.5 g of MDI is added, stirred quickly for 20 seconds, and poured into a PTFE tray for curing in a 100 degrees oven for 24 Shape memory polyurethane can be obtained within hours.

Embodiment 2

[0035] Add 40g PBA (molecular weight 4000g / mol) into a 100ml three-necked flask with vacuum interface, thermometer and mechanical stirring. The oil bath is heated to 100 degrees, and vacuum dehydration is carried out at a vacuum of 100 Pa for 1.5 hours. After that, the vacuum is released and the temperature is lowered to 80 degrees Celsius. 5 g of MDI is added, and the reaction temperature is controlled to 80 degrees Celsius for 2 hours under the protection of nitrogen. Then, 65 g of DMAc was added to dissolve, and 30 g of DMAc solution containing 2% EDA was slowly added dropwise under stirring, and the reaction was continued for 2 hours to obtain a shape memory polyurethane solution. The shape memory polyurethane can be obtained by precipitating and drying the polyurethane solution in water.

[0036] It is understandable that the shape memory polyurethane can also adopt other temperature-sensitive shape memory polyurethanes whose crystallization-melting temperature is the transi...

Embodiment 3

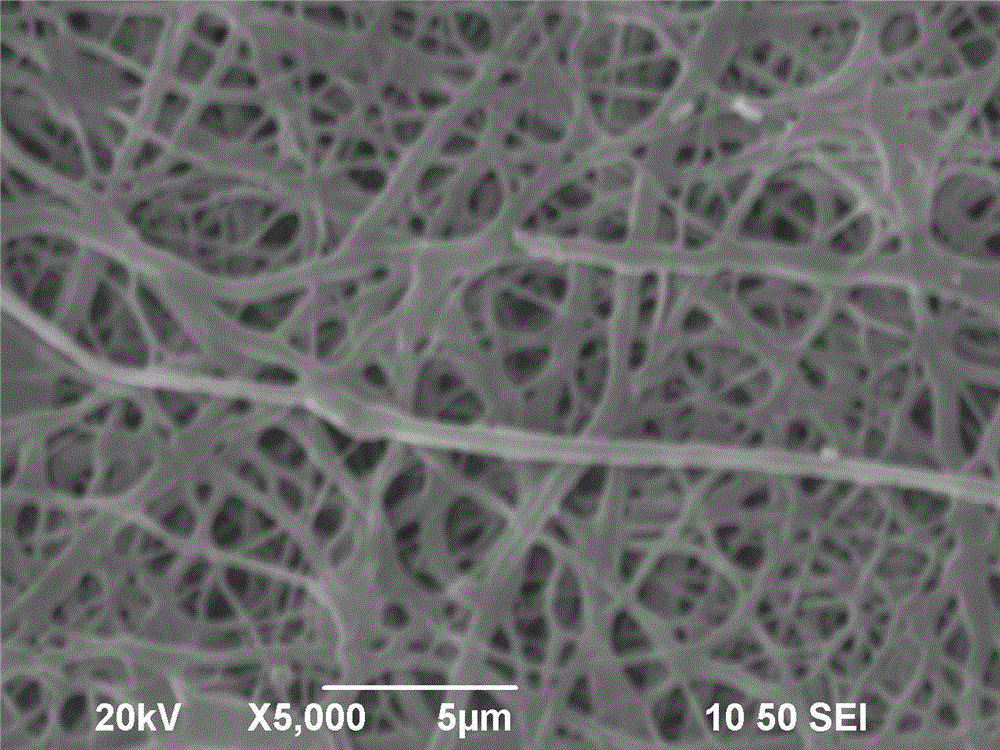

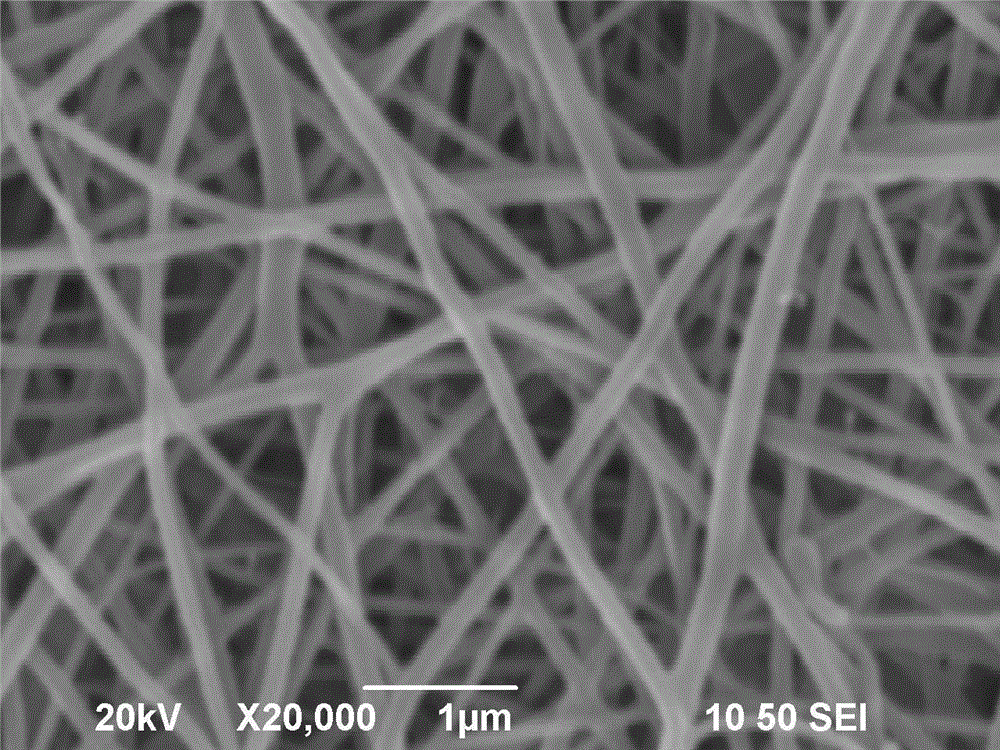

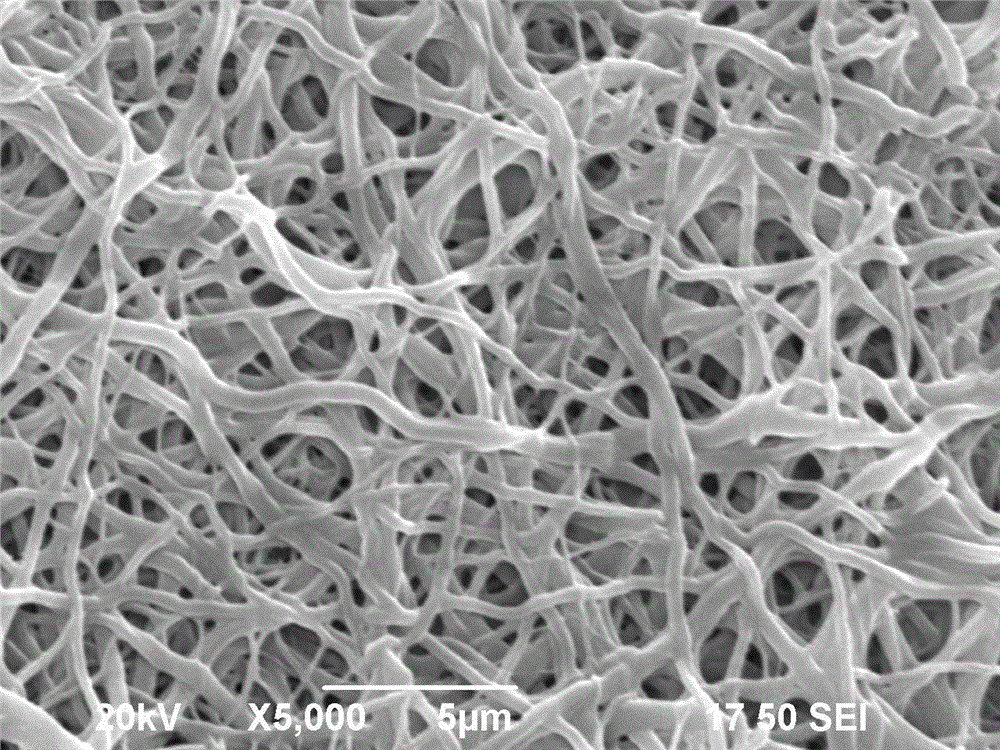

[0039] Weigh 0.15g of chitosan with a molecular weight of 200,000, a degree of deacetylation of 85%, and a viscosity of 500mpa.s, 0.15g of gelatin with a molecular weight of 30,000 and a Bloom value of 200, and 0.70g of the shape memory prepared in Example 1. Polyurethane is dissolved in a mixed acidic solvent with a weight ratio of formic acid: glacial acetic acid = 1:1 to make its concentration 10%. Afterwards, the composite nanofiber membrane was prepared by the electrospinning method. The electrospinning parameters were: the voltage was 15kv, the distance between the nozzle and the collecting plate was 10cm, the rotation of the collecting plate was 10rpm, the temperature was 22±2℃, and the humidity was 35±3%. .

[0040] Finally, post-treatment is performed. The post-treatment step is: soak the composite nanofiber membrane in a concentration of 1*10 -5 mol / L silver sulfate solution for 3h; the environment is naturally dry.

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com