Photocuring enzyme cross-linking bioink, preparation method of bioink and 3D printing method

A bio-ink and 3D printing technology, applied in the field of bio-3D printing, can solve the problem of single cross-linking method, 3D bionic structure is difficult to take into account cell compatibility, mechanical strength and degradability, single component of bio-3D printing ink, etc. problem, to achieve the effect of high cytocompatibility, high degradability and high cell adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] A preparation method of photocurable enzyme cross-linked bio-ink, comprising the steps of:

[0037] S1, preparing fibrin stock solution and methacrylic anhydride gelatin solution in advance;

[0038] The preparation process of fibrin stock solution is to mix sterile fibrinogen powder with 1×~10× cell culture medium solution, shake and dissolve at 0℃~40℃ to obtain fibrin stock solution, and the obtained fibrin stock solution is in- Store at 80℃~37℃ for later use;

[0039] The preparation of methacrylic anhydride gelatin liquid is to blend methacrylic anhydride gelatin and photoinitiator powder, the weight ratio of photoinitiator to methacrylic anhydride gelatin is 0.01~50:1, and then add 1×~10 X’s cell culture medium solution was stirred at 0°C to 80°C and protected from light for 0.5 to 6 hours to obtain a methacrylic anhydride gelatin solution, and the obtained methacrylic anhydride gelatin solution was kept at -80°C to 37°C in the dark. Store at ℃ for later use;

...

Embodiment 2

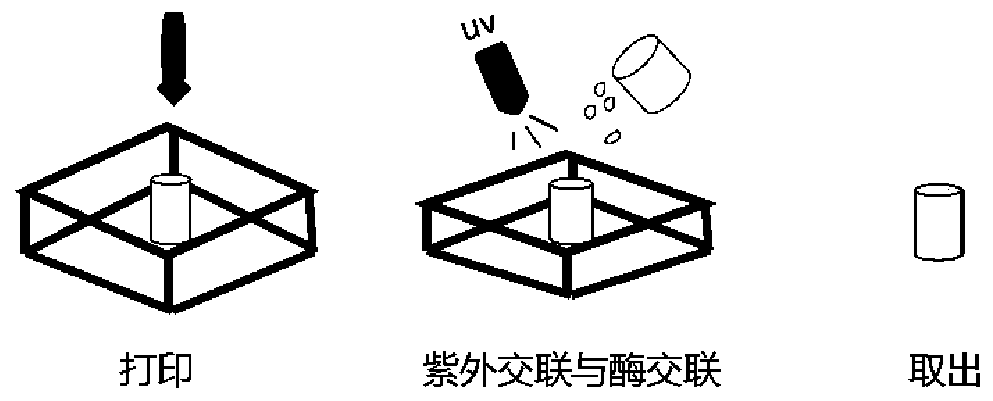

[0046] A method for 3D printing of a biomimetic structure using photocurable enzyme cross-linked bio-ink, comprising the steps of:

[0047] (1) Load the photocurable enzyme cross-linked bio-ink into the printing silo of the 3D printer, set the temperature of the silo to 0°C to 45°C, the moving speed of the nozzle to 0-100mm / s, and the extrusion pressure to 0-100mm / s 25MPa, printing platform temperature is 0°C to 45°C;

[0048] (2) Print according to the required digital model, irradiate with ultraviolet light while printing, and perform photocrosslinking on the printed structure; the wavelength of ultraviolet light used is 500-315nm, and the light intensity is 5-500 mw / cm 2 , the irradiation time is 1-90s; (3) Add cross-linking solution on the surface of the printed structure, so that the cross-linked solution completely immerses the printed structure, and put it into the incubator for 10 minutes to 2 hours;

[0049] (4) Transfer the printed structure to a complete medium and...

Embodiment 3

[0055] A photocurable enzyme cross-linked bio-ink described in this example has the same composition and preparation method as in Example 1, the difference being that in the photo-cured enzyme cross-linked bio-ink, the mass percentage of fibrinogen 1-10 wt%, the mass percentage of methacrylic anhydride gelatin is 0.1-15 wt%, and the mass percentage of photoinitiator is 0.1-1 wt%.

[0056] It can be obtained from experiments that reducing the amount of solid materials in the bioink formulation does not affect the high cytocompatibility, high mechanical strength, high degradability and non-cytotoxic properties of the double network hydrogel system, in which bioactive cells Proliferation and differentiation were good.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com