Rapid hemostatic hydrogel and preparation method thereof

A hydrogel and fast technology, which is applied in the fields of pharmaceutical formulation, application, and medical science, can solve the problems of low mechanical strength, low mechanical strength, and weak adhesion of hydrogel, and achieve good cell compatibility and high Mechanical strength, easy peeling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

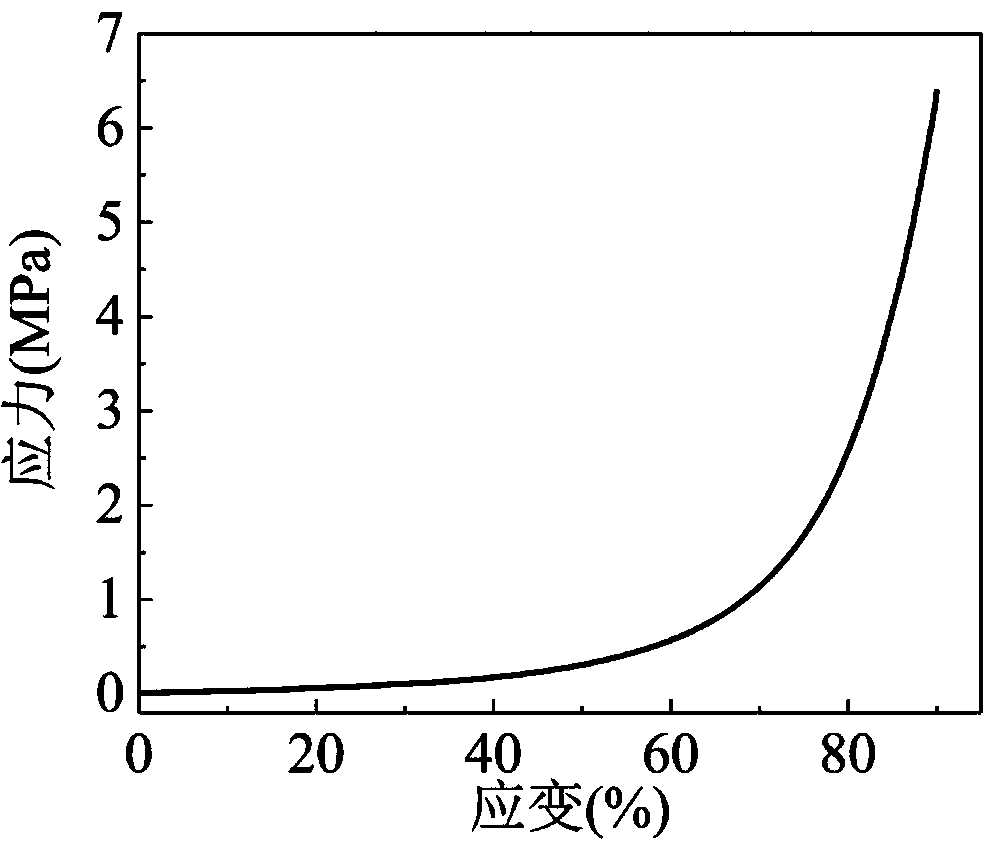

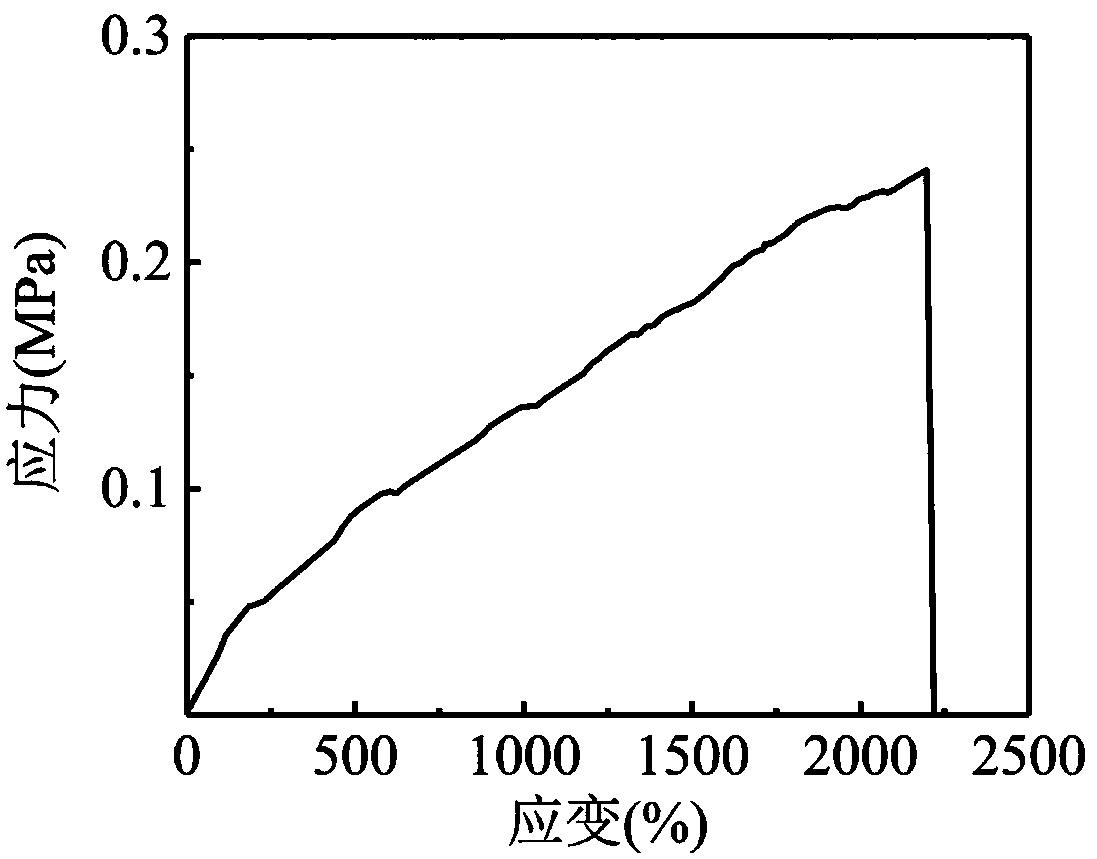

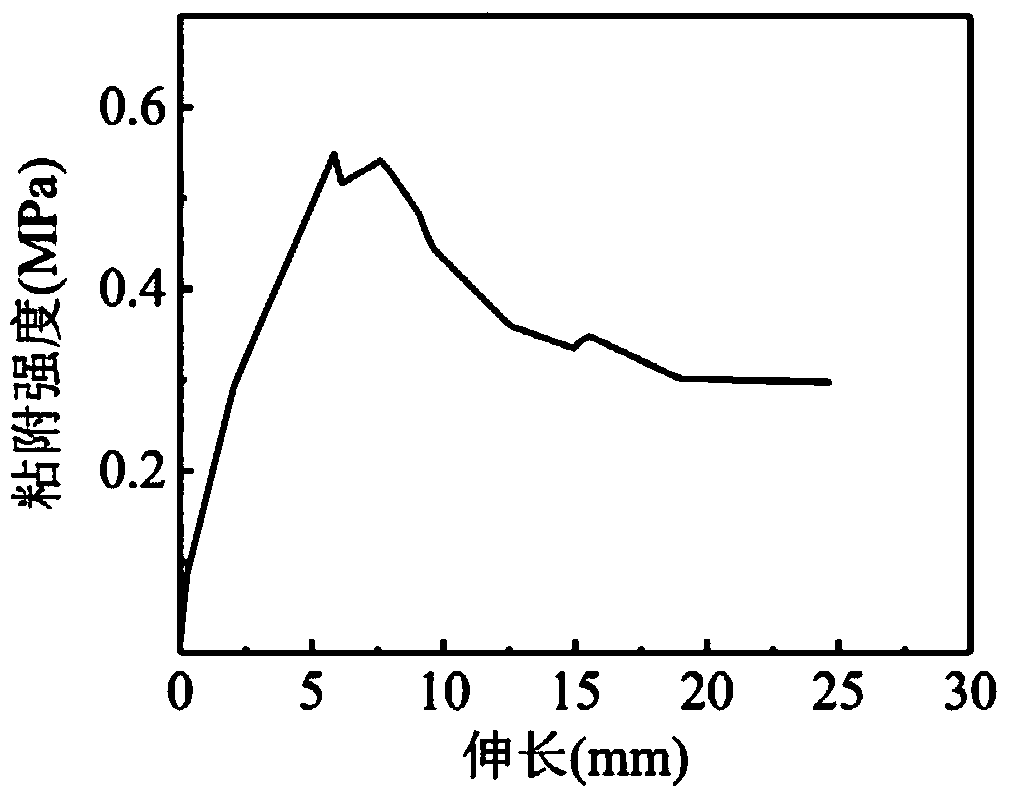

Embodiment 1

[0028] Add acrylamide (AM) (5 g) and nano-kaolin (KA) (0.03 g) to 12 g of deionized water at room temperature, stir for 6 h, and then ultrasonicate for 1 h to mix them evenly to obtain a mixed solution I; after transferring to an ice-water bath , add tannic acid (TA) (0.32g), N,N'-methylenebisacrylamide (12.5mg), ammonium persulfate (25mg) to the mixed solution I in turn, and stir for 20min to obtain the mixed solution II; The mixed solution II was added with accelerator tetramethylethylenediamine (20 μL) and stirred for 10 minutes, then transferred to a mold, and polymerized at 40°C for 8 hours to obtain a sample, numbered PAM-TA-KA1. The compressive strength, tensile strength and elongation at break are shown in Table 1, and the adhesion strength to different substrates is shown in Table 2.

Embodiment 2

[0030] Add AM (5g) and KA (0.07g) to 12g deionized water at room temperature, stir for 6 hours, and then ultrasonically mix them for 1 hour to obtain a mixed solution I; after transferring to an ice-water bath, add TA in turn to the mixed solution I (0.32g), N,N,-methylenebisacrylamide (12.5mg), ammonium persulfate (25mg) to obtain mixed solution II; after stirring for 20min, add accelerator tetramethylethylenediamine ( 20 μL), stirred for 10 minutes, transferred to a mold, and polymerized at 40°C for 8 hours to obtain a sample, numbered PAM-TA-KA2. The compressive strength, tensile strength and elongation at break are shown in Table 1, and the adhesion strength to different substrates is shown in Table 2.

Embodiment 3

[0032] Add AM (5g) and KA (0.10g) to 12g deionized water at room temperature, stir for 6 hours, and then ultrasonically mix them for 1 hour to obtain a mixed solution I; after transferring to an ice-water bath, add TA in turn to the mixed solution I (0.32g), N,N'-methylenebisacrylamide (12.5mg), ammonium persulfate (25mg) to obtain mixed solution II; after stirring for 20min, add accelerator tetramethylethylenediamine ( 20 μL), stirred for 10 minutes, transferred to a mold, and polymerized at 40°C for 8 hours to obtain a sample, numbered PAM-TA-KA3. The compressive strength, tensile strength and elongation at break are shown in Table 1, and the adhesion strength to different substrates is shown in Table 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com