Preparation method for water-resistant nano microcrystalline cellulose/polyvinyl alcohol/polyacrylic acid/silicon dioxide composite nanofiber membrane

A technology of composite nanofibers and nanocrystals, applied in spinning solution preparation, textile and papermaking, non-woven fabrics, etc., to achieve the effects of improved comprehensive mechanical properties, controllable diameter and thickness, and good biocompatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

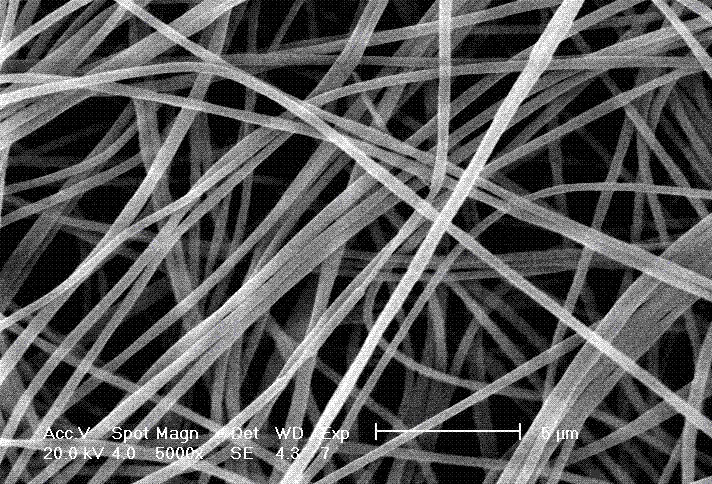

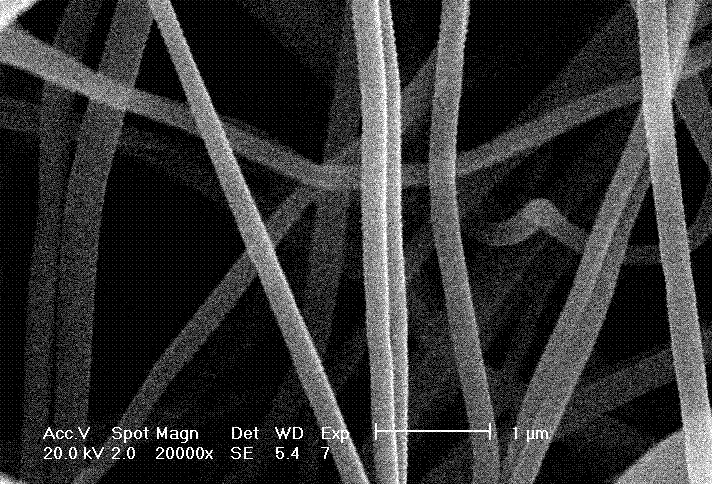

Image

Examples

Embodiment 1

[0027] (1) Preparation of nanocrystalline cellulose: Microcrystalline cellulose (MCC) was mixed with 64% H 2 SO 4Add it into a three-necked flask at a solid-to-liquid ratio of 1:10 g / mL, stir and heat at 50°C for 1 h, wash the product with deionized water and centrifuge until the pH of the solution is neutral, and obtain an NCC suspension. The obtained NCC suspension was centrifuged at high speed for 3 times (5min, 8000rpm), and finally the centrifuged suspension was vacuum freeze-dried for 48h, and ground into powder for later use;

[0028] (2) Preparation of 5% polyvinyl alcohol and 10% polyacrylic acid aqueous solution: add 5g polyvinyl alcohol to 95g deionized water, heat in a water bath at 70°C for 5 hours to obtain 5% polyvinyl alcohol aqueous solution; add 10g polyacrylic acid to 90g deionized water In water, stir at room temperature for 12 hours to obtain 10% polyacrylic acid aqueous solution;

[0029] (3) Mix 5% polyvinyl alcohol and 10% polyacrylic acid aqueous sol...

Embodiment 2

[0037] (1) Preparation of nanocrystalline cellulose: Microcrystalline cellulose (MCC) was mixed with 64% H 2 SO 4 Add it into a three-necked flask at a solid-to-liquid ratio of 1:10 g / mL, stir and heat at 50°C for 1 h, wash the product with deionized water and centrifuge until the pH of the solution is neutral, and obtain an NCC suspension. The obtained NCC suspension was centrifuged at high speed for 3 times (5min, 8000rpm), and finally the centrifuged suspension was vacuum freeze-dried for 48h, and ground into powder for later use;

[0038] (2) Preparation of 5% polyvinyl alcohol and 10% polyacrylic acid aqueous solution: add 5g polyvinyl alcohol to 95g deionized water, heat in a water bath at 70°C for 5 hours to obtain 5% polyvinyl alcohol aqueous solution; add 10g polyacrylic acid to 90g deionized water In water, stir at room temperature for 12 hours to obtain 10% polyacrylic acid aqueous solution;

[0039] (3) Mix 5% polyvinyl alcohol and 10% polyacrylic acid aqueous so...

Embodiment 3

[0046] (1) Preparation of nanocrystalline cellulose: Microcrystalline cellulose (MCC) was mixed with 64% H 2 SO 4 Add it into a three-necked flask at a solid-to-liquid ratio of 1:10 g / mL, stir and heat at 50°C for 1 h, wash the product with deionized water and centrifuge until the pH of the solution is neutral, and obtain an NCC suspension. The obtained NCC suspension was centrifuged at high speed for 3 times (5min, 8000rpm), and finally the centrifuged suspension was vacuum freeze-dried for 48h, and ground into powder for later use;

[0047] (2) Preparation of 5% polyvinyl alcohol and 10% polyacrylic acid aqueous solution: add 5g polyvinyl alcohol to 95g deionized water, heat in a water bath at 70°C for 5 hours to obtain 5% polyvinyl alcohol aqueous solution; add 10g polyacrylic acid to 90g deionized water In water, stir at room temperature for 12 hours to obtain 10% polyacrylic acid aqueous solution;

[0048] (3) Mix 5% polyvinyl alcohol and 10% polyacrylic acid aqueous so...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com