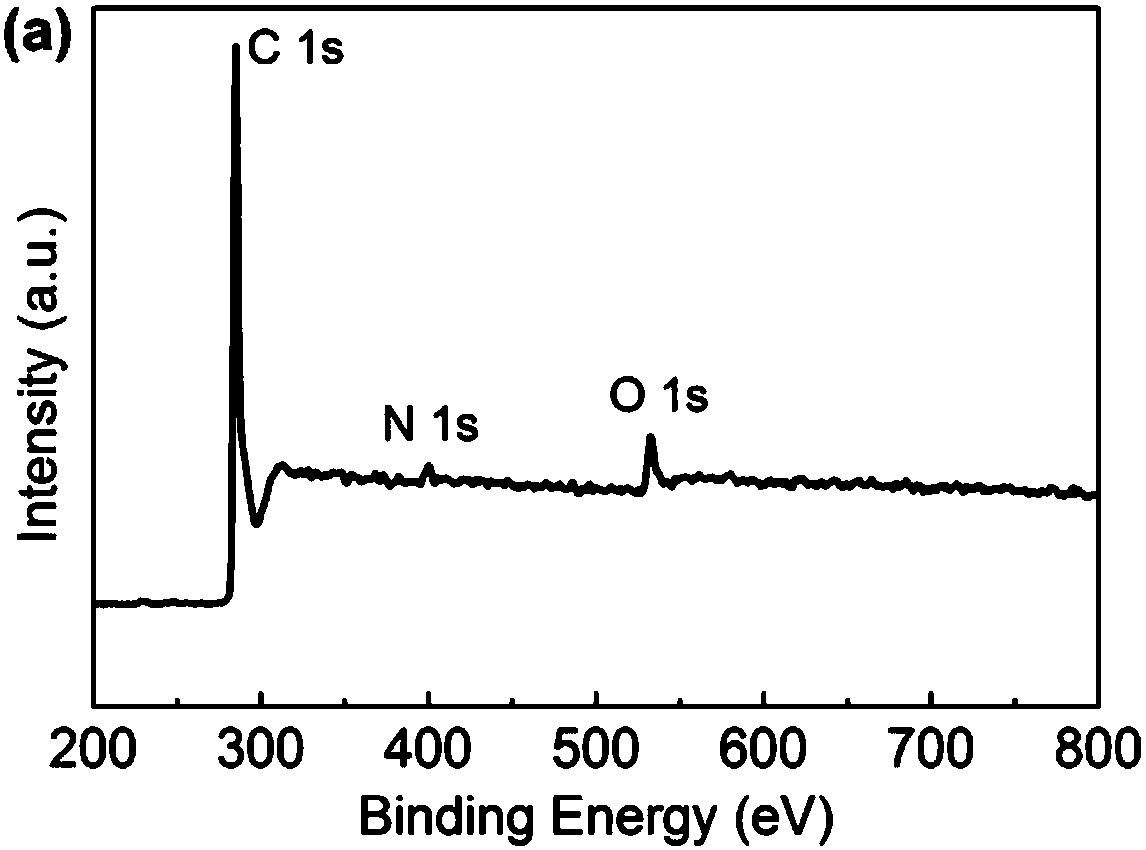

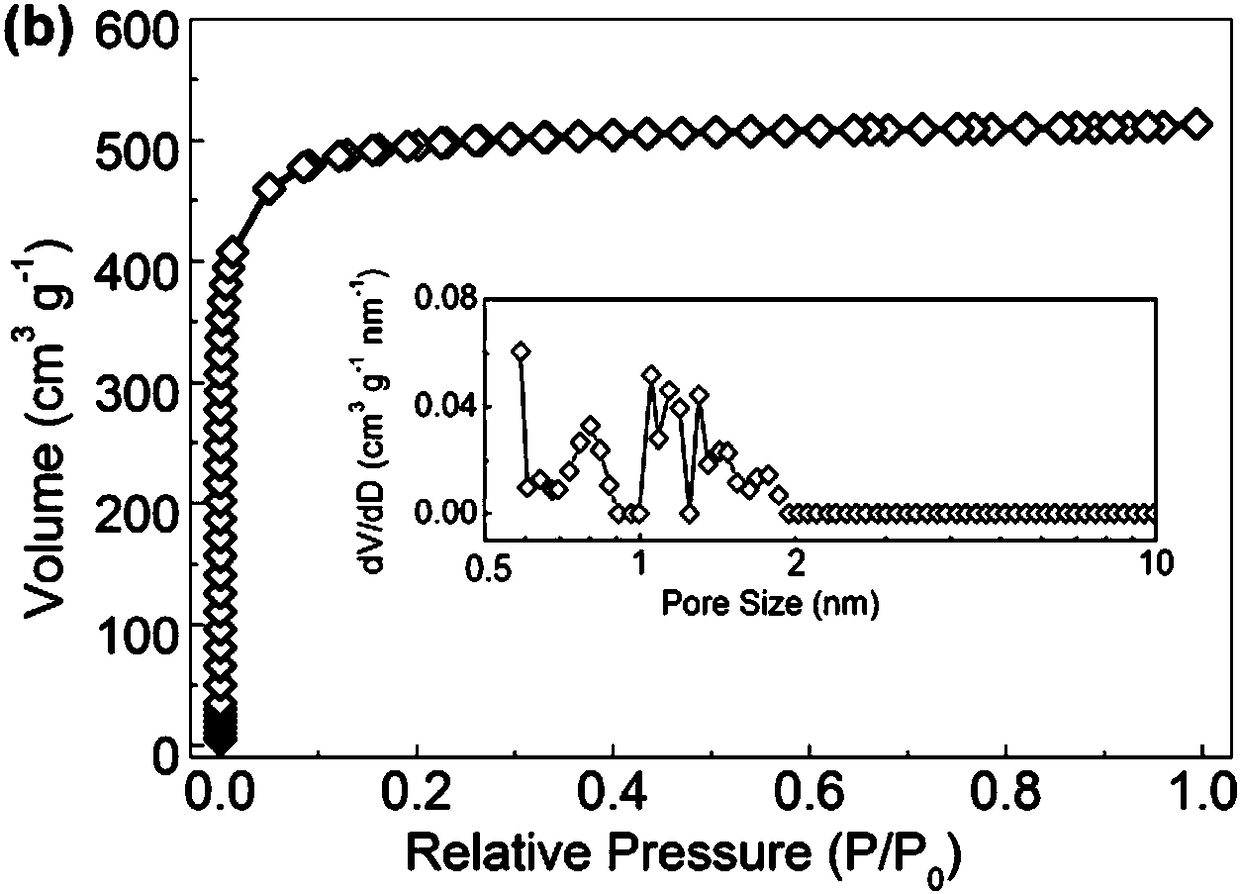

Nitrogen-doped micro-pore carbon spheres for super-capacitor electrode material and preparation method thereof

A nitrogen-doped microporous carbon and supercapacitor technology, which is applied in hybrid capacitor electrodes, carbon preparation/purification, chemical instruments and methods, etc., can solve the problems of complex synthesis process, low specific capacitance, low energy density, long reaction time, etc. , to achieve the effect of simple operation, high monodispersity and short reaction time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] This embodiment provides a nitrogen-doped microporous carbon sphere, the preparation method of which comprises:

[0044] a. Add absolute ethanol and deionized water into a beaker at a volume ratio of 1:1 to form a mixed solution of 80 mL; weigh 0.3 g of tri-block copolymer F108 and add it to the mixed solution at a speed of 2000r / min Stir for 20min;

[0045] b. Take 3mL of ammonia water (mass fraction is 25%), 1.2g of phenol and 4.5mL of formaldehyde were added to the solution obtained in step a, and stirred at a speed of 2000r / min for 30min at room temperature to obtain a mixed base solution;

[0046] c. Transfer the mixed base liquid to a 100mL polytetrafluoroethylene reactor, react at 170°C for 6 hours, cool, wash the product with alcohol and water, and dry at 80°C for 12 hours to obtain phenolic resin balls;

[0047] d. Put the phenolic resin ball in N 2 carbonization at 700°C for 3 h under atmosphere protection, and then in N 2 Cool to room temperature under atm...

Embodiment 2

[0051] This embodiment provides a nitrogen-doped microporous carbon sphere, the preparation method of which comprises:

[0052] a. Add absolute ethanol and deionized water to a beaker at a volume ratio of 4.3:1 to form a 80mL mixed solution; weigh 0.5g of triblock copolymer F108 and add it to the mixed solution at a speed of 2000r / min Stir for 20min;

[0053] b. Take 3mL of ammonia water (mass fraction is 25%), 1.2g of phenol and 4.5mL of formaldehyde were added to the solution obtained in step a, and stirred at a speed of 2000r / min for 30min at room temperature to obtain a mixed base solution;

[0054] c. Transfer the mixed base liquid to a 100mL polytetrafluoroethylene reactor, react at 170°C for 6 hours, cool, wash the product with alcohol and water, and dry at 80°C for 12 hours to obtain phenolic resin balls;

[0055] d. Put the phenolic resin ball in N 2 carbonization at 700°C for 3 h under atmosphere protection, and then in N 2 Cool to room temperature under atmospher...

Embodiment 3

[0059] This embodiment provides a nitrogen-doped microporous carbon sphere, the preparation method of which comprises:

[0060] a. Add absolute ethanol and deionized water into a beaker at a volume ratio of 1:2.3 to form a 80mL mixed solution; weigh 0.4g of triblock copolymer F127 and add it to the mixed solution at a speed of 3000r / min Stir for 10 minutes;

[0061] b. Take 3mL of ammonia water (mass fraction is 25%), 1.2g of phenol and 4.5mL of formaldehyde were added to the solution obtained in step a, and stirred at a speed of 2000r / min for 20min at room temperature to obtain a mixed base solution;

[0062] c. Transfer the mixed base liquid to a 100mL polytetrafluoroethylene reactor, react at 150°C for 9 hours, cool, wash the product with alcohol and water, and dry to obtain phenolic resin balls;

[0063] d. Put the phenolic resin ball in N 2 carbonization at 500°C for 4 h under atmosphere protection, and then 2 Cool to room temperature under atmosphere to obtain nitroge...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Pore size distribution | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

| Current density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com