Method for manufacturing fusion pellet based on microfluid

A fusion target and microfluidic technology, applied in the field of preparation of inertial confinement nuclear fusion pellets, can solve the problems of large consumption of raw materials and cumbersome operation, and achieve the effects of low preparation cost, strong controllability, and controllable wall thickness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

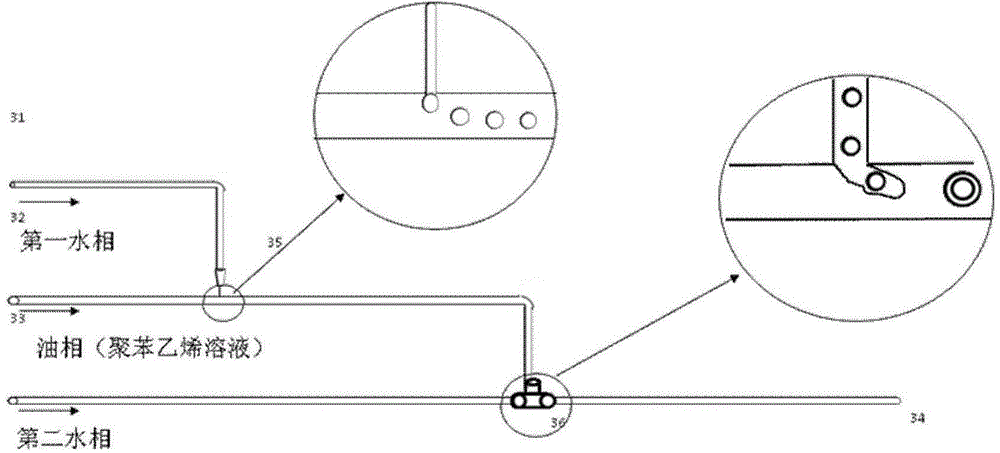

[0027] Example 1: Preparation method of a polystyrene fusion target pellet with a diameter of 500 μm and a wall thickness of 15 μm

[0028] 1. Preparation of channels:

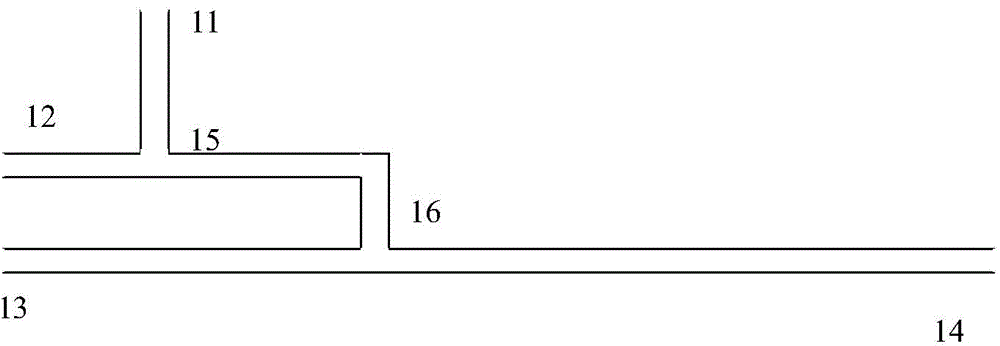

[0029] ①. Make a small hole on the wall of a Teflon tube with a length of 15 cm and an inner diameter of 500 μm, and insert a pre-ground No. 6 medical needle. Note that the needle should be inserted in the middle of the tube. Entrance;

[0030] ②. One end of the Teflon tube is inserted into a No. 6 needle as the entrance of the cyst wall solution (polystyrene solution);

[0031] ③. Connect the other end of the Teflon tube with the other two 15 cm long Teflon tubes of 500 μm internal diameter with a Peek tee with an internal diameter of 500 μm, and insert a No. 6 needle into one end of one of the Teflon tubes as the mobile phase (polyvinyl alcohol aqueous solution ) entrance.

[0032] 2. Preparation of microemulsion:

[0033] ①. Dissolve 3.5g polystyrene (PS) in a mixed solution of 25ml benzene and 25ml 1,2...

Embodiment 2

[0043] Example 2: Preparation method of a polystyrene fusion target pellet with a diameter of 1000 μm and a wall thickness of 20 μm

[0044] 1. Preparation of channels:

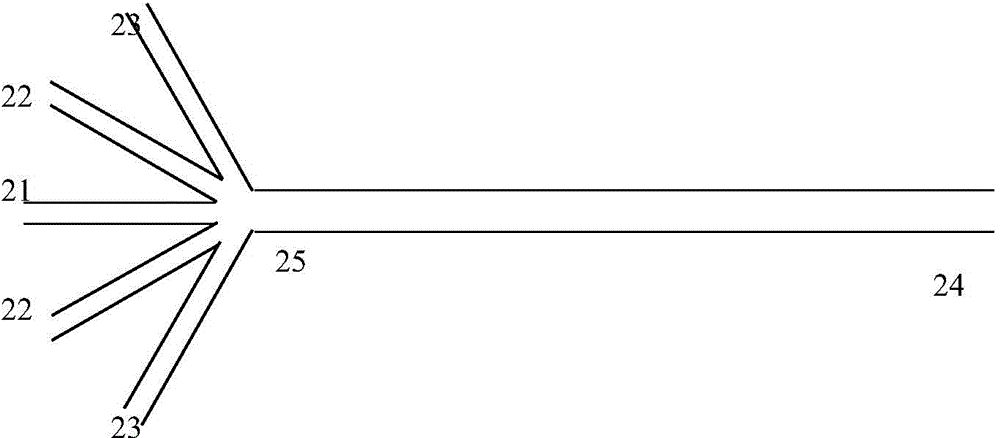

[0045] ①. Use a Peek tee with an inner diameter of 500 μm to connect three Teflon tubes with a length of 15 cm and an inner diameter of 500 μm, and one end of the two tubes is respectively inserted into a No. Ethylene solution) inlet;

[0046] ②. Put a section of Teflon tube with an inner diameter of 1000 μm on the outside of another Teflon tube without a needle tip, and connect two other Teflon tubes with a length of 15 cm and an inner diameter of 1000 μm through a stainless steel tee with an inner diameter of 1000 μm. One end is inserted into a No. 6 needle covered with a Teflon tube with an inner diameter of 500 μm, as the entrance of the mobile phase (polyvinyl alcohol aqueous solution);

[0047] 2. Preparation of microemulsion:

[0048] ①. Dissolve 3.5g polystyrene (PS) in a mixed solution of 25ml ben...

Embodiment 3

[0058] Example 3: Preparation method of foamed phenolic resin (RF / PF) fusion target pellet with a diameter of 500 μm and a wall thickness of 20 μm

[0059] 1. Preparation of channels:

[0060] ①. Make a small hole on the wall of a Teflon tube with a length of 15 cm and an inner diameter of 500 μm, and insert a No. base naphthalene) inlet;

[0061] ②. Insert a No. 6 needle into one end of the Teflon tube as the entrance of the capsule wall solution (phenolic resin solution);

[0062] ③. Connect the other end of the Teflon tube with the other two Teflon tubes with an inner diameter of 500 μm and two other 15 cm long Teflon tubes with an inner diameter of 500 μm, and insert a No. 6 needle into one end of one of the Teflon tubes as the mobile phase (mixed silicone oil) Entrance.

[0063] 2. Preparation of microemulsion:

[0064] ①.Dissolve 5.72g resorcinol in 54ml ultrapure water, add 7.8ml37% formaldehyde solution, 0.028g2.8wt%Na 2 CO 3 The solution was stirred and heated i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com