Double-beam high-speed milling machine tool

A high-speed milling and double-beam technology, which is applied in the field of aviation parts processing, can solve the problems of insufficient production capacity and low processing efficiency, and achieve the effects of improving efficiency, improving processing efficiency, and saving floor space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] Specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

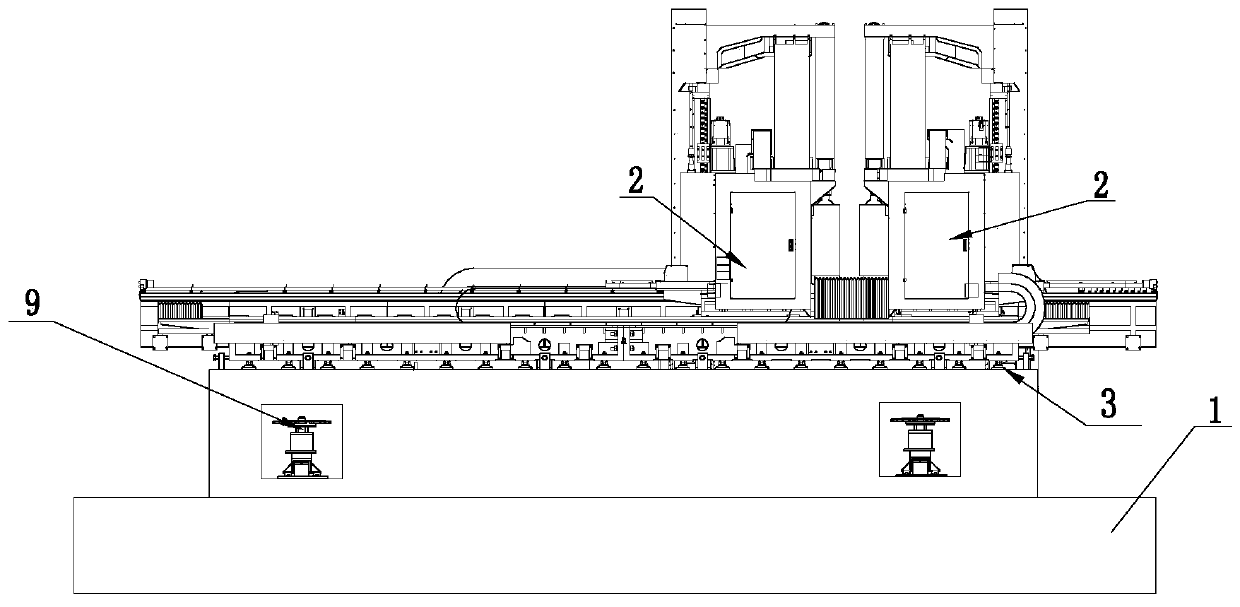

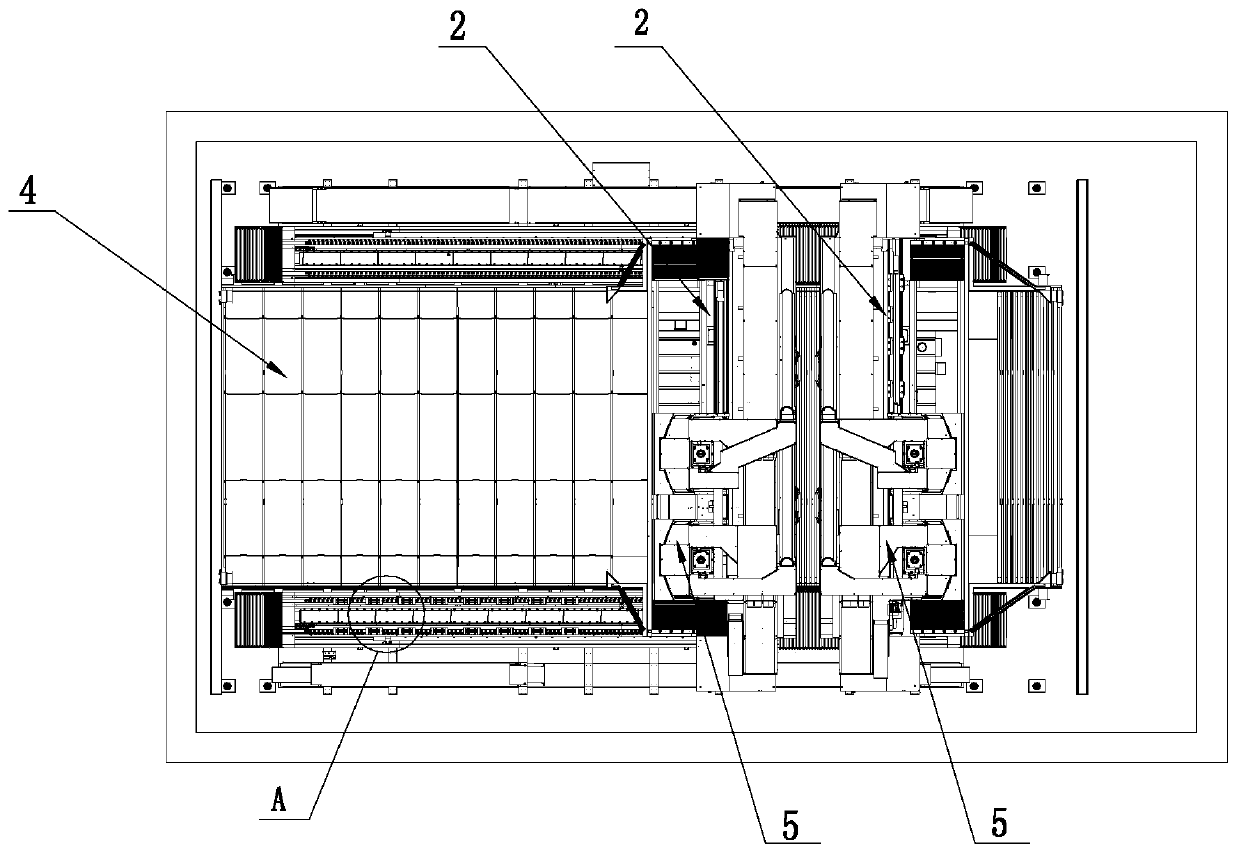

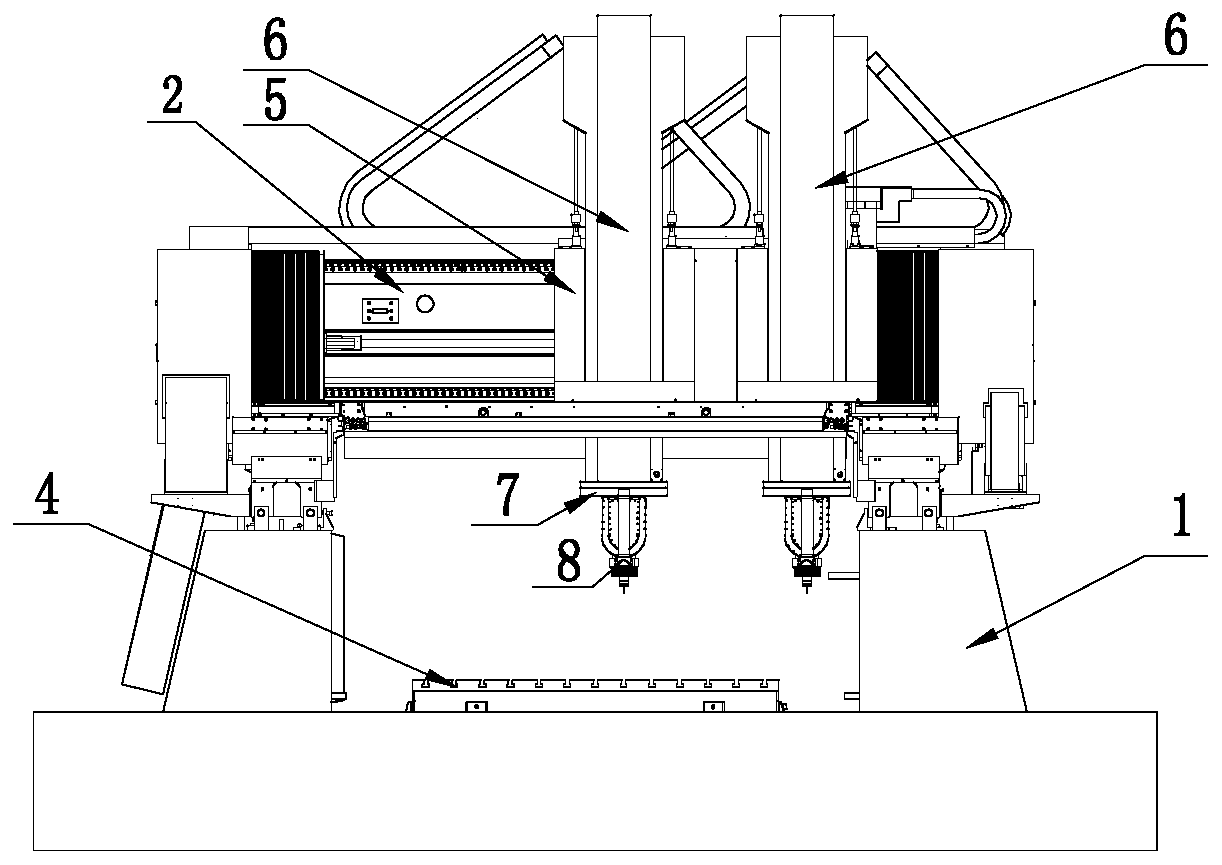

[0022] like Figure 1-Figure 5 As shown, the present invention comprises machine tool bed 1, and machine tool bed 1 comprises the cement lower bed of cement forming and the casting upper bed of casting forming, and cement lower bed is connected with foundation, and the cement lower bed and casting upper bed Between them are connected by pad iron 3, and a workbench 4 for positioning workpieces is formed on the upper bed of the casting. On the bed and drive the displacement along the X-axis direction through the crossbeam driving mechanism.

[0023] The two beams are successively installed with two carriages 5 which are slidably installed by the guide rail slider, and each carriage drives the ball screw auxiliary mechanism through the carriage driving mechanism to drive the carriage to displace in the Y-axis direction. Each pallet is equipped ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com