Patents

Literature

73results about How to "Controllable wall thickness" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

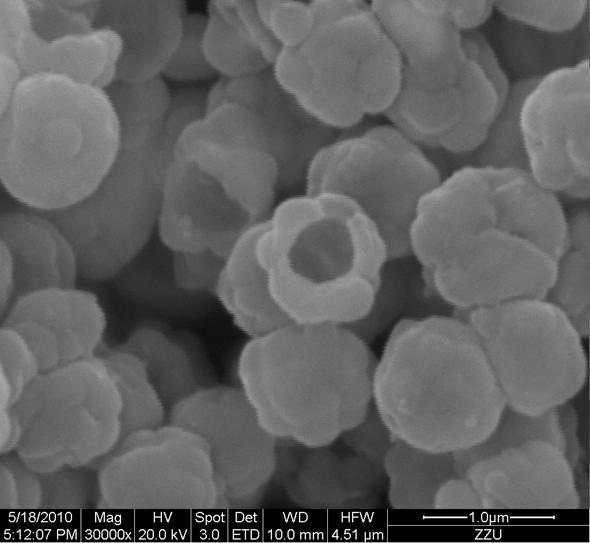

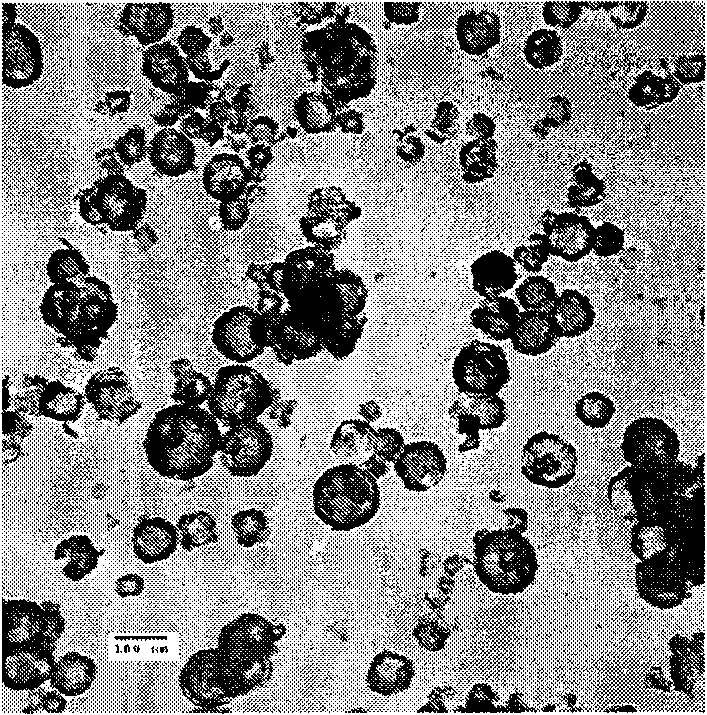

Preparation method of polysilsesquioxane hollow microspheres

The invention relates to a preparation method of polysilsesquioxane hollow microspheres. In the method, a trifunctional silane monomer is used as a raw material, an organic solvent is used as a template and the polysilsesquioxane hollow microspheres are prepared by utilizing the oil-in-water (O / W) suspension polymerization. According to the invention, the raw material is easy to obtain, the reaction condition is mild, the method is simple and convenient to operate, the step of removing a template core does not need to be carried out, and the cost is low. The hollow microspheres prepared by the method disclosed by the invention are white powder particles, have a polysilsesquioxane organic-inorganic hybrid material as a component, have low density and good mechanical strength, do not contain a surfactant, have physiological inert and can be loaded with object molecules. The particle sizes of the polysilsesquioxane hollow microspheres can be controlled in the range of 200nm to 5.0mum. The polysilsesquioxane hollow microspheres can be used as high-end packing, light scattering particles, a medicament and catalyst carrier, a microreactor and the like and are widely used for the fields of chemical industry, cosmetics, catalysis, separation, medicinal preparation, environmental protection and the like.

Owner:SHANDONG UNIV

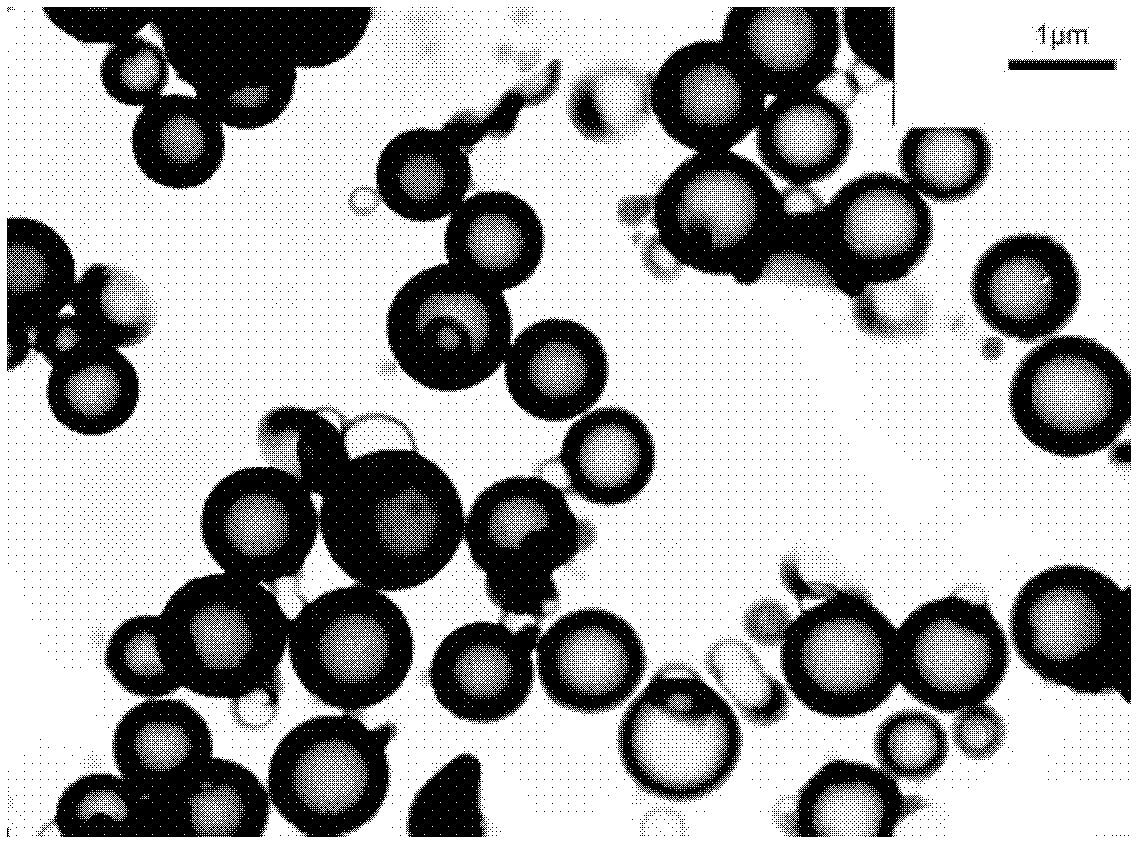

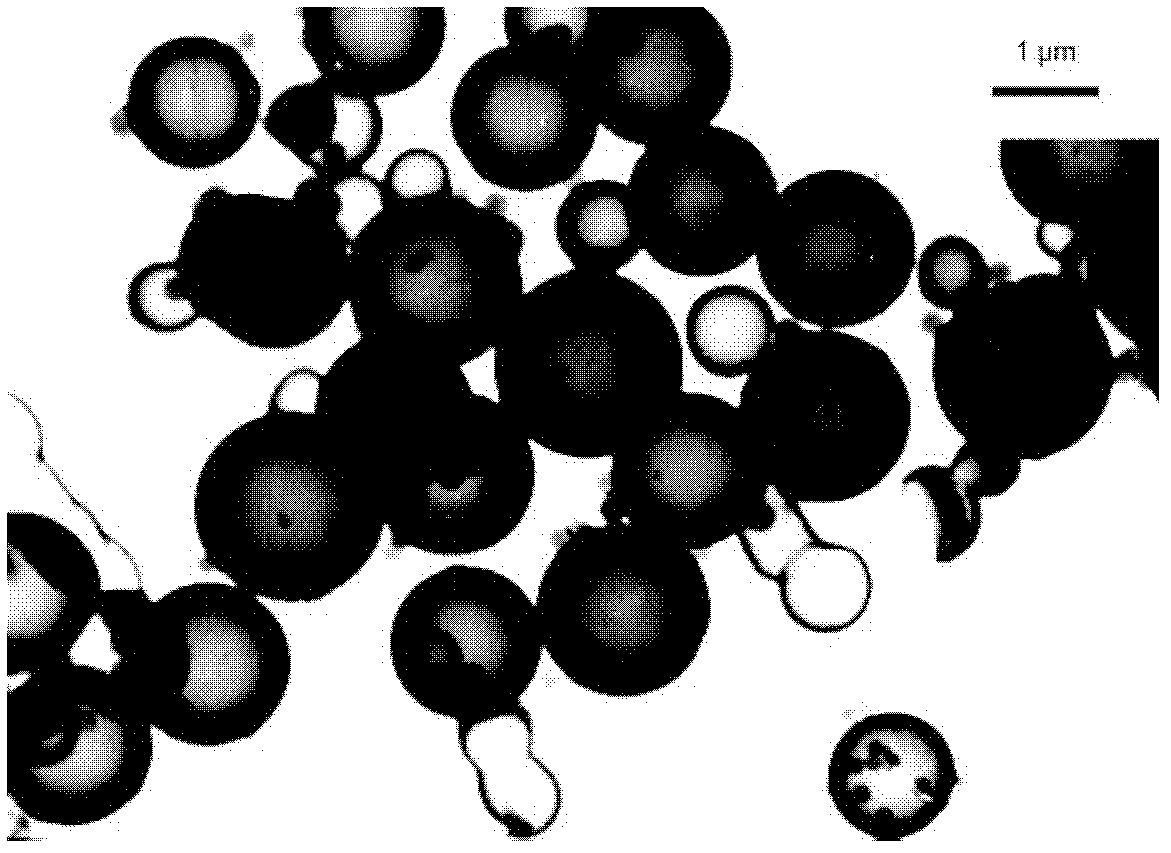

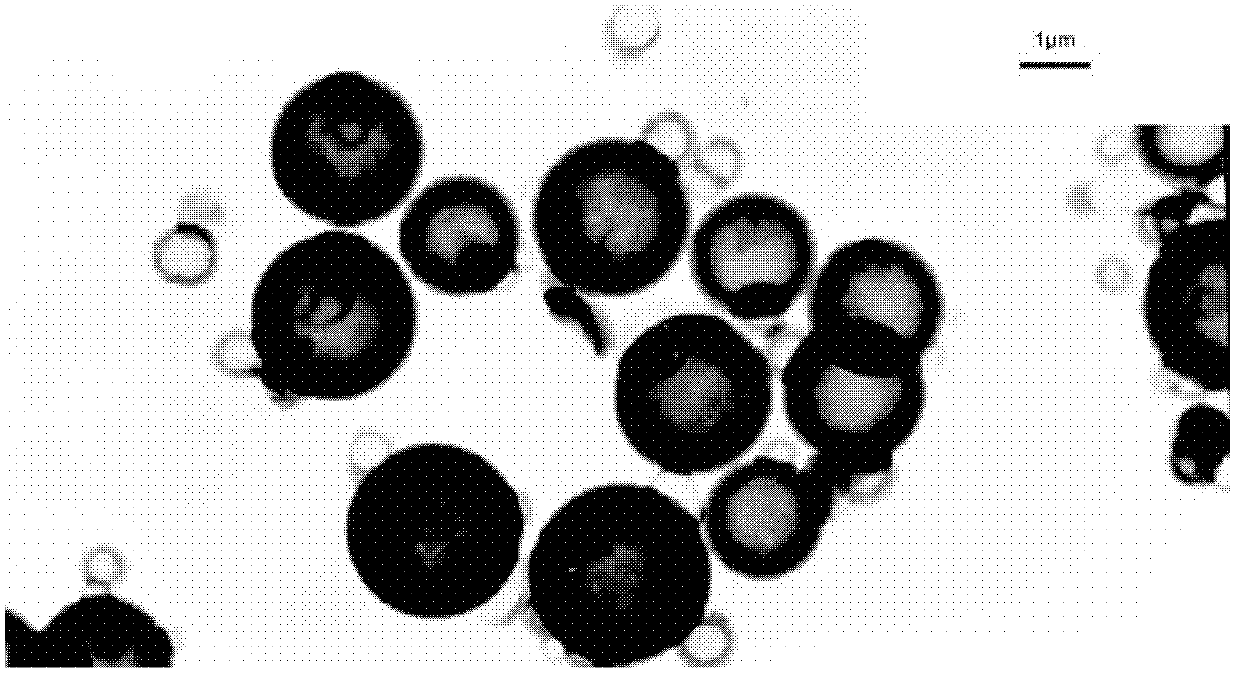

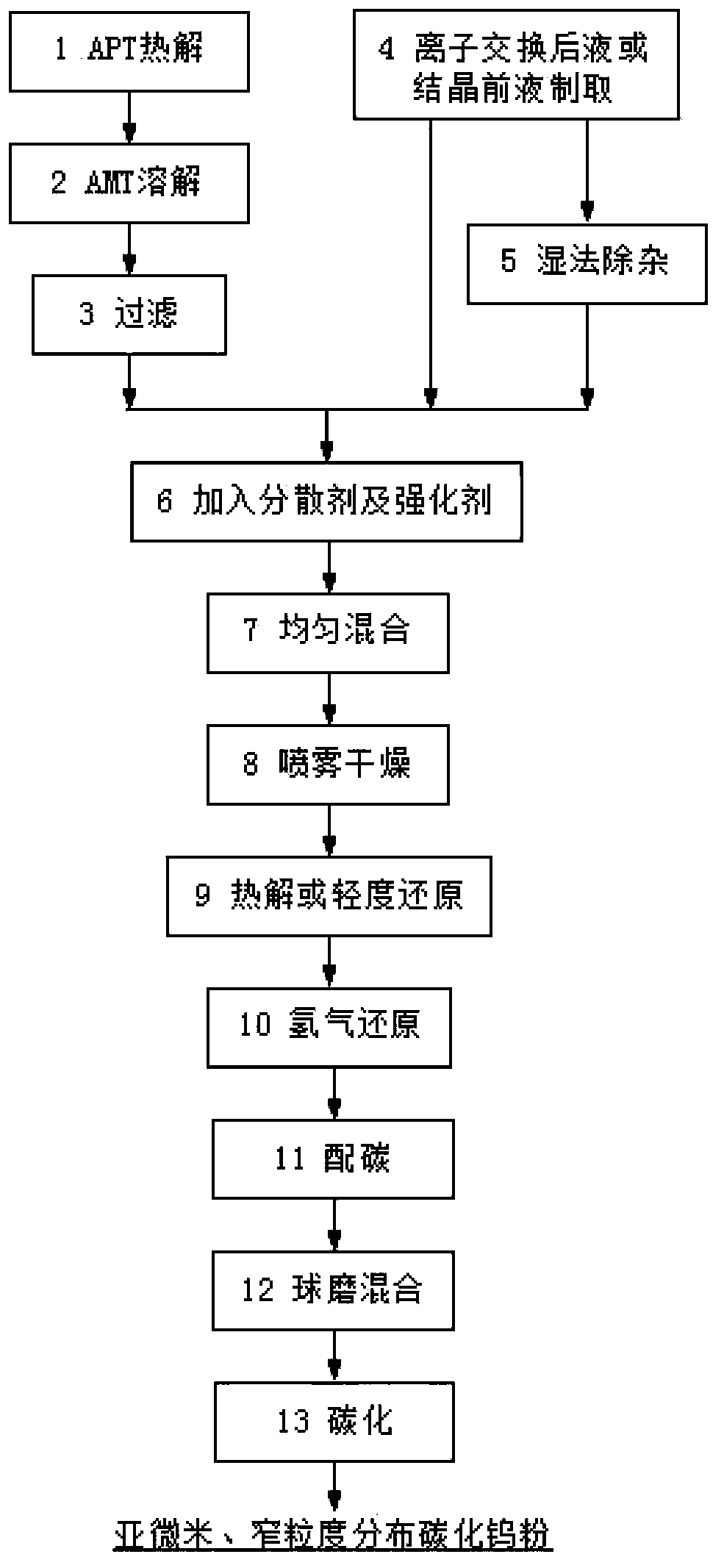

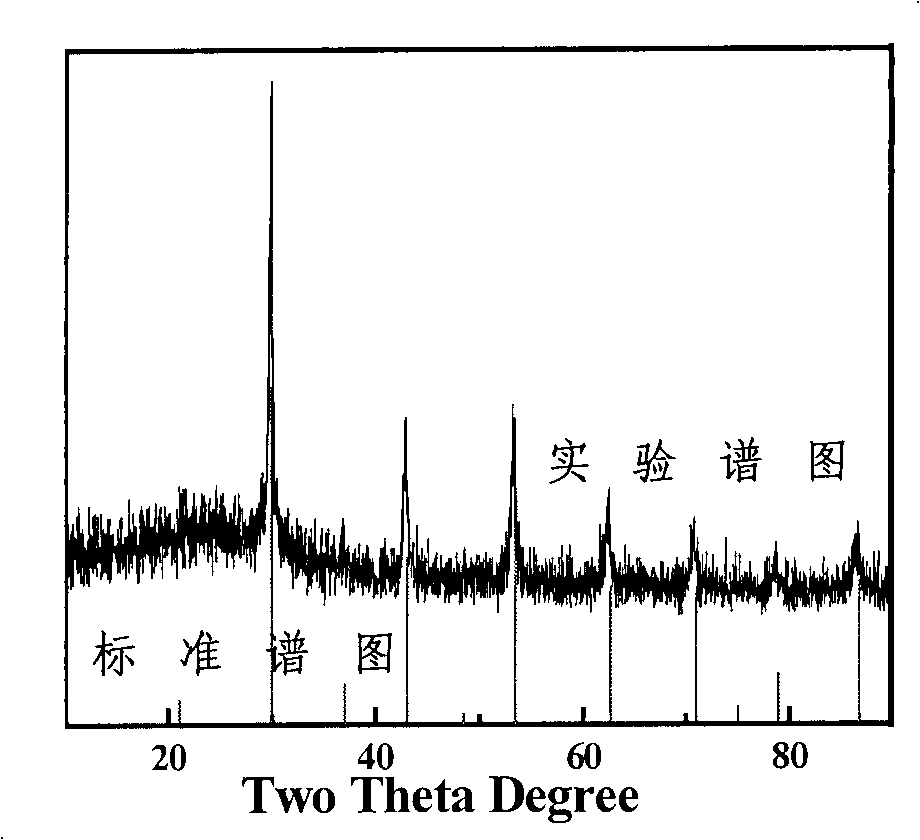

Submicron narrow particle size distribution type tungsten powder and tungsten carbide powder and preparation method thereof

ActiveCN103570020AControllable wall thicknessPurity does not affectTungsten/molybdenum carbideTungstateKetone

The invention relates to submicron narrow particle size distribution type tungsten powder and tungsten carbide powder and a preparation method thereof, and belongs to the field of metallurgic powder preparation of refractory metal powder. The submicron narrow particle size distribution type tungsten powder and tungsten carbide powder are characterized in that the average particle size is 0.1 to 1.0 micron, and the maximum particle size is not greater than twice of the average particle size. The preparation method comprises the following steps: taking an ammonium tungstate solution as a raw material and a high molecular surfactant as a dispersing agent; reinforcing the dispersion effect through alcohol or ketone; quickly crystallizing and drying by spray drying to obtain fine particle hollow thin-walled spherical ammonium tungstate crystals; and performing pyrolysis, hydrogen gas reduction and carbonizing; and then generating submicron narrow particle size distribution type tungsten powder and tungsten carbide powder in situ. According to the preparation method, the submicron narrow particle size distribution type tungsten powder and tungsten carbide powder can be prepared in situ; and the technology is reformed and upgraded on the basis of the existing production condition of the enterprise, so that the scale production is easily realized, the production efficiency is high, and the effect is great.

Owner:GRIMAT ENG INST CO LTD

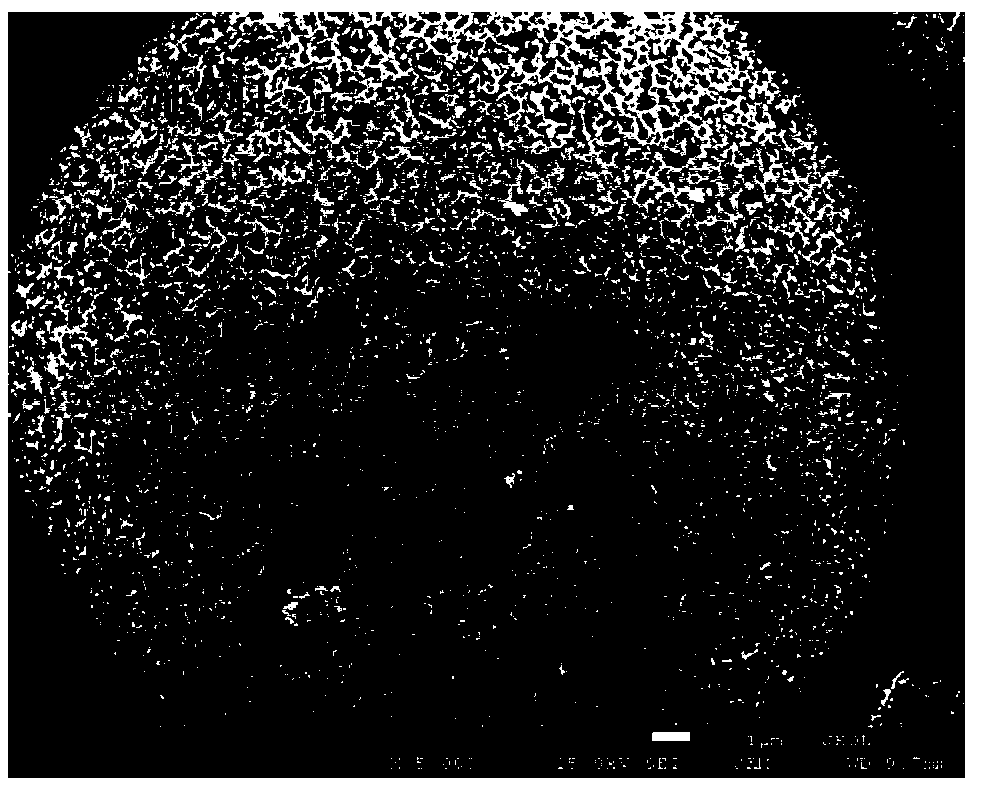

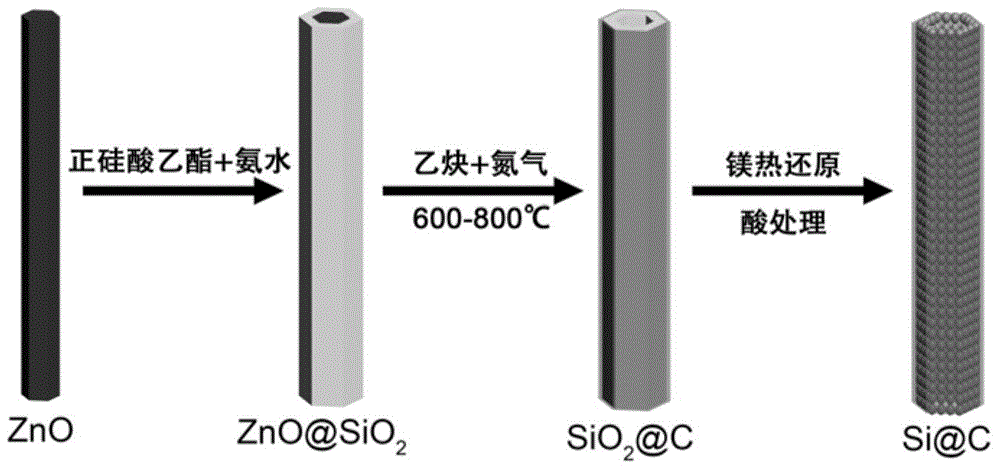

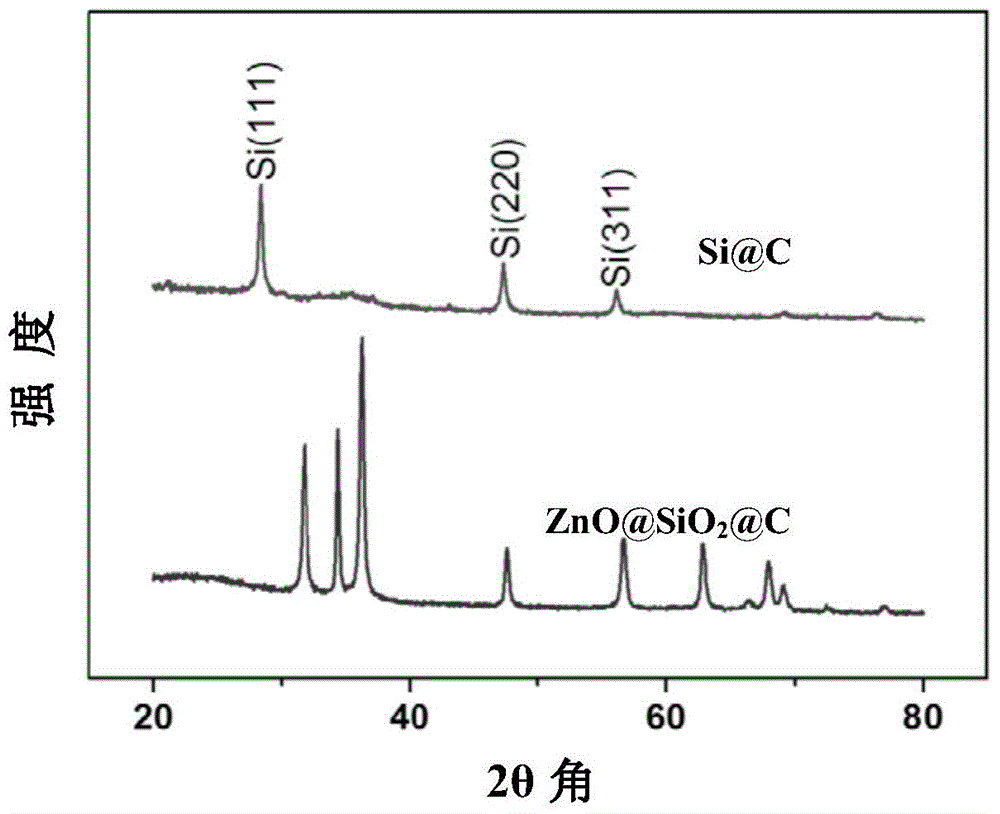

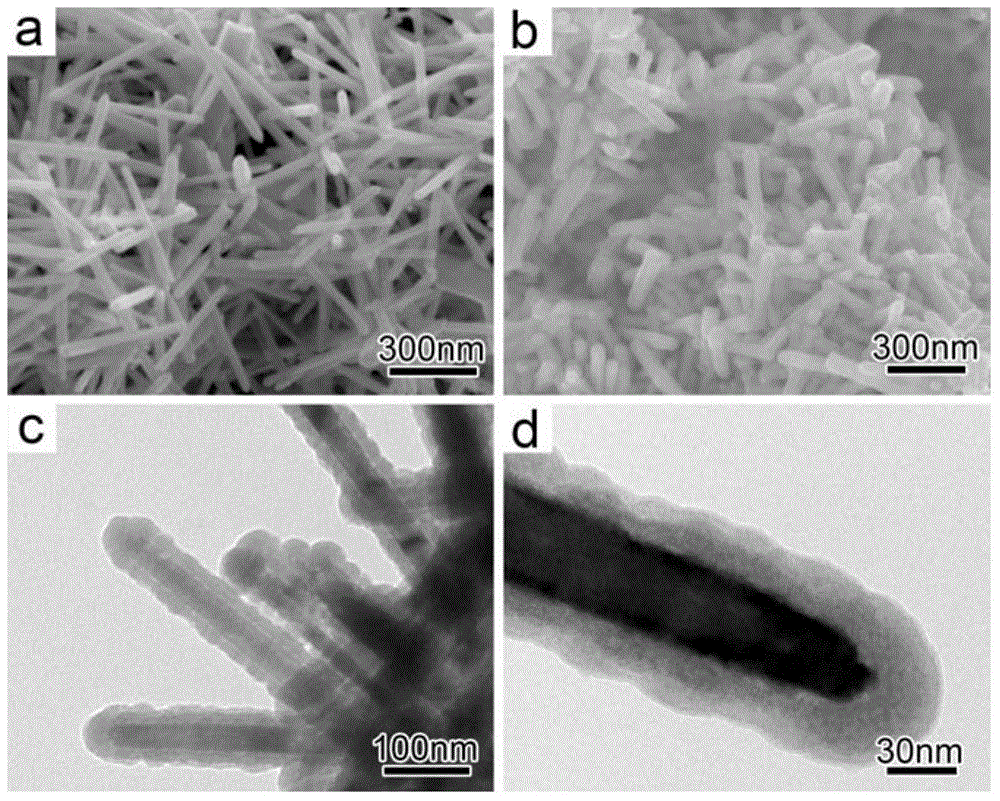

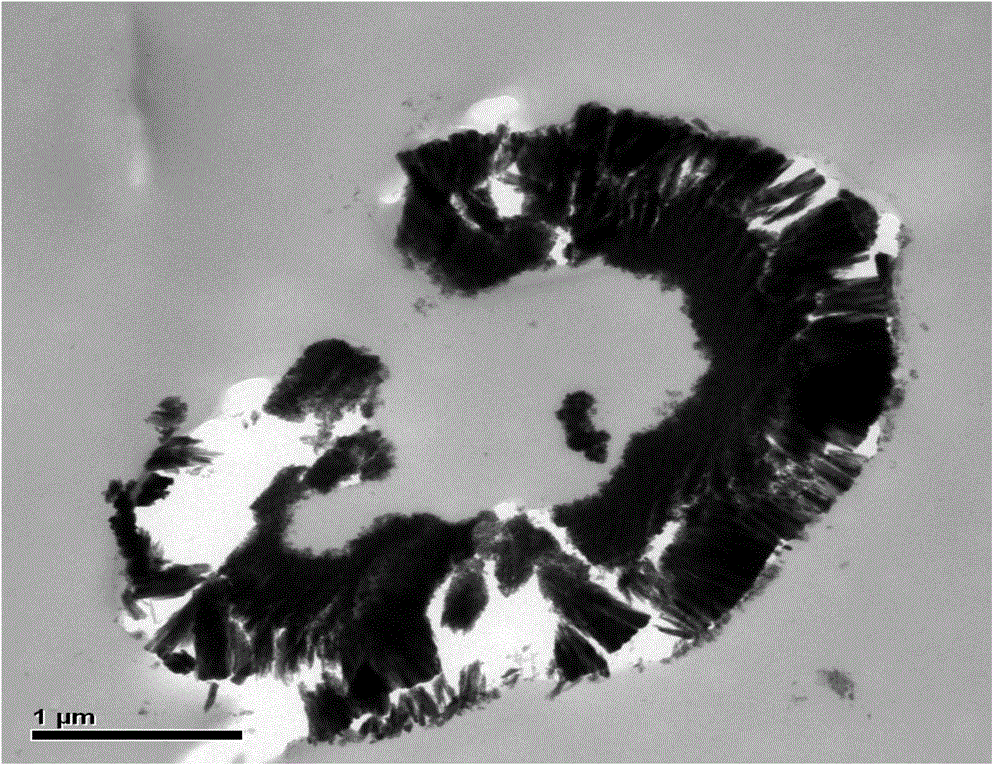

Silicon-carbon composite nano-tube preparation method

ActiveCN104979539AThe removal process is simple and thoroughGood lookingMaterial nanotechnologyCell electrodesCarbon compositesSolvent

The present invention discloses a silicon-carbon composite nano-tube preparation method, which comprises: dissolving zinc oxide nano-rods in a solvent, adjusting to achieve an alkaline state, mixing with tetraethyl orthosilicate, reacting, carrying out centrifugation drying to obtain a silicon dioxide coated core-shell structure material, recording as ZnO@SiO2, adding the ZnO@SiO2 to a reactor, heating in the presence of an inert gas, introducing acetylene gas, reacting, depositing a carbon coating layer on the silicon dioxide coated core-shell structure material surface, recording as ZnO@SiO2@C, carrying out a magnesium thermal reduction reaction on the ZnO@SiO2@C, removing the zinc oxide nano-rod template, and carrying out a post-treatment to obtain the silicon-carbon composite nano-tubes. According to the present invention, the zinc oxide nano-rods are adopted as the template to prepare the silicon-carbon composite nano-tubes, the preparation process is simple, the template removing is convenient and complete, the large-scale industrial production is easily achieved, and the new approach for synthesizing other types of the nano-tubes is provided.

Owner:浙江锂宸新材料科技有限公司

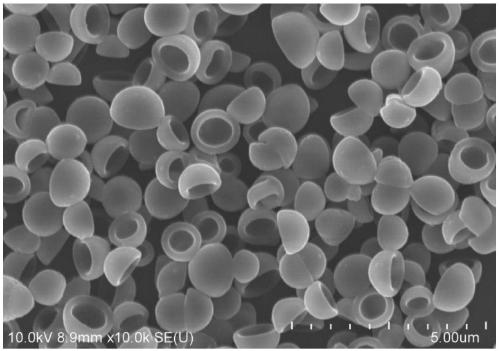

Preparation method of hollow carbon bowl powder

InactiveCN109553082AGood dispersionControllable particle size distributionMaterial nanotechnologyCarbon preparation/purificationIonBiological waste

The invention discloses a preparation method of hollow carbon bowl powder, and belongs to the technical field of preparation of inorganic materials. According to the method, a direct biological raw material or waste is adopted as a carbon source, a soft template is used as a template, and the hollow carbon bowl powder material with high dispersity, controllable particle size distribution and size,an inner hollow structure, morphology of a concave bowl-shaped structure, controllable wall thickness of the carbon bowl, and the like is prepared. The preparation method comprises the following steps: taking the carbon source, deionized water and the soft template agent as raw materials, respectively dissolving the carbon source and two surfactants in the deionized water to form three solutions,then mixing the three solutions according to a certain ratio, uniformly carrying out stirring to obtain a mixed solution, putting the mixed solution into a hydrothermal reaction kettle, and carryingout heating for a reaction to obtain a product. The method has the advantage that the direct biological raw material or biological waste is used as the carbon source, and aims to provide the novel utilization mode of biological wastes, so that emission of wastes is reduced, the wastes are converted into the functional carbon material, the process is simple, and the preparing and removing processesof a template in a hard template method is omitted.

Owner:UNIV OF SCI & TECH BEIJING

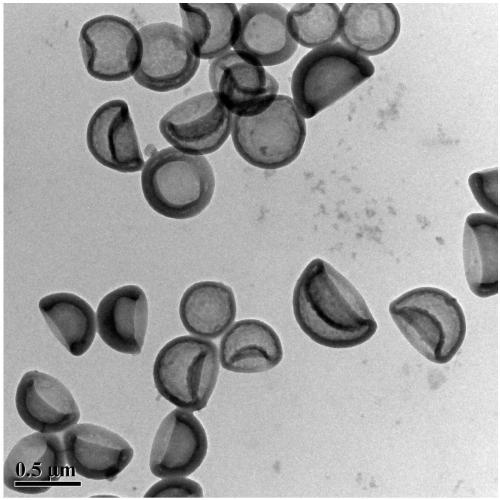

Hollow polyphosphazenes microsphere with magnetic particles embedded in casing layer and preparation method thereof

InactiveCN102585517ANo sheddingSimple preparation processCatalyst carriersOrganic-compounds/hydrides/coordination-complexes catalystsMicrosphereMicroparticle

The invention belongs to the technical field of new materials and biological materials and discloses a hollow polyphosphazenes microsphere with magnetic particles embedded in a casing layer and a preparation method thereof. The method comprises dispersing 0.02-0.1g of polystyrene microspheres into 30-300mL of ethanol; then adding 0.01-0.1g of phosphonitrilic chloride trimerl, 0.02-0.2g of 4,4'-phosphonitrilic chloride trimerl, 0.005-0.025g of magnetic particles and 1-10mL of triethylamine into the ethanol according to mass / volume ratio; after an ultrasonic reaction of 3-10 hours at the temperature of 20-60 DEG C, performing centrifugal separation, washing and drying to obtain a composite microsphere with polystyrene serving as a core and with polyphosphazenes serving as a casing, wherein the magnetic particles are embedded in the polyphosphazenes; and adding the obtained composite microspheres into tetrahydrofuran or carbon tetrachloride, evenly stirring the mixture, performing magnetic separation, drying a separated product for 12-24 hours, and obtaining the hollow polyphosphazenes microsphere with the magnetic particles embedded in the casing layer. The hollow polyphosphazenes microsphere has a unique structure that the magnetic particles are embedded inside the casing layer of the hollow microsphere, and the preparation method of the hollow polyphosphazenes microsphere withmagnetic particles embedded in the casing layer is simple in preparation process and simple and convenient to operate.

Owner:ZHENGZHOU UNIV

Hollow carbon sphere preparing method

ActiveCN104310368AParticle size controllableControllable wall thicknessSimple Organic CompoundsActive agent

The invention discloses a hollow carbon sphere preparing method, and belongs to the technical field of preparing methods of inorganic nonmetal materials. An oxygen-containing organic compound is adopted as a carbon source. A finished product is prepared by adding the oxygen-containing organic compound, a carburizer and a surfactant into a reactor, uniformly mixing by stirring to form reverse microemulsion, heating to 70-200 DEG C to react the compounds for 24-96 h, stopping heating, filtering, washing and drying. The method has advantages of high powder purity, low energy consumption, good monodispersity, good solubility, good chemical stability, easy controllable preparation, large-scale production, and the like.

Owner:CHANGZHOU XIAOGUO INFORMATION SERVICES

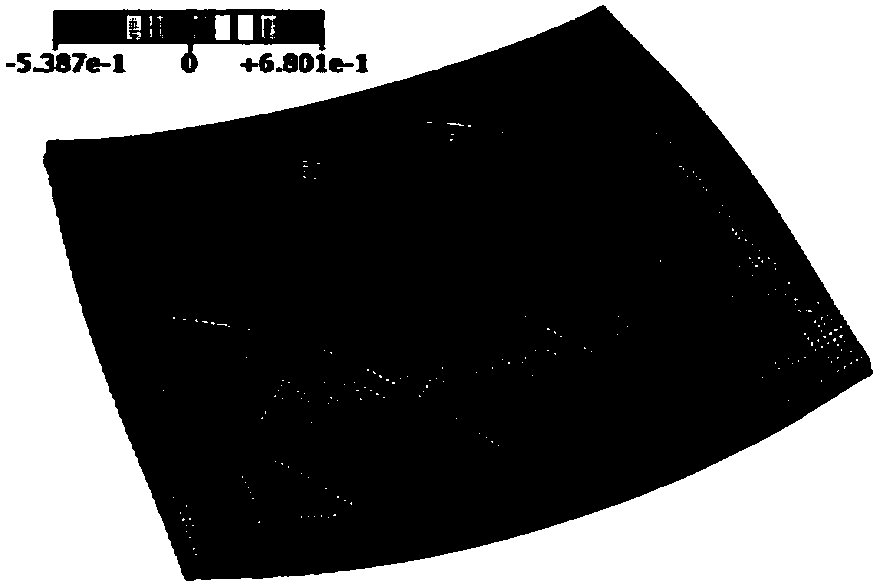

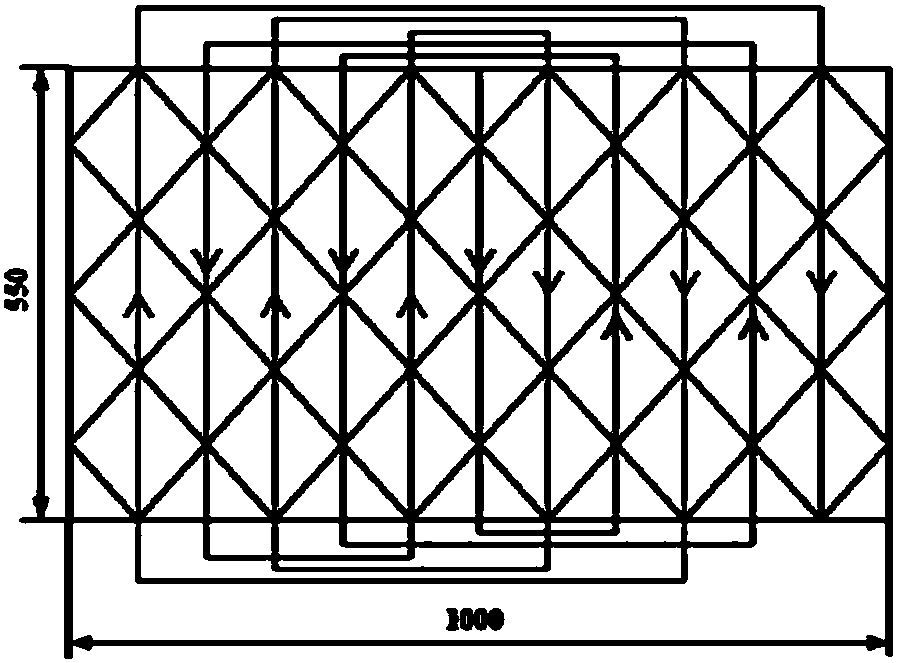

Milling method for controlling wall thickness uniformity of a thin-wall structural member

ActiveCN109840337AAvoid being too rigidGood for deformation controlMilling equipment detailsSpecial data processing applicationsFinite element analysis softwareMachining deformation

The invention discloses a wall thickness uniformity control milling method for a thin-wall structural part. A workpiece model and J C constitutive model are imported into ABAQUS finite element analysis software. milling path simulation is carried out according to the optimal milling process parameters determined by the high-speed milling test; According to a simulation result, a combination scheme of different overall feeding modes and feeding paths in a cavity is formulated, and finally, an optimal feeding path scheme is determined through a wallboard milling test, so that workpiece deformation is most beneficial to keeping of wall thickness uniformity in the milling process, and wall thickness uniformity control is achieved. The whole feeding path is bilaterally symmetrical, a compositefeeding mode combining spiral feeding and cycloid feeding is adopted in a single cavity, the machining time is short, and the stability of the machining process is improved; The machining deformationof the wallboard structural part is reduced by 40%, the machining efficiency is improved, the service life of a cutter is prolonged, and the machining cost is reduced.

Owner:SHANGHAI JIAO TONG UNIV +1

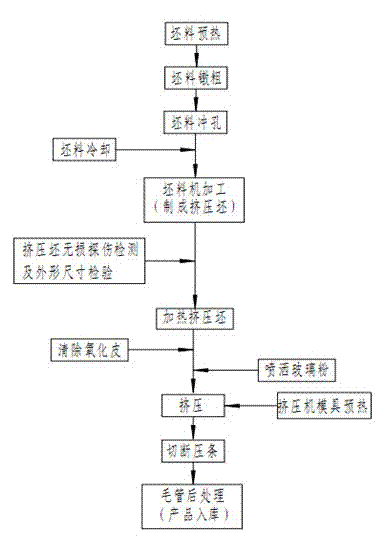

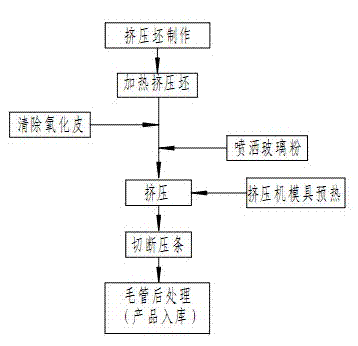

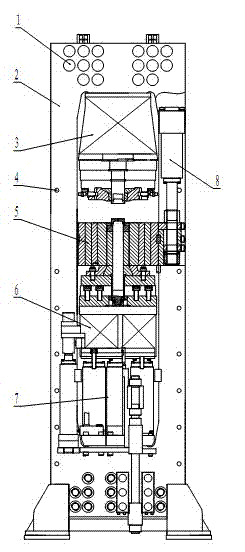

Method for preparing large-diameter seamless tubular product by squeezing equipment

ActiveCN103691761AGuarantee product qualityReduce eccentricityHigh volume manufacturingProcess engineering

The invention provides a method for preparing a large-diameter seamless tubular product by squeezing equipment, which is used for scale production of large-diameter special alloy tubes. The method comprises the following steps: firstly, pre-processing a blank on a blank producing machine; performing turning on the outer circumference, the end face and the inner hole wall of the blank by machine tool equipment; heating the blank in a heating furnace or an electric furnace; squeezing to form a tubular billet on a large-scale squeezing machine; and finally, processing the tubular billet. The method comprises the following operation steps: a, pre-heating the squeezed blank; b, upsetting the blank; c, punching the blank; d, machining the squeezed blank; e, heating the squeezed blank; f, carrying out a squeezing process; g, cutting off an excess pressure part and taking out the squeezed tubular billet; and h, post-processing the tubular billet. According to the method provided by the invention, the large-scale squeezing equipment and the process steps with high operability are utilized, so that not only can the quality of the large-diameter seamless tubular product be ensured, but also large-diameter tubular products can be produced in scale.

Owner:HEBEI HONGRUN NUCLEAR EQUIP SCI & TECH CO LTD

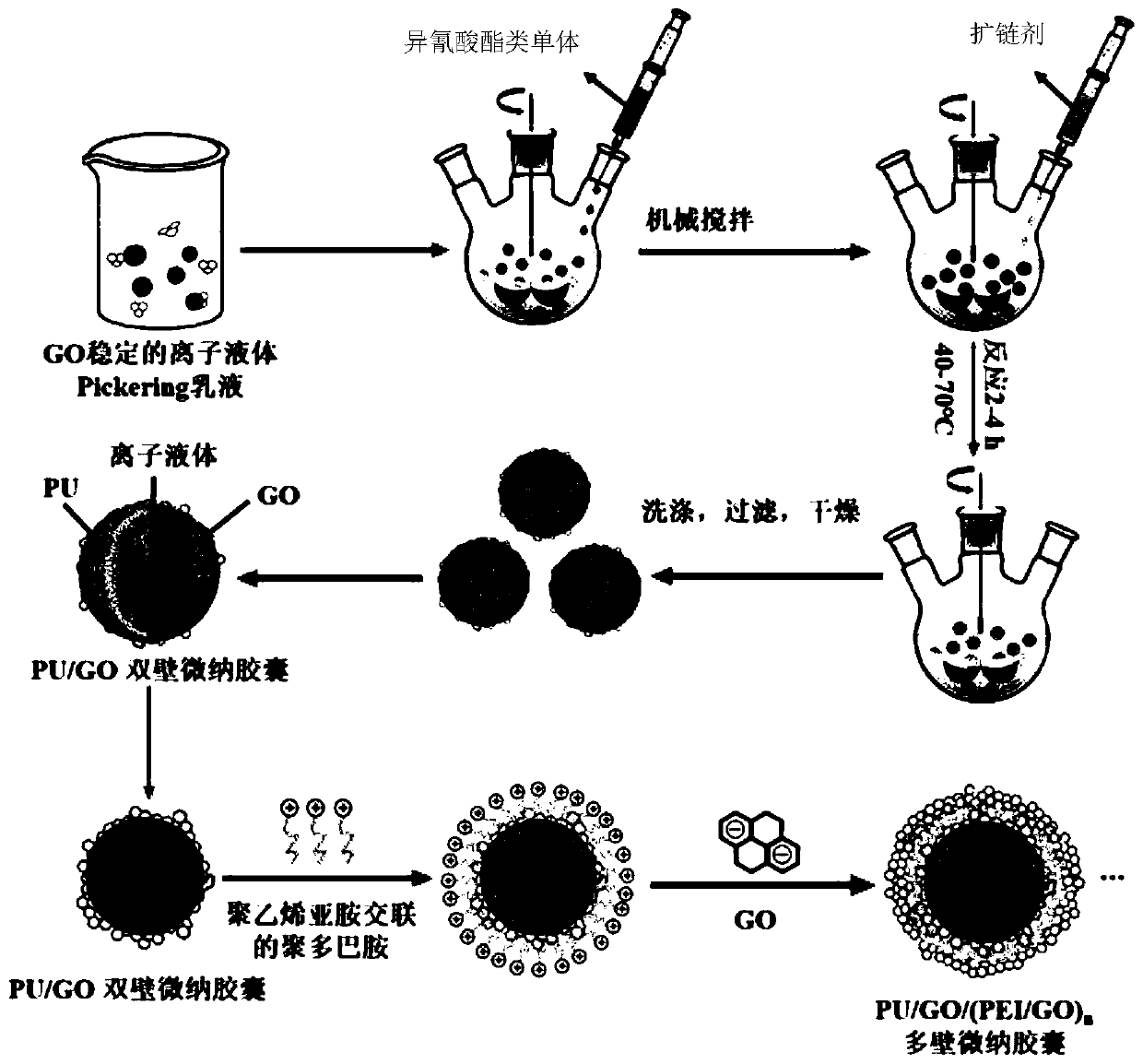

Graphene oxide hybrid multi-wall self-lubricating micro-nano capsule and preparation method thereof

ActiveCN110681324AImprove thermo-oxidative stabilityIncrease relative volatilityMicroballoon preparationMicrocapsule preparationIonic liquidMixed systems

The invention relates to a graphene oxide hybrid multi-wall self-lubricating micro-nano capsule and a preparation method thereof. An ionic liquid is adopted as a core material of the micro-nano capsule, and the structure of the wall material is polyurea / graphene oxide / (polyethyleneimine / graphene oxide)n inside out. The preparation method includes the steps: (1) preparing a mixture including graphene oxide, an ionic liquid and water; (2) mixing the mixture and an isocyanate monomer, then adding a chain extender, and performing heating for a reaction so as to obtain an ionic liquid-coated polyurea / graphene oxide double-walled micro-nano capsule; (3) preparing a mixed system containing polyethyleneimine, dopamine hydrochloride and a buffer solution; (4) mixing the micro-nano capsule obtainedin the step (2) with the mixed system, and performing a reaction at room temperature so as to obtain a dopamine-polyethyleneimine-modified polyurea / graphene oxide double-walled micro-nano capsule; and(5) mixing the micro-nano capsule obtained in the step (4) with a graphene oxide aqueous solution, and performing stirring for a reaction.

Owner:NORTHEAST GASOLINEEUM UNIV

Double-loaded core-shell hydrogel, preparation method and application thereof

ActiveCN109734174AAchieve the effect of removing ammonia nitrogenWide variety of sourcesWater contaminantsTreatment with aerobic and anaerobic processesFreeze-dryingNutrient solution

The invention discloses a double-loaded core-shell hydrogel, a preparation method and an application thereof. The method includes, firstly, mixing natural polymer with adsorption functional groups anda polyacrylic acid aqueous solution, adding denitrifying bacteria, a nutrient solution and a pH regulator to obtain a core matrix after complete mixing; then adding Ca2+-containing salt and gluconicacid lactone into the nuclear matrix to obtain a mixed solution; secondly, pouring the mixed solution into a mold, dripping a hydrophilic natural polymer solution, and foaming to obtain a porous foaming shell matrix; thirdly, preforming physical crosslinking gelation forming on the porous foamed core-shell matrix to obtain a porous core-shell wet gel; placing the porous core-shell wet gel in deionized water, dialyzing and freeze drying to obtain a single-load core-shell hydrogel; and finally, soaking the single-loaded core-shell hydrogel in nitrobacteria solution and freeze-drying to obtain the double-loaded core-shell hydrogel; The preparation method has simple process operation, no pollution and wide source of raw materials, and the prepared double-loaded core-shell hydrogel has the effect of removing ammonia nitrogen.

Owner:SHAANXI UNIV OF SCI & TECH

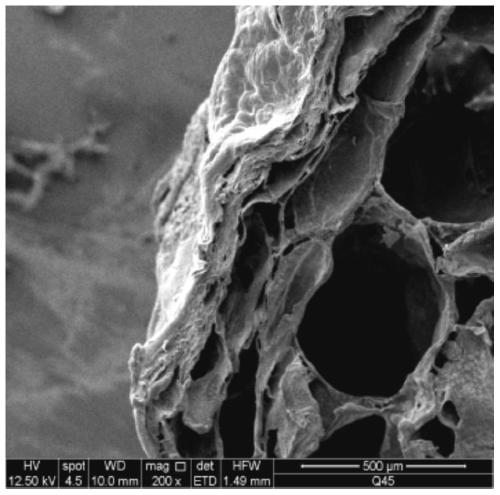

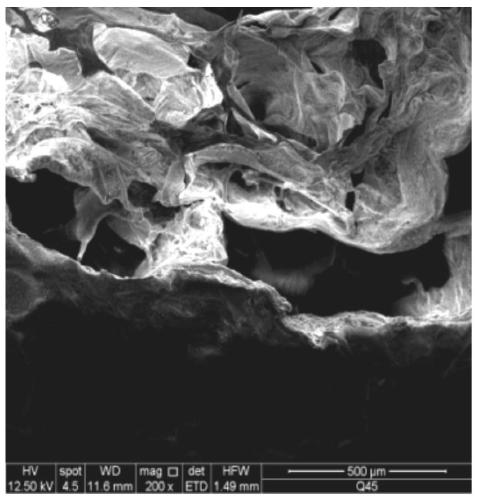

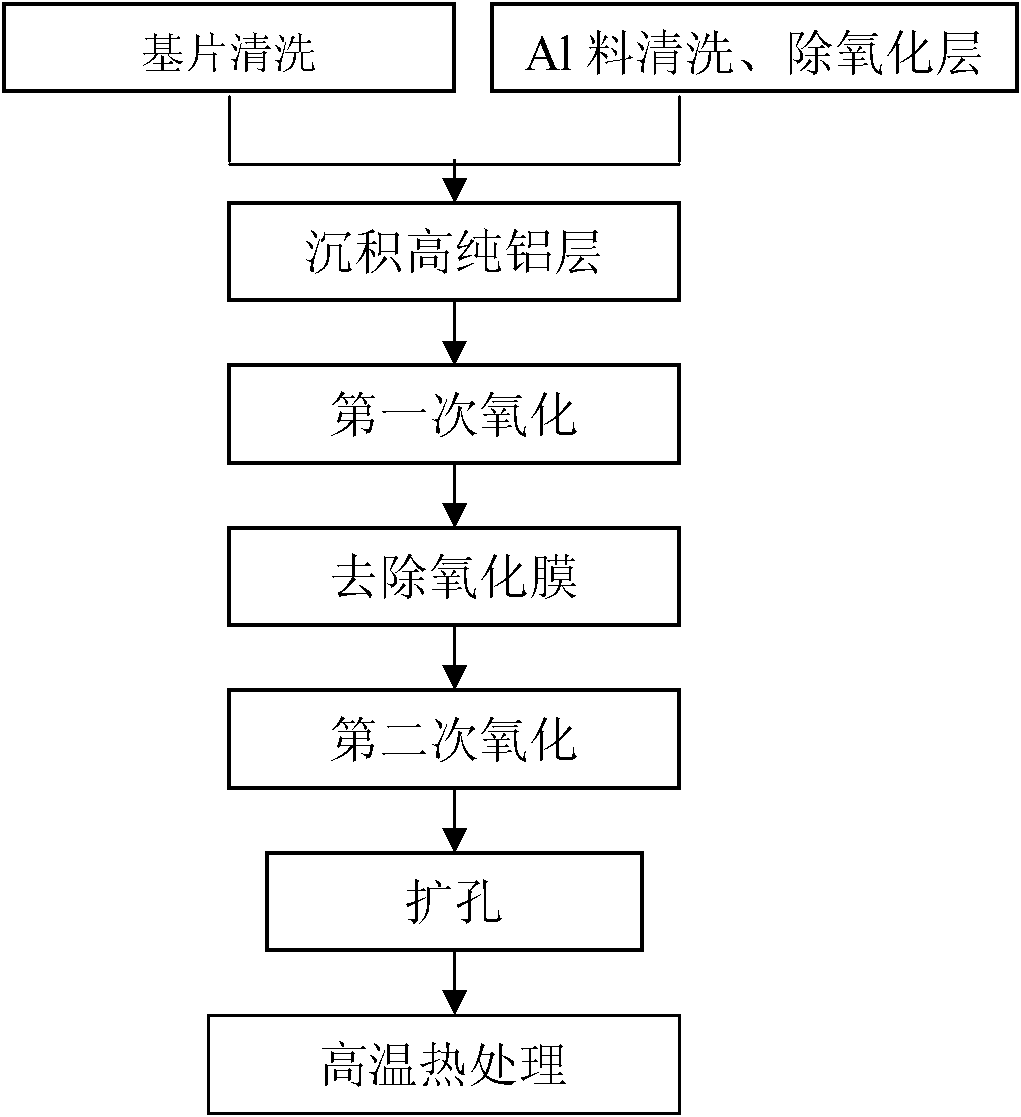

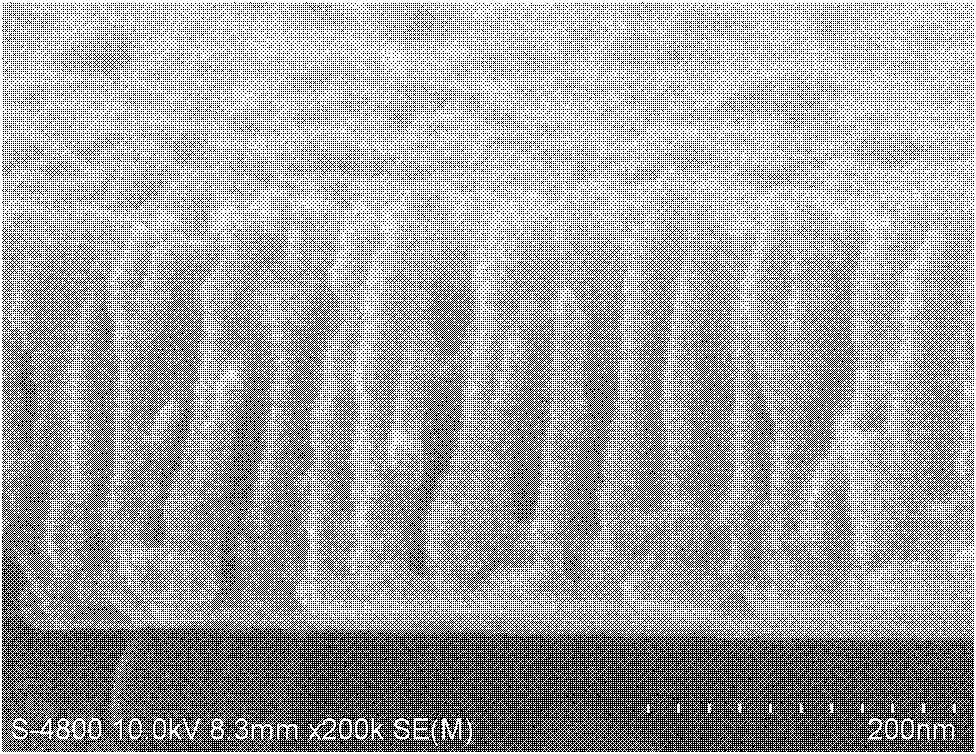

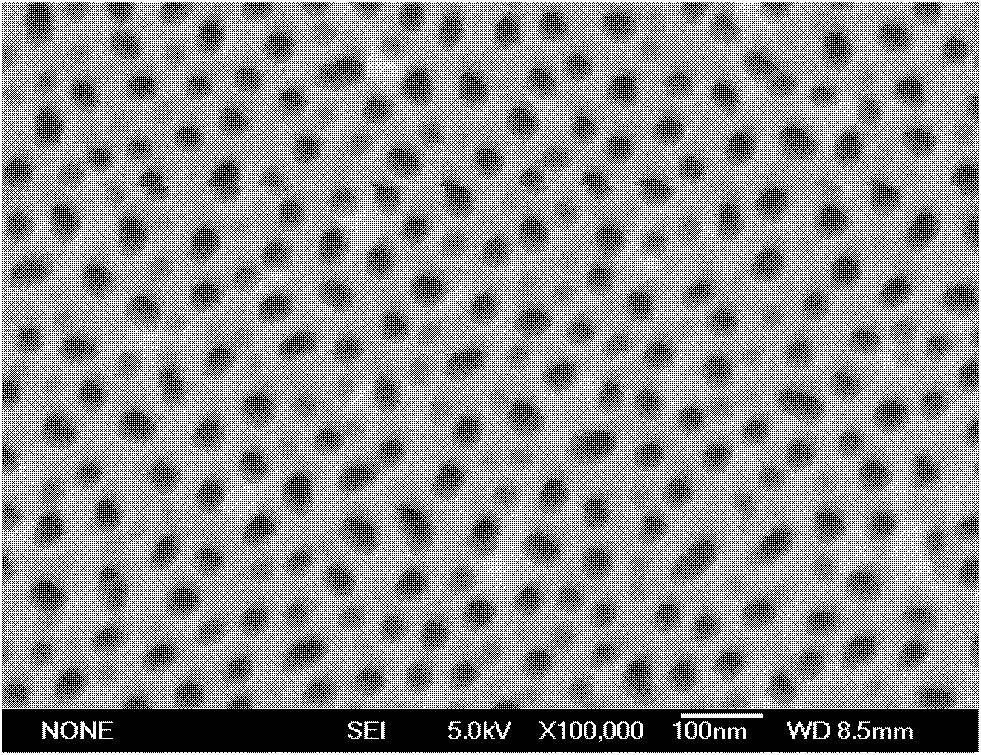

Preparation method of high transmission glass-based porous aluminum oxide substrate

InactiveCN101886247AHigh mechanical strengthEasy to get materialsAnodisationVacuum evaporation coatingAnode oxidationPore diameter

The invention provides a preparation method of a novel glass-based porous aluminum oxide substrate. The preparation method comprises the following steps of: firstly, preparing a high purity aluminum film by using glass as a substrate and adopting a vacuum thermal evaporation method; secondly, generating a porous aluminum oxide layer by using a primary anode oxidation method or a secondary anode oxidation method; thirdly, optimizing pore diameters of the porous aluminum oxide layer by using a pore expanding process; and fourthly, improving the transmission of the whole glass-based porous aluminum oxide substrate by using high temperature annealing treatment. The glass-based porous aluminum oxide substrate has favorable mechanical strength, ordered aluminum oxide pore heights and high transmission of visible light.

Owner:WUHAN UNIV OF TECH

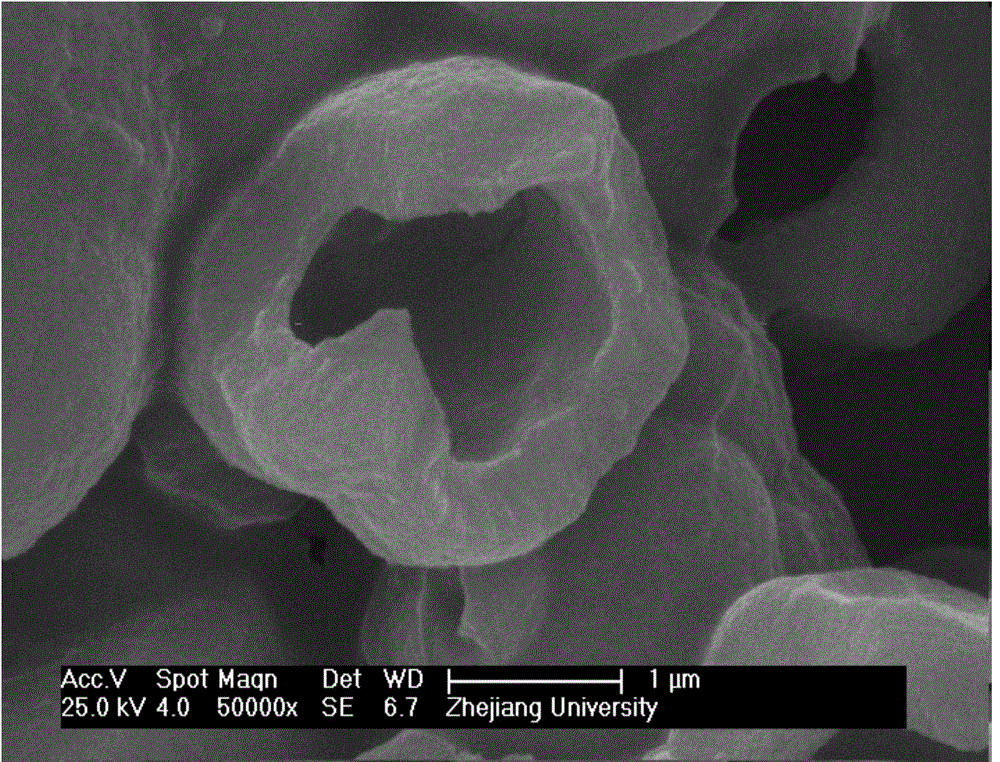

Preparation method of open tin dioxide hollow spheres

InactiveCN104876259AUniform sizeControllable wall thicknessMaterial nanotechnologyTin oxidesTin dioxideAlcohol

The invention relates to the field of nanomaterial preparation and aims at providing a preparation method of open tin dioxide hollow spheres. The preparation method of open tin dioxide hollow spheres comprises the following steps: mixing absolute ethyl alcohol with deionized water to obtain a solvent, next, dissolving sodium stannate in a solvent and thoroughly stirring to obtain a tin salt solution; next, weighing urea and adding the urea to the tin salt solution, stirring and performing ultrasonic treatment to obtain a mixed solution; next, transferring the mixed solution to a polytetrafluoroethylene lined stainless steel reaction kettle, performing a hydrothermal reaction, naturally cooling and then centrifugally separating or filtering the product of the hydrothermal reaction to obtain precipitate, and finally, washing and drying the precipitate to obtain the high-purity open hollow sphere tin dioxide powder. The tin dioxide powder prepared by use of the method is capable of avoiding floating and enrichment of SnO2 in use, improving the stability of an Ag / SnO2 and prolonging the service life of the material, and then suitable for large-scale industrial production.

Owner:ZHEJIANG UNIV

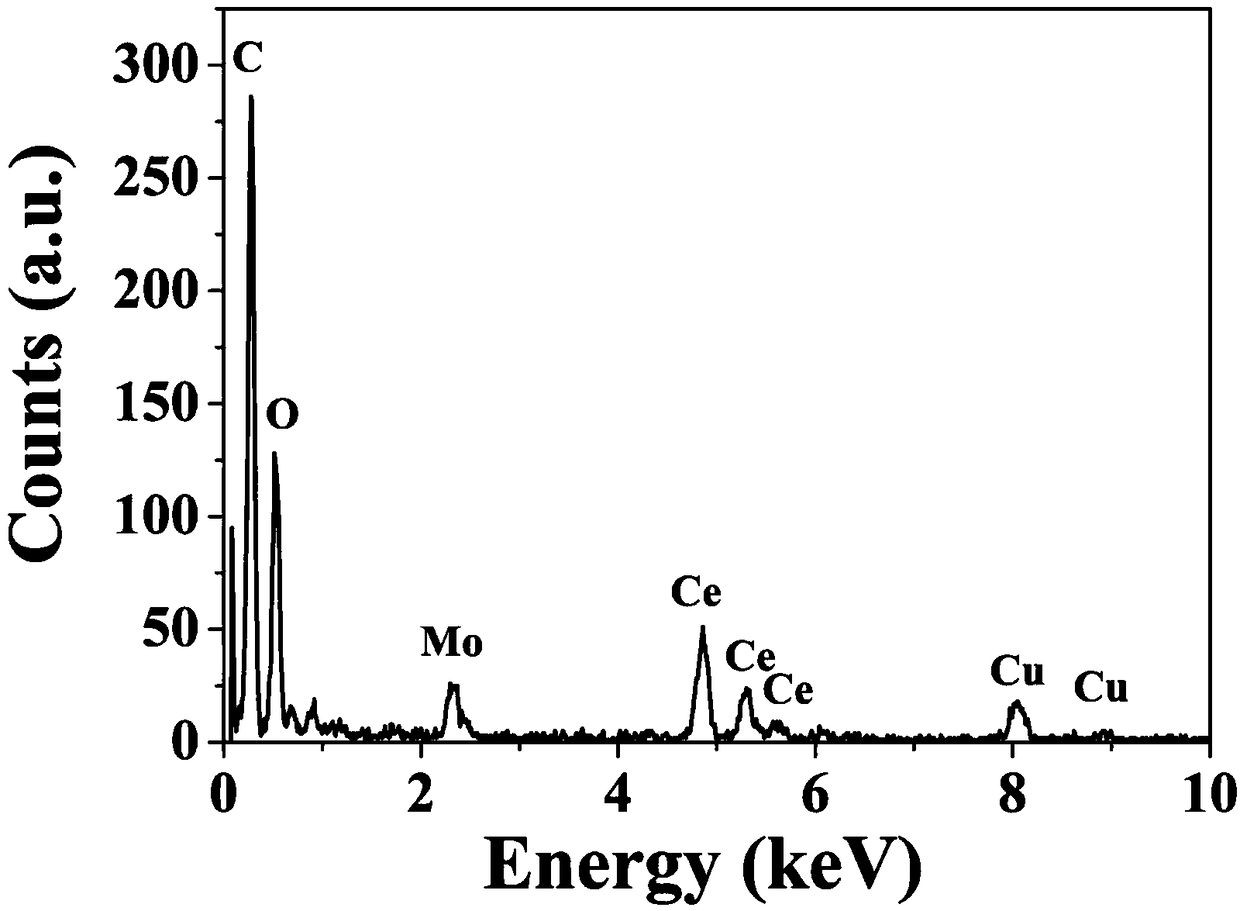

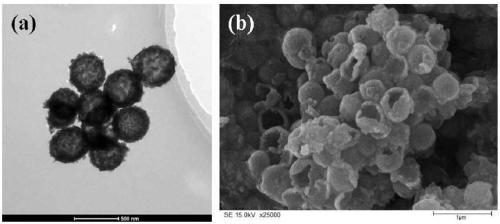

Method for preparing rare-earth transition metal composite oxide porous hollow spheres

InactiveCN109160544AEvenly distributedThickness is easy to controlMaterial nanotechnologyHeterogenous catalyst chemical elementsRare earthCatalytic oxidation

The invention discloses a method for preparing rare-earth transition metal composite oxide porous hollow spheres and belongs to the field of inorganic nanometer materials and heterogeneous catalysis.The method comprises the following steps: 1, dissolving a rare-earth metal source and a transition metal source in a polyol medium, and synthesizing a solid spherical alkoxide precursor with excellentdispersion by adopting a solvothermal method; and 2, performing heat treatment on the precursor under specific conditions, and synthesizing the rare-earth transition metal composite oxide porous hollow spheres based on an unbalanced heat treatment method. The method disclosed by the invention has the advantages that the raw material price is low, the hollow structure material is directly obtained, and the prepared rare-earth transition metal composite oxide porous hollow spheres have the advantages of being uniform in metal element dispersion, controllable in composition and size, capable ofrealizing porous distribution of the shell layer and controllable in thickness; and when the hollow spheres are applied to a catalytic reaction, the contact area between the substrate molecule and catalytic active sites can be greatly enlarged, the interface synergy among different components of the rare-earth transition metal oxides contributes to transmission of reactive oxygen species at the heterogenous interface and transfer of electrons, and the activity of the catalytic oxidation reaction is obviously improved.

Owner:CHINA UNIV OF MINING & TECH

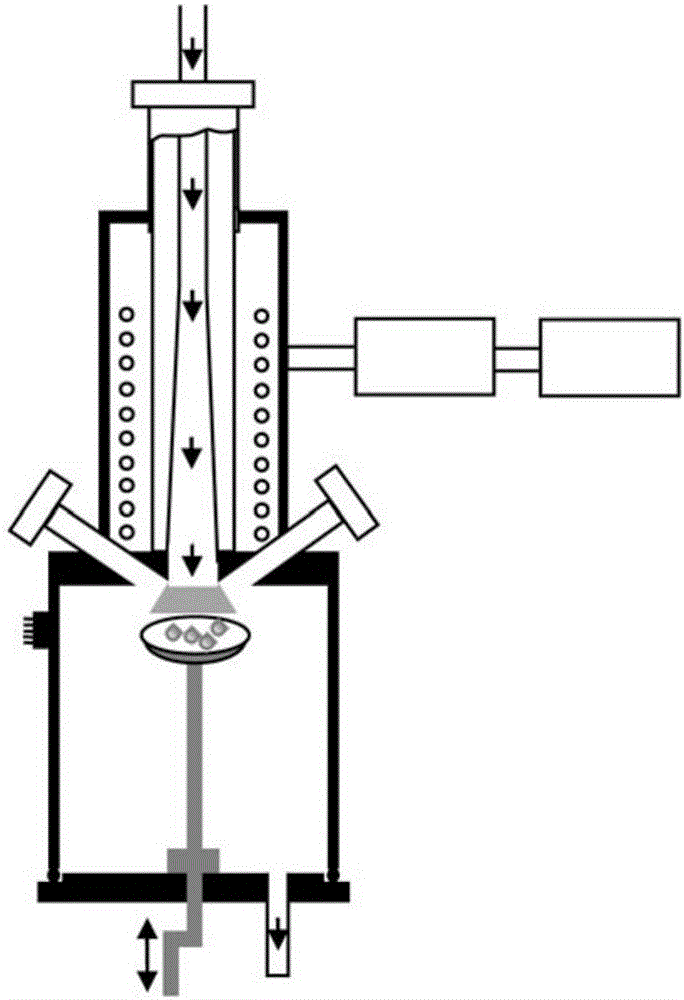

Method for manufacturing fusion pellet based on microfluid

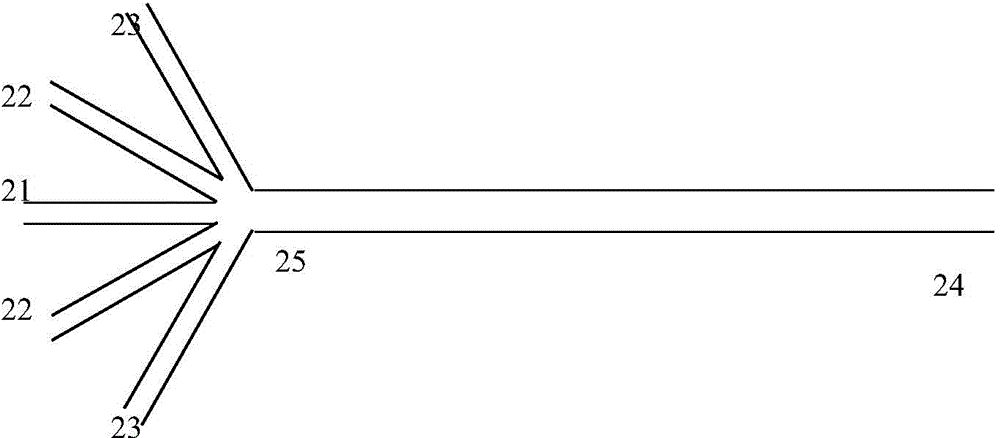

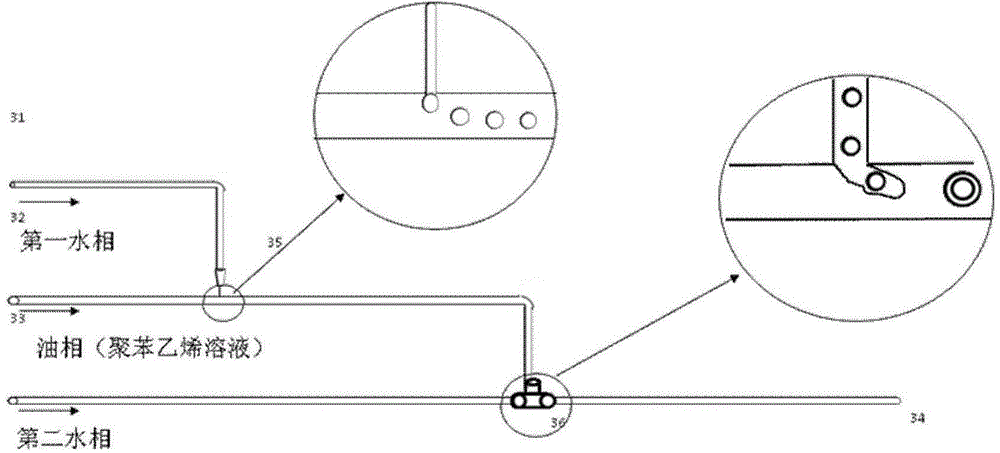

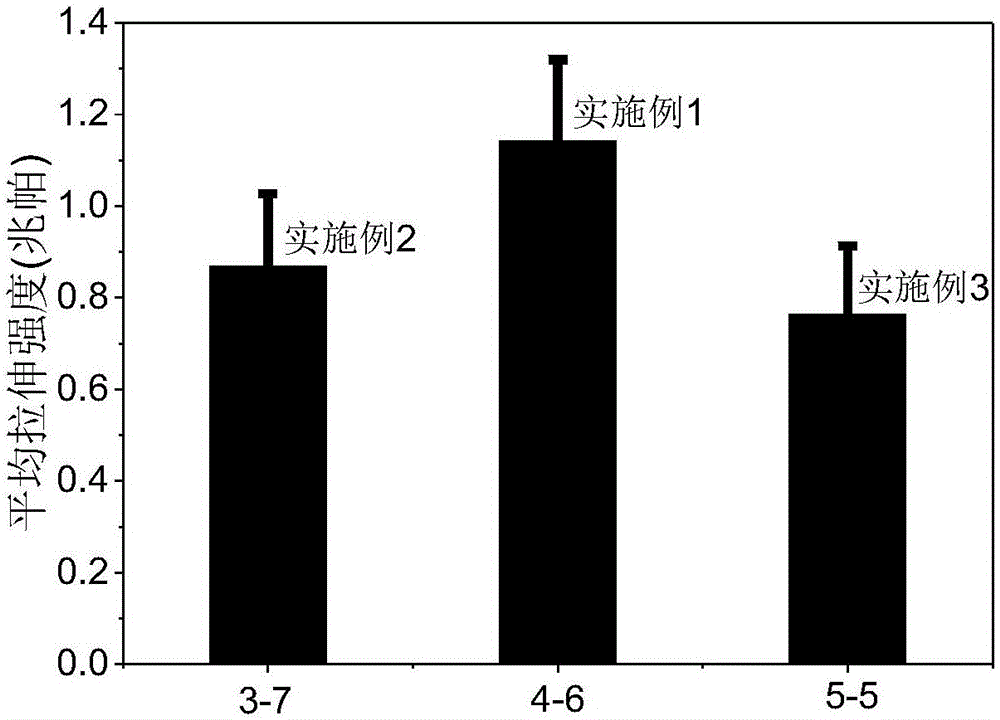

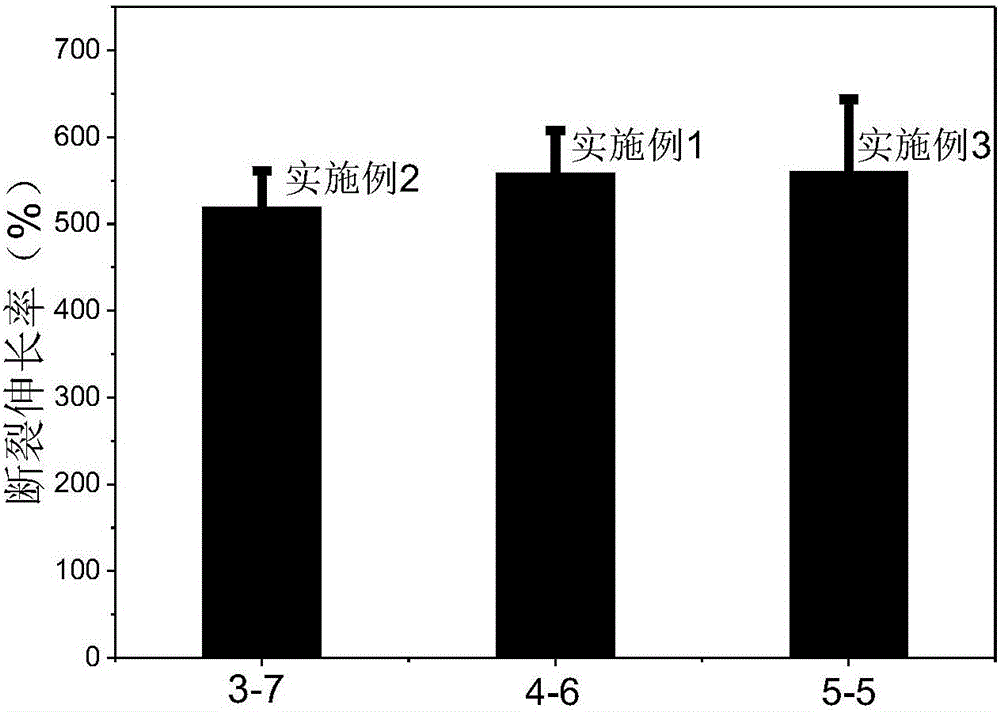

InactiveCN104091620AAchieved diameterControllable diameterNuclear energy generationThermonuclear fusion reactorEmulsionChannel network

The invention relates to a method for manufacturing a fusion pellet based on a microfluid channel, in particular to a method for manufacturing an inertial confinement nuclear fusion pellet based on a microfluid channel technology. According to the method, dual microemulsion is formed by pellet solutions or a front fusion body in a flowing phase by adopting a microfluid channel network system, the inner diameter and the outer diameter of the dual microemulsion are adjusted in real time through an image collecting and analysis system and a flow control system, and finally a preset size is achieved. Then, hollow micro balls meeting the ICF target requirements are formed through curing and drying based on a liquid drop formwork. According to the manufacturing method, the hollow micro balls which are uniform in size and controllable in ball wall can be manufactured, and the ICF requirements are met. The manufacturing method particularly comprises the first step of manufacturing the microfluid channel, the second step of manufacturing the microemulsion, the third step of obtaining the size of the microemulsion, the fourth step of controlling the inner diameter and the outer diameter of the dual emulsion and the fifth step of manufacturing the fusion pellet.

Owner:SOUTHEAST UNIV

Polyvinyl alcohol hydrogel, method for preparing same and application of polyvinyl alcohol hydrogel

The invention relates to polyvinyl alcohol hydrogel, a method for preparing the same and application of the polyvinyl alcohol hydrogel, and belongs to the field of polymeric hydrogel. The method for preparing the polyvinyl alcohol hydrogel includes heating and dissolving polyvinyl alcohol and organic solvents at the temperature of 110-145 DEG C to obtain polyvinyl alcohol solution; allowing the obtained polyvinyl alcohol solution to stand still to naturally cool the polyvinyl alcohol solution until the temperature of the polyvinyl alcohol solution reaches the room temperature so as to obtain polyvinyl alcohol with gel structures; removing the organic solvents from the polyvinyl alcohol with the gel structures to obtain the polyvinyl alcohol hydrogel. The organic solvents are blended solvents with dimethyl sulfoxide and N-N, dimethylformamide, and a volume ratio of the dimethyl sulfoxide to the N-N, dimethylformamide is 0.25-1; the mass concentration of the obtained polyvinyl alcohol solution is 10-30%. The polyvinyl alcohol hydrogel, the method and the application have the advantages that an appropriate proportion of solvents are applied when the polyvinyl alcohol solution is prepared, and accordingly the polyvinyl alcohol hydrogel can be prepared from the obtained polyvinyl alcohol solution in standing and natural cooling modes.

Owner:ZHENGZHOU UNIV

Method for manufacturing steel-plastic composite pipe with rotational moulded inner wall and composite glass fiber outer wall

The invention relates to a method for manufacturing a steel-plastic composite pipe with a rotational moulded inner wall and a composite glass fiber outer wall. The method aims to solve the forming problem of the steel-plastic composite pipe, the outer wall of the steel-plastic composite pipe is made of composite glass fibers, and the inner wall of the steel-plastic composite pipe is a plastic layer. The method includes the steps of manufacturing a middle steel pipe layer, founding of a rotational moulded inner layer and winding of resin glass fibers containing sand. A smooth rotational moulded inner layer of the inner wall is obtained, the process is simple, special pressing moulds are not needed, parameters such as the wall thickness and coverage are easy to control and can meet design requirements easily, viscosity between layers is strong, the bonding degree is high, and the method is especially suitable for manufacturing steel-plastic composite pipes with large apertures.

Owner:ZHEJIANG SHUANGLIN PLASTIC MACHINERY

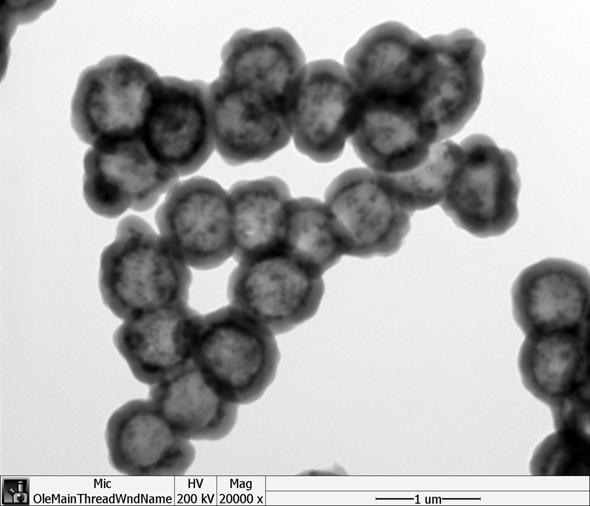

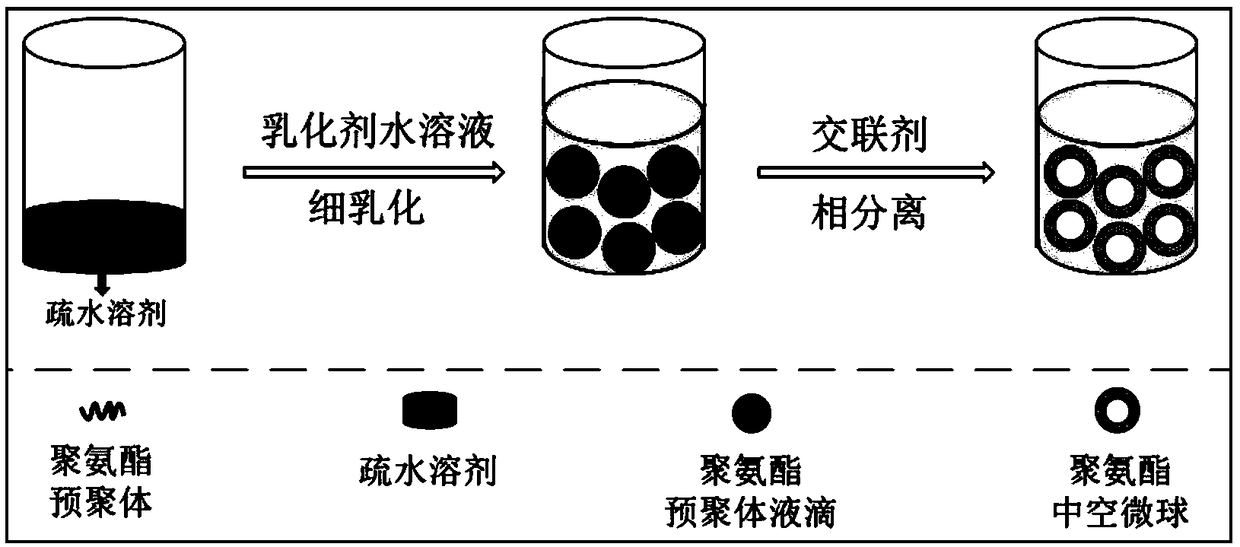

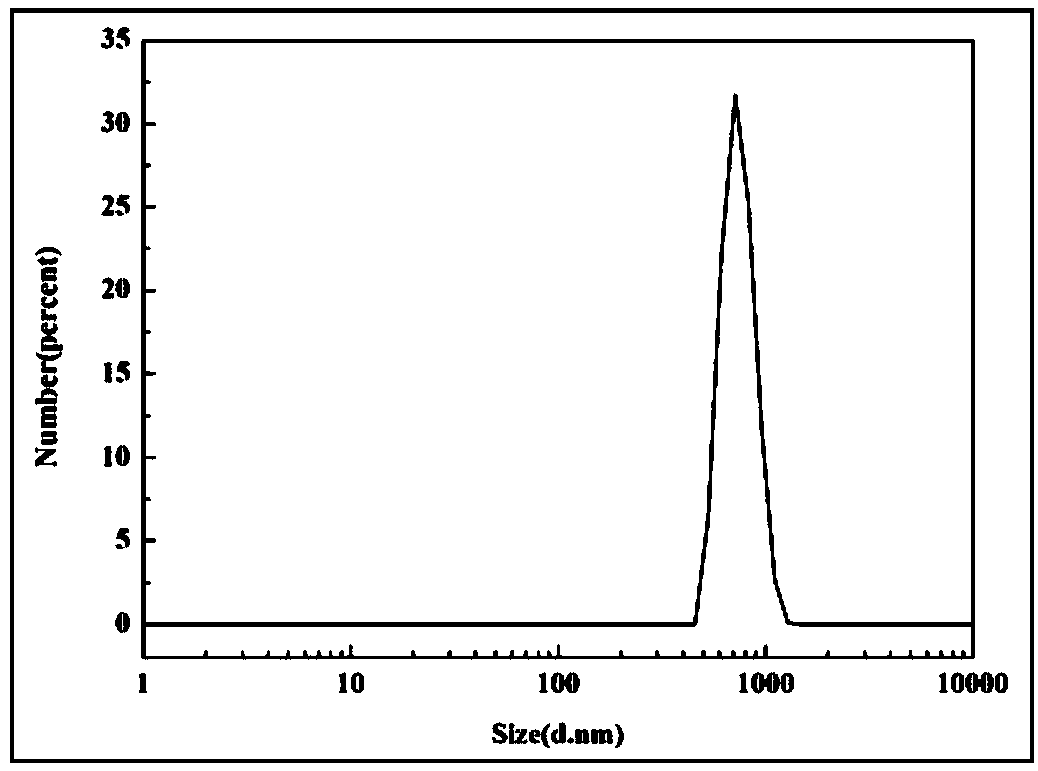

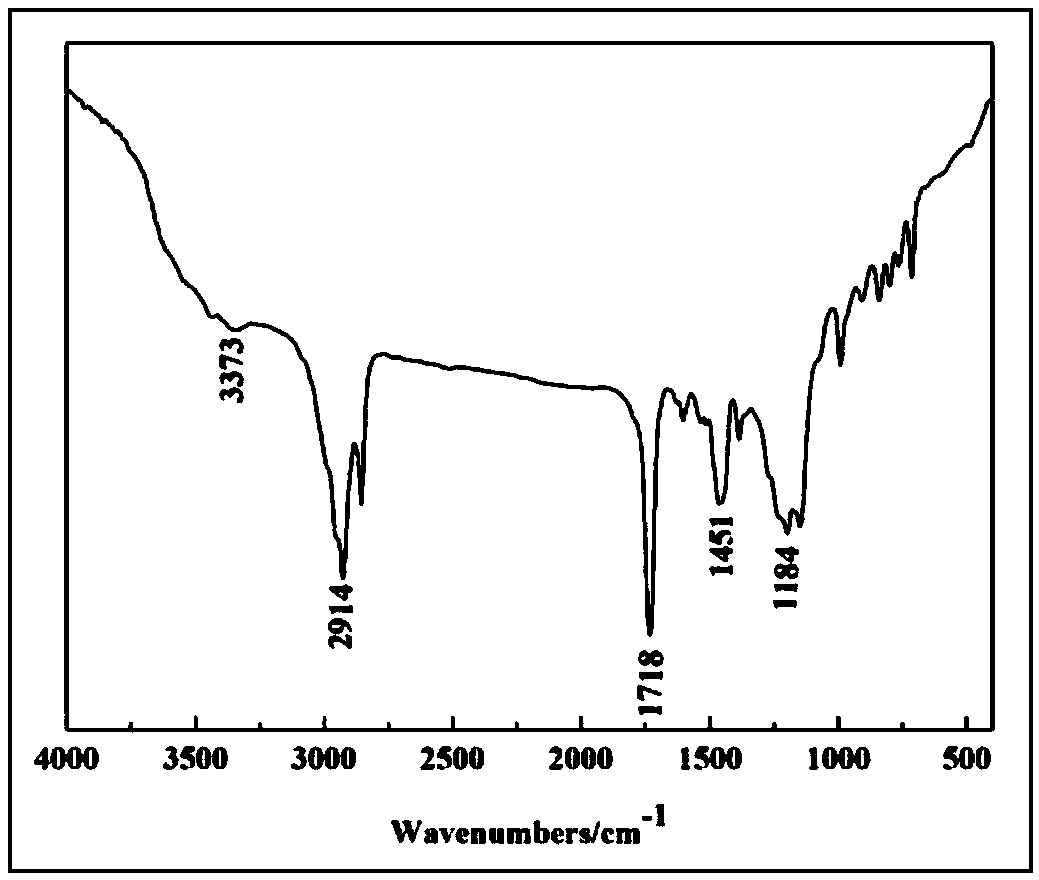

Preparation method of polyurethane hollow microspheres

InactiveCN108794721AImprove stabilityGood hollow structureMicroballoon preparationMicrocapsule preparationMicrospherePapermaking

The invention discloses a preparation method of polyurethane hollow microspheres. The preparation method of the polyurethane hollow microspheres comprises the following steps: synthesizing a polyurethane prepolymer at first; and then carrying out homogeneous emulsification preparation on the polyurethane prepolymer, a hydrophobic solvent and water by miniemulsion polymerization. By a miniemulsionprocess, the prepared polyurethane hollow microspheres are adjustable in size, the wall thickness is controllable, the stability is good, and the water dispersibility is excellent. The polyurethane hollow microspheres have excellent shielding property, by the hollow structure, the heat insulation property of a coating layer can be improved, and the polyurethane hollow microspheres can be used as covering pigment, an ultraviolet-resistant additive, a hand feeling modifier and the like, and can be widely applied to the industries of coatings, papermaking, leather and the like.

Owner:ANHUI UNIVERSITY

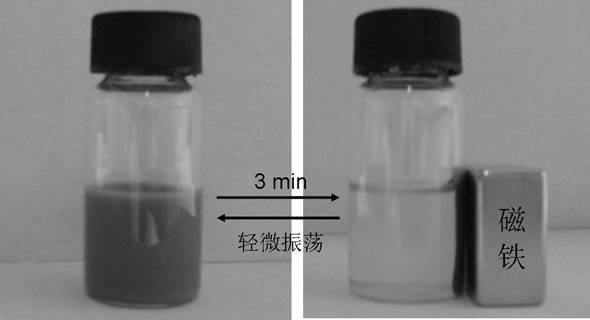

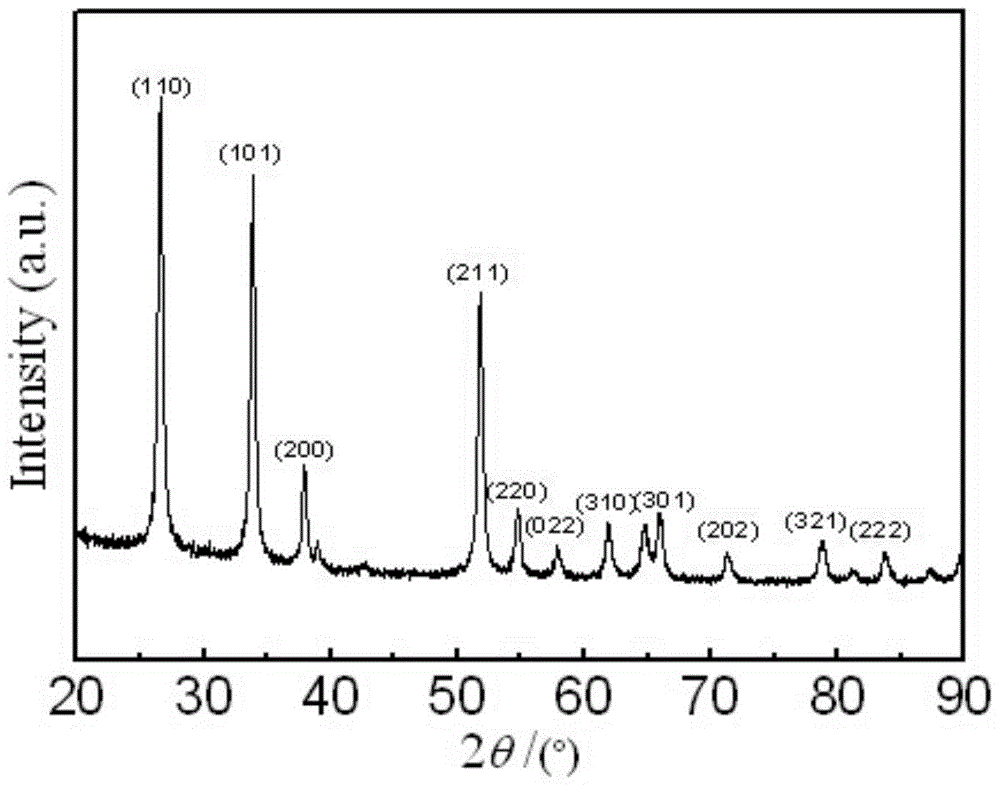

Method of preparing perovskite type zirconate hollow nano material

InactiveCN101407337AControllable wall thicknessGood dispersionZirconium compoundsCooking & bakingZirconate

The invention relates to a preparation method of a perovskite type zirconate hollow nano-material, comprising the following steps: 1. under the condition of stirring, 0.001 to 0.005 Mol of perovskite type compound with general form of ABO3 and containing barium or strontium metal compounds at A and zirconium metal compounds at B is dissolved in 20 to 30mL of deionized water, a suitable amount of inorganic alkali is added and stirred for 20 to 60 minutes, the evenly dispersed mixed liquor is obtained; 2. the mixed liquor is put into a polyfluortetraethylene reaction container with the volume of 40mL, sealed and put into a baking oven, the temperature in which is 180 to 220 DEG C, and reacted for 12 to 48 hours; 3. after natural cooling of the reaction product, upper lye is removed, under the condition of magnetic stirring, the deionized water is used to wash the product powder for 30 to 60 minutes; 4. after centrifugal separation, ultrasonic cleaning is carried out for 20 to 40 minutes, then 10 to 30mL of the acetic acid or formic acid is added to wash for 30 to 60 minutes; and 5. after the centrifugal separation, washing by absolute ethyl alcohol and drying in the baking oven at the temperature of 50 to 60 DEG C of the product powder, the target product is obtained.

Owner:TIANJIN POLYTECHNIC UNIV

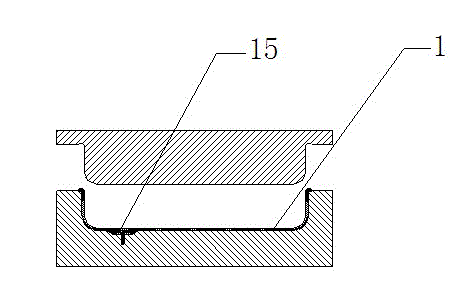

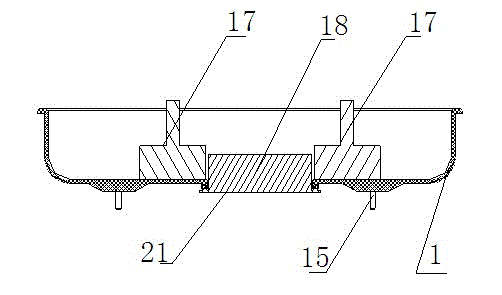

Automobile urea box and forming method thereof

ActiveCN103061855ALow costLow priceExhaust apparatusSilencing apparatusStructural engineeringManufacturing engineering

The invention relates to an automobile urea box and a forming method thereof. The automobile urea box and the forming method are characterized in that the forming method comprises the steps of (1) using an injection molding method to produce an upper half casing and a lower half casing; (2) assembling built-in parts of the upper half casing and the lower half casing after the upper half casing and the lower half casing are formed; (3) welding the assembled upper half casing and the assembled lower half casing integrally; and (4) assembling components and parts on the surfaces of the upper half casing and the lower half casing. By means of the forming method, the design free degree of the built-in parts of a box body can be improved, a large amount of raw materials can be saved, the automobile urea box is simple in structure and good in soundness, the production efficiency is improved, and a production period is shortened.

Owner:YAPP AUTOMOTIVE PARTS

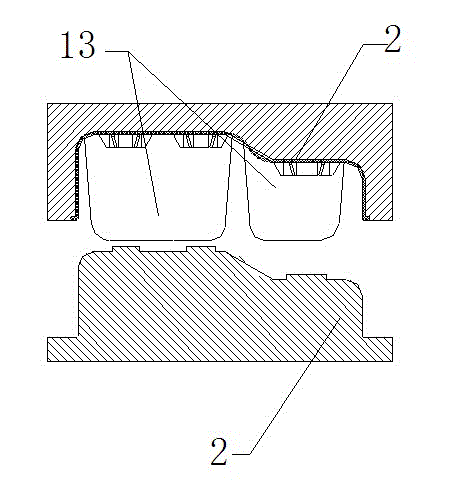

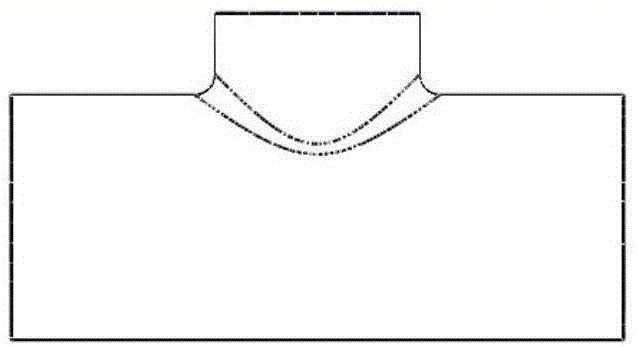

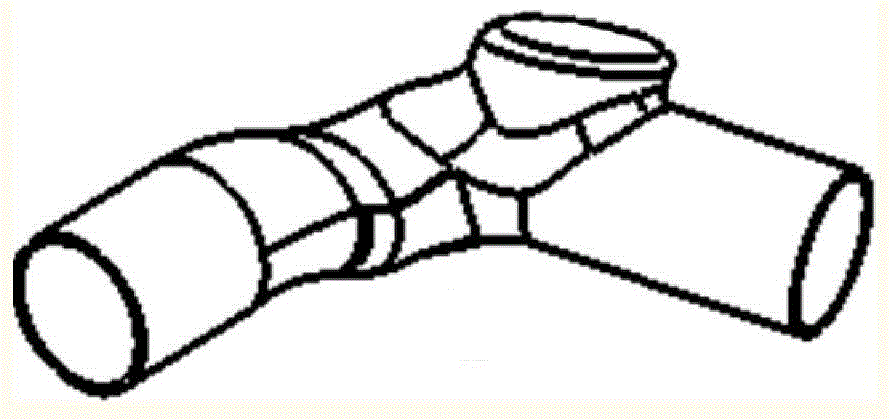

Method for preparing bend t-branch pipe

ActiveCN106734340AControllable wall thicknessUniform distribution of pipe wallEngineeringHigh pressure

The invention discloses a method for preparing a bend t-branch pipe. The method includes the steps that a round pipe blank is cut at first according to the length required by a forming part; then an internal high-pressure forming technology is adopted to prepare the round pipe blank into a T-shaped straight tee directly; the T-shaped straight tee is bent, namely a straight tee part which has already been formed is put into a mold cavity, a mold is closed, and then the straight tee part is formed into a preforming part required; the preforming part is subjected to annealing treatment, and machining stress is removed; and a bent t-branch pipe is put into an internal high-pressure mold for conducting internal high-pressure forming after annealing, and the outer surface of the part is attached to the mold cavity to obtain a final product. The method for preparing the bend t-branch pipe has the advantages that the thickness reduction degree at the bent position is low and the using requirements can be met.

Owner:NINGBO SIMING AUTOMOBILE TECH

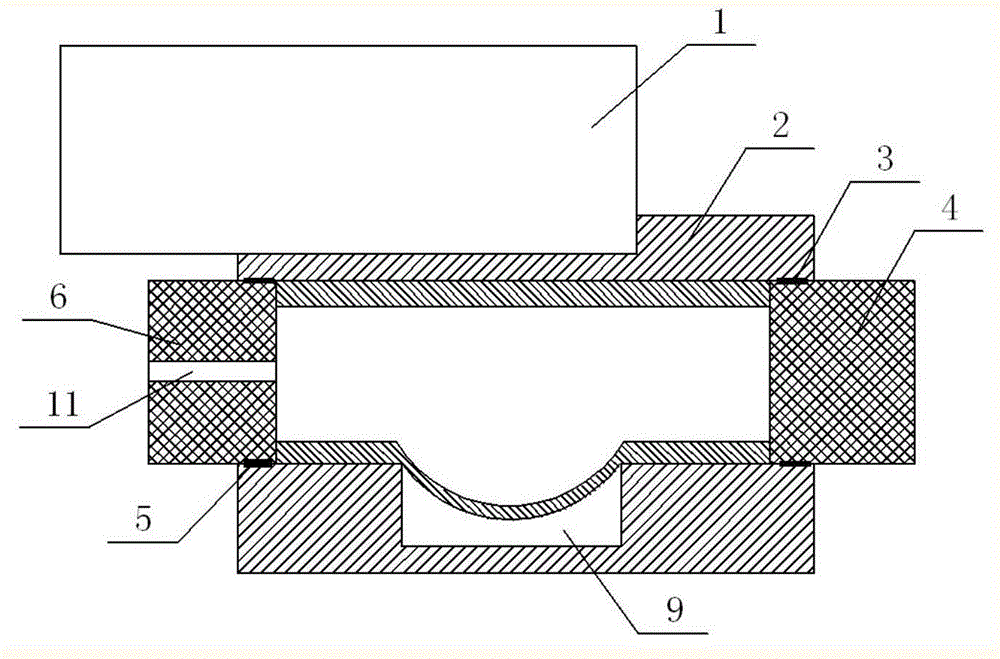

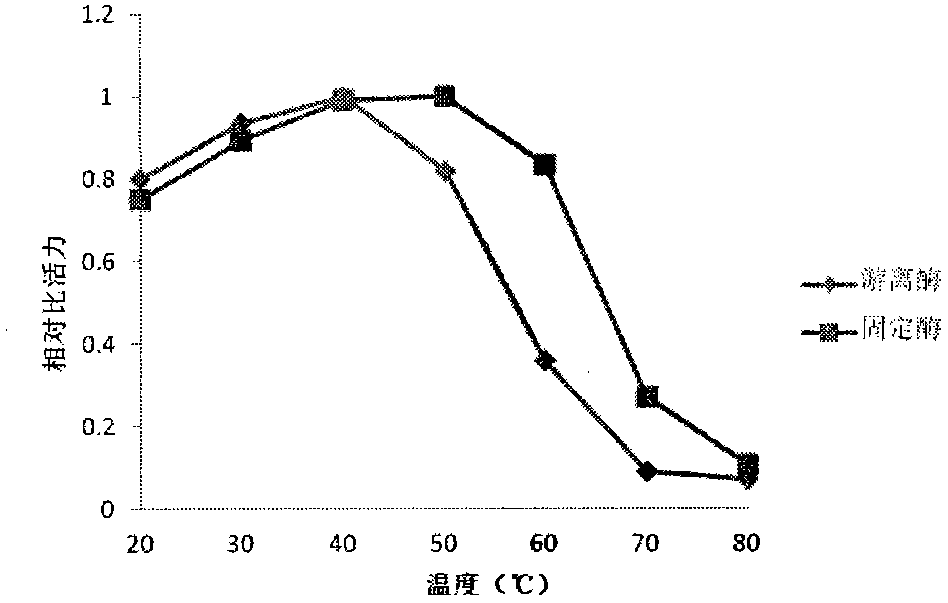

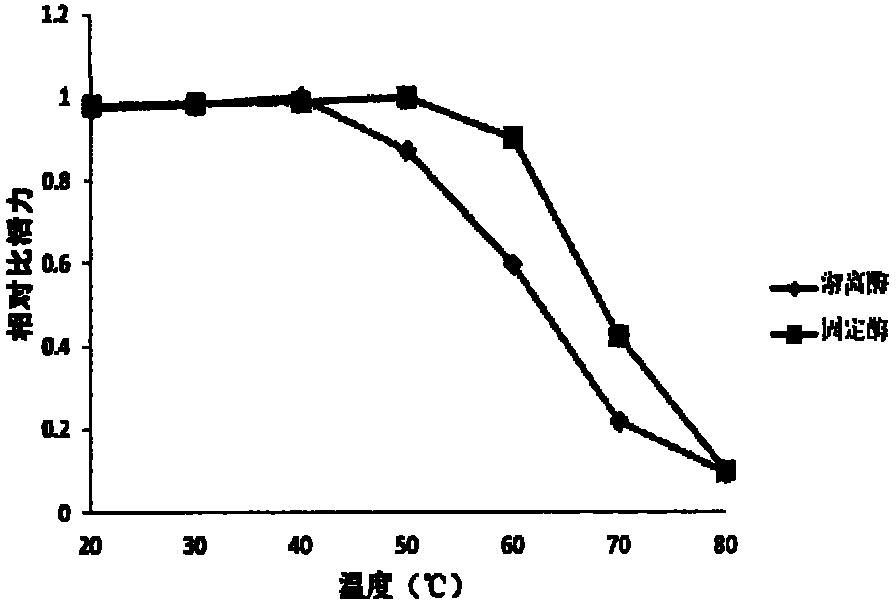

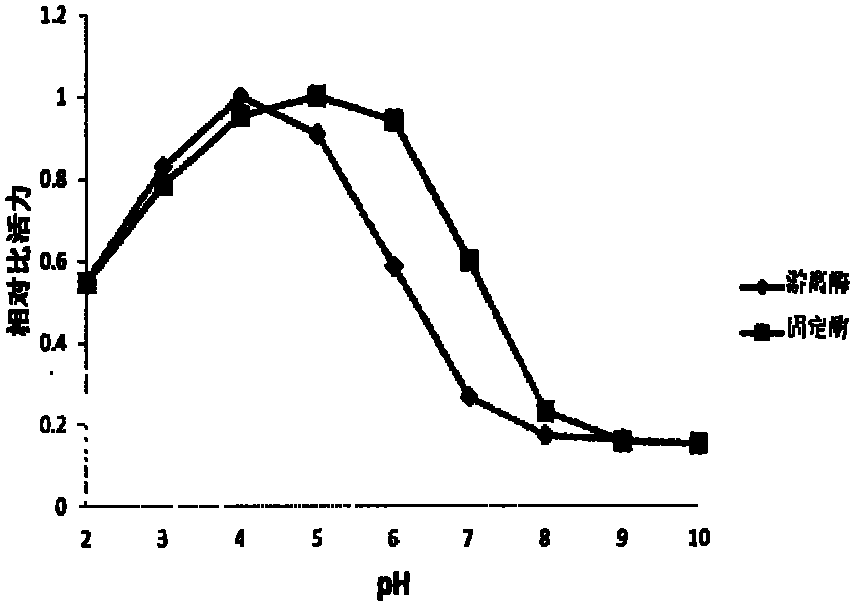

Method of preparing linoleate isomerase micro-capsules on the basis of polyelectrolyte layer-by-layer self-assembly technology

InactiveCN104974996AControllable wall thicknessIncrease the areaOn/in organic carrierHalf-lifeAmorphous calcium carbonate

The invention provides a method of preparing linoleate isomerase micro-capsules on the basis of a polyelectrolyte layer-by-layer self-assembly technology and can solve a problem that free linoleate isomerase is poor in tolerance, is poor in stability and cannot be recycled in industrial production. The method of the invention includes the following steps: with an amorphous calcium carbonate crystal, which is obtained through co-precipitation of calcium carbonate and the linoleate isomerase, as a template and with polyallylamine hydrochloride and sodium polystyrenesulfonate as coating materials, preparing the linoleate isomerase micro-capsules through the polyelectrolyte layer-by-layer self-assembly technology. The micro-capsule is high in activity, excellent in stability and long in half life.

Owner:INNER MONGOLIA AGRICULTURAL UNIVERSITY

Phase-variable microcapsule and its production

InactiveCN100496698CImprove compactnessHigh heat resistanceMicroballoon preparationMicrocapsule preparationAlkaneHeat resistance

The invention is concerned with phase transition tiny capsule and its production. The phase transition tiny capsule relates to solid purse shell and phase transition inner core and the core is packed in the solid purse shell. The shell is thermosetting phenol-formaldehyde resin and the core is one or some alkane with 14 to 20 carbons. The method is easy to control the thickness of wall and the proportion of tiny purse shell and core is same as the ration of material. The shape of tiny purse shell is good with smooth surface and is not reuniting with certain shell and core structure. It has wide range of melting point and the capsule is well during the phase transition with long work time. The rigidity aromatic ring does well in bearing heat, and the capsule shell is phenol-formaldehyde resin and has good tight character and high anti-heating temperature.

Owner:INST OF CHEM CHINESE ACAD OF SCI

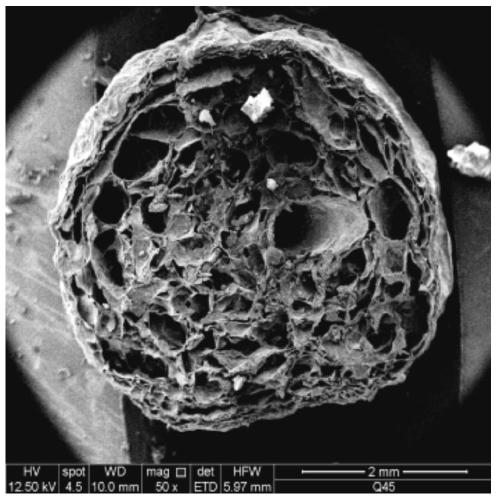

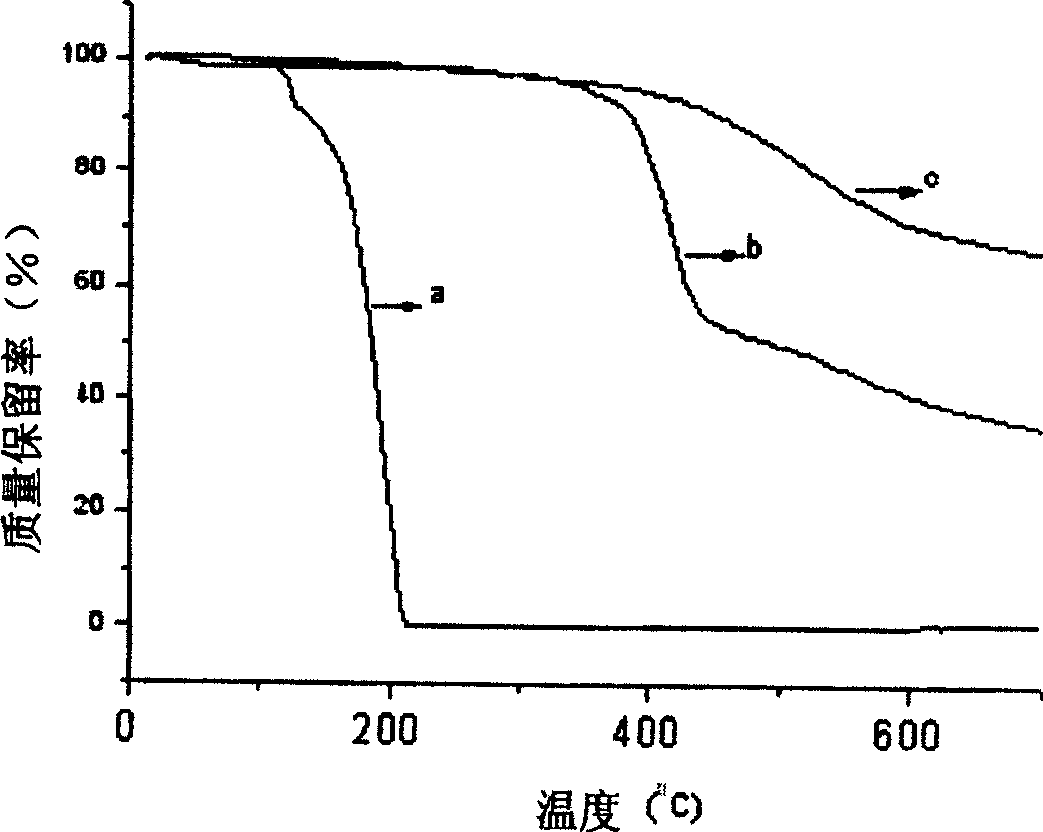

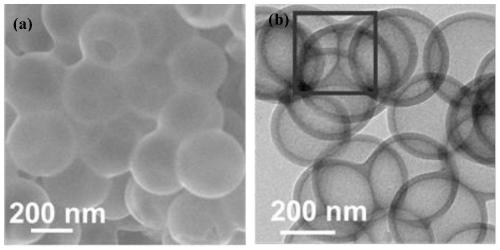

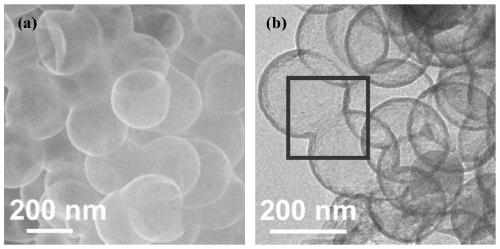

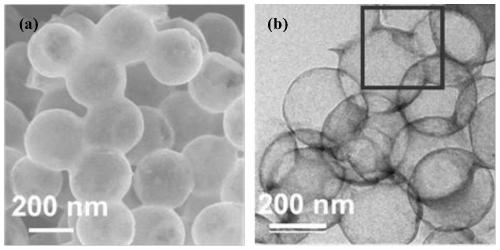

Hollow carbon sphere and preparation method and application thereof

The invention discloses a hollow carbon sphere and a preparation method and application thereof. Firstly, a solution containing resin monomers, a surfactant, ammonia, water and alcohol is prepared, then orthosilicate is added into the solution, and orthosilicate is hydrolyzed to prepare silicon-dioxide suspension; a formaldehyde solution is added into the silicon-dioxide suspension for a polymerization reaction, and a silicon-dioxide resin composite sphere is obtained; the silicon-dioxide resin composite sphere is calcined to prepare a silicon-dioxide carbon composite sphere; silicon dioxide in the silicon-dioxide carbon composite sphere is removed through acid or alkali, and the hollow carbon sphere is obtained. The silicon-dioxide resin composite sphere is synthesized in one step, in other words, the synthesis of silicon dioxide and the resin coating process are combined to solve the problem that the two-step method of the prior art is cumbersome and needs fine regulation. The prepared hollow carbon sphere has a controllable wall thickness, a large pore volume and a large specific surface area.

Owner:FUJIAN INST OF RES ON THE STRUCTURE OF MATTER CHINESE ACAD OF SCI

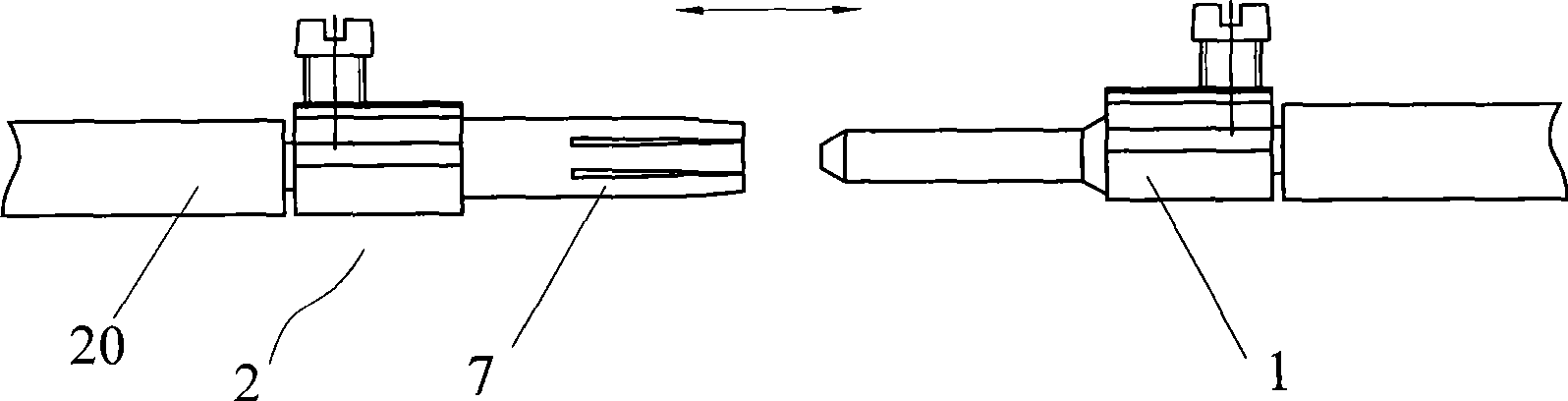

Plug of wiring terminal

ActiveCN101510640AIncrease profitReduce the amount of processingCoupling contact membersClamped/spring connectionsState of artMetal strips

The invention discloses a plug of a wire terminal. In the prior art, a plug is processed by the following steps: a column is made of a metal strip or block by a lathe, then a hole is drilled in the column by a drill press and later an expansion joint is cut by a cutting knife. Such a process has many steps, complicated technology, large processing difficulties and low production efficiency; and the plug in the technical proposal is formed by fixing a sheath block and a sheath body, wherein the sheath body is obtained by stamping a metal piece and the stamping technology is used for the manufacturing and fast formation, thus being convenient. The plug in the technical proposal is characterized by simple processing steps, small processing difficulties, high production efficiency, little processing amount, high utility rate of raw materials, secured processing quality and high yield rate, and is used in the assembly of various wire terminals and widely applicable to the wire connection of electronic and electric appliances.

Owner:JIANGMEN KREALUX ELECTRICAL APPLIANCES

Manufacturing process of cross beam of planer type milling machine

InactiveCN102756079AControllable wall thicknessIncrease productivityFoundry mouldsFoundry coresIntermediate frequencyCasting mold

The invention discloses a manufacturing process of a cross beam of a planer type milling machine. The manufacturing process comprises the following steps: making a mold of the cross beam of the planer type milling machine; putting resin sand into a mold so as to make a resin sand model; drying and patching a modeled casting mold; brushing a coating at the surface of the casting mold; preparing a pond furnace material; filling the pond furnace material into an intermediate frequency furnace to obtain a pond furnace; drying the pond furnace; making a fire in the intermediate frequency furnace; loading materials into the pond furnace; smelting materials in the intermediate frequency furnace; opening the intermediate frequency furnace to release molten iron; pouring the molten iron into a cast mold by using a crane ladle for pouring; staying the cast mold for 1-5 minutes; when a solidified layer reaches a desired thickness, pouring out excessive molten iron; after the cast mold is cooled, cleaning the cast mold so as to obtain a desired cast; carrying out shot-blasting to the cast; polishing and cleaning the cast; and brushing an anti-rust paint to the cast so as to obtain a finished product. The manufacturing process of the cross beam of the planer type milling machine, disclosed by the invention, has the advantages as follows: the production can be continuously carried out, the lifting is reduced, the production efficiency is increased and the production cost is reduced.

Owner:陆宝庆

Water band

The invention provides a water band production method. The method comprises the following steps of: distributing a plurality of straight terylene lines outside PVC inner glue of a water band in a direction parallel to the central line of the water band to form a first linear fiber layer; forming a second coiled fiber layer outside the first linear fiber layer in a spiral mode; forming a third coiled fiber layer on the outer surface of the second coiled fiber layer in a spiral mode in the opposite direction; introducing the fiber layer into a specific die; and coating soft PVC on the inner side and outer side of the coiled fiber layer to perform moulding at one time. The inner and outer glue layers of the water band prepared by the method are mutually fused and combined together tightly and inseparably. Thus, the wall thickness is more easily controlled, the production process is simplified, the power consumption is greatly reduced and the cost is reduced. The water band is more resistant to high pressure, lighter, more wear resistant and more suitable for water delivery at a long distance.

Owner:GUANGDONG HELI PLASTIC CO LTD

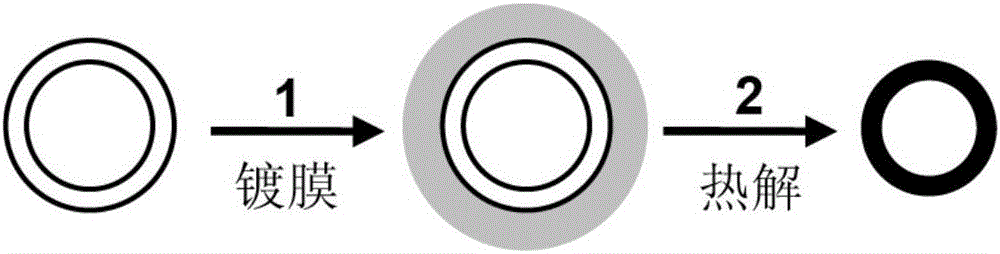

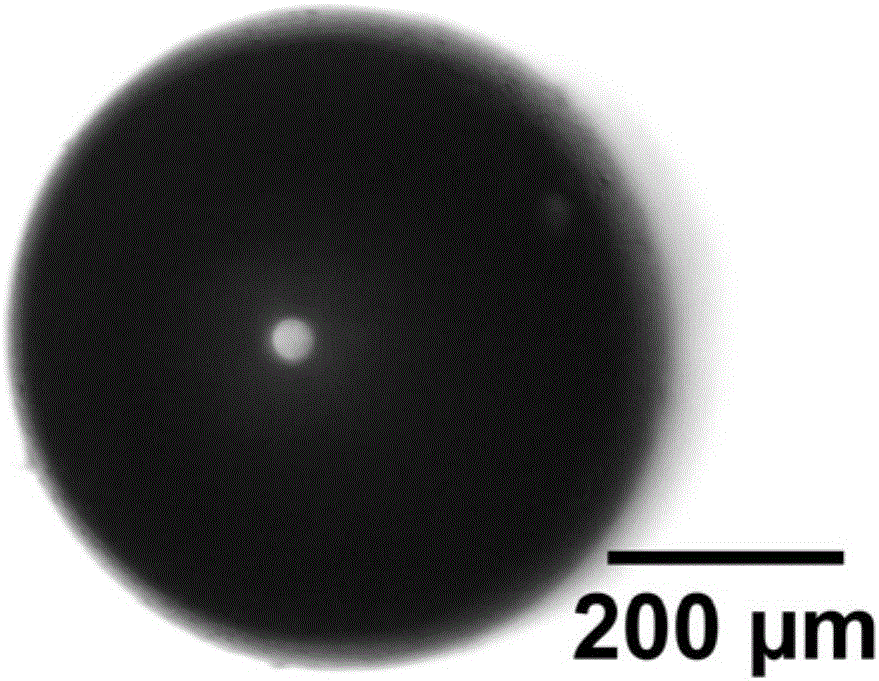

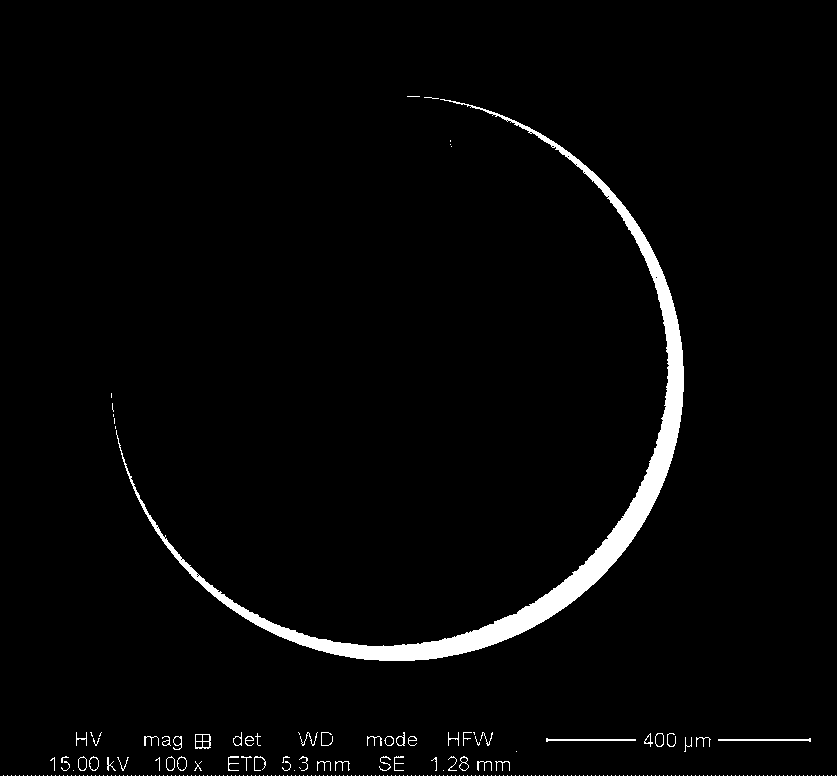

Method for preparing SiC hollow microspheres

The invention belongs to the field of laser inertial confinement fusion, and concretely relates to a method for preparing SiC hollow microspheres. The method comprises the following steps: uniformly depositing a silicon doped glow-discharge polymer on the surface of poly-alpha-methylstyrene or polystyrene hollow microspheres in a chemical vapor deposition manner, decomposing and removing the poly-alpha-methylstyrene or polystyrene hollow microspheres at the inner layer, and pyrolyzing the silicon doped glow-discharge polymer at the outer layer to form SiC in order to obtain the SiC hollow microspheres. The SiC hollow microspheres prepared through the method have the characteristics of controllable diameter and wall thickness, good sphericility and high wall thickness uniformity, and is applied to fusion igniting engineering as a pelleting layer of a fusion target pellet.

Owner:LASER FUSION RES CENT CHINA ACAD OF ENG PHYSICS

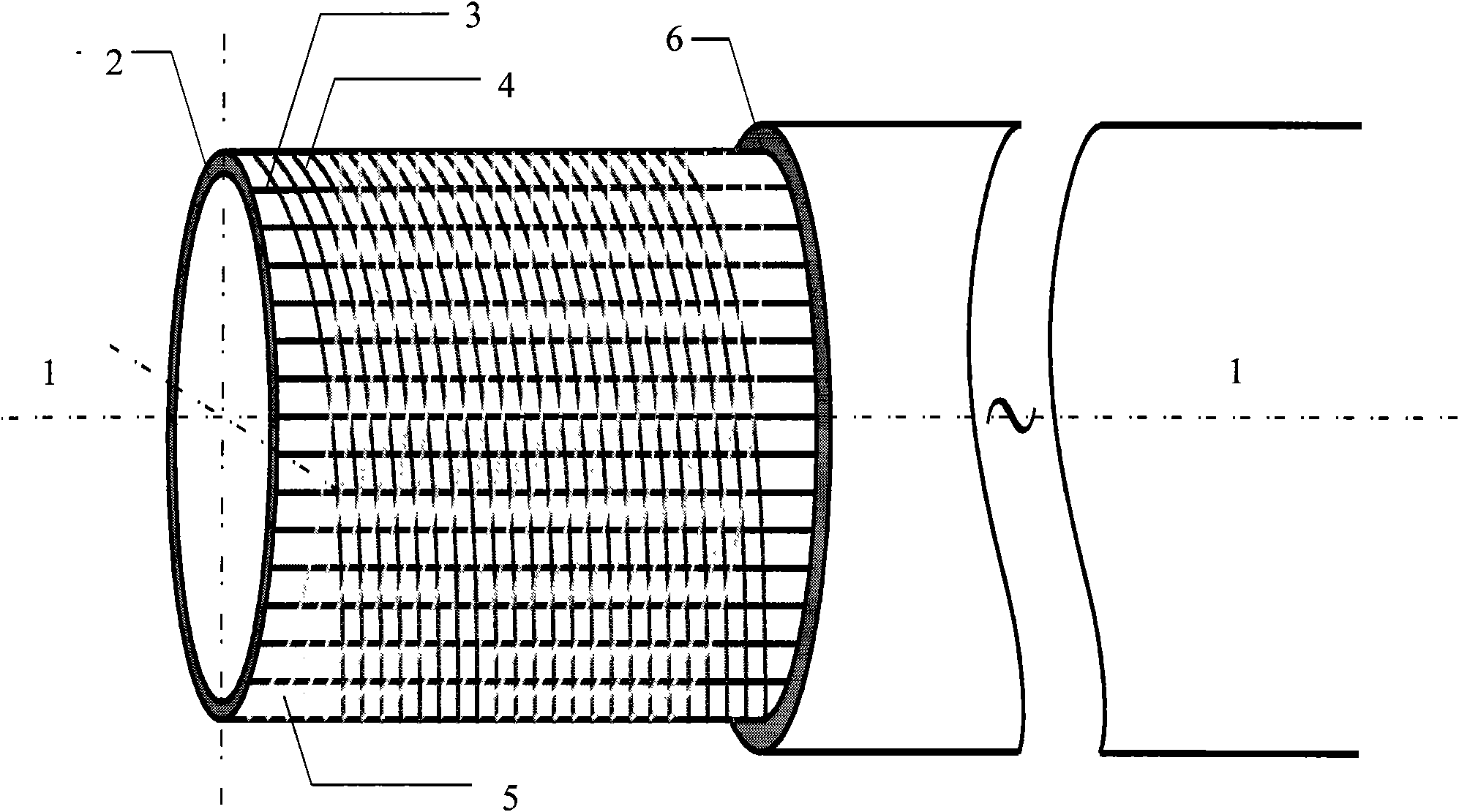

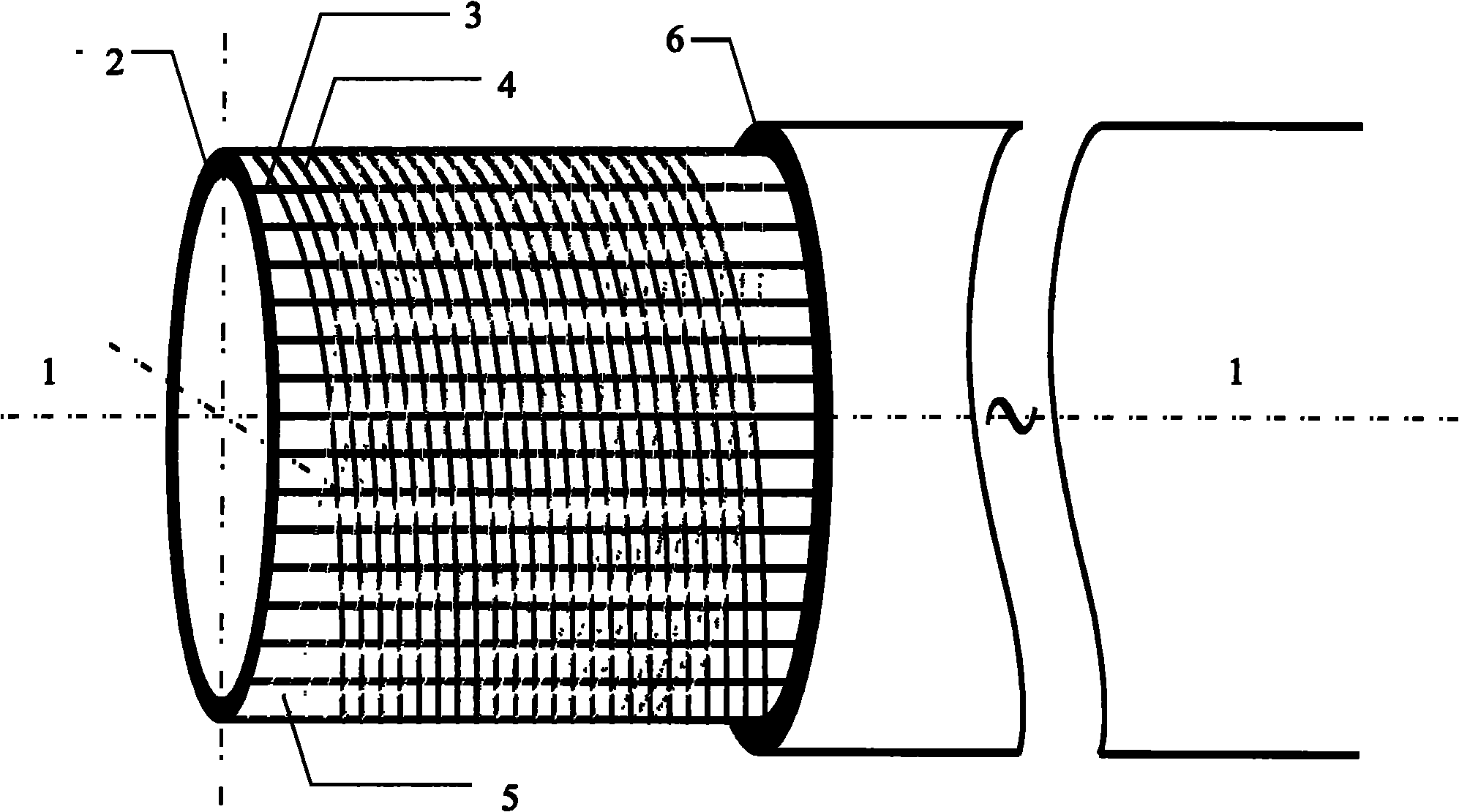

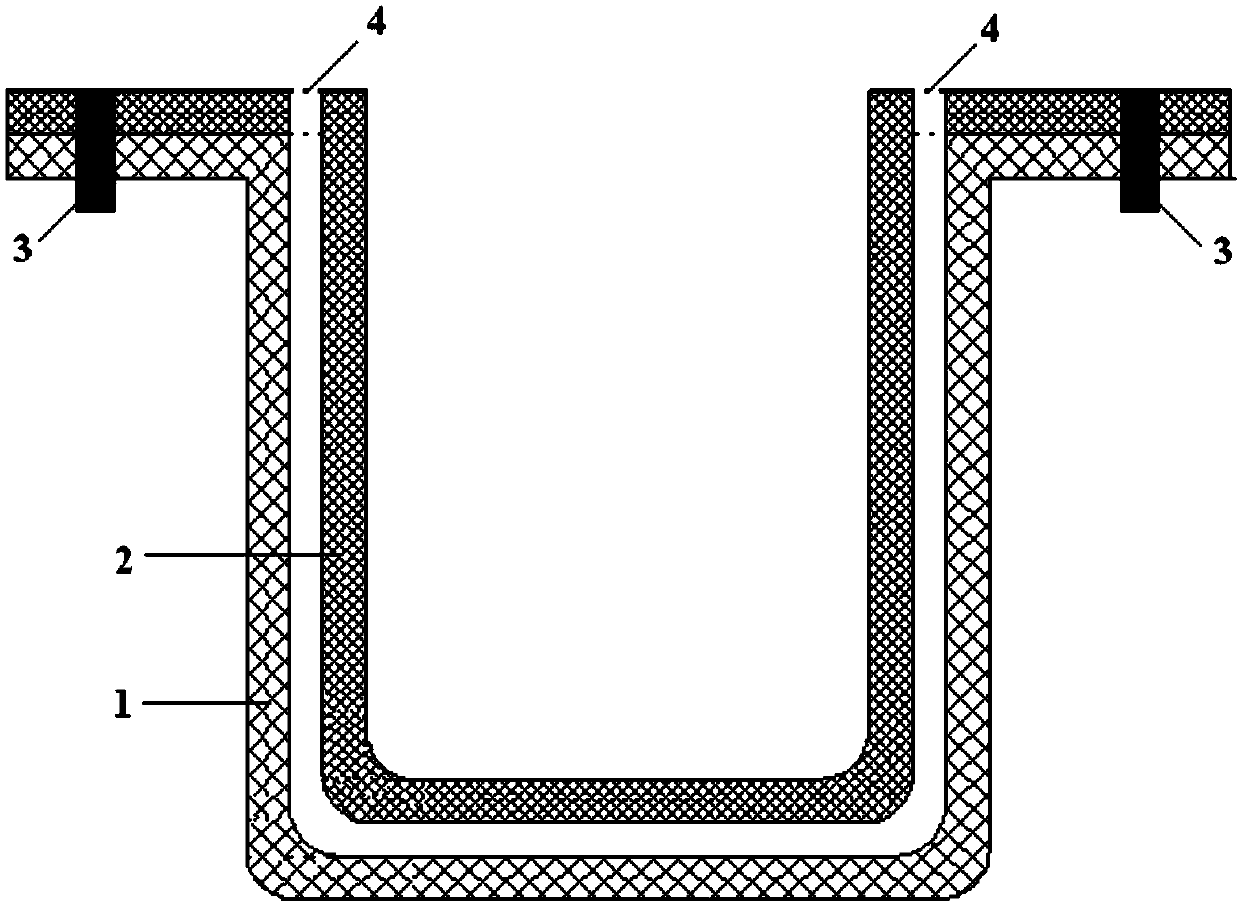

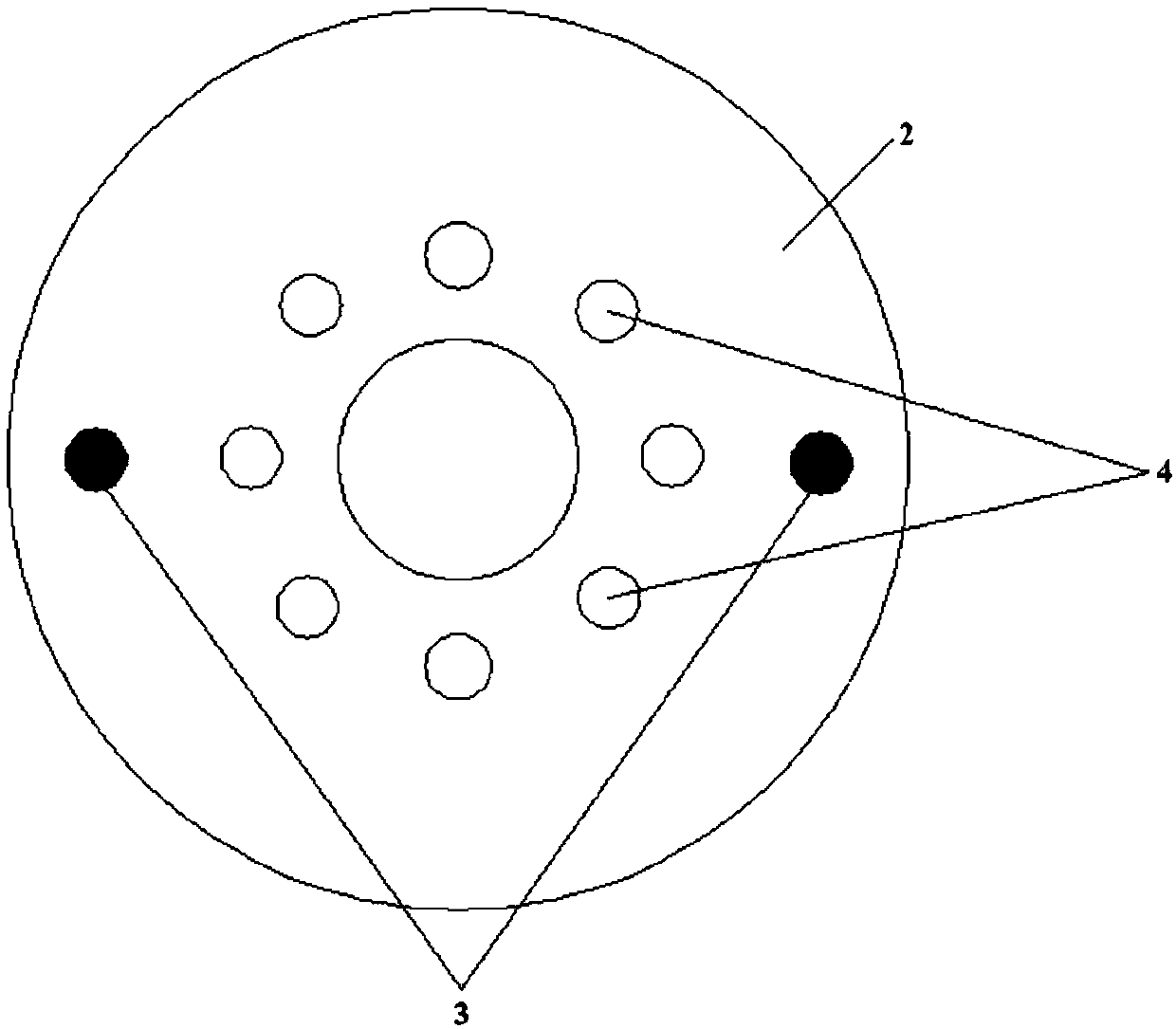

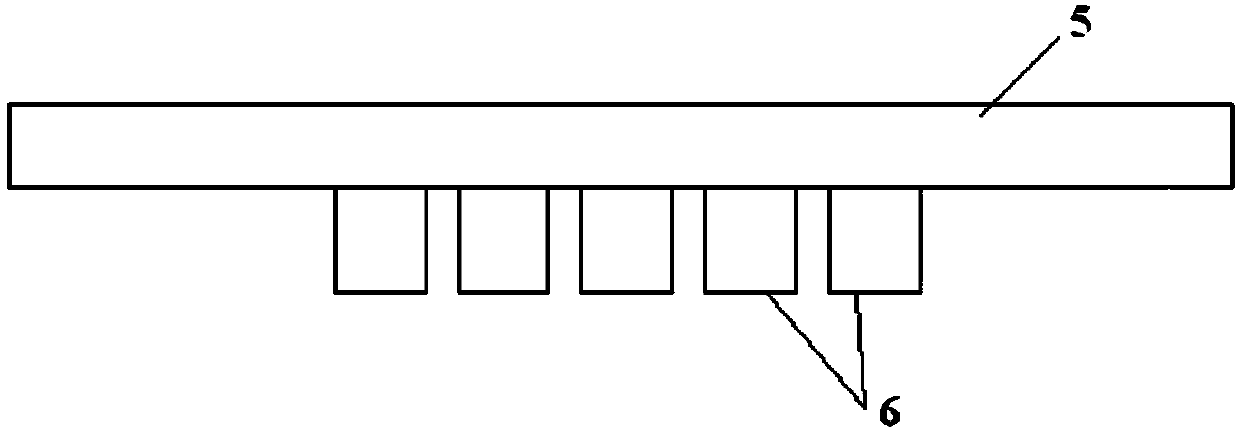

High-temperature dust-removing and filtering sleeve and preparation method thereof

ActiveCN108675746AGuaranteed removal effectControllable wall thicknessDispersed particle filtrationTransportation and packagingFlue gasPore diameter

The invention provides a high-temperature dust-removing and filtering sleeve. The high-temperature dust-removing and filtering sleeve comprises a first dust-removing pipe, a second dust-removing pipeand a plug, wherein a bottom-end pipe opening of the first dust-removing pipe is inward sealed to form a blind hole, and a top-end pipe opening of the first dust-removing pipe extends outward to forman annular plane; the porosity of the first dust-removing pipe is 85 percent to 95 percent and the pore diameter of air pores is 30 mum to 50 mum; the second dust-removing pipe is embedded into the first dust-removing pipe; the bottom-end pipe opening of the second dust-removing pipe is inward sealed to form a blind hole, and the top-end pipe opening of the second dust-removing pipe extends outward to form an annular plane; the outer diameter of the second dust-removing pipe is smaller than the inner diameter of the first dust-removing pipe and a cavity is formed; a plurality of exhausting holes, which penetrate through the cavity, are formed in the annular plane of the second dust-removing pipe; the porosity of the second dust-removing pipe is 75 percent to 85 percent and the pore diameter of the air pores is 10 mum to 30 mum; the plug is used for sealing the second dust-removing pipe; the plug is provided with exhausting hole plugs corresponding to the exhausting holes. The high-temperature dust-removing and filtering sleeve provided by the invention adopts a specific structure and rapid and deep filtering can be realized; when being used for purifying high-temperature flue gas and dust, the high-temperature dust-removing and filtering sleeve has a relatively good effect and relatively high efficiency.

Owner:LUYANG ENERGY SAVING MATERIALS CO LTD

Preparing method for hydrocarbon polymer hollow microspheres

InactiveCN105504123AControllable wall thicknessHigh concentricityChemical vapor deposition coatingPolymer scienceMicrosphere

The invention provides a preparing method for hydrocarbon polymer hollow microspheres. The preparing method comprises the steps that firstly, a poly-alpha methyl styrene mandrel material is arranged in a sample tray of a low-pressure plasma polymerization device; secondly, vacuum pumping is carried out, mixed gas of trans-dibutene and hydrogen is introduced, and the air pressure is adjusted to range from 5 Pa to 30 Pa; thirdly, a 40.68 MHz radio-frequency power supply is switched on, power is adjusted to range from 5 W to 25 W, and trans-dibutene and hydrogen are ionized and form plasma; fourthly, the sample tray rotates to drive the poly-alpha methyl styrene mandrel material to roll in the sample tray, the height of the sample tray is adjusted to enable the poly-alpha methyl styrene mandrel material to be located in a plasma sheath, glow discharge hydrocarbon polymer coating and plating are started, and the coating and plating time is determined according to the needed thickness of a coating; fifthly, a product prepared in the third step is heated to 300 DEG C in a nitrogen environment, the temperature is kept for 24 hours, and the hydrocarbon polymer hollow microspheres are obtained after cooling. The hydrocarbon polymer hollow microspheres prepared through the method are controllable in diameter and wall thickness and good in concentricity and uniformity.

Owner:LASER FUSION RES CENT CHINA ACAD OF ENG PHYSICS

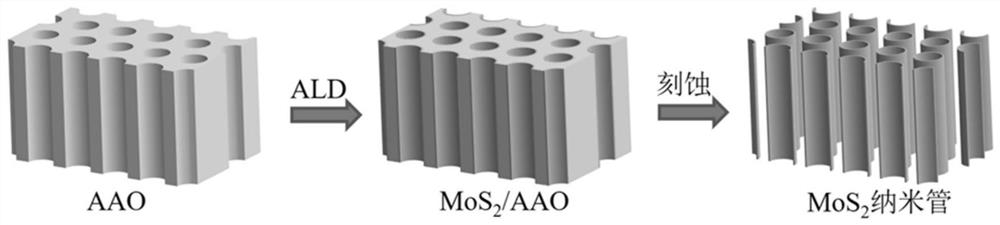

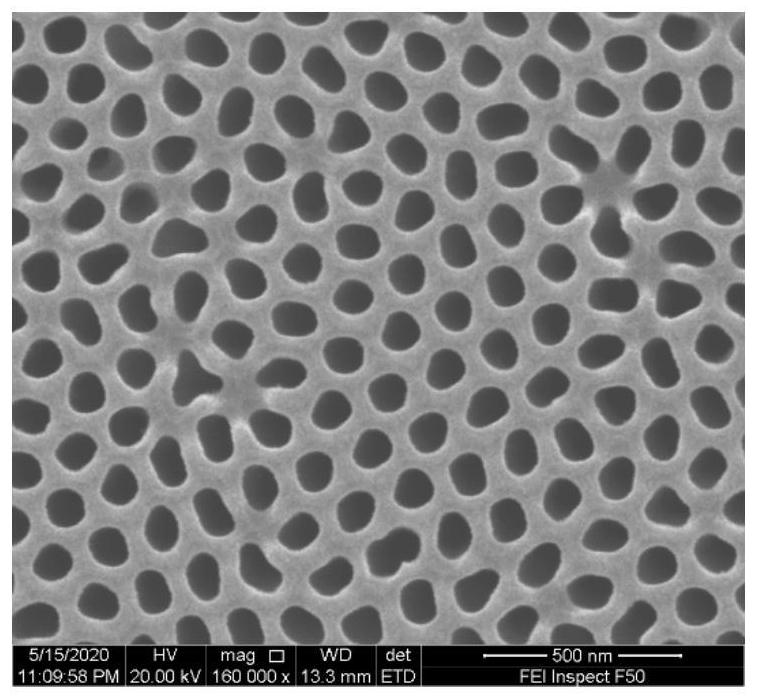

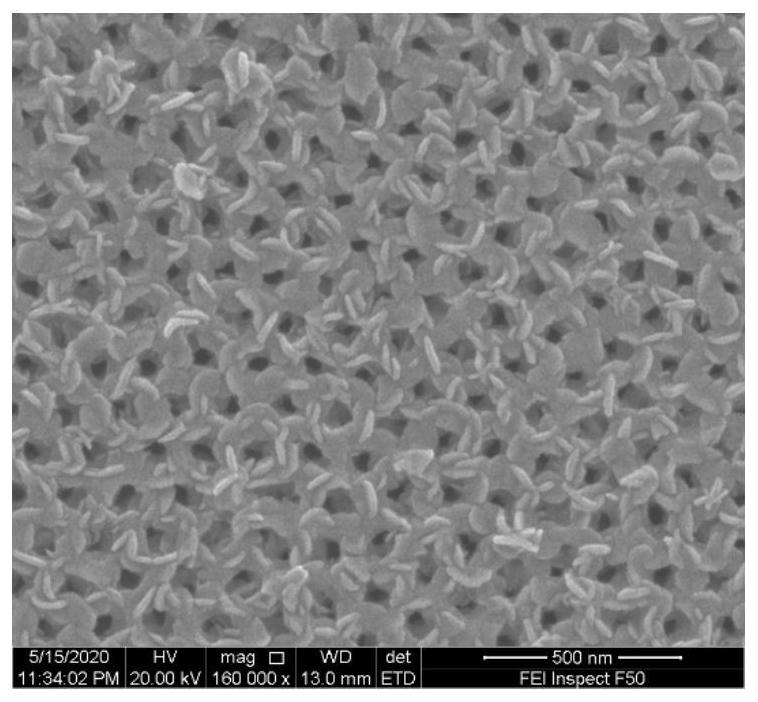

Preparation method of molybdenum disulfide nanotube and molybdenum disulfide nanotube

InactiveCN112607778AMeet temperature requirementsPipe diameter controllableMaterial nanotechnologyMolybdenum sulfidesNanoholePore diameter

The invention discloses a preparation method of a molybdenum disulfide nanotube, and the method comprises the following steps: by taking anodic aluminum oxide as a template, growing molybdenum disulfide with controllable thickness on the surface of a nanopore of the anodic aluminum oxide template by adopting an atomic layer deposition technology; and etching the anodic aluminum oxide by using an etching solution to obtain the MoS2 nanotube array. By selecting AAO templates with different pore diameters and heights and controlling the cycle number of ALD, the diameter, the length and the wall thickness of the MoS2 nanotube can be accurately regulated and controlled. The method solves the problem that the pipe diameter and the wall thickness of the molybdenum disulfide nanotube are uncontrollable, and the prepared molybdenum disulfide nanotube has good repeatability and orientation consistency, can be used in the fields of catalysis, semiconductors and the like, and is suitable for large-scale industrial production.

Owner:SOUTHEAST UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com