Preparation method of polysilsesquioxane hollow microspheres

A technology of polysilsesquioxane and hollow microspheres, which is applied in the field of new materials, can solve the problems of limited size range of microspheres and cumbersome operation steps, and achieve controllable particle size and wall thickness, good mechanical strength, and production equipment simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

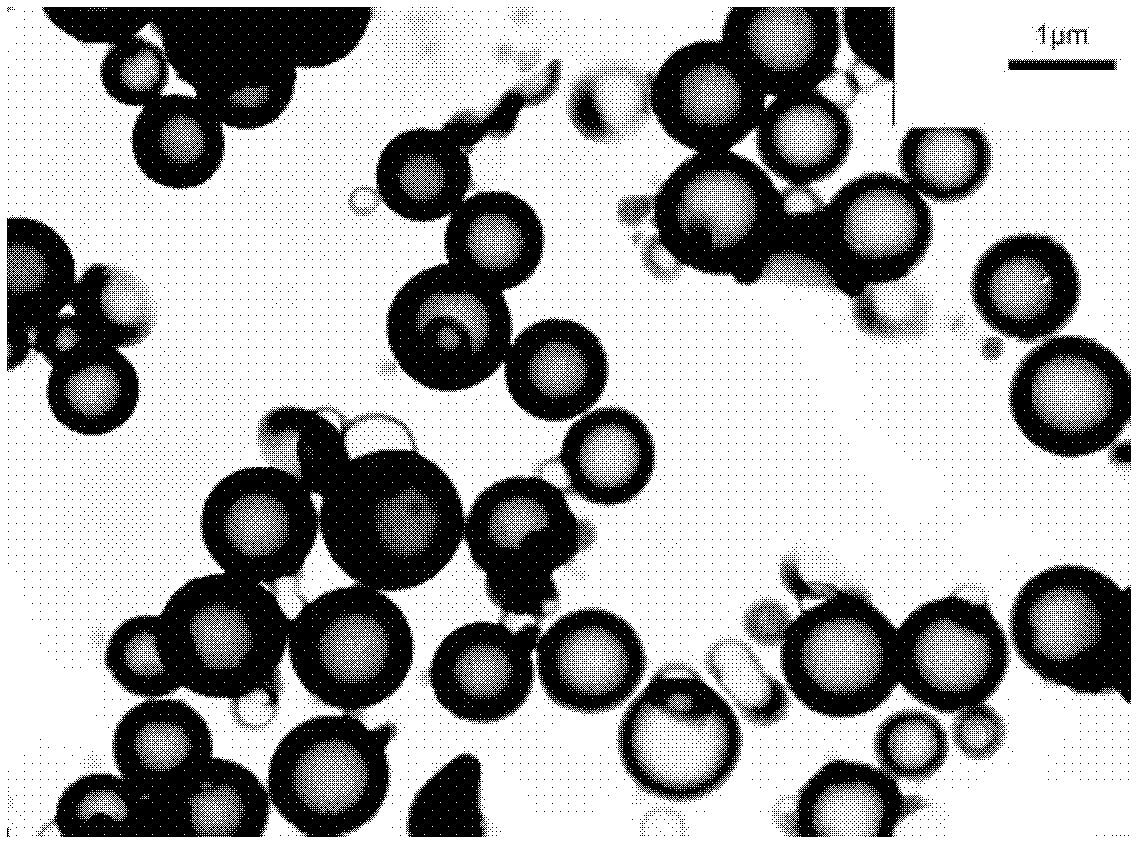

[0038] In a 50.0mL beaker, add 2.0mL toluene and 5.0mL methyltriethoxysilane, stir to make the mixture uniform, add this solution to a 250.0mL three-neck round bottom flask, add 100.0mL deionized water, and control the temperature 5.0°C, start stirring and keep the rotation speed at 800rpm, stir for 30.0min, mix well, add 1.0mL 1.0M NaOH solution, maintain the same temperature and stirring speed, polymerize for 8.0h, and obtain a white suspension product. The product is separated by centrifugation and air-dried at room temperature to obtain polymethylsilsesquioxane hollow microspheres in the form of white powder. The particle size of the hollow microsphere is 0.7-1.0 μm, and the wall thickness is 100-200 nm. Such as figure 1 shown.

Embodiment 2

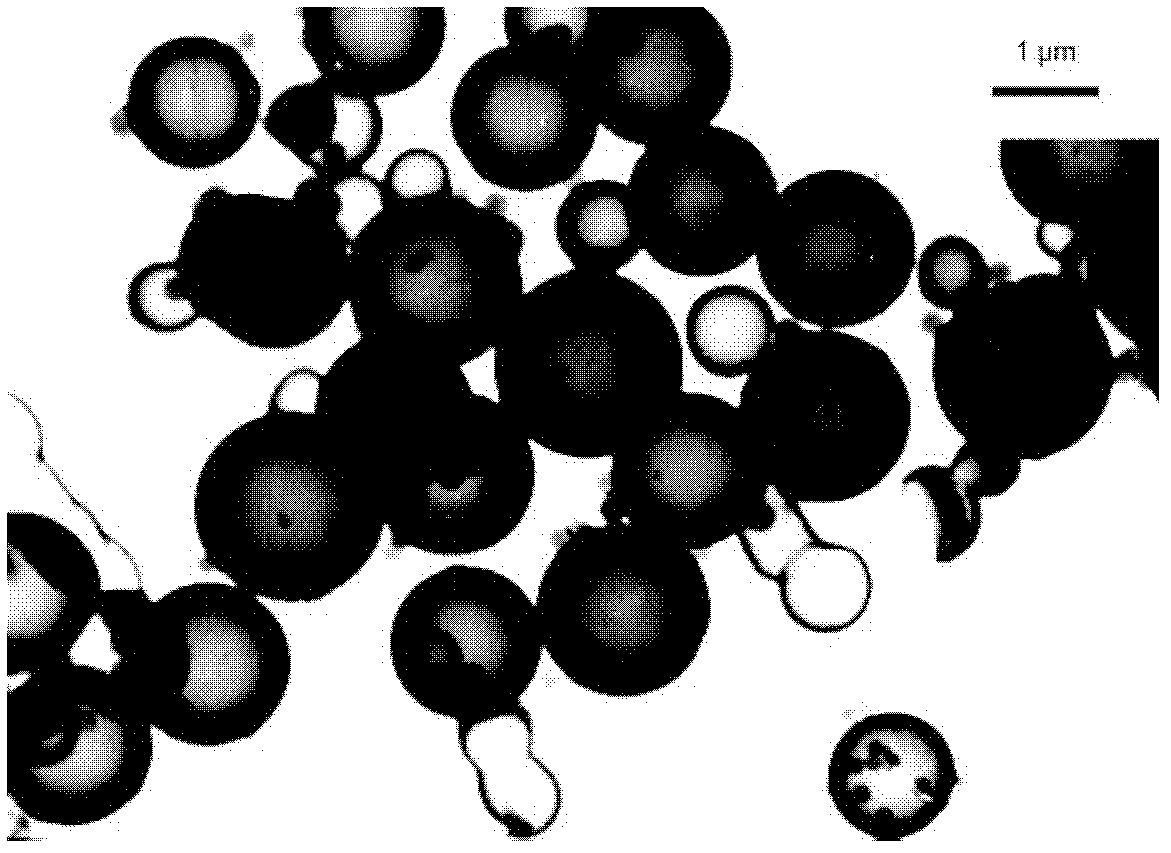

[0040] In a 50.0mL beaker, add 2.0mL toluene and 7.0mL methyltriethoxysilane, stir to make the mixture uniform, add this solution to a 250.0mL three-neck round bottom flask, add 100.0mL deionized water, and control the temperature 5.0°C, start stirring and keep the rotation speed at 800rpm, stir for 30.0min, mix well, add 1.0mL 1.0M NaOH solution, maintain the same temperature and stirring speed, polymerize for 8.0h, and obtain a white suspension product. The product is separated by centrifugation and air-dried at room temperature to obtain polymethylsilsesquioxane hollow microspheres in the form of white powder. The particle size of the hollow microsphere is 1.5-2.0 μm, and the wall thickness is 300-500 nm. Such as figure 2 shown.

Embodiment 3

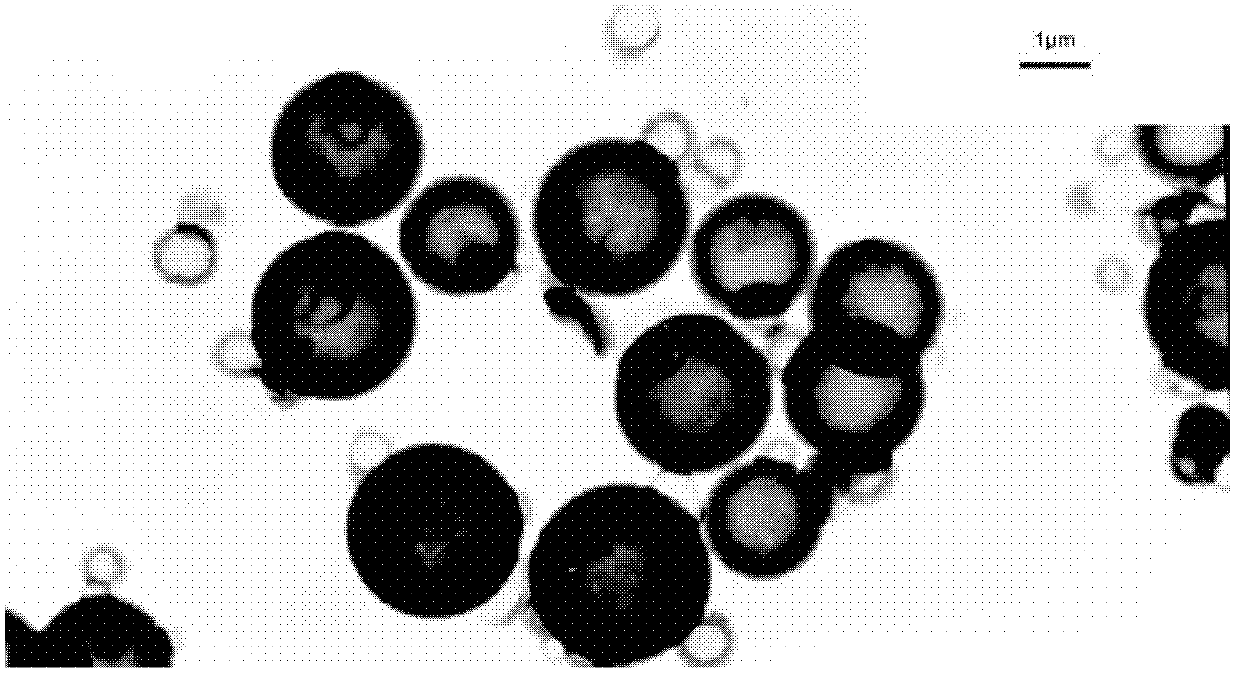

[0042] In a 50.0mL beaker, add 2.0mL toluene and 5.0mL methyltriethoxysilane, stir to make the mixture uniform, add this solution to a 250.0mL three-neck round bottom flask, add 100.0mL deionized water, and control the temperature 5.0°C, start stirring and keep the rotation speed at 500rpm, stir for 30.0min, mix well, add 1.0mL 1.0M NaOH solution, maintain the same temperature and stirring speed, polymerize for 8.0h, and obtain a white suspension product. The product is separated by centrifugation and air-dried at room temperature to obtain polymethylsilsesquioxane hollow microspheres in the form of white powder. The particle size of the hollow microsphere is 1.8-2.3 μm, and the wall thickness is 300-500 nm. Such as image 3 shown.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com