Method for preparing SiC hollow microspheres

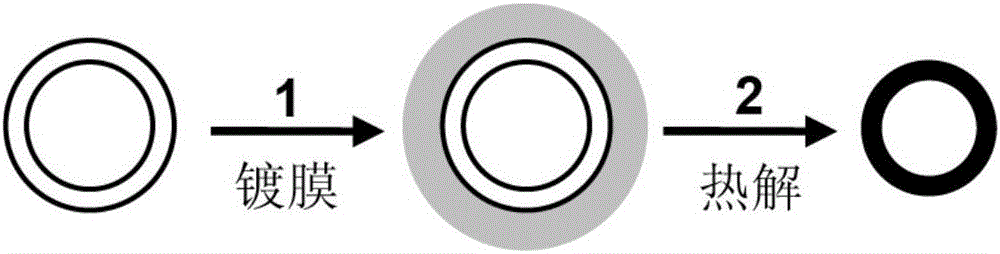

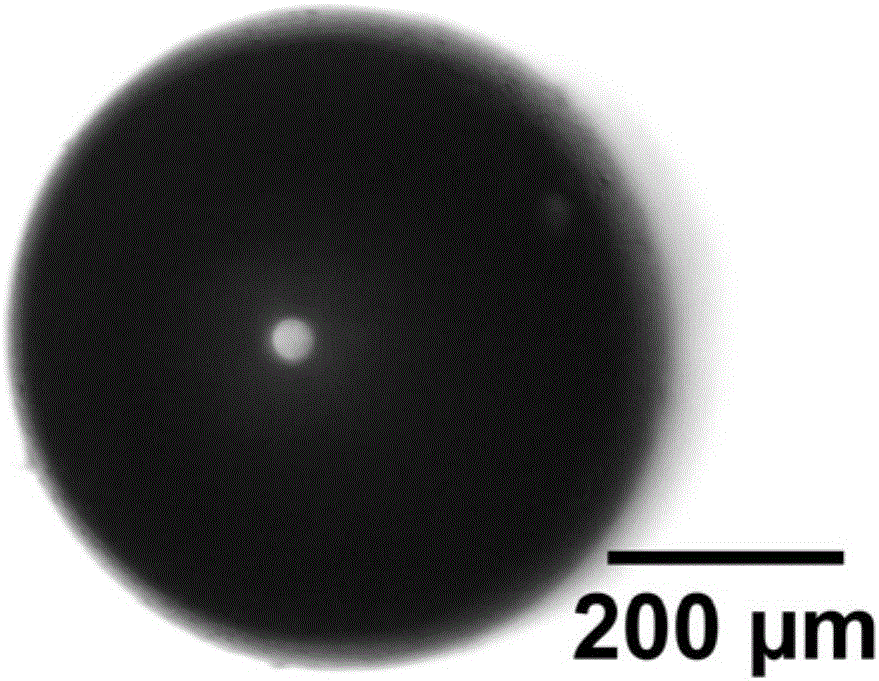

A technology of hollow microspheres and silicon doping, applied in the field of laser inertial confinement fusion, which can solve the problems of large diameter dispersion and failure to meet the requirements, and achieve the effects of good sphericity, simple operation, and high uniformity of wall thickness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

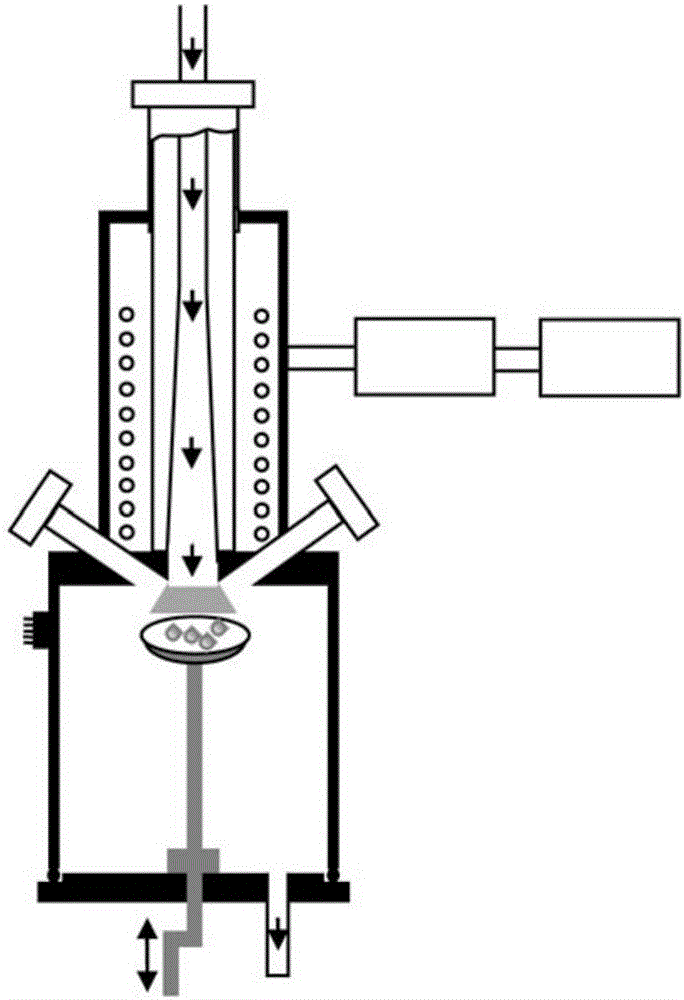

[0042] Step 1. Select poly-α-methylstyrene hollow microspheres with a diameter range of 900±50 μm, and place the microspheres in the sample tray of the chemical vapor deposition device;

[0043] Step 2, vacuumize the closed device, then feed the mixed gas of tetramethylsilane, trans-dibutene and hydrogen, and adjust the air pressure in the device to 15Pa; 0.1ml / min, 0.4ml / min, 10ml / min;

[0044] Step 3. Turn on the 40.68MHz RF power supply and adjust it to 10W to ionize the working gas to form plasma;

[0045] Step 4, start the vacuum motor to drive the poly-α-methylstyrene hollow microspheres to roll in the sample tray, so that the silicon-doped glow discharge polymer is deposited on the surface of the microspheres for 54 hours;

[0046] Step 5. Place the microspheres prepared in step 4 in a crucible, place them in the quartz tube of the tube furnace, close the quartz tube, evacuate, and feed argon as a protective gas; first heat it at a rate of 1°C / min to 300°C, and keep t...

Embodiment 2

[0049] Step 1. Select poly-α-methylstyrene hollow microspheres with a diameter range of 2000±20 μm, and place the microspheres in the sample tray of the chemical vapor deposition device;

[0050] Step 2, vacuumize the closed device, then feed the mixed gas of tetramethylsilane, trans-dibutene and hydrogen, and adjust the air pressure in the device to 15Pa; 0.3ml / min, 0.4ml / min, 10ml / min;

[0051] Step 3. Turn on the 40.68MHz RF power supply and adjust it to 20W to ionize the working gas to form plasma;

[0052] Step 4, start the vacuum motor to drive poly-α-methylstyrene hollow microspheres to roll in the sample tray, so that the silicon-doped glow discharge polymer is deposited on the surface of the microspheres for 60 hours;

[0053] Step 5. Place the microspheres prepared in step 4 in a crucible, place them in the quartz tube of the tube furnace, close the quartz tube, evacuate, and feed argon as a protective gas; first heat to 350°C, and keep the temperature for 14 hours...

Embodiment 3

[0056] Step 1. Select poly-α-methylstyrene hollow microspheres with a diameter range of 900±50 μm, and place the microspheres in the sample tray of the chemical vapor deposition device;

[0057] Step 2. Vacuumize the closed device, then feed the mixed gas of tetramethylsilane, trans-dibutene and hydrogen, and adjust the air pressure in the device to 25Pa; 0.3ml / min, 0.4ml / min, 10ml / min;

[0058] Step 3. Turn on the 40.68MHz RF power supply and adjust it to 40W to ionize the working gas to form plasma;

[0059] Step 4, start the vacuum motor to drive the poly-α-methylstyrene hollow microspheres to roll in the sample tray, so that the silicon-doped glow discharge polymer is deposited on the surface of the microspheres for 54 hours;

[0060] Step 5. Place the microspheres prepared in step 4 in a crucible, place them in the quartz tube of the tube furnace, close the quartz tube, evacuate, and feed argon as a protective gas; first heat it at a rate of 1°C / min to 300°C, and keep t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com