Preparation method of high transmission glass-based porous aluminum oxide substrate

A technology of porous alumina and alumina, which is applied in the directions of anodic oxidation, sputtering plating, ion implantation plating, etc., can solve the problems of fragility, low strength, and limited optical performance of devices, and achieve high mechanical strength and effective High order and good transmittance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

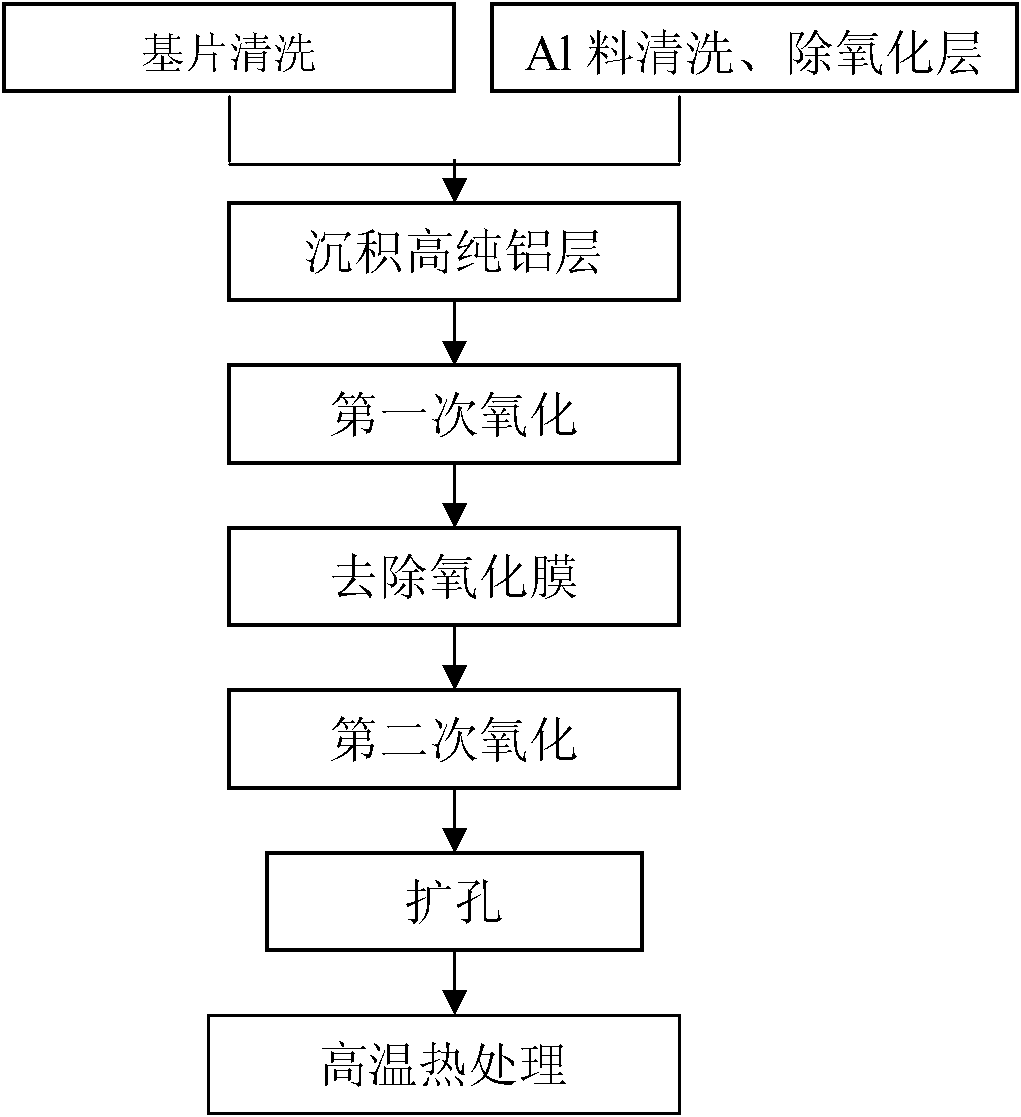

[0015] The preparation method of the high-transmittance glass-based porous alumina substrate is: firstly, the glass is used as the substrate, and the high-purity aluminum film is prepared by the vacuum thermal evaporation method; then the porous alumina layer is formed by the primary or secondary anodic oxidation method; The process optimizes the pore diameter of the porous alumina layer; finally, a high-temperature annealing treatment is used to improve the transmittance of the entire glass-based porous alumina substrate.

[0016] The preparation method specifically comprises the following steps:

[0017] 1) Preparation of high-purity aluminum film by vacuum thermal evaporation method:

[0018] Heating the high-purity aluminum material by vacuum resistance heating or electron beam heating, and depositing a high-purity aluminum film with controllable thickness on the glass substrate;

[0019] 2) Carry out high-temperature heat treatment to the glass-based aluminum film obtain...

Embodiment 1

[0046] Embodiment 1: technical solution

[0047] 1) Use an aluminum material with a purity of 99.999%, roughly clean it with deionized water and absolute ethanol; then soak it in 0.2mol / L NaOH solution for 5 minutes to remove the natural oxide film on the surface of the aluminum sheet;

[0048] 2) Using the vacuum resistance heating method, the pretreated high-purity aluminum material is placed in a conductive ceramic boat for pre-melting, and then the cleaned glass substrate is placed on the substrate holder in the vacuum chamber, and different thicknesses are prepared by crystal oscillator control. high-purity aluminum membrane.

[0049] 3) Heat the sample after resistance evaporation to 480°C with the furnace, then keep it warm for 1 hour, and then cool it to room temperature with the furnace;

[0050] 4) Put the treated glass-based aluminum film in step 3) into 0.2 mol / l sodium hydroxide solution for 5 minutes before oxidation, then prepare analytically pure oxalic acid and...

Embodiment 2

[0055] Embodiment 2: technical solution

[0056] Step 5) The hole-enlarging treatment time is 120min, and the rest are the same as in Example 1.

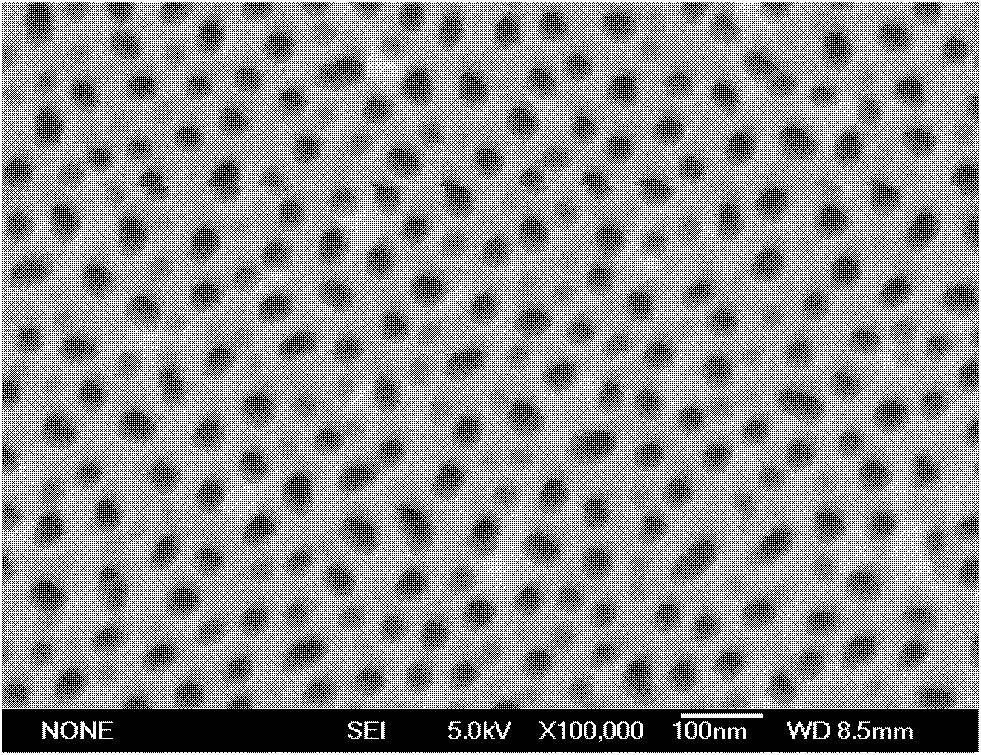

[0057] The transmittance of the glass-based porous alumina substrate prepared in Example 2:

[0058] The average pore diameter is about 47nm; Figure 4 As shown, the transmittance in the visible light band is greater than 60%, and the maximum can reach 70%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Average pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com