Method of preparing perovskite type zirconate hollow nano material

A technology of perovskite and nanomaterials, which is applied in the field of preparation of zirconate nanomaterials, can solve the problems of cumbersome steps and high cost, and achieve good powder dispersion, convenient operation, easy control of size and shell wall thickness Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0023] The preparation method (abbreviation preparation method) of the perovskite type zirconate hollow nano material designed by the present invention comprises the following process steps:

[0024] 1. Under stirring conditions, the general formula of 0.001-0.005Mol is ABO 3 Dissolve perovskite-type compounds including metal compounds of barium or strontium at A site and metal compounds of zirconium at B site in 20-30 mL of deionized water, add an appropriate amount of strong inorganic base, and stir for 20-60 minutes to obtain a uniformly dispersed mixture; The A-position barium metal compound refers to one or more mixtures of barium nitrate, barium chloride, barium oxide and barium hydroxide; the A-position strontium metal compound refers to strontium nitrate, strontium chloride, barium oxide One or more mixtures of strontium and strontium hydroxide; the B-site zirconium metal compound is one or more mixtures of zirconium oxychloride, zirconium chloride and zirconium oxide;...

Embodiment 1

[0039] Preparation of BaZrO 3 Hollow nanomaterials. Its process method is as follows:

[0040] (1) Add 0.48g of barium nitrate, 0.538g of zirconium oxychloride and 17.96g of potassium hydroxide to 20mL of deionized water in sequence, and stir at room temperature for 20 minutes to obtain a uniformly dispersed mixed solution;

[0041] (2) The mixed solution obtained in step (1) is put into a 40mL stainless steel reaction kettle lined with polytetrafluoroethylene, sealed, and reacted at 200° C. for 24 hours;

[0042] (3) After the reaction product in step (2) is naturally cooled, remove the upper layer of lye, and under magnetic stirring conditions, wash the resulting product powder with deionized water for 60 minutes, to wash away the lye on the surface of the sample;

[0043] (4) After centrifuging the product powder after washing in step (3), use ultrasonic cleaning for 40 minutes to further wash off the inorganic base adsorbed on the sample powder, then add 20 mL of acetic ...

Embodiment 2

[0047] Preparation of SrZrO 3 Hollow nanomaterials. Its process method is as follows:

[0048] (1) Add 0.146g of strontium nitrate, 0.201g of zirconium oxychloride and 29.45g of potassium hydroxide into 15mL of deionized water in sequence, and stir at room temperature for 20 minutes to obtain a uniformly dispersed mixed solution;

[0049] (2)-(5) are with embodiment 1; Promptly obtain SrZrO 3 Hollow nanoparticle material.

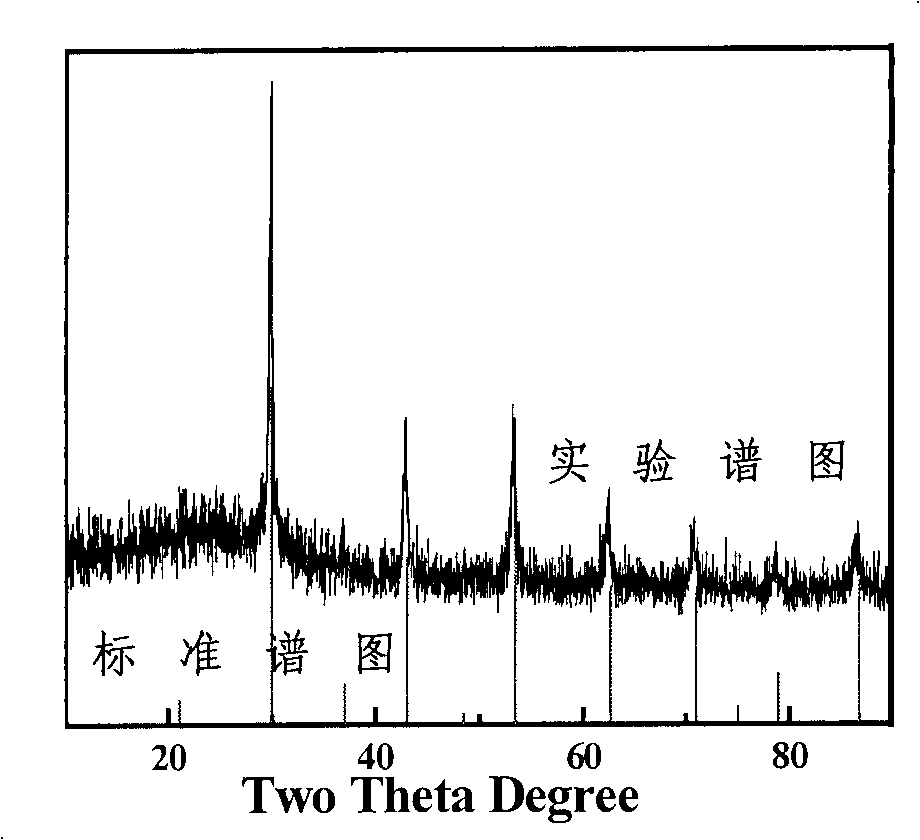

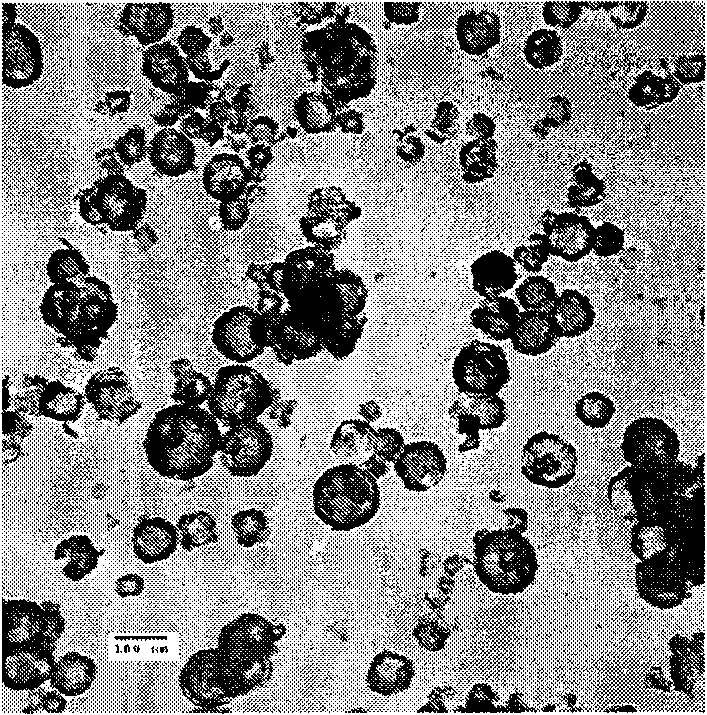

[0050] After testing, the material SrZrO obtained in this example 3 Characteristic peaks of hollow nanocage samples and perovskite structure SrZrO 3 standard spectrum Figure 1 To (see Figure 4 ), the nanocage particle size is 100-150nm (see Figure 5 ).

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com