Preparation method of molybdenum disulfide nanotube and molybdenum disulfide nanotube

A molybdenum disulfide and nanotube technology, applied in the field of nanomaterials, can solve the problems of difficulty in controlling the diameter of MoS2 nanotubes and the thickness of the tube wall, and achieve the effects of easy removal, controllable wall thickness and uniform distribution.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

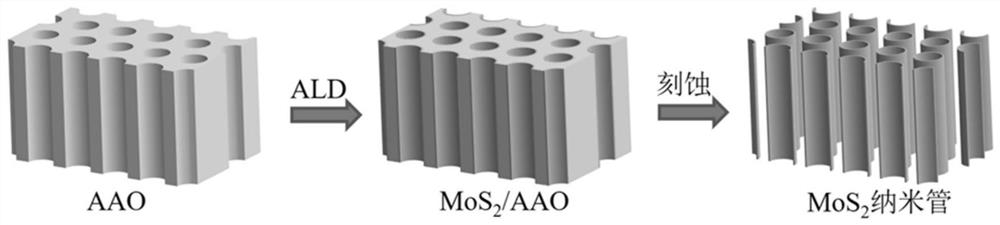

[0026] The steps of the preparation method of the present invention are:

[0027] After the commercial AAO template (aperture: 2-500nm, height: 100nm-500μm) is cleaned and plasma treated (time 1-30min), it is put into the cavity of a commercial atomic layer deposition equipment. In the ALD process, molybdenum pentachloride (MoCl 5 ) is molybdenum source, hydrogen sulfide (H 2 S) as a sulfur source, with nitrogen (N 2 ) as carrier and purge gas. Raise the temperature of the molybdenum source to 100-300°C to fully decompose and gasify the molybdenum source; keep the temperature of the ALD reaction chamber at 300-800°C. After reaching the required temperature, pass MoCl into the cavity according to this 5 (chemisorption on the surface of AAO via hydroxyl groups); N 2 (reaction residue and by-products are rinsed away); H 2 S (with MoCl 5 Reaction to generate MoS 2 ); N 2(Reaction residues and by-products are rinsed away). These four steps constitute an ALD cycle. Since t...

Embodiment 1

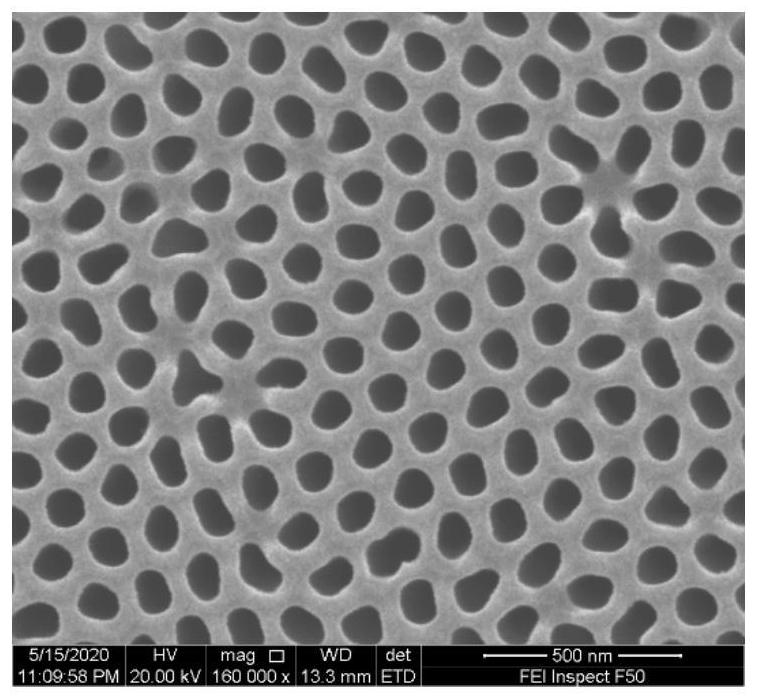

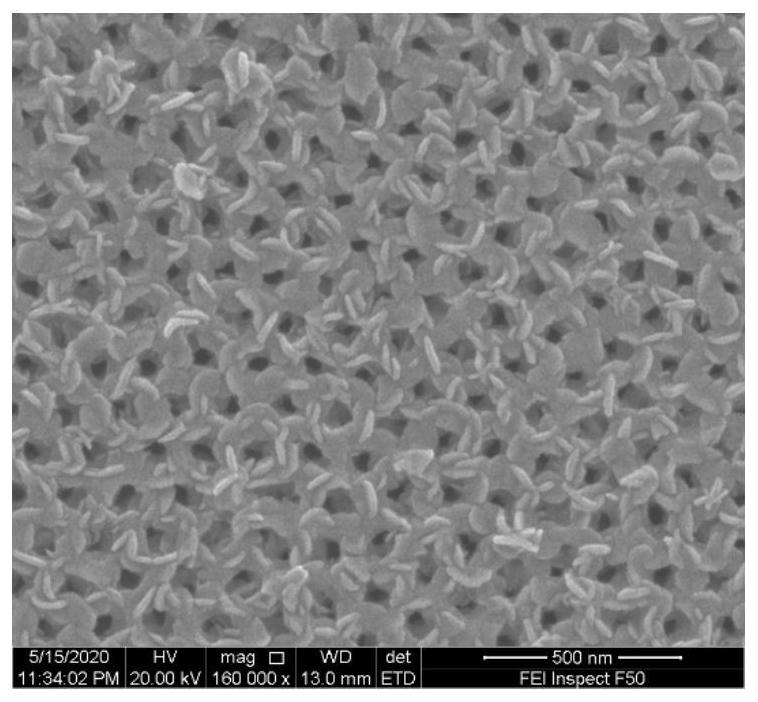

[0029] The AAO with a nanopore diameter of 200 nm and a height of 50 μm was cleaned, treated with plasma for 10 min, and then placed in an atomic layer deposition device. molybdenum pentachloride (MoCl 5 ) is molybdenum source, hydrogen sulfide (H 2 S) as a sulfur source, with nitrogen (N 2 ) as carrier and purge gas. Raise the temperature of the molybdenum source to 200°C; keep the temperature of the ALD reaction chamber at 500°C. After reaching the required temperature, pass MoCl into the cavity according to this 5 (flow rate: 50sccm; access time: 1s); N 2 (flow rate: 50sccm; access time: 30s); H 2 S (flow rate: 50sccm; access time: 1s); N 2 (flow rate: 50sccm; access time: 30s) as a cycle. In this way, cycled 50 times to get MoS 2 / AAO. Finally, the MoS 2 / AAO is immersed in sodium hydroxide (NaOH) solution, and the AAO template is etched away to obtain molybdenum disulfide nanotubes with a diameter of 200nm, a length of 50μm, and a wall thickness of 10nm.

Embodiment 2

[0031] The AAO with a nanopore diameter of 100 nm and a height of 20 μm was cleaned, treated with plasma for 5 minutes, and placed in an atomic layer deposition device. molybdenum pentachloride (MoCl 5 ) is molybdenum source, hydrogen sulfide (H 2 S) as a sulfur source, with nitrogen (N 2 ) as carrier and purge gas. Raise the temperature of the molybdenum source to 200°C; keep the temperature of the ALD reaction chamber at 500°C. After reaching the required temperature, pass MoCl into the cavity according to this 5 (flow rate: 50sccm; access time: 1s); N 2 (flow rate: 50sccm; access time: 30s); H 2 S (flow rate: 50sccm; access time: 1s); N 2 (flow rate: 50sccm; access time: 30s) as a cycle. In this way, cycled 50 times to get MoS 2 / AAO. Finally, the MoS 2 / AAO is immersed in sodium hydroxide (NaOH) solution, and the AAO template is etched away to obtain molybdenum disulfide nanotubes with a diameter of 100nm, a length of 20μm, and a wall thickness of 10nm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com