Patents

Literature

120results about How to "Suitable for industrial implementation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Multistation material transmission manipulator

InactiveCN101633023AImprove efficiencyQuality improvementProgramme-controlled manipulatorMetal-working feeding devicesPunchingManipulator

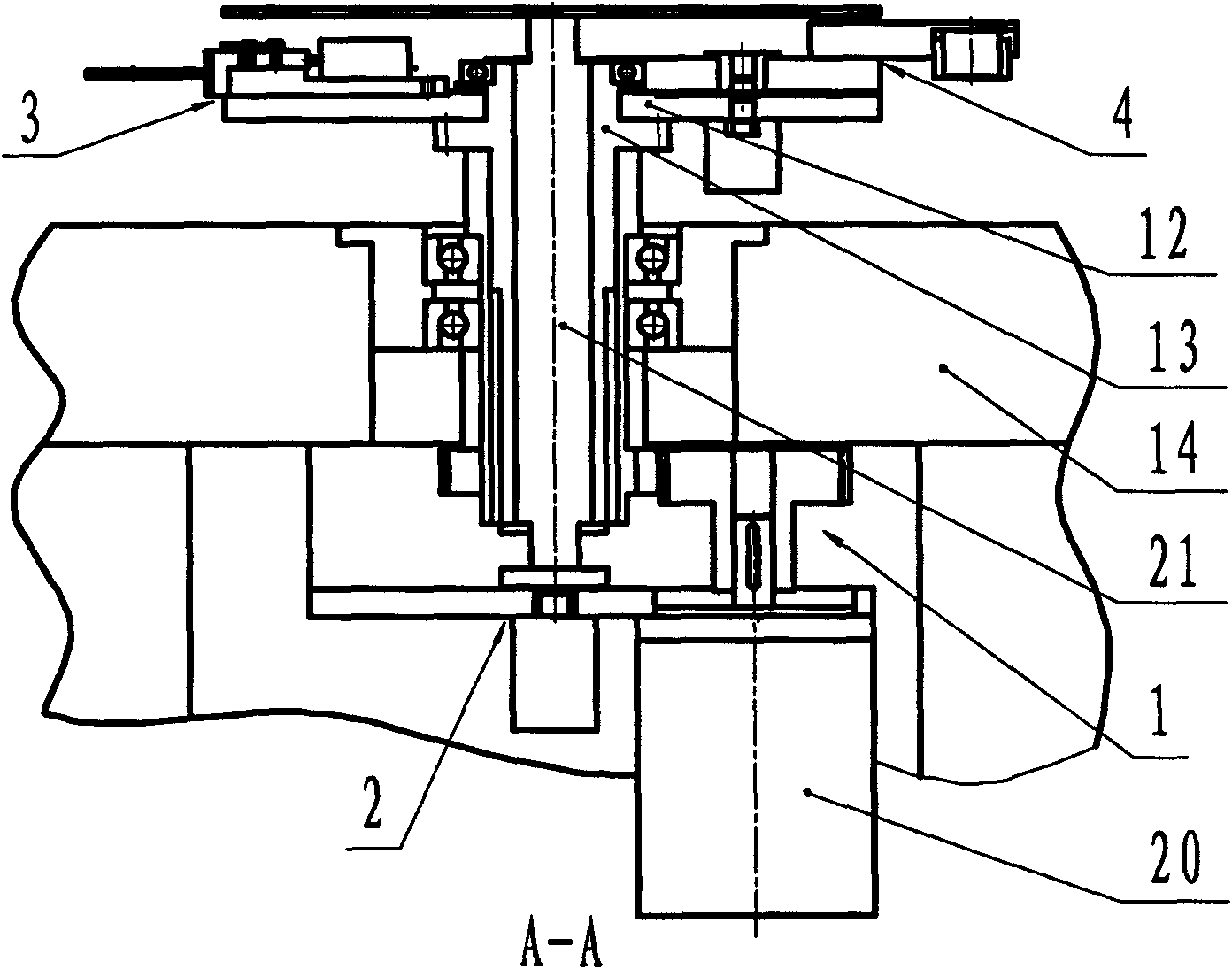

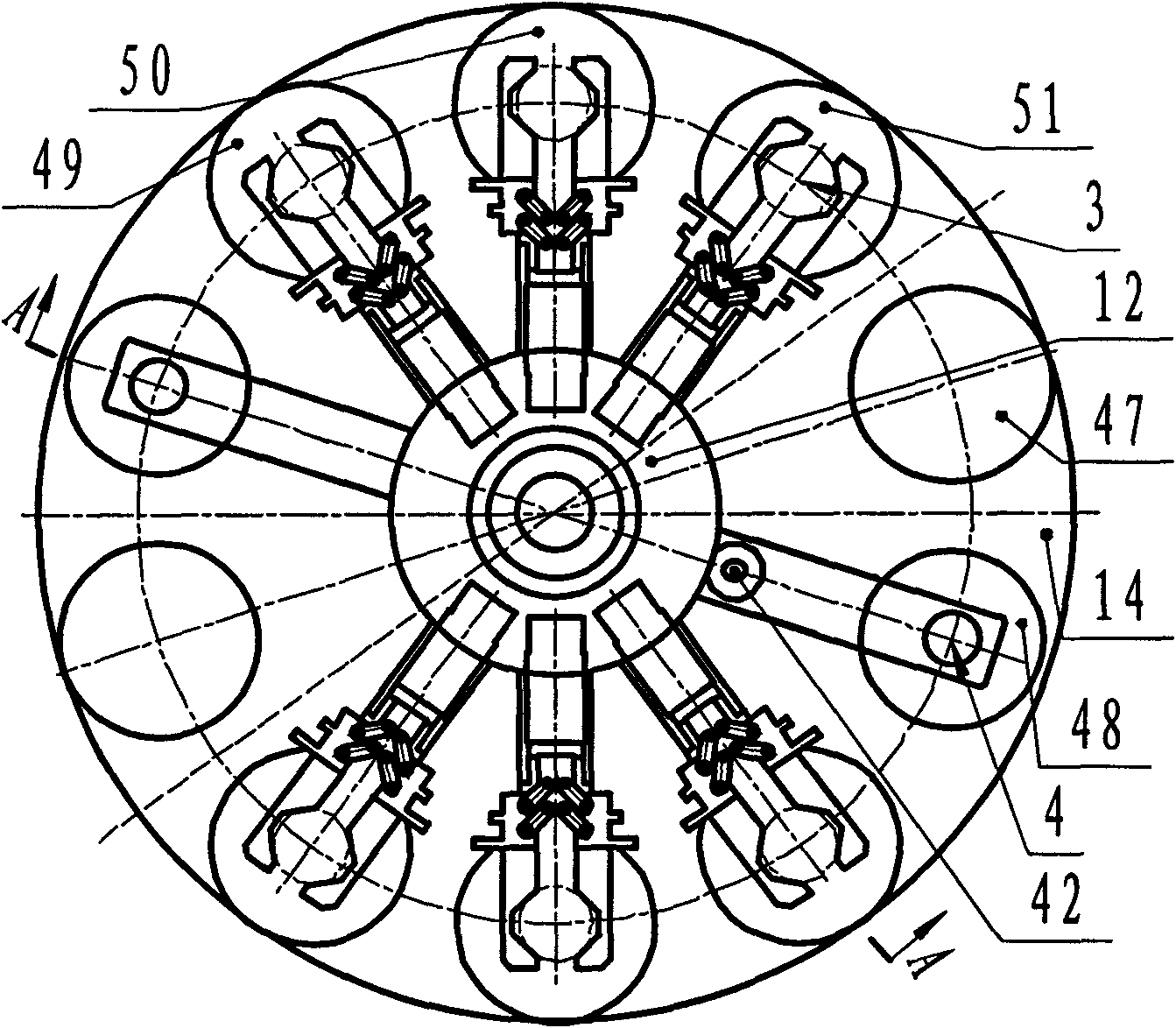

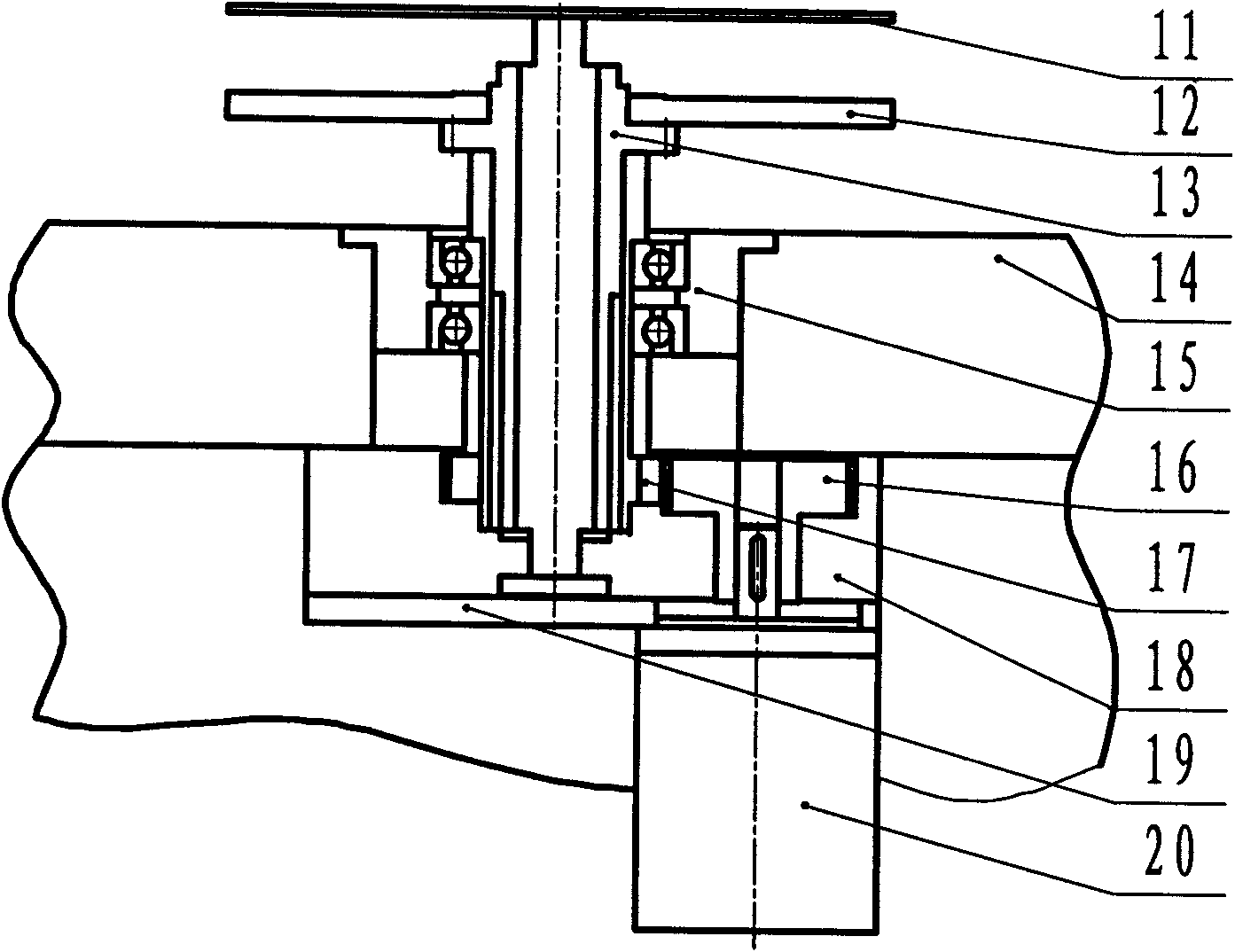

The invention relates to a multistation material transmission manipulator which is characterized in that the manipulator is used for a rotary sealing ring framework punching forming technique and mainly comprises a big template, a swing mechanism, a lifting mechanism, six finger mechanisms and two electromagnetic chucks, wherein the big template is round; the swing mechanism and the lifting mechanism are arranged at the center of the big template; 10 positioning slots are distributed on the periphery of the big template; the six finger mechanisms and the two electromagnetic chucks are divided into two groups, uniformly arranged on the swing mechanism in a radial shape and central symmetrical mode and are corresponding to the position of the positioning slot; and the finger mechanisms and the electromagnetic chucks are all arranged on the top of a rotary disc of the swing mechanism. The manipulator can automatically and continously finish the material transmission and carrying operation (among three working stations of stretching, reverse-drawing and punching) in the punching forming process of the rotary sealing ring framework.

Owner:HEBEI UNIV OF TECH

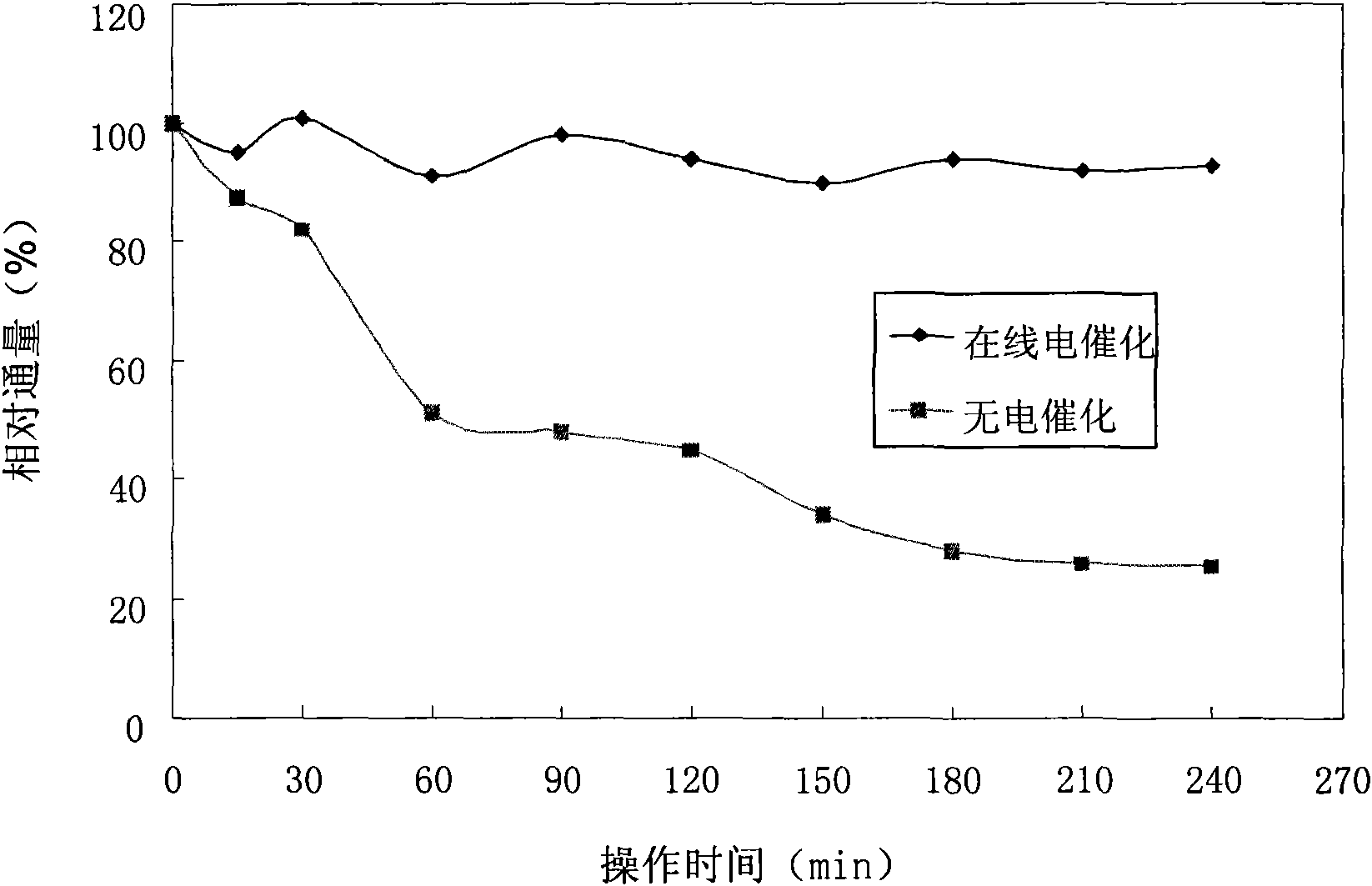

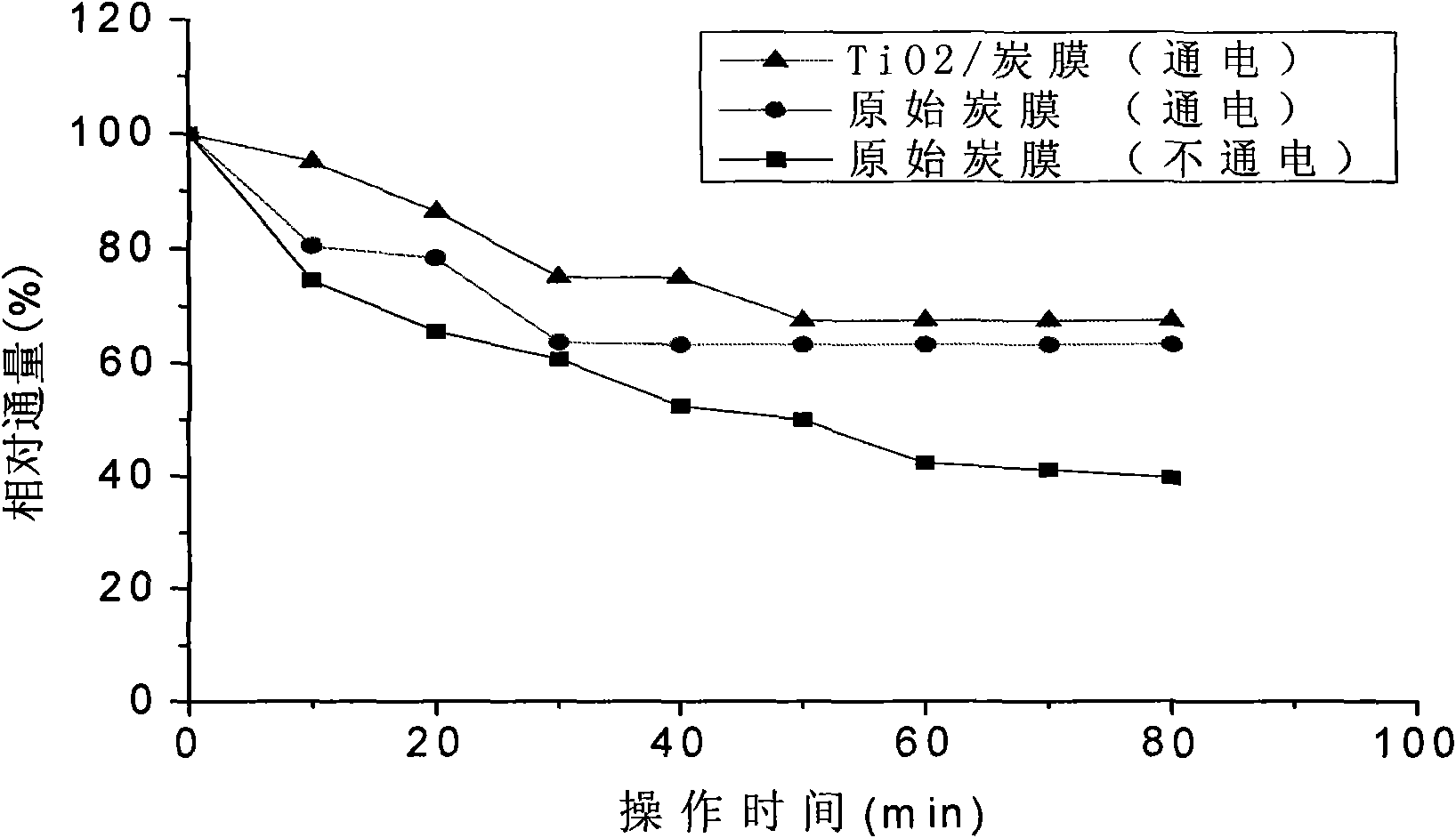

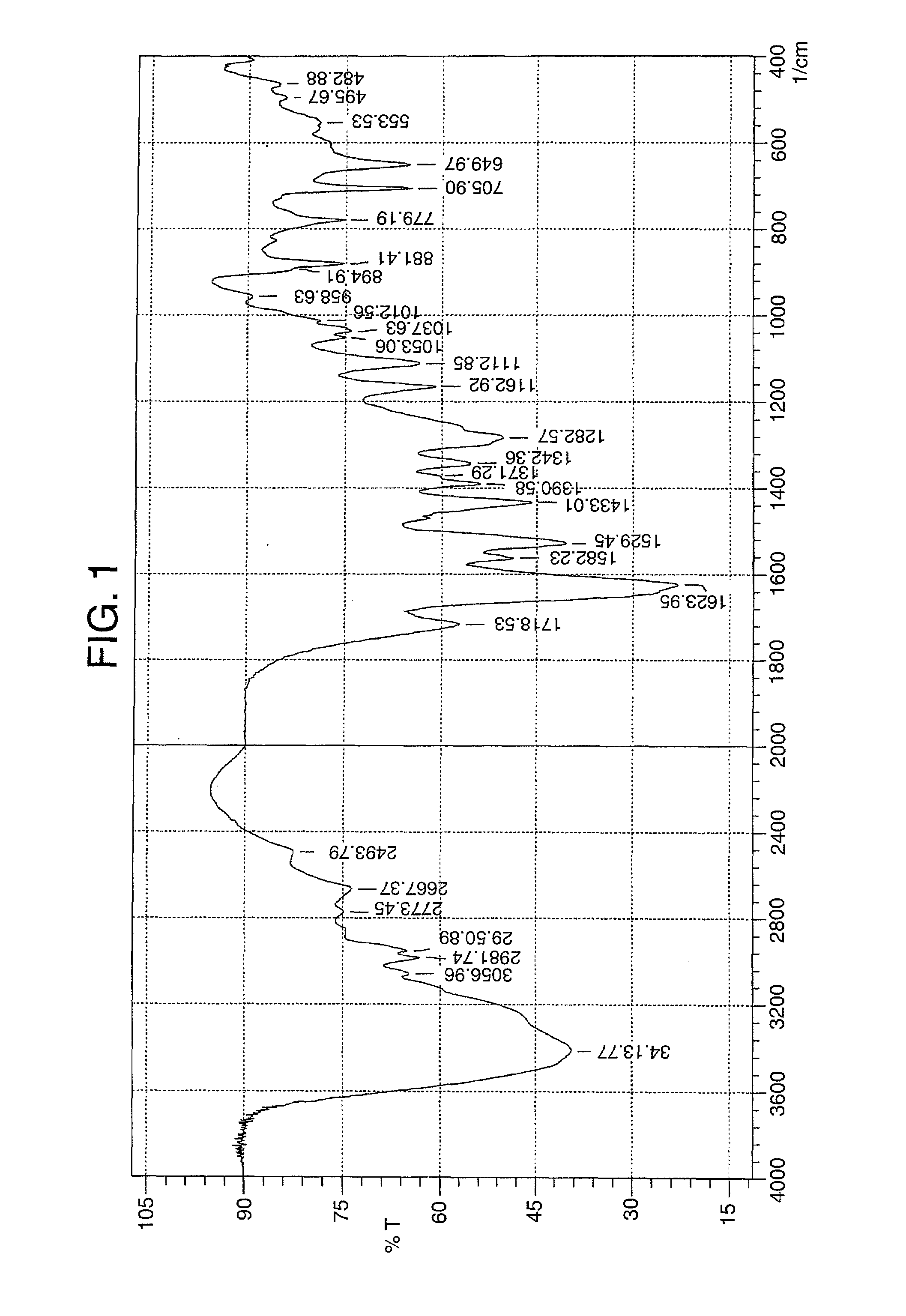

Novel electro-catalytic composite membrane material and preparation method thereof

InactiveCN101559332ATo achieve reinforcementRealize self-cleaningSemi-permeable membranesWater/sewage treatment by electrochemical methodsLow voltageSeparation technology

The invention relates to a novel electro-catalytic composite membrane material and a preparation method thereof. The novel electro-catalytic composite membrane material is characterized in that the material can couple electro-catalytic technology and membrane separation technology. The preparation method comprises the following steps: taking a microporous separation membrane with electric conductivity, namely a carbon membrane, as a substrate, adopting a sol-gel method, mixing a metallic compound, water, a solvent, a catalyst, other additives and the like to be configured into a precursor solution, and obtaining an electro-catalytic composite membrane by sol ageing, film coating, drying and heat treatment; and preparing the composite membrane with superior performances by pretreating a substrate and controlling the mixture ratio of raw materials, the soakage time, the pulling speed, the sintering temperature and the like. The novel electro-catalytic composite membrane material takes the electro-catalytic composite membrane as an anode and a metallic material as a cathode to treat wastewater and realizes the reinforcement of the membrane separation process and the self-cleaning function under the action of a low-voltage electric field. The electro-catalytic membrane material has the advantages of low energy consumption, high separation efficiency, strong antifouling property and the like, and can be widely used for treating and recycling heavily polluted wastewater such as oily wastewater, dye wastewater, paper-making wastewater and the like. The preparation method has the advantages of simple preparation process, cheap equipment, easily-obtained raw materials, convenient operation and suitability for industrialized implementation.

Owner:DALIAN HUAXINYUAN TECHNOLOGY DEVELOPMENT LIMITED COMPANY

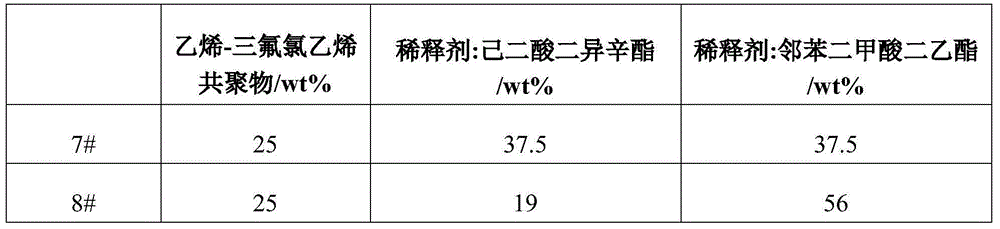

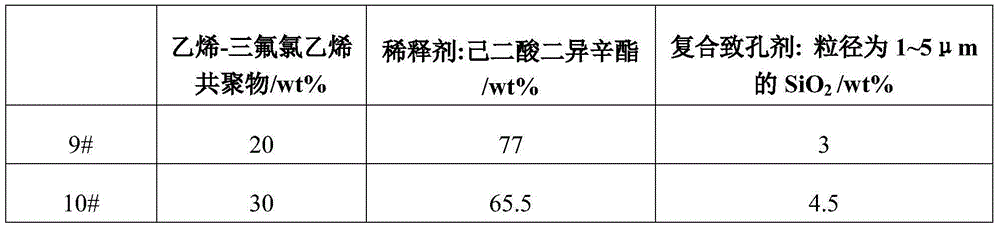

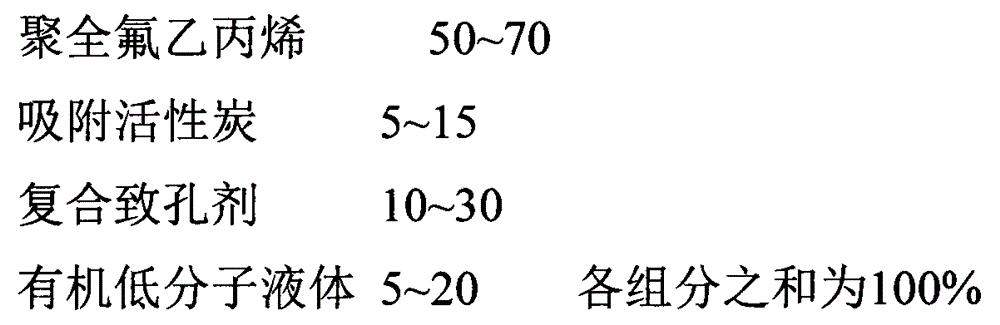

Hollow fiber porous membrane in perfluoro polymer and preparation method thereof

InactiveCN101884878ALower melt processing temperatureLow viscositySemi-permeable membranesTetrafluoroethyleneFiber

The invention discloses a hollow fiber porous membrane in a perfluoro polymer and a preparation method thereof. A membrane forming system of the membrane comprises the following components in percentage by weight: 40 to 60 percent of perfluoro polymer; 10 to 30 percent of polymer additive, 10 to 30 percent of composite pore-forming agent and 5 to 20 percent of organic low-molecular liquid; the perfluoro polymer is a copolymerized modified product of tetrafluoroethylene and a perfluoro second monomer; the polymer additive is fluor alkaline-containing polymers or a mixture thereof; the composite pore-forming agent comprises a soluble pore-forming agent and a non-soluble pore-forming agent; and the organic low-molecular liquid is a diluent of the polymer additive with a high boiling point. The preparation method comprises the following steps of: forcibly mixing the polymer additive, the composite pore-forming agent and the organic low-molecular liquid; uniformly mixing the mixture and the perfluoro polymer particles; and injecting the mixture into a double-screw machine, performing melt blended spinning at a temperature of between 300 and 360 DEG C and finally performing a conventional post-processing to obtain the hollow fiber porous membrane.

Owner:TIANJIN POLYTECHNIC UNIV

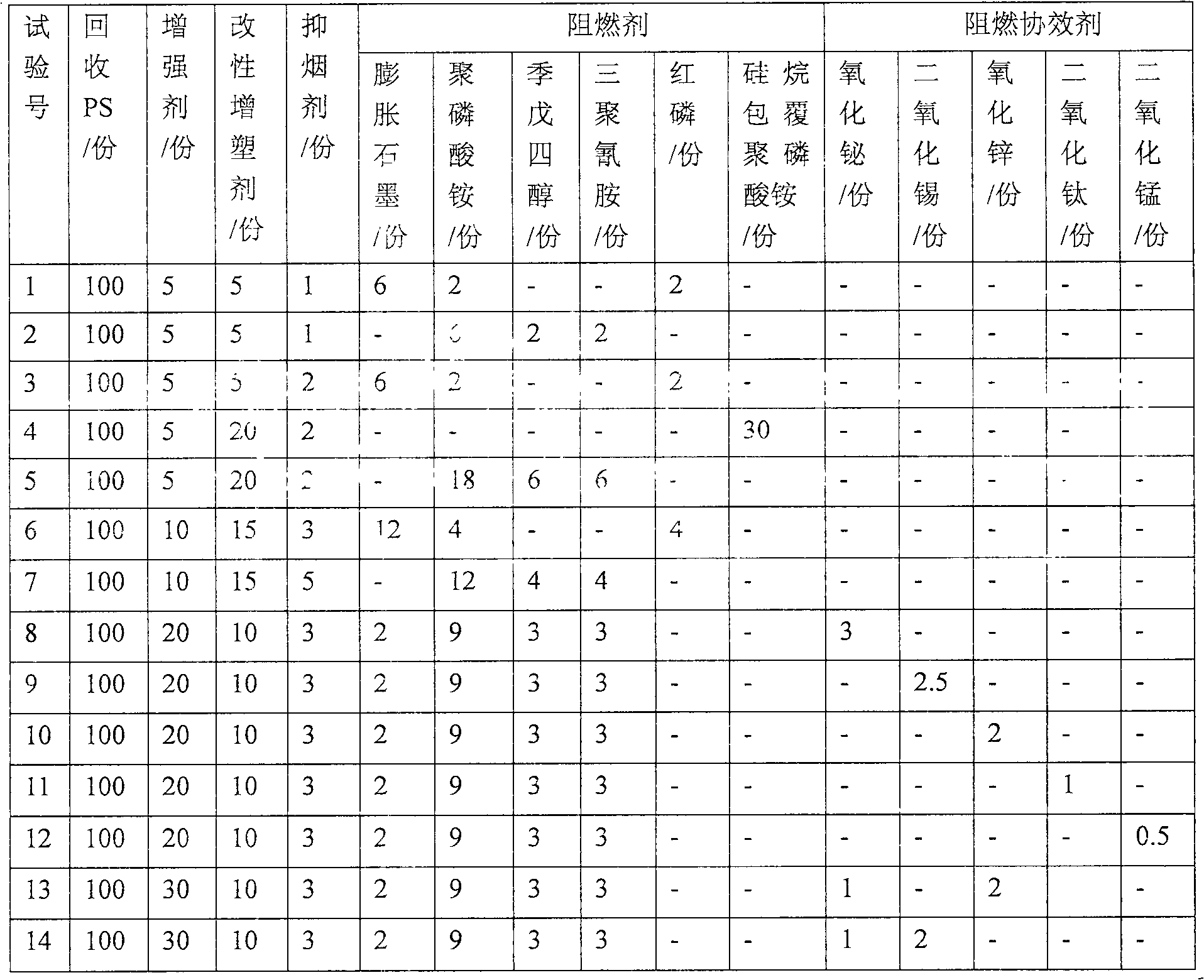

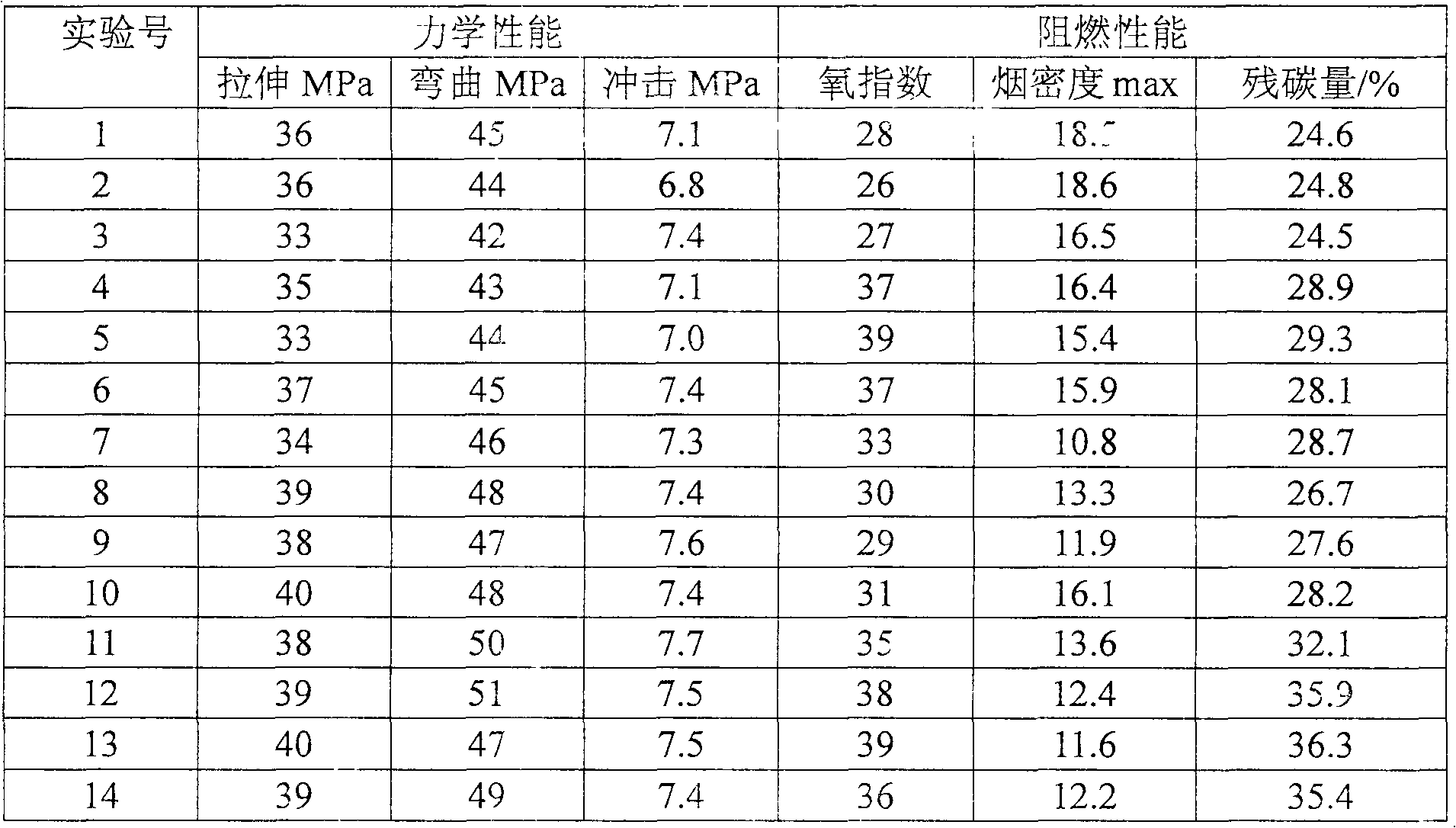

Preparation method of flame retarding styrene polymer composite material

The invention discloses a preparation method of a flame retarding styrene polymer composite material. The raw materials of the composite material (weight) includes 100 parts of recovered styrene polymer, 10-30 parts of flame retardant, 1-5 parts of smoke inhibitor and 5-30 parts of intensifier. The preparation method includes the following steps: 1. stirring the intensifier in a high speed mixingmachine to have the water content of 1-2% at the temperature of 105-150 DEG C and at the revolving speed of 600-1000r / min; 2. crushing the recovered styrene polymer product in a high speed crushing machine and then adding the crushed product in a double-screw machine to be extruded and pelletized; 3. sequentially adding the pellet, dry wood powder, flame retardant and smoke inhibitor in the high speed mixing machine for 5-10 min of premixing, and then discharging the mixture to a low speed cold mixing machine for 5-10 min of mixing to obtain premix; and 4. melting down the premix through the double-screw machine until or single-screw machine for pelleting to obtain the flame retarding styrene polymer composite material.

Owner:TIANJIN POLYTECHNIC UNIV

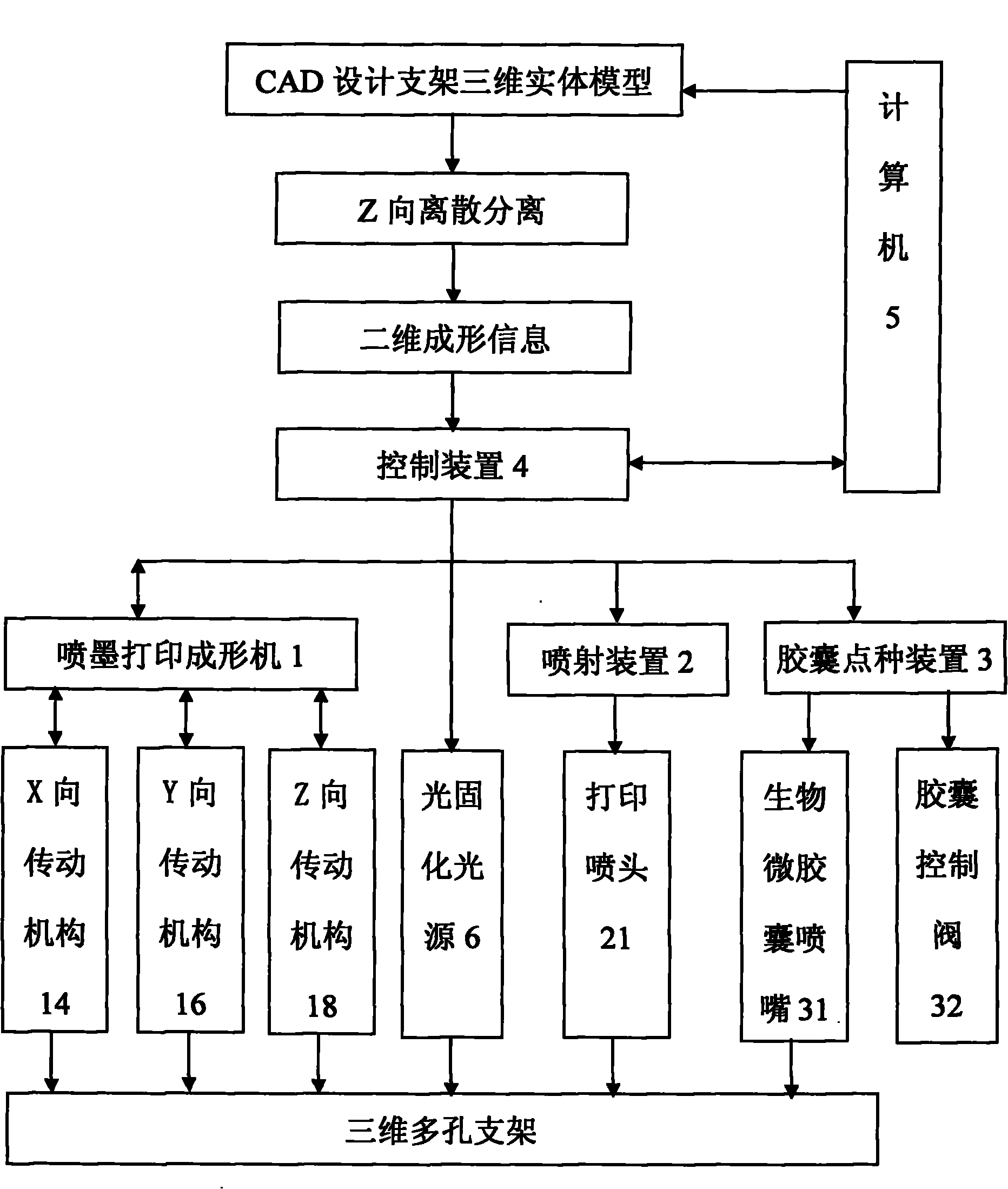

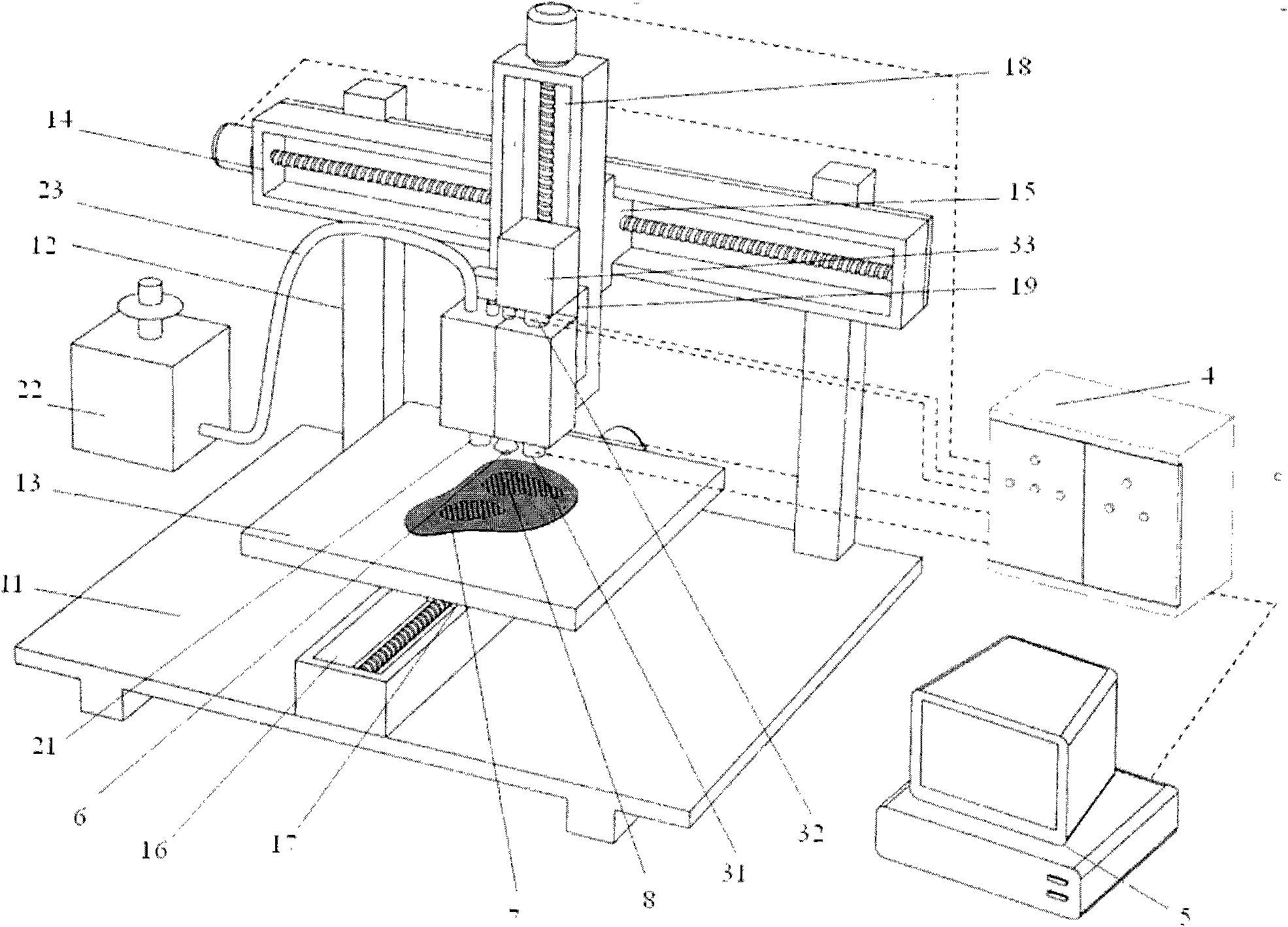

Method and device for preparing three-dimensional porous support for tissue engineering

InactiveCN101884574APosition is easy to controlControllable Aperture SizeStentsProsthesisControl systemLayer wise

The invention discloses a method and device for preparing a three-dimensional porous support for tissue engineering. The preparation method comprises the following steps of: 1, slicing and layering a support according to a certain thickness firstly to obtain two-dimensional cross section information of each layer of the support; 2, preparing a first layer slice of the support by using a three-dimensional inkjet printing spray head under the control of CAD software, dibbling microcapsule particles on the first layer slice of the support by using a bio-microcapsule preparation nozzle, and stacking the microcapsule particles to form gaps required by a support design; 3, moving the three-dimensional inkjet printing spray head and the bio-microcapsule preparation nozzle for the height of one layer slice of the support to finish the forming preparation of a second layer of the support; and 4, repeating the method layer by layer until the three-dimensional porous support is prepared. The device for preparing the three-dimensional porous support is suitable for the preparation method, and comprises a three-dimensional inkjet printing forming machine, a jetting device, a bio-microcapsule dibbling device and a control system.

Owner:HEBEI UNIV OF TECH

Animal hair solvent and preparation method and use of keratin solution

InactiveCN101979428AHigh molecular contentGuaranteed stabilityFibre treatmentAdditive ingredientSulfite salt

The invention discloses an animal hair solvent and the preparation method and use of keratin solution. The solvent is characterized in that tris(2-carboxyethyl)phosphine hydrochloride, tris(2-cyanoethyl)phosphine or trisphosphine is used as a main ingredient and is mixed with 1 to 8 percent of assistant which may be at least one of mercaptoacetic acid, mercaptoethanol, sodium hydrogensulfite, potassium bisulfate, sodium sulfite, potassium sulfite, sodium hypophosphite, ethanol, methanol and urea. The preparation method adopts the following processes: 1, preparing animal hair solution by using the animal hair solvent of the invention; 2, dissolving animal hair in the solution to prepare keratin solution; and 3, adding a proper amount of acid to perform the post-treatment of the keratin solution. The use is to use the keratin solution as textile finishing liquor or the main functional ingredient of the textile finishing liquor.

Owner:TIANJIN POLYTECHNIC UNIV +1

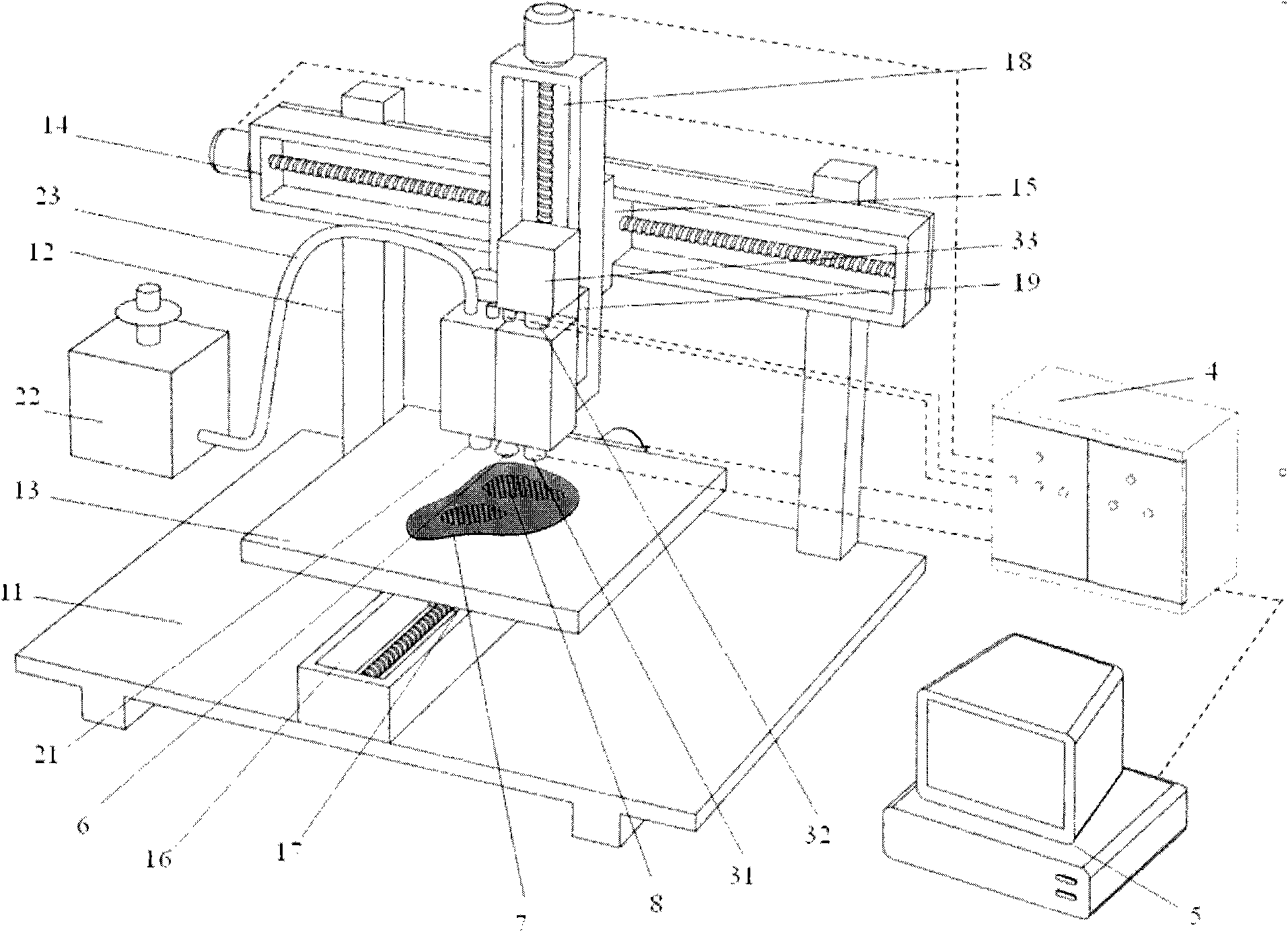

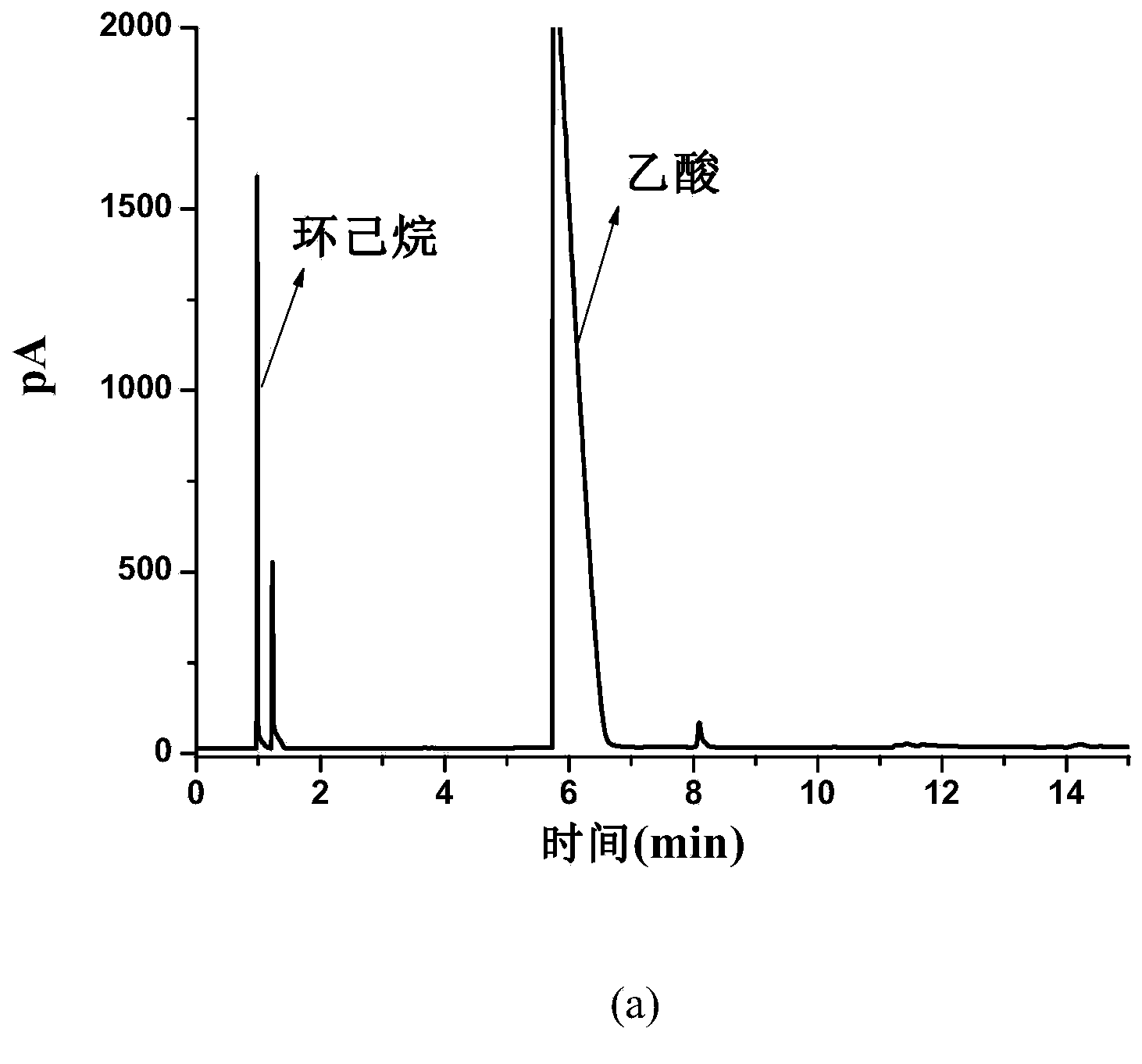

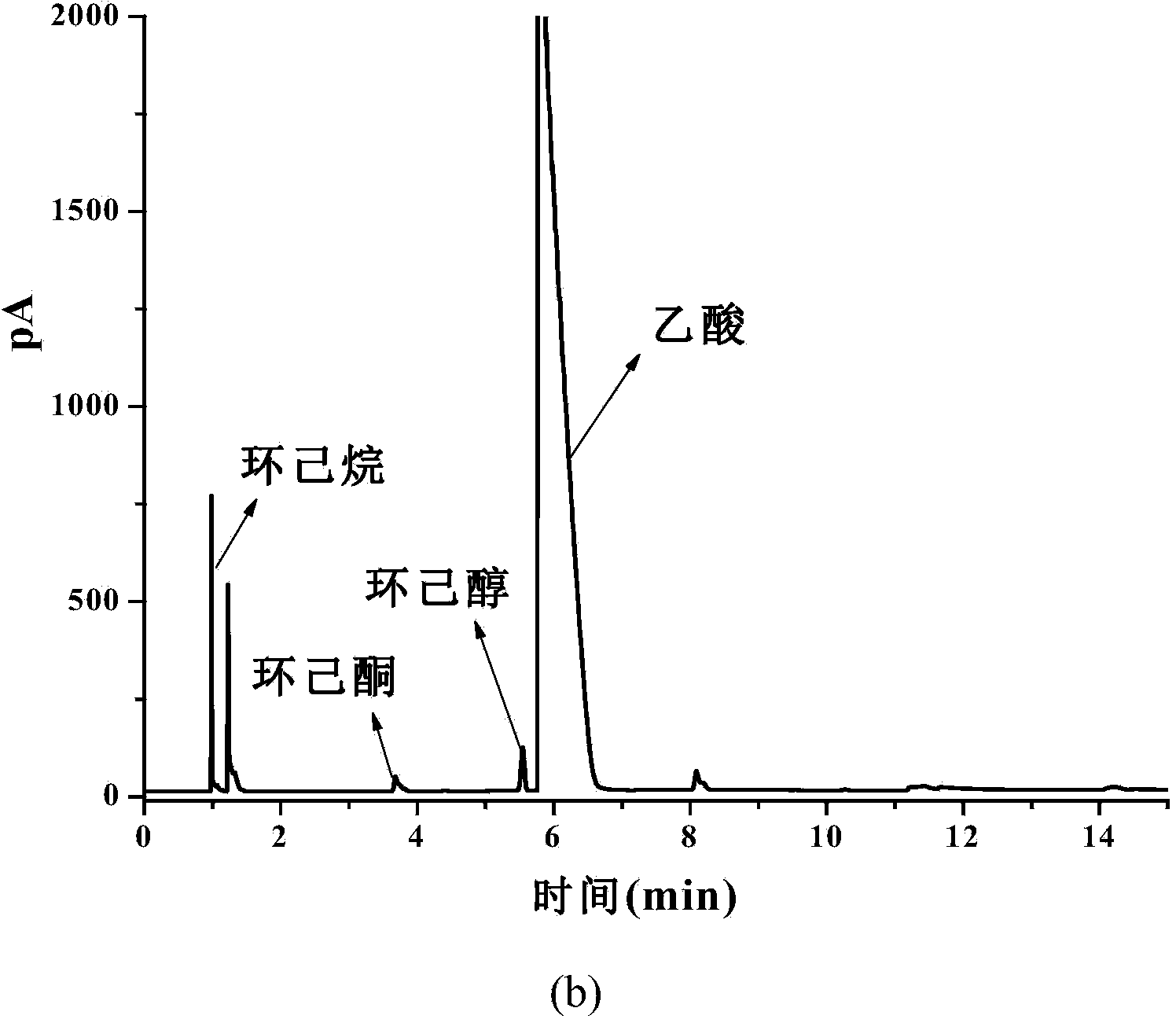

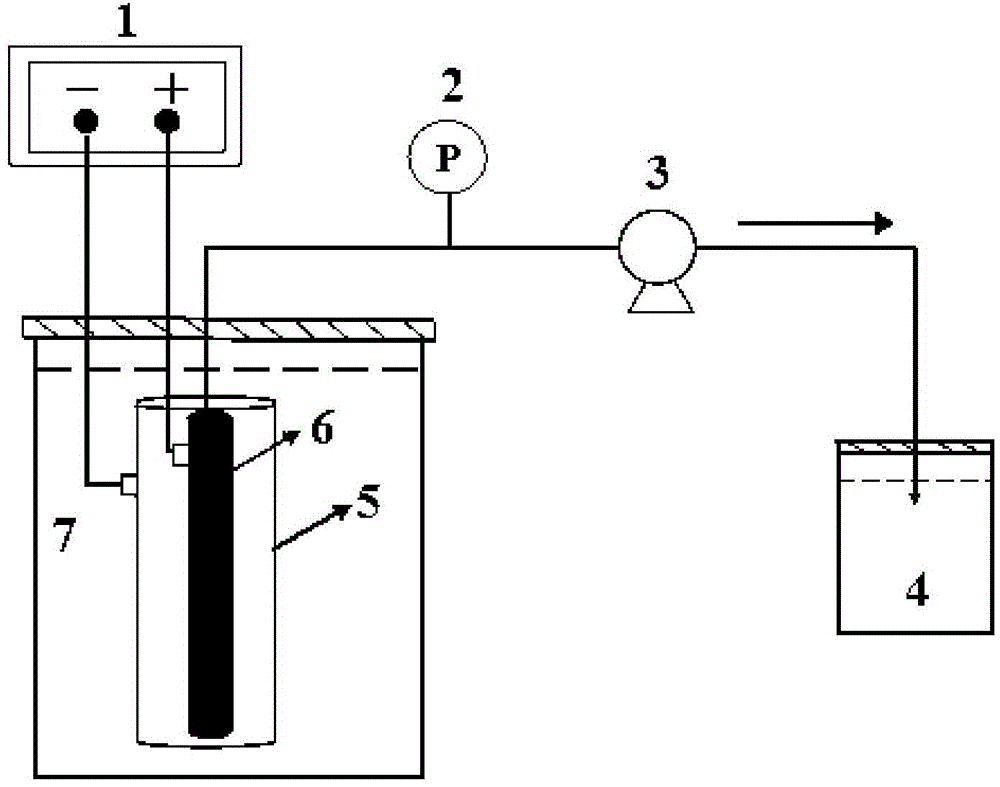

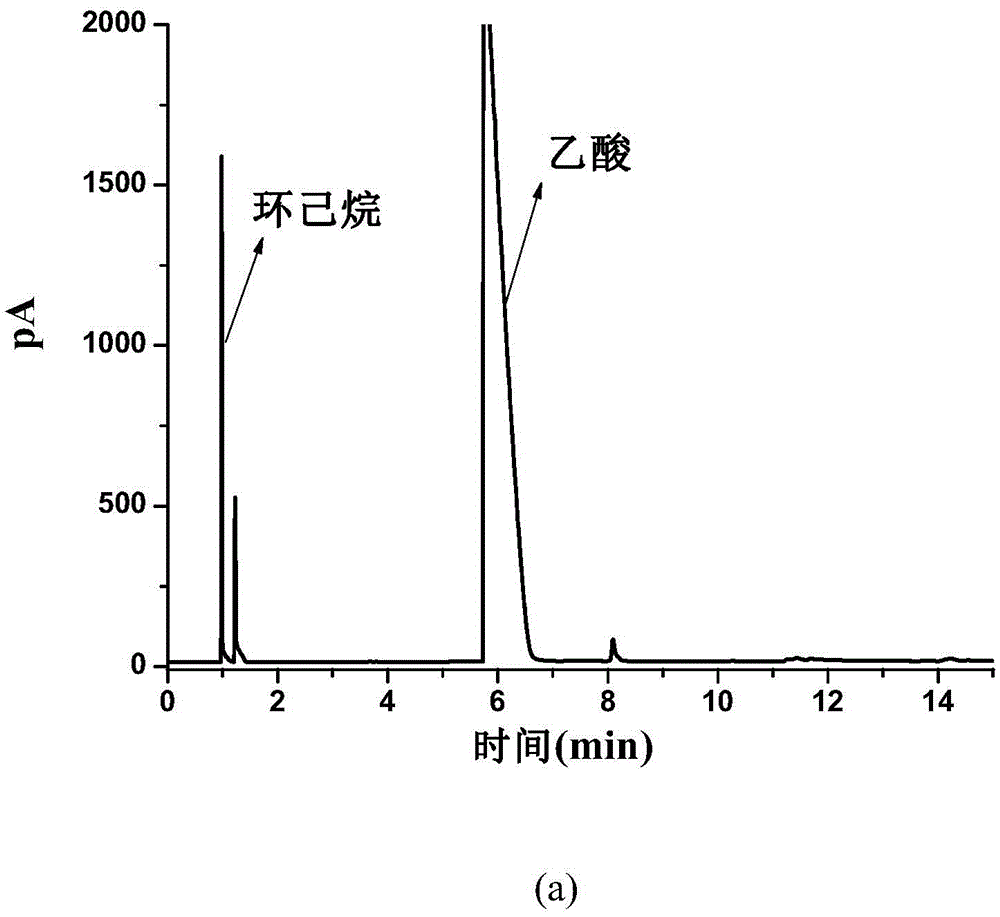

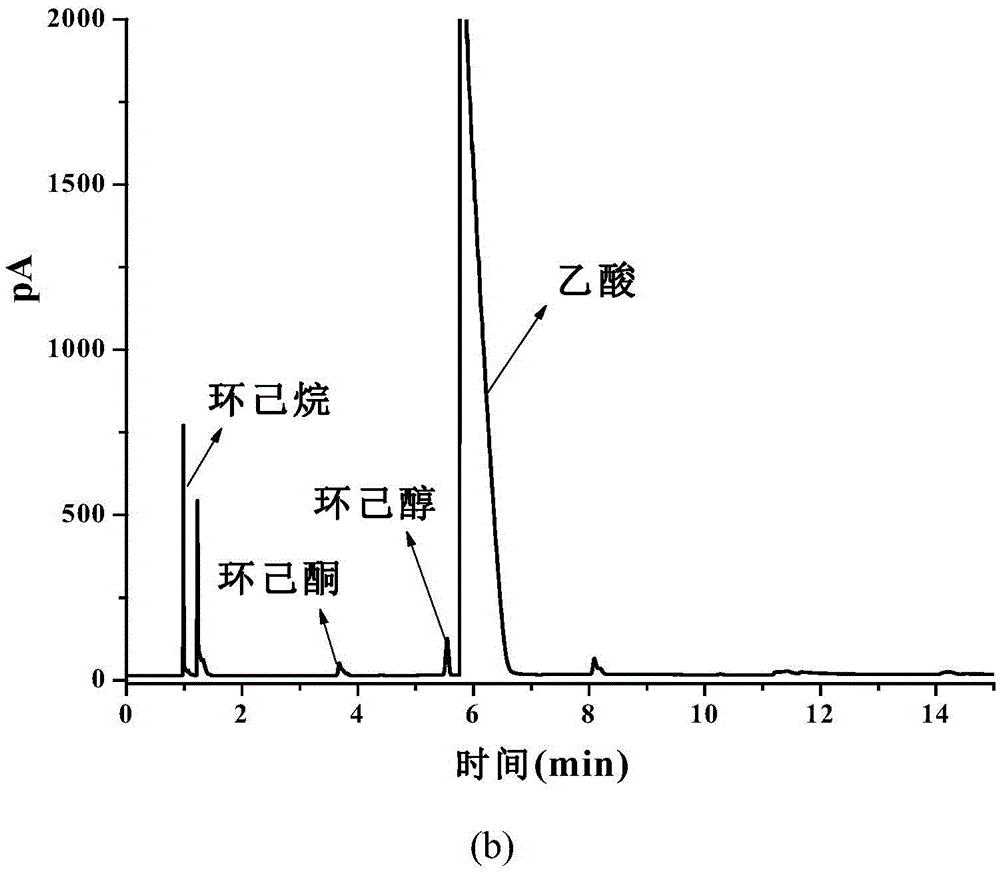

Method for preparing cyclohexanol and cyclohexanone by virtue of electrochemically catalytic oxidation of cyclohexane

InactiveCN104032327AHigh selectivityEasy to operateElectrolysis componentsElectrolytic organic productionAuxiliary electrodePeristaltic pump

The invention discloses a method for preparing cyclohexanol and cyclohexanone by virtue of electrochemically catalytic oxidation of cyclohexane in the technical field of organic electrochemical synthesis. The method comprises the following steps: forming an electrocatalytic membrane reactor by taking a metal oxide loaded porous metal electrocatalytic membrane as an anode and an auxiliary electrode as a cathode; with a mixed water solution of cyclohexane, an organic solvent and electrolyte as a reaction raw material solution, catalytically oxidizing cyclohexane on the surface of the membrane and in a hole by using metal oxide loaded on the membrane to form products, namely cyclohexanol and cyclohexanone under a certain working voltage and current density condition; meanwhile, sucking the products to a permeation side under a certain membrane permeation flux condition by means of negative pressure generated by a peristaltic pump to realize real-time online separation or transfer; then, separating and purifying a membrane permeation solution to finally obtain the products, namely cyclohexanol and cyclohexanone. Compared with the traditional process, the method has the advantages of high efficiency, environment friendliness, high selectivity, simplicity in operation and the like, is suitable for industrial implementation and has wide application prospect.

Owner:TIANJIN POLYTECHNIC UNIV

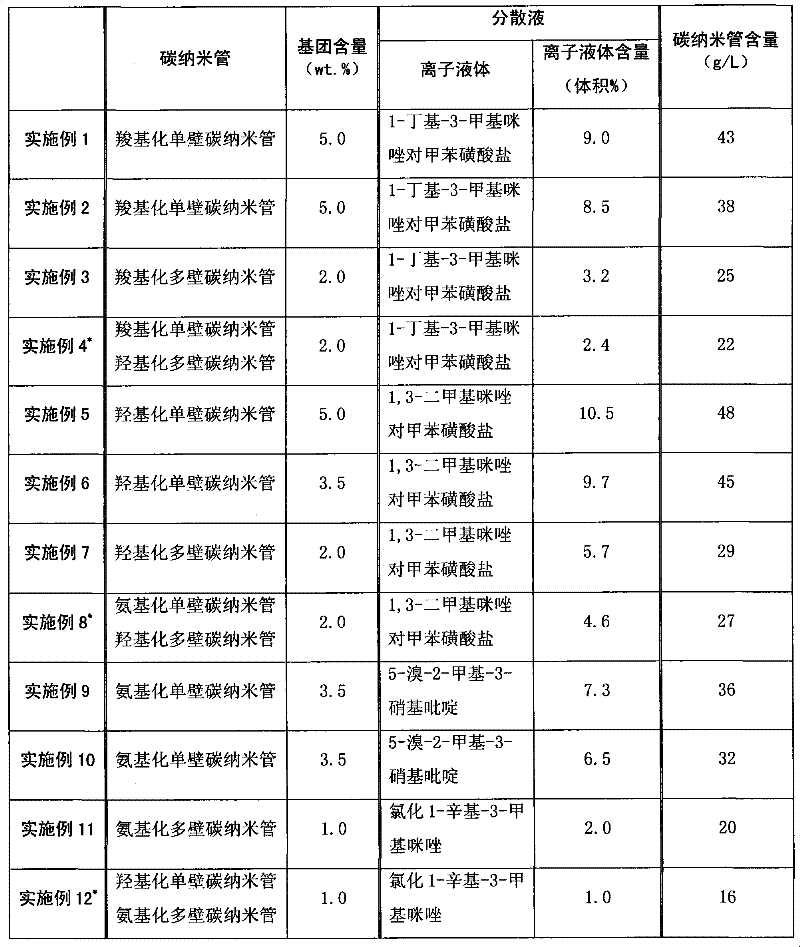

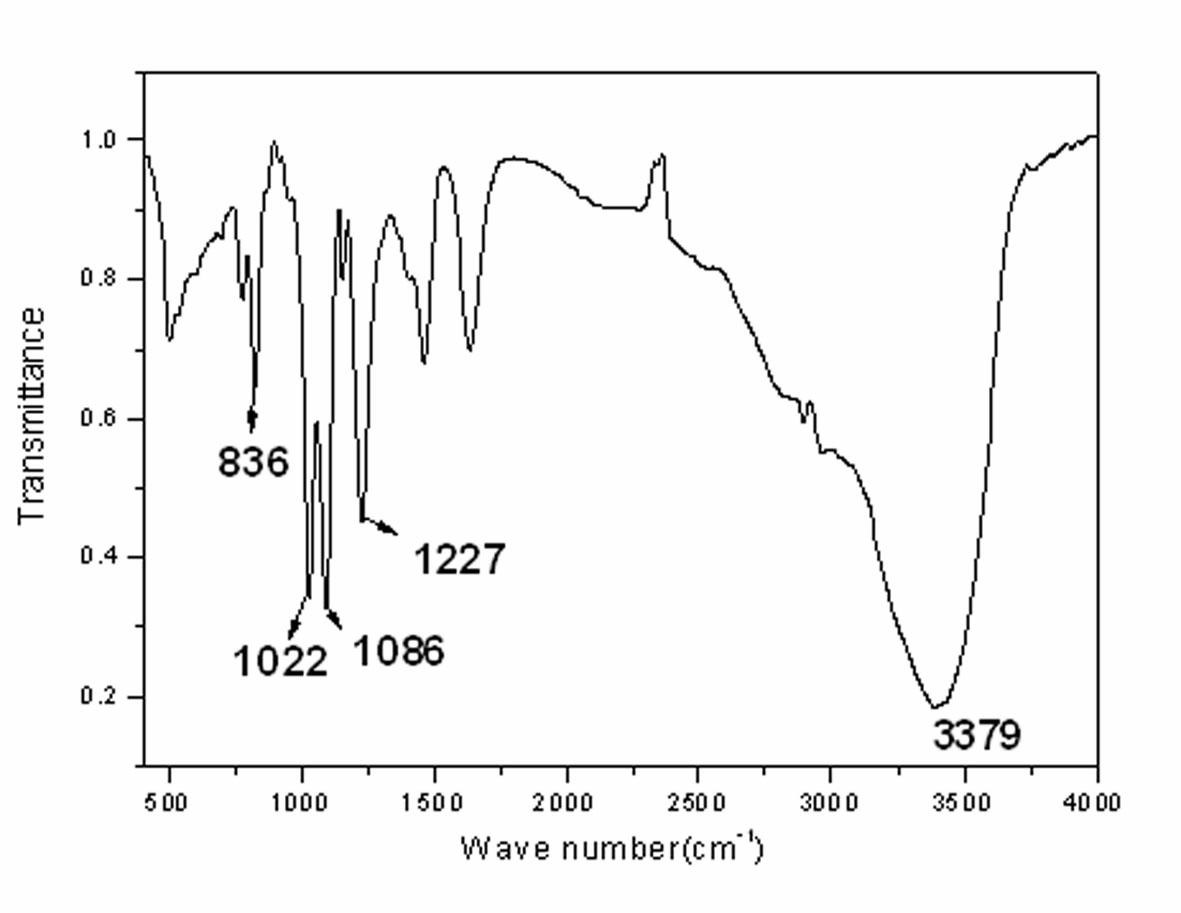

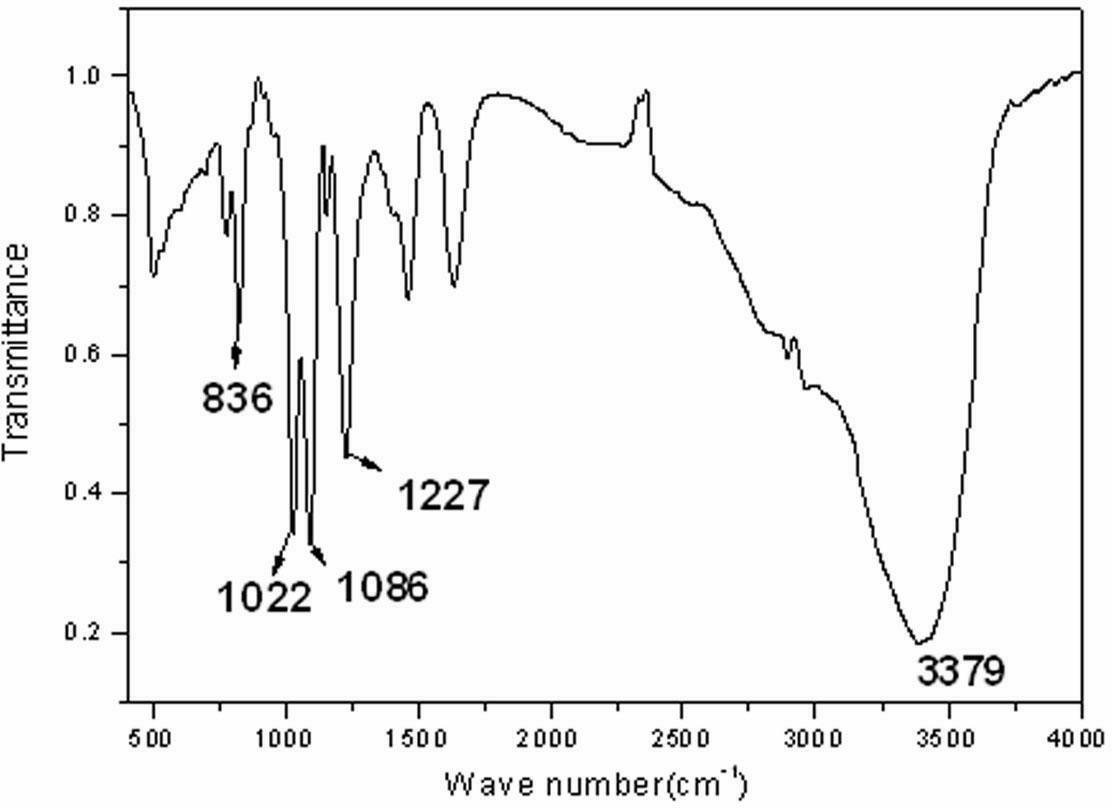

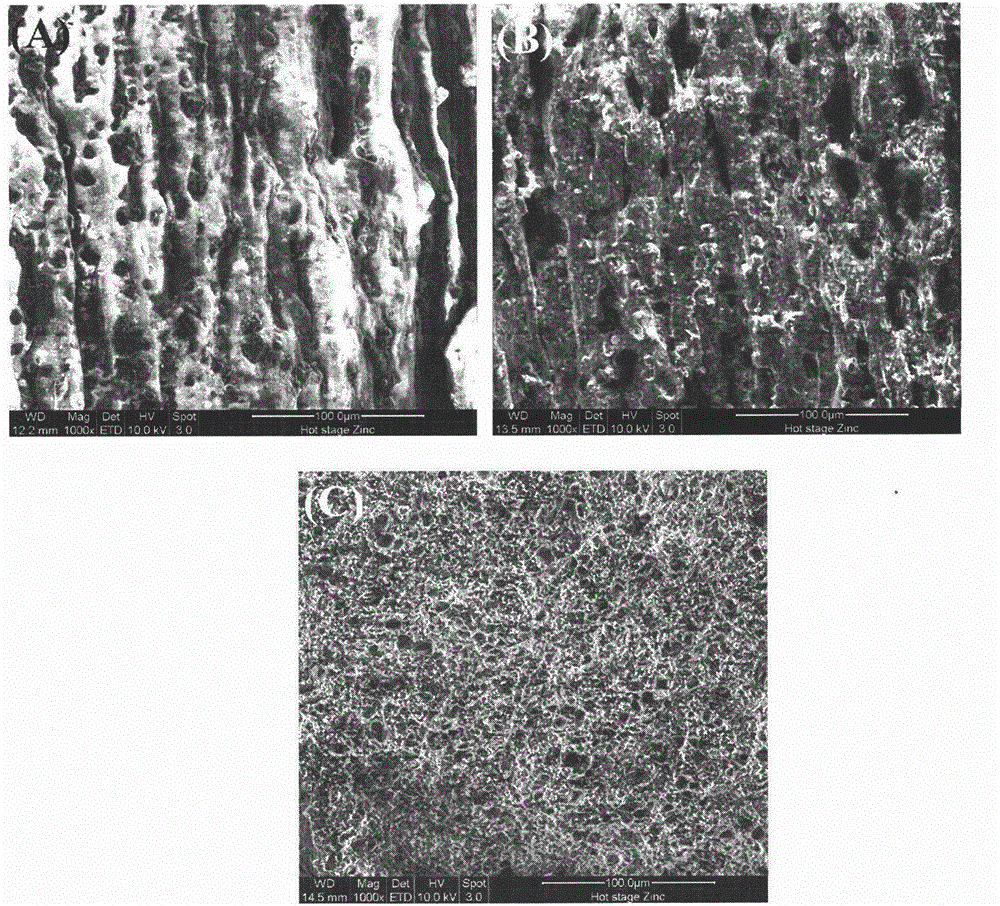

Methods of Improving the Strength of Carbon Fiber

InactiveCN102296457AHigh strengthSuitable for industrial implementationCarbon fibresFiberCarbon fibers

A method for improving the strength of carbon fibers, comprising: 1) soaking the carbon fibers in an aqueous solution of nitric acid, washing the carbon fibers with deionized water until the washing liquid is neutral after soaking; 2) preparing a carbon nanotube dispersion into a spraying liquid, carbon The nanotubes are functionalized carbon nanotubes, which are obtained from hydroxylated carbon nanotubes, carboxylated carbon nanotubes or aminated carbon nanotubes. The dispersion liquid is a mixture of ionic liquid and water, and the ionic liquid is obtained from 1,3 -Dimethylimidazole p-toluenesulfonate, 1-butyl-3-methylimidazole p-toluenesulfonate, 1-octyl-3-methylimidazole chloride or 5-bromo-2-methyl-3 - One of the nitropyridines, the content of carbon nanotubes in the spraying liquid is 16-48g / L; 3) The spraying liquid is applied with positive static electricity of 10-40kV, and the carbon fiber tow is flattened and grounded to form a spraying liquid acceptor, and then passes through Electrostatic spraying sprays the spray liquid on the carbon fiber surface. The tensile strength of carbon fiber can be increased by more than 100%.

Owner:CHINA PETROLEUM & CHEM CORP

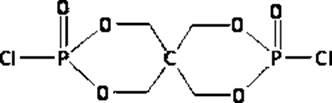

Reactive intumescent flame retardant for polyurethane and synthesis method of reactive intumescent flame retardant

InactiveCN102585135ADoes not affect mechanical propertiesHigh phosphorus and nitrogen flame retardant ingredientsGroup 5/15 element organic compoundsHalogenHigh carbon

The invention discloses a reactive intumescent flame retardant for polyurethane and a synthesis method of the reactive intumescent flame retardant, relates to a flame retardant technology, in particular to a novel intumescent flame retardant which contains an acid source, a carbon source and a gas source simultaneously and contains a hydroxyl group serving as an active group. The chemical name ofthe reactive intumescent flame retardant for polyurethane is 3,9-di{N,N-di(2-ethoxyl)-amino}-2,4,8,10-4-oxo-3,9-diphosphate spiro-3,9-dioxo-[5,5]-undecane. The structure of the reactive intumescent flame retardant is shown as a formula (I). The synthesis method comprises the following steps of: adding 3,9-di{N,N-di(2-ethoxyl)-amino}-2,4,8,10-4-oxo-3,9-diphosphate spiro-3,9-dioxo-[5,5]-undecane into water; dropwise adding diethanolameine and triethylamine at the temperature of 0-5 DEG C; reacting at the temperature of 50-60 DEG C for 4-6 hours; concentrating under reduced pressure; purifying; and performing vacuum drying to obtain the flame retardant. The flame retardant and the synthesis method of the reactive intumescent flame retardant have the advantages of integration of phosphorus, nitrogen and carbon, high phosphorus and nitrogen flame-retardant ingredients, no containing of halogen, nontoxicity, environmental friendliness, high carbon forming property, high compatibility with apolyurethane system, simple process, mild synthesis condition and suitability for industrial implementation.

Owner:ZHONGBEI UNIV

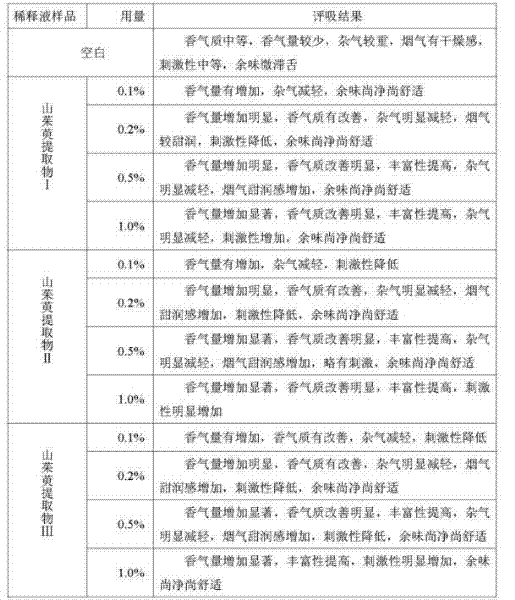

Method for preparing cornus officinalis extract, application in cigarettes and cigarette

InactiveCN102389162AHigh clarityImprove stabilityTobacco treatmentEssential-oils/perfumesChromatographic separationMicrowave

The invention discloses a method for preparing cornus officinalis extract, an application in cigarettes and the cigarette. The method for preparing the cornus officinalis extract comprises the following steps: preparing the cornus officinalis; using the ultrasonic wave to extract collaborated with microwaves; extracting the liquid and concentrating; centrifuging and separating; separating by column chromatography; and concentrating to obtain the cornus officinalis extract. The cornus officinalis extract prepared by the invention is applied to the cigarettes, the use is convenient, the quality and level of the cigarette are improved, the smoke is rich and sweet, and the palate aftertaste is improved. The method combines the advantages of the ultrasonic wave with the homogenization of the microwave vibration, so the stress of each point in the sample medium is the same, the range of the target extract is large, the combination force of the target object and the sample substrate is reduced, the process that the target object enters the liquid from the solid phase is accelerated, and the sample process quantity is large. The cornus officinalis extract is obtained after extracting and refining by column chromatography with gentle conditions, which provides a new perfume material for natural tobaccos.

Owner:SHENZHEN TOBACCO IND +1

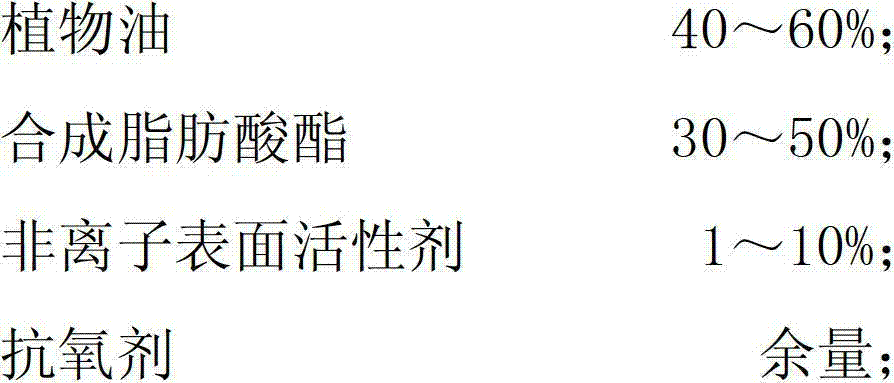

Cord thread spinning oil

InactiveCN103161068AImprove spinnabilityHigh spinnability, uniform fiber draft, high breaking strengthFibre typesSynthetic polymer filament chemical after-treatmentRapeseedEngineering

The invention discloses cord thread spinning oil. The cord thread spinning oil comprises, by mass, 40-60% of plant oil, 30-50% of compound fatty acid ester, 1-10% of non-ion surfactant, and the balance antioxidant. The plant oil is selected from at least one of peanut oil, soya-bean oil, linseed oil, castor oil, health oil, and rapeseed oil, refined processing is carried out on the plant oil, iodine value is higher than 70, the compound fatty acid ester is pentaerythritol ester or trimethylolpropane ester, and the non-ion surfactant is fatty alcohol-polyoxyethylene ether, fatty alcohol polyurethane propylene ether or fatty alcohol polyoxyethylene polyoxypropylene.

Owner:TIANJIN POLYTECHNIC UNIV

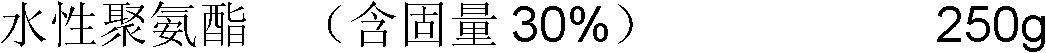

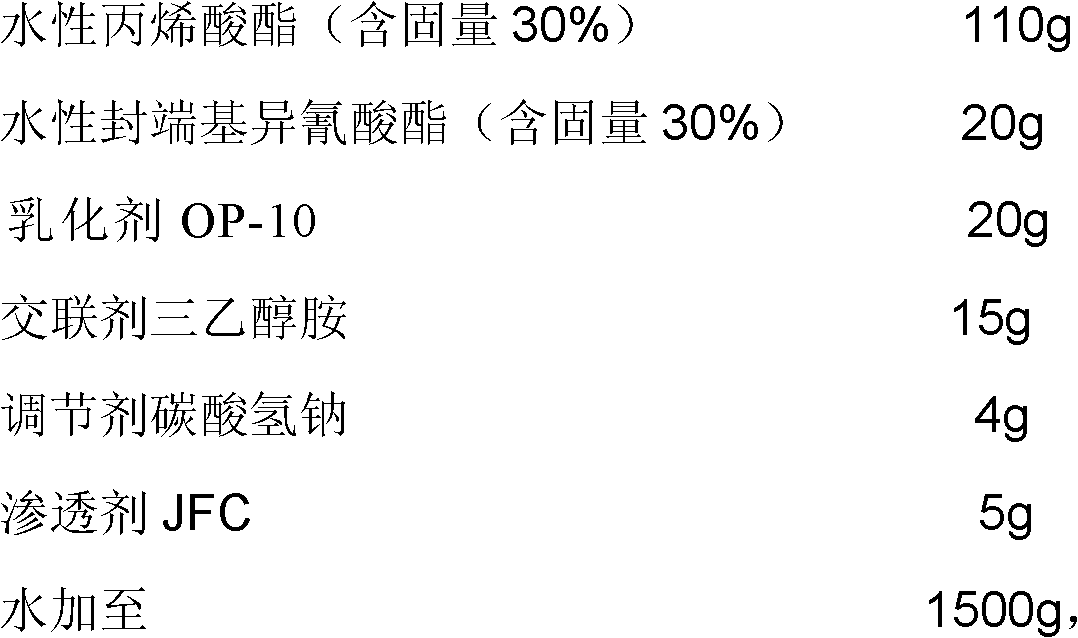

Hair slip prevention finishing agent and finishing method for rabbit hair fabric

ActiveCN102505485AGood anti-lint effectSoft touchLiquid/gas/vapor removalAnimal fibresSodium bicarbonateAcrylic resin

The invention discloses a hair slip prevention finishing agent and a finishing method for a rabbit hair fabric. The finishing agent comprises resin finishing liquor and hand feeling improvement finishing liquor. The resin finishing liquor consists of the following components in percentage by mass: 5.5 to 25 percent of waterborne polyurethane, 4 to 15 percent of watercraft acrylic resin, 0.5 to 1.5 percent of waterborne terminated isocyanate, 1.5 to 2.5 percent of emulsifier OP-10, 0.1 to 1.0 percent of regulator sodium bicarbonate or sodium carbonate, and the balance of water. The hand feeling improvement finishing liquor consists of the following components in percentage by mass: 5 to 25 percent of amino-modified silicone oil softener and the balance of water. In the finishing method, the finishing agent disclosed by the invention and a one-step finishing process (1) and a two-step finishing process (2) are adopted. The finishing agent disclosed by the invention is easy to prepare, has low cost, is convenient to use and has good hair slip prevention effect. The finishing method disclosed by the invention has simple process and is suitable for industrial implementation.

Owner:TIANJIN POLYTECHNIC UNIV

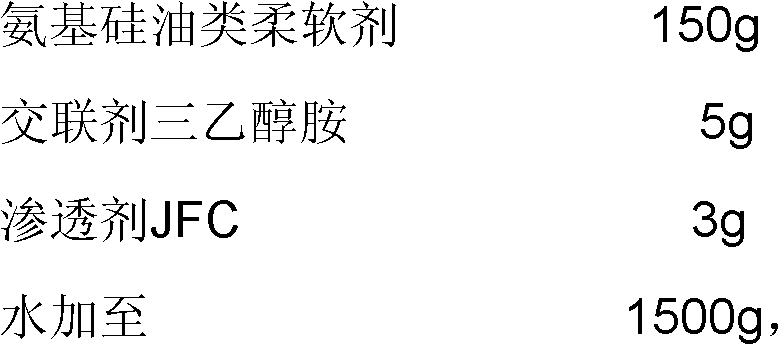

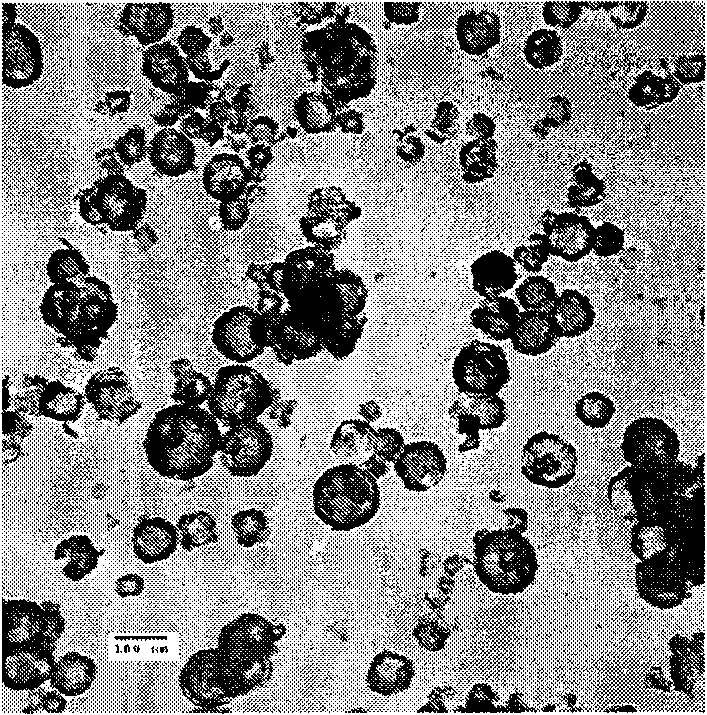

Catalyst for catalytically hydrolyzing sodium borohydride to prepare hydrogen and preparation method thereof

ActiveCN102029159AFulfil requirementsMeet the requirements), suitable for industrial implementationHydrogen productionMetal/metal-oxides/metal-hydroxide catalystsSilicon oxideReducing agent

The invention discloses a catalyst for catalytically hydrolyzing sodium borohydride to prepare hydrogen and a preparation method thereof. The catalyst is characterized in that the catalyst is a composite catalyst formed by taking silicon oxide as the carrier and coating more than one metal nanoparticle layers on the carrier; the diameter of the silicon oxide particle is 100-1000nm; the metal nanoparticle is nickel or nickel boride; the diameter of the metal nanoparticle is 10-200nm; and the mass of the metal nanoparticle is 5-50% that of the carrier. The preparation method comprises the following steps: 1, preparing the silicon oxide carrier: firstly preparing defined amount of ammonia water and ethanol into mixed liquor, then adding tetraethoxysilane to the mixed liquor and stirring the mixture to react to prepare silicon oxide carrier particle suspension; and 2, coating the nickel or nickel boride metal nanoparticle: taking 100ml of silicon oxide suspension, adding defined amount ofmetal salt solution to the suspension, after stirring and uniform mixing, adding excessive reducing agents for reaction, thus obtaining nickel or nickel boride-silicon oxide catalyst suspension.

Owner:TIANJIN POLYTECHNIC UNIV

Formula for preparing fluorocopolymer porous membranes and method for preparing porous membranes according to formula

ActiveCN104607062ALow film forming temperatureSuitable for industrial implementationMembranesSemi-permeable membranesHollow fibreFiber

Owner:苏州孝义家光电科技有限公司

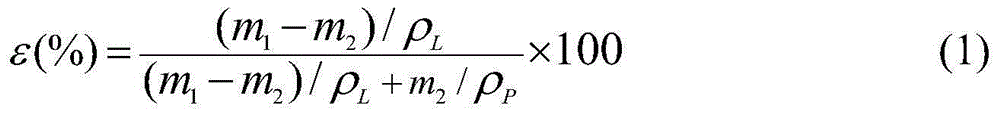

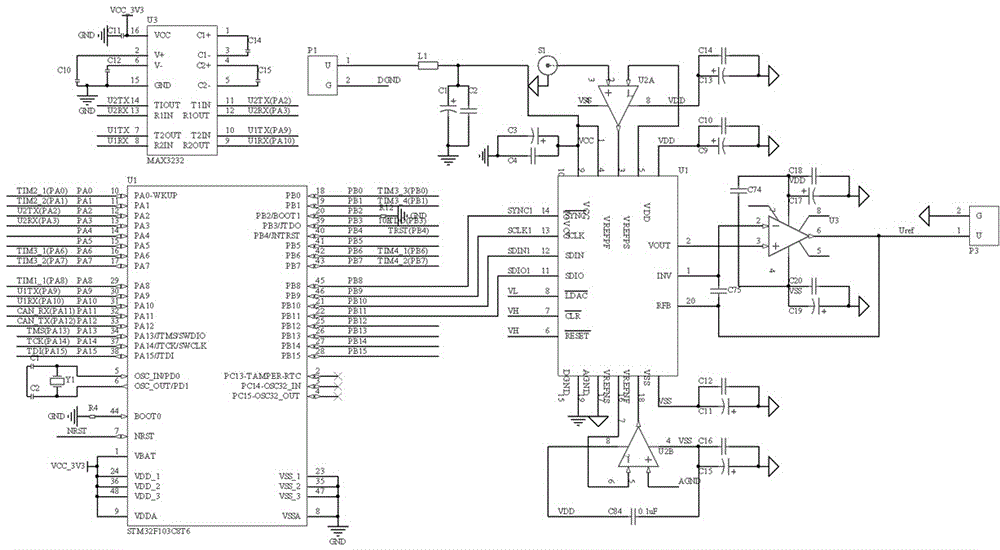

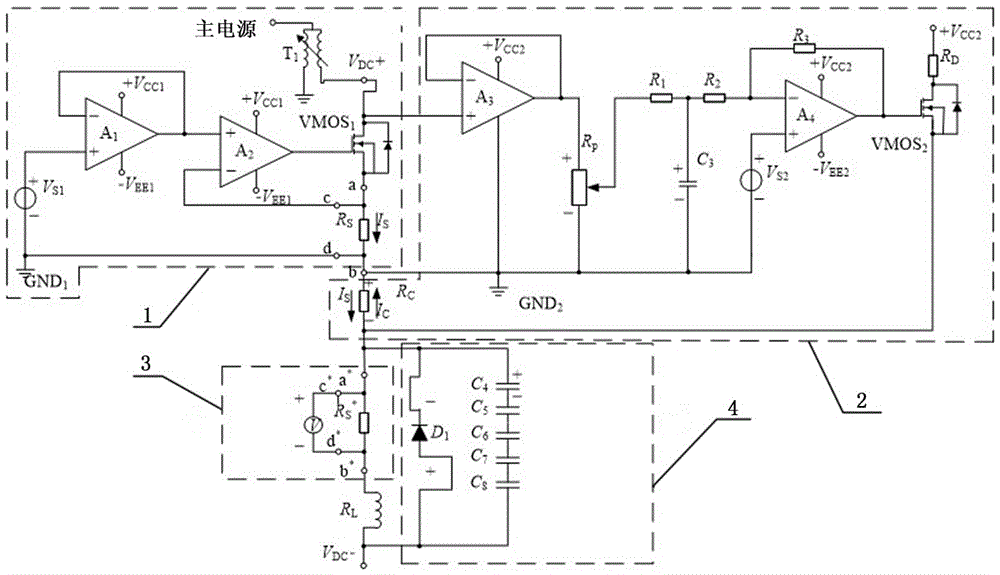

Portable wide-limit high-stability constant current source

InactiveCN106125813AAdjustable outputCompact structureElectric variable regulationMicrocomputer systemTransformer

The invention relates to a portable wide-limit high-stability constant current source. The portable wide-limit high-stability constant current source structurally comprises an ARM single-chip microcomputer system, a touch screen module, a boosting module, a negative feedback amplifying module, a DA control module, a constant current source adjusting module, a current compensation module, a temperature measuring and keeping module, a sampling resistor module, a detecting module, a constant current source power supplying module, a power source module and other parts. The portable wide-limit high-stability constant current source can output high-precision voltage reference of any voltage value from 0 V to 10 V, the relative standard deviation of output voltage within a short time can reach 2.34*10<-7>, and the voltage stability is 3.4*10<-8>. The constant current source overcomes the defects that in a traditional constant current source adjusting tube voltage drop control circuit, a grade-distribution transformer needs to be manufactured specially, sudden current change before and after switching is caused by uneven voltage grade distribution, a motor control circuit and a voltage regulator machinery speed reducing device are complex and huge, and after a switching power source is introduced, current stability and ripple waves are disturbed greatly.

Owner:HEBEI UNIVERSITY

A kind of manufacture method of biodegradable starch-based fiber

InactiveCN102277655ALow costSimple processFilament forming substance formingMelt spinning methodsVegetable oilGlycerol

The invention discloses a method for manufacturing biodegradable starch-based fibers. The process is as follows: 1. Put the biodegradable resin in a vacuum oven at 60-80°C and dry it for 16-24 hours before use; the biodegradable resin refers to A blend of the following substances and weight ratios: cornstarch: polycaprolactone: polylactic acid: plasticizer: compatibilizer = 50: 16: 11: 12: 1; the plasticizer is glycerin, diglycol At least one of alcohol, sorbitol, ethylene glycol or propylene glycol; the compatibilizer is at least one of vegetable oil, mineral oil, titanate coupling agent or aluminate coupling agent; 2. dry The resin is melt-spun with a twin-screw spinning machine, the spinning temperature is 155-190°C, the temperature of the spinneret is 10-30°C lower than the average temperature of the screw heating area, and the primary fiber is obtained, and then stretched at a temperature of 70-80°C 2 to 4 times, and then dried and wound to obtain biodegradable starch-based fibers.

Owner:TIANJIN POLYTECHNIC UNIV

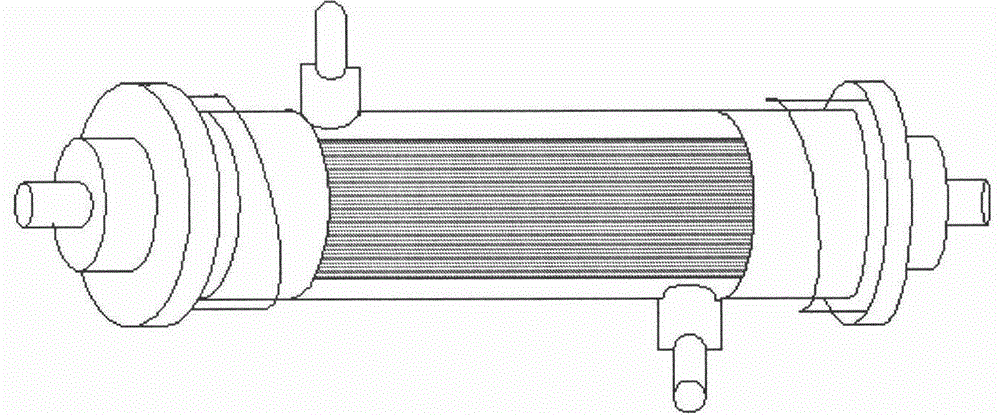

Catalytic hollow fiber membrane and preparation method thereof

InactiveCN104941464AEnhanced adsorption functionSimple processSemi-permeable membranesWater/sewage treatment by irradiationFenton reactionActivated carbon

The invention discloses a catalytic hollow fiber membrane and a preparation method thereof. The method for preparing the catalytic hollow fiber membrane comprises the following steps: pouring adsorptive activated carbon, a composite pore-foaming agent and organic low molecular liquid into a mixing tank for performing forced mixing at a certain mass ratio, forming a viscous mixture, uniformly mixing with a tetrafluoroethylene-hexafluoropropylene copolymer resin, injecting into a double-screw extruder, performing melt spinning at the temperature of 270-330 DEG C, and preparing a hollow fiber membrane; performing the conventional water extraction and after-drawing, casting the hollow fiber membrane into a membrane assembly, adsorbing 0.05mol / L Fe<3+> to the membrane by virtue of dynamic adsorption under the negative pressure condition, thereby obtaining the catalytic hollow fiber membrane; and finally, degrading the organic matter by utilizing a Fenton reaction.

Owner:TIANJIN POLYTECHNIC UNIV

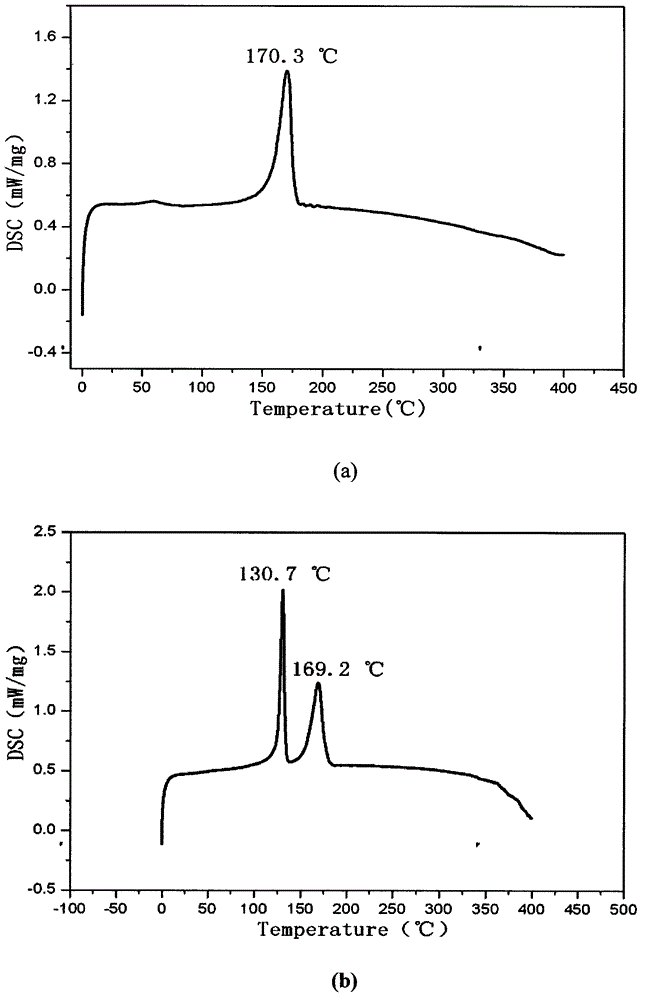

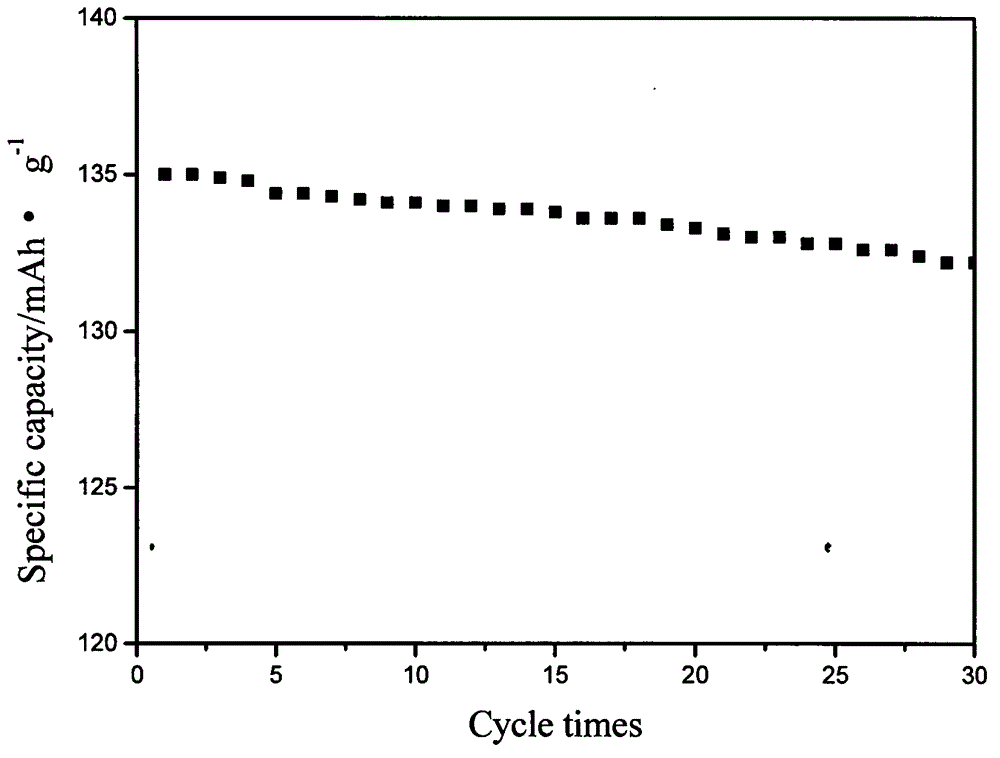

Polyolefin non-woven fabric enhanced gel polymer electrolyte membrane and preparation method thereof

InactiveCN102983357AImprove thermal performanceImprove mechanical propertiesSecondary cellsWater bathsN dimethylformamide

The invention discloses a polyolefin non-woven fabric enhanced gel polymer electrolyte membrane and a preparation method thereof. The preparation method comprises the following steps of: adding a polymer in a mixed solvent of acetone and N, N-dimethylformamide (DMF) according to a certain volume ratio, so as to prepare a clear polymer solution; carrying out surface modification on non-woven fabric by a radiation grafting method, so that the bonding force between the non-woven fabric and the polymer can be improved; coating the polymer solution on the modified non-woven fabric in a scraping manner, and soaking the coated non-woven fabric for water bath, so as to remove the solvent and dry; and soaking a prepared composite membrane in electrolyte for activation, so as to obtain the enhanced gel polymer electrolyte membrane. The non-woven fabric enhanced gel polymer electrolyte membrane provided by the invention has the advantages of good mechanical property, good thermal property and high ion conductivity. The preparation method provided by the invention has the advantages of simple process and low cost, and is applicable to industrial production.

Owner:TIANJIN POLYTECHNIC UNIV

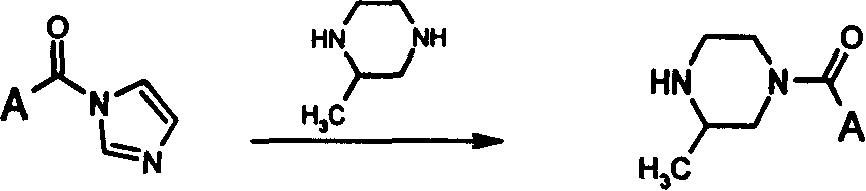

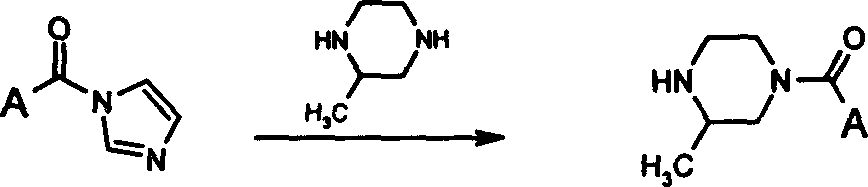

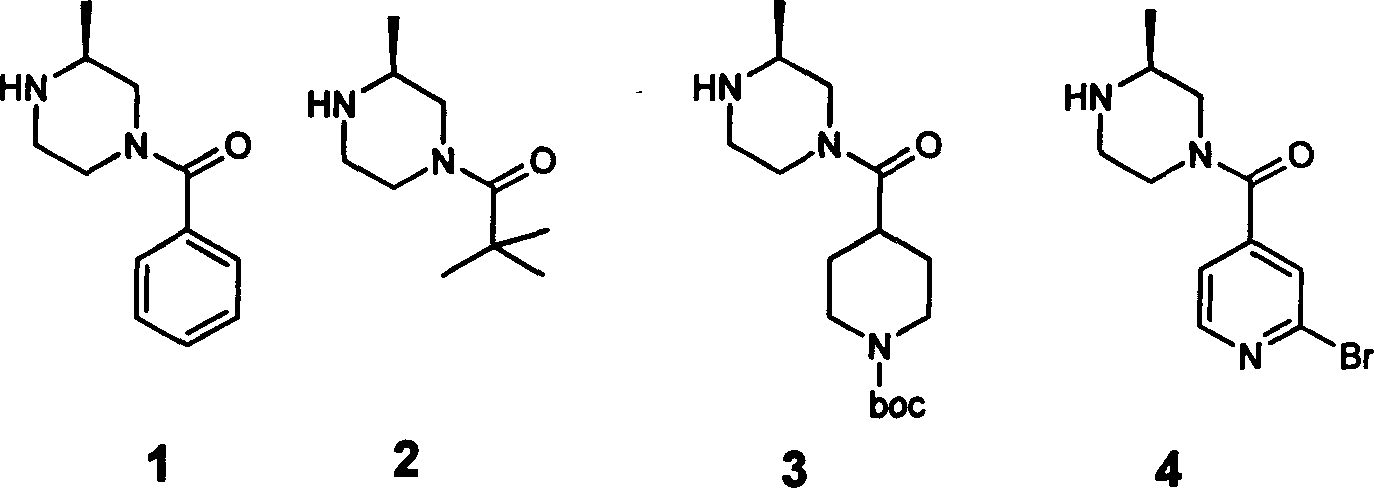

Process for preparing 4-acyl substituted-2-methylpiperazines

ActiveCN1827610AEliminate potential safety hazardsRaw materials are cheap and easy to getOrganic chemistryAluminium chlorideCarboxylic acid

The invention relates to a method for preparation of selective monoacylated piperazine by N,Ní»-carbonyldiimidazole(CDI) activating carboxyl acid and especially to a method for preparation of 4-acylsubstitution-2-methylpiperazine compound by selectively monoacylating 4-nitrogen atom of 2-methylpiperazine ring.It is characterized in that it prepares carbonyl diimidazolederivant by the reaction of between N,Ní»-carbonyldiimidazole and carboxyl acid, and monoacylated 4-acylsubstitution-2-methylpiperazine compound is obtained by monoacylated condensation reaction between 2-methylpiperazine and the substances of the former step. In relation to the present technology, the said invention selects N,Ní»-carbonyldiimidazole which is cheap and easy for commercial manufacture as effective substitute agent of diethyl aluminium chloride, essentially removes potential safety hazard, avoids the explosive diethyl aluminium chloride, and is of simple operation and high reaction yield rate.

Owner:深圳市天明医药科技开发有限公司

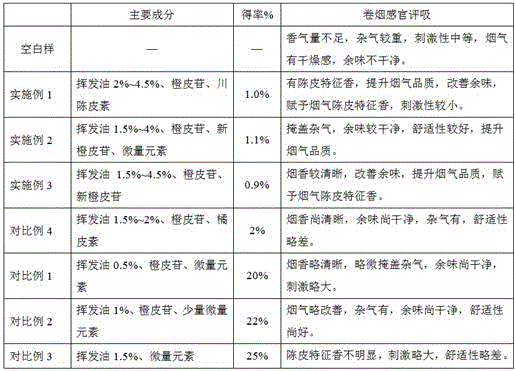

Preparation method of pericarpium citri reticulatae absolute oil and application of pericarpium citri reticulatae absolute oil in cigarettes

InactiveCN106221935AHigh yield of extractReduce qualityTobacco treatmentEssential-oils/perfumesFlavorOperability

The invention discloses a preparation method of pericarpium citri reticulatae absolute oil. The pericarpium citri reticulatae absolute oil is obtained through the steps of pericarpium citri reticulatae crushing, pericarpium citri reticulatae fermenting, pericarpium citri reticulatae extracting, extracting and filtering, concentrating, alcohol precipitating and concentrating. According to the obtain pericarpium citri reticulatae absolute oil, the content of flavonoids such as hesperidin, nobiletin and tangeretin and the content of volatile oil such as limonene are high, therefore, the unique aroma of pericarpium citri reticulatae is effectively kept, and the natural flavor is clearer when the pericarpium citri reticulatae absolute oil is applied to the cigarettes; in addition, the application range of the absolute oil can be wider, the state and solubility problems of a pericarpium citri reticulatae extract are solved, and the absolute oil can be better applied to the cigarettes; the preparation process is simple, the operability is high, the whole production process is efficient, and the method is suitable for industrialized implementation; on the other hand, when the pericarpium citri reticulatae absolute oil prepared through the method is applied to the cigarettes, the mouthfeel and the aftertaste of cigarette smoking can be improved, the special natural flavor can be given to the cigarettes, and the smoke quality can be promoted.

Owner:YUNNAN YANGRUI TECH GRP

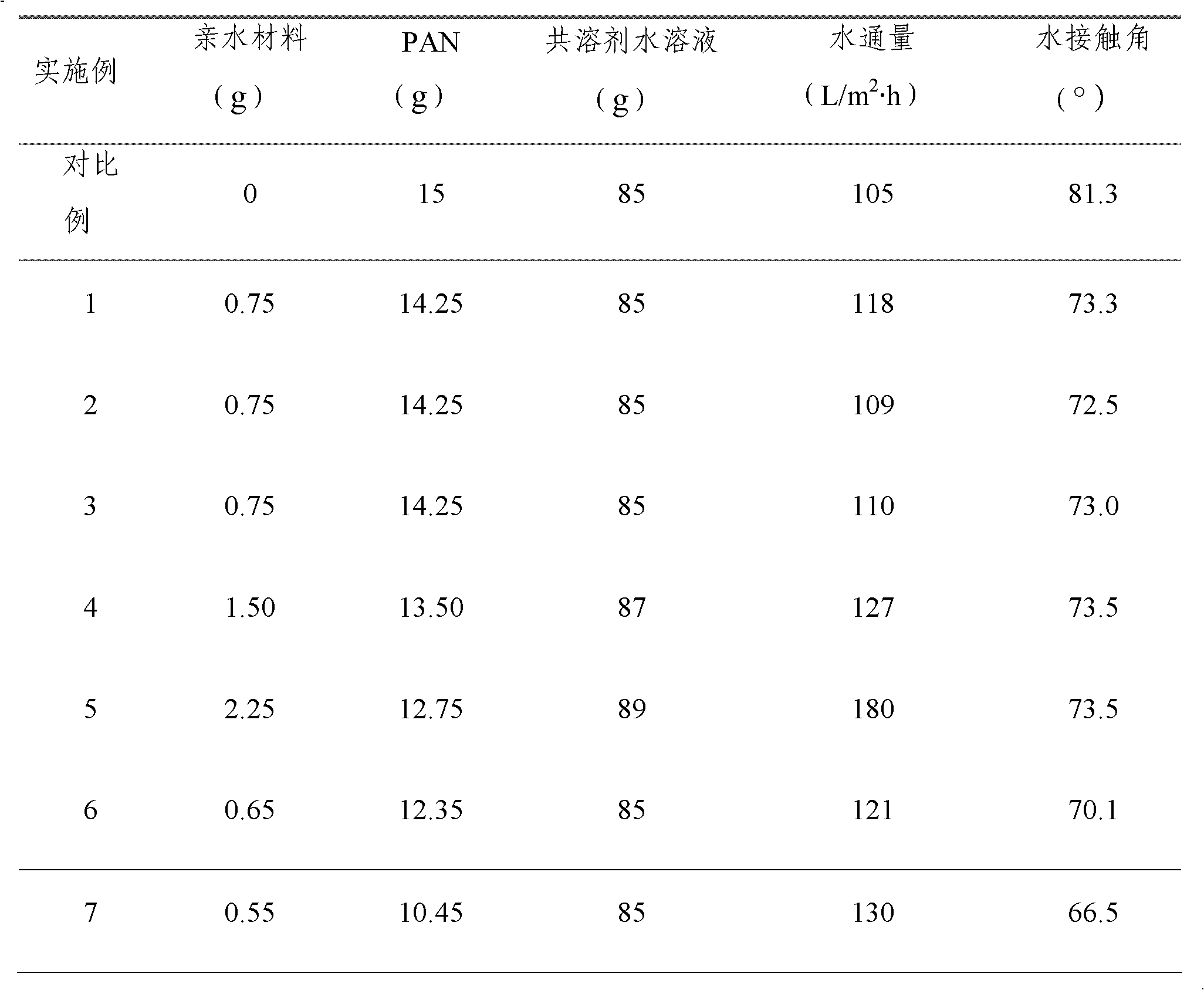

Preparation method of modified polyacrylonitrile film

The invention discloses a preparation method of a modified polyacrylonitrile film, and the process comprises the following steps: 1. hydrophilic material solution preparation, that is cutting a hydrophilic material into a length of 2-10 mm, adding into a cosolvent, stirring and dissolving; wherein the hydrophilic material is natural high-molecular polymer with a carboxyl, an amino or a hydroxyl on a main chain or a side chain, and comprises at least one of bombyx mori silk fibroin, tussah silk fibroin, or spider silk fibroin; the cosolvent is a common solvent for polyacrylonitrile and the hydrophilic material, comprises a NaSCH aqueous solution or a ZnCl2 aqueous solution, and has a mass concentration of 50-60%; the dissolving temperature is 70-90 DEG C, and the time is 0.5-1 h; the mass concentration of the hydrophilic material solution is 0.5-3%; 2. blended solution preparation, that is adding polyacrylonitrile into the hydrophilic material solution, stirring and dissolving, performing heat preservation under vacuum, allowing the solution to stand for deaeration so as to obtain the blended solution; 3. routine film scraping and posttreatment.

Owner:TIANJIN POLYTECHNIC UNIV

Hawk tea extract, preparation method thereof and application of extract in cigarette

InactiveCN104336775AGuaranteed contentImprove product qualityTobacco treatmentBiotechnologyOrganic solvent

The invention discloses hawk tea extract, a preparation method thereof, and an application of the extract in cigarette and relates to the plant extract and application thereof. The preparation method for the hawk tea extract includes steps that (1) pre-processing; (2) ultrasonic extracting; (3) purifying through ethanol; (4) membrane separation; (5) condensing. The hawk tea extract is diluted through organic solvent without toxicity and pungent smell, and the dilution ratio is 10 to 15 times; before preparing the cigarette, the hawk extract diluted liquid is sprayed to the surface of the tobacco leaf according to the mass ratio of 0.1-1%. The hawk tea extract is convenient to use and capable of greatly improving the interior quality of the cigarette, reducing the offensive odor, increasing the smoke gas amount and improving the mouth feel; the interior quality of the cigarette is greatly improved.

Owner:CHINA TOBACCO JIANGXI IND CO LTD

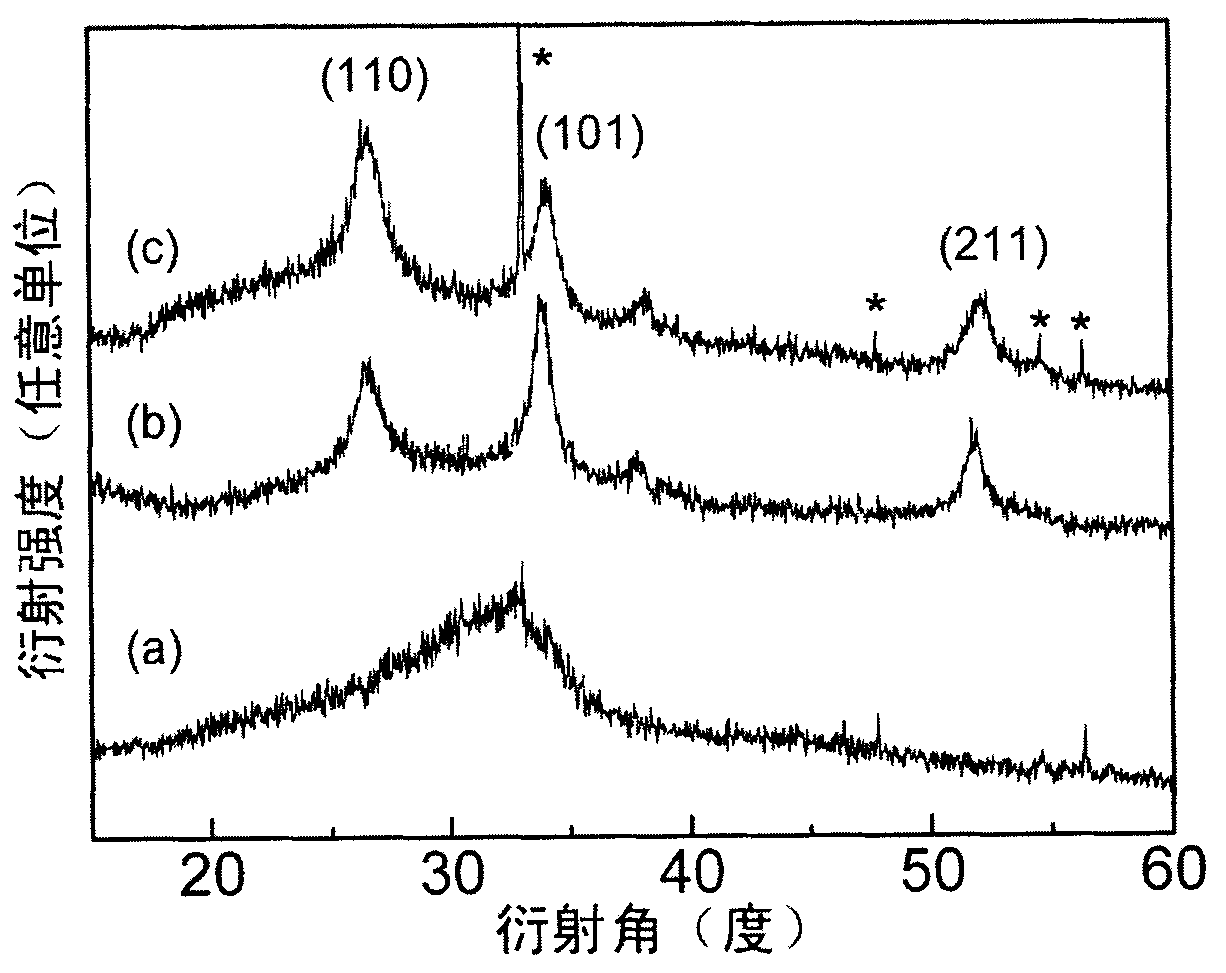

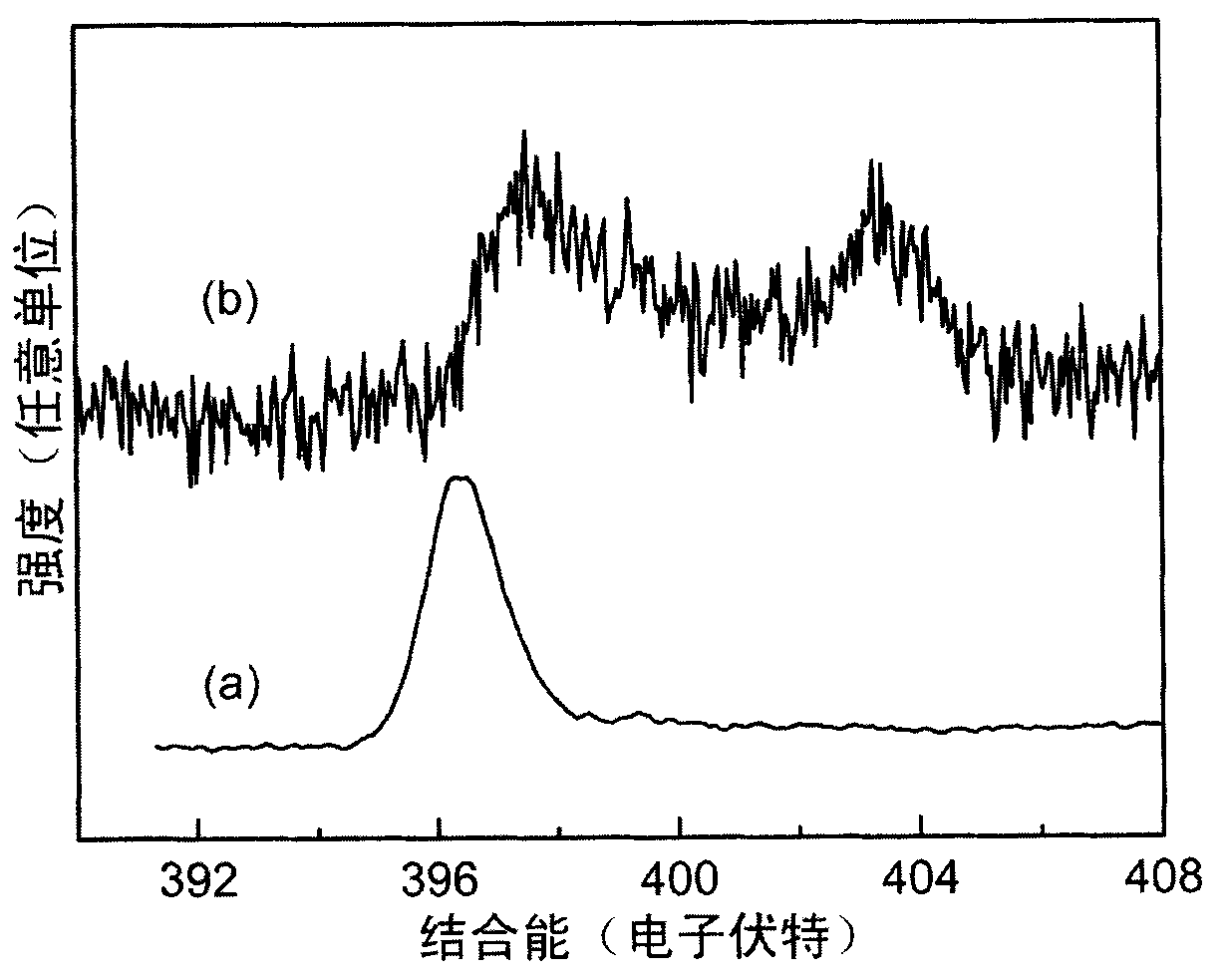

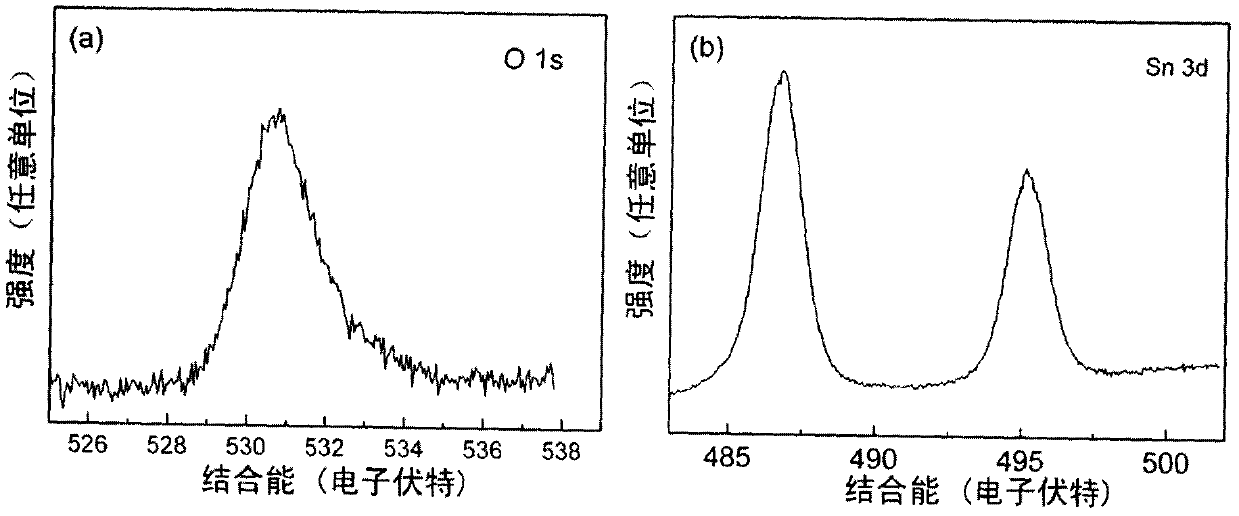

Nitrogen-doped p-type tin dioxide film and preparation method thereof

InactiveCN103290357AGood light transmissionPreparation method scienceVacuum evaporation coatingSputtering coatingTin dioxideGas detector

The invention discloses a nitrogen-doped p-type tin dioxide film and a preparation method thereof. The film is characterized in that the tin dioxide film is doped with 1-30% of element nitrogen, the 1s electron binding energy is 394.5-398.5 electron volts, the conduction type of the film is p type, the resistivity is 0.14-12 ohm*cm, the hole mobility is 0.62-3.6 cm<2> / Vs, and the carrier concentration is 10<17>-10<19> / cm<3>. The method comprises the following steps: respectively arranging a metal tin target and a substrate on a cathode in a vacuum chamber of a magnetron sputtering apparatus and in a sample stage, wherein the distance between the metal tin target and the substrate is 8-12 cm; after the vacuum degree of the vacuum chamber is no more than 5.0*10<-4> Pa, sputtering for 30-60 minutes under the condition that the vacuum chamber is in a nitrogen-argon mixed atmosphere, thus obtaining a tin nitride film; and arranging the tin nitride film in an air or argon-oxygen mixed atmosphere, and annealing at 350-600 DEG C for 60-120 minutes, thus obtaining the target product. The nitrogen-doped p-type tin dioxide film has the advantages of p-type conduction and light transmission property, and can be widely used in the fields of photoelectronic devices, solar batteries, transparent conductive electrodes, gas sensing devices and the like.

Owner:HEFEI INSTITUTES OF PHYSICAL SCIENCE - CHINESE ACAD OF SCI

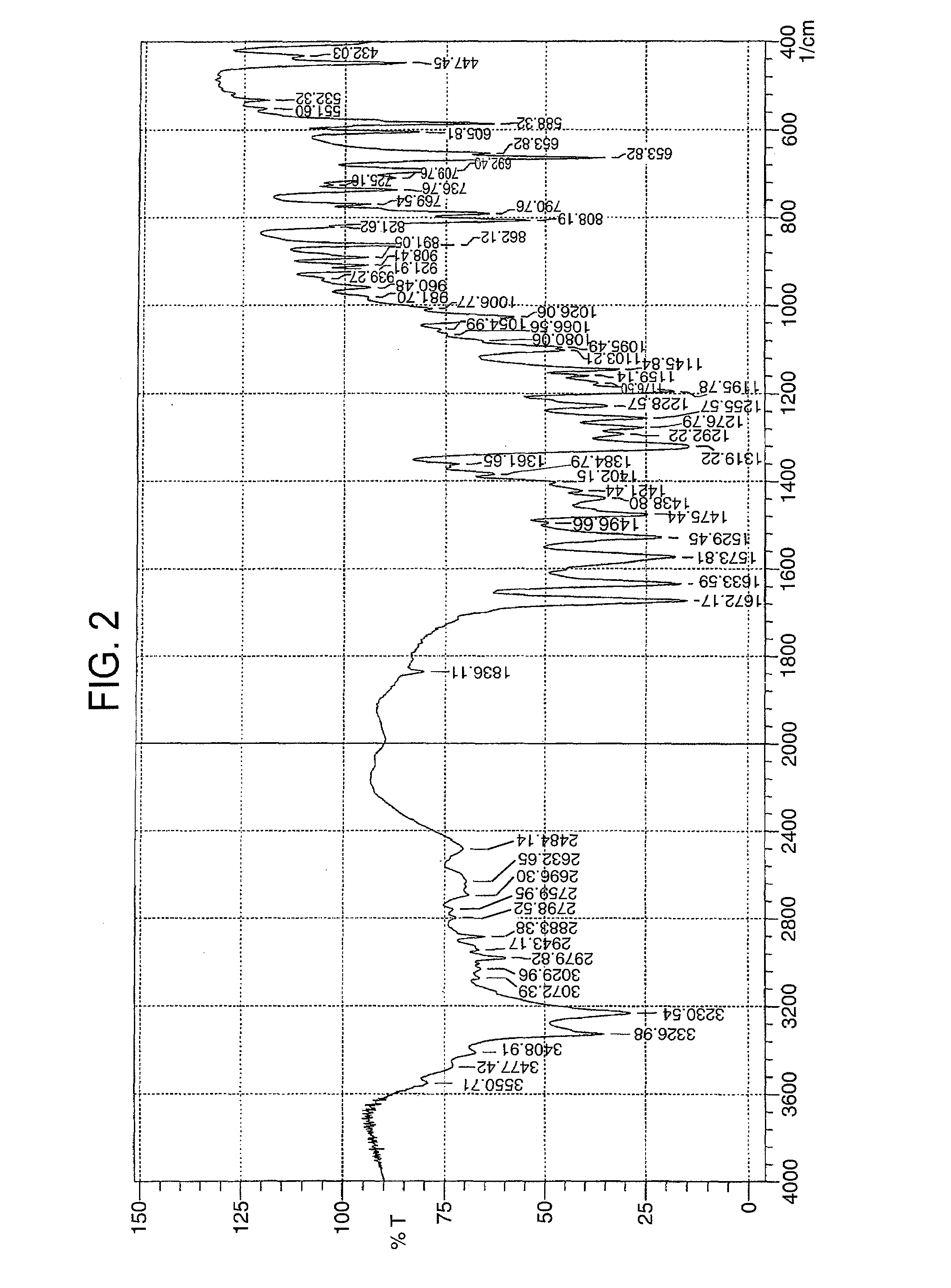

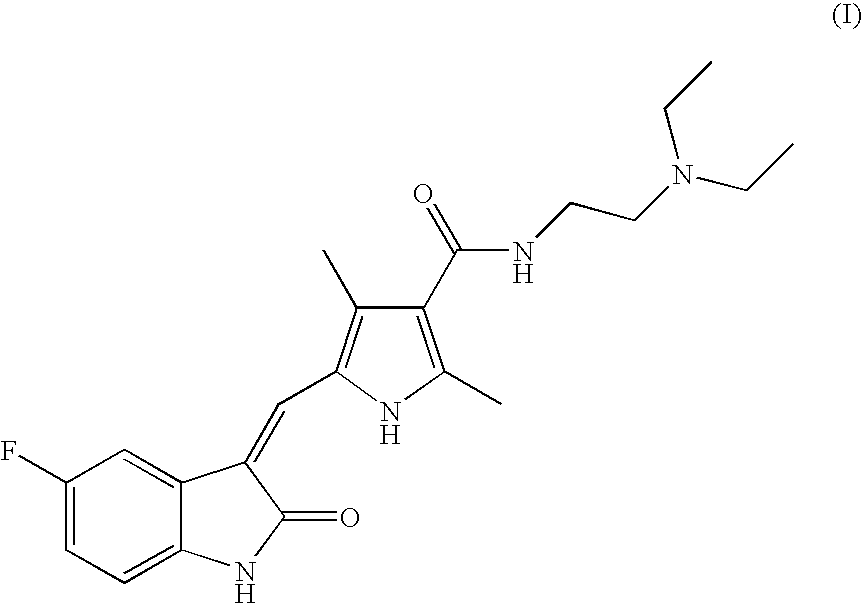

Process For Preparing A 3-Pyrrole Substituted 2-Indolinone Malate Salt

The invention relates to the malic acid salt of N-[2-(diethylamino)ethyl]-5-formyl-2,4-dimethyl-1H-pyrrole-3-carboxamide, to the use thereof as an intermediate for preparing the malic acid salt of sunitinib, and to pharmaceutical compositions comprising said malic acid salt of sunitinib.

Owner:MEDICHEM

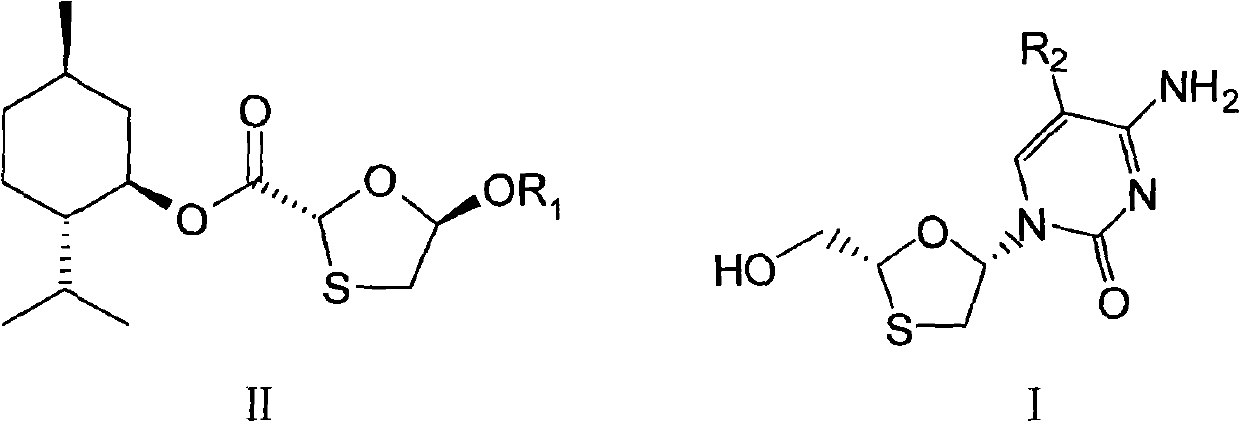

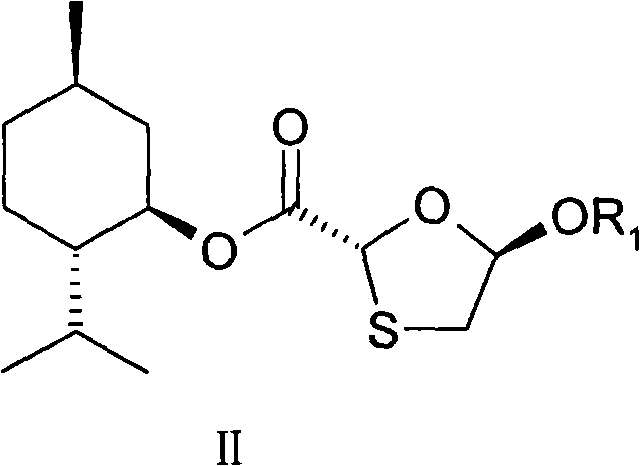

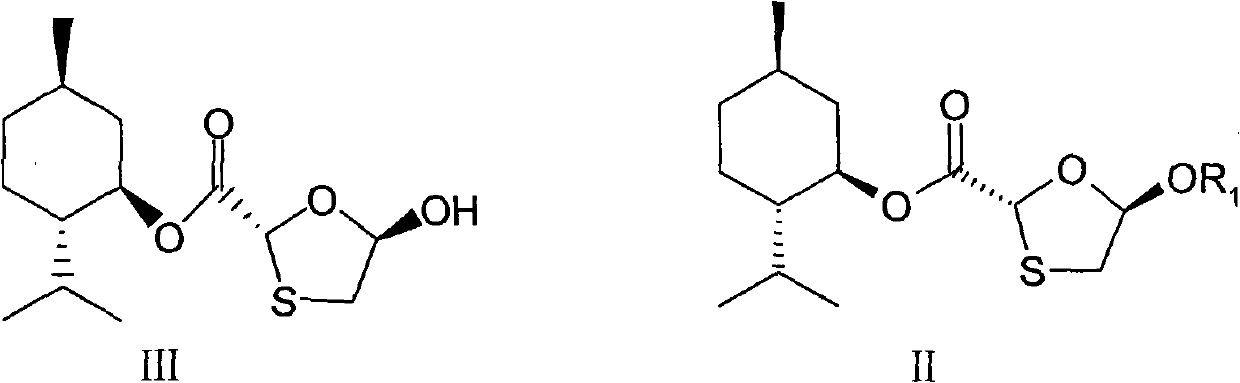

High optical purity nucleoside intermediates and preparation method thereof

InactiveCN102101856AHigh optical purityHigh purityOrganic chemistryCombinatorial chemistryHigh-performance liquid chromatography

The invention relates to high optical purity nucleoside intermediates, namely compounds in a formula II, and a preparation method thereof. In the formula, R1 is alkyl acyl. The high performance liquid chromatography (HPLC) purity of the high optical purity nucleoside intermediates is more than or equal to 95 percent; and the chiral HPLC purity is more than or equal to 95 percent. By adopting the high optical purity nucleoside intermediates, high optical purity nucleoside medicines, namely compounds shown in a formula I are easier to prepare; and the method for preparing the high optical purity compounds shown as the formula II has the advantages that: raw materials are readily available, the method is easy and convenient to operate and the obtained product has high optical purity.

Owner:CHONGQING PHARMA RES INST

A kind of method for preparing cyclohexanol and cyclohexanone by electrochemical catalytic oxidation of cyclohexane

InactiveCN104032327BEfficient responseGreenElectrolysis componentsElectrolytic organic productionCyclohexanonePeristaltic pump

Owner:TIANJIN POLYTECHNIC UNIV

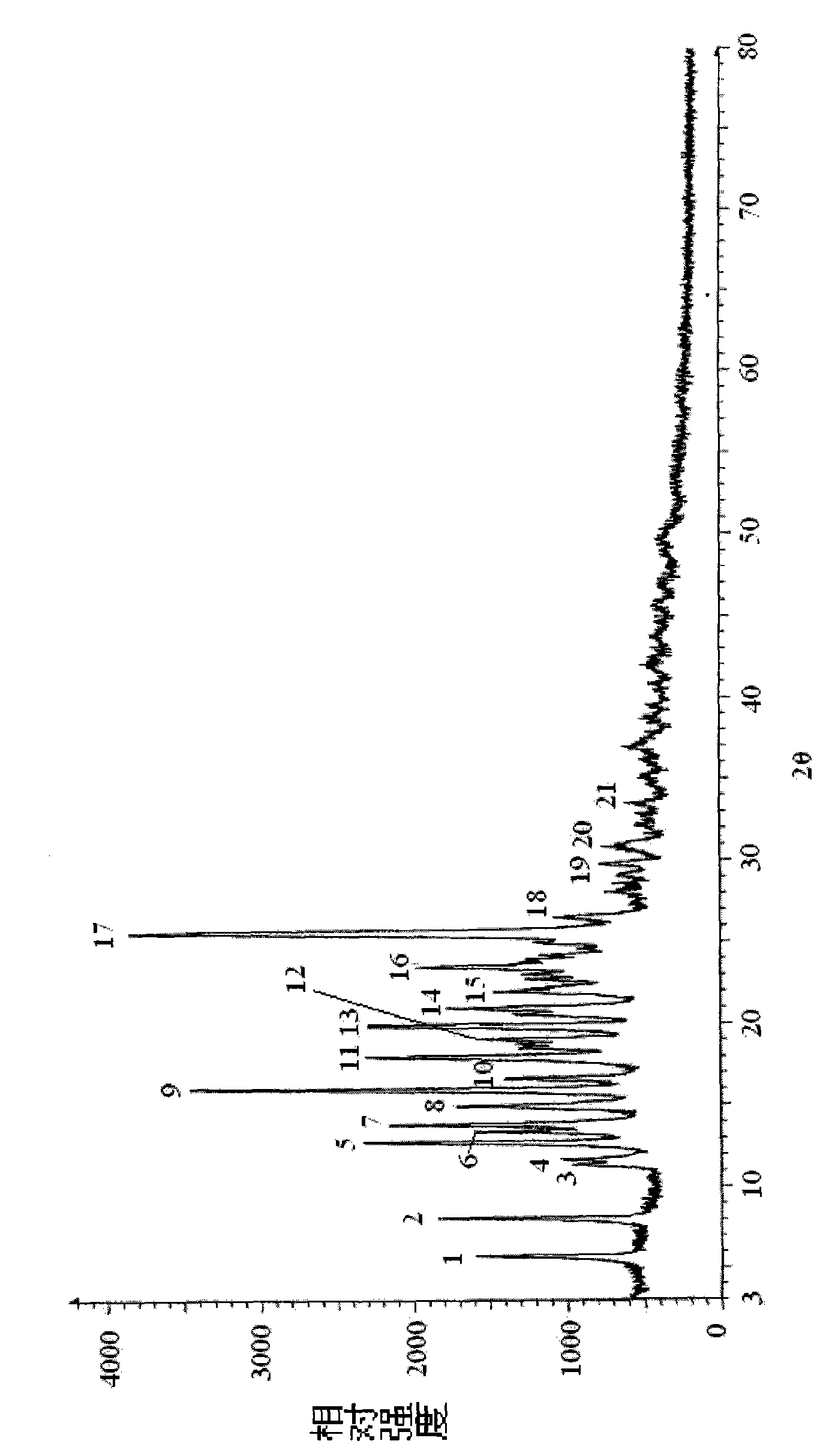

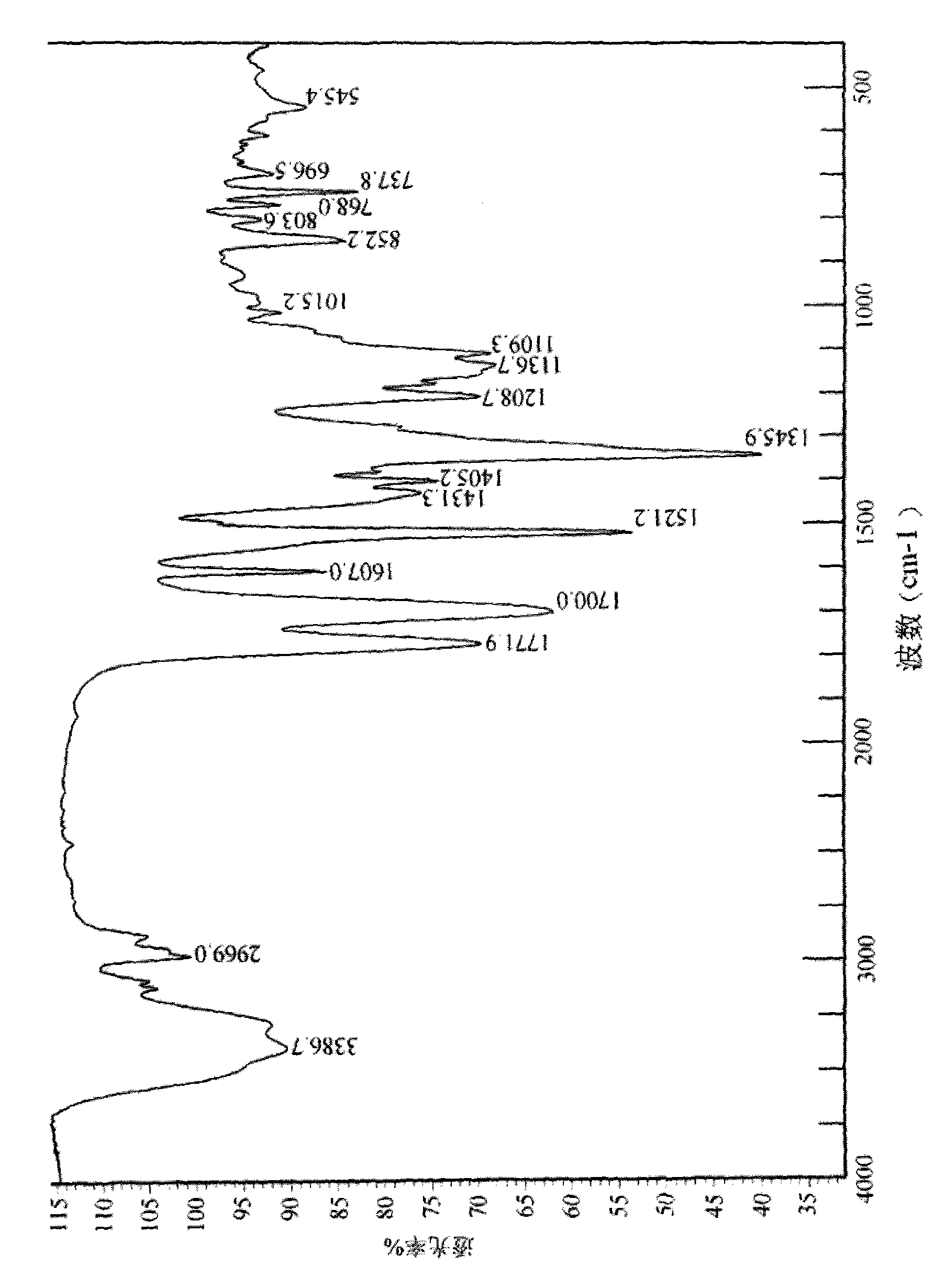

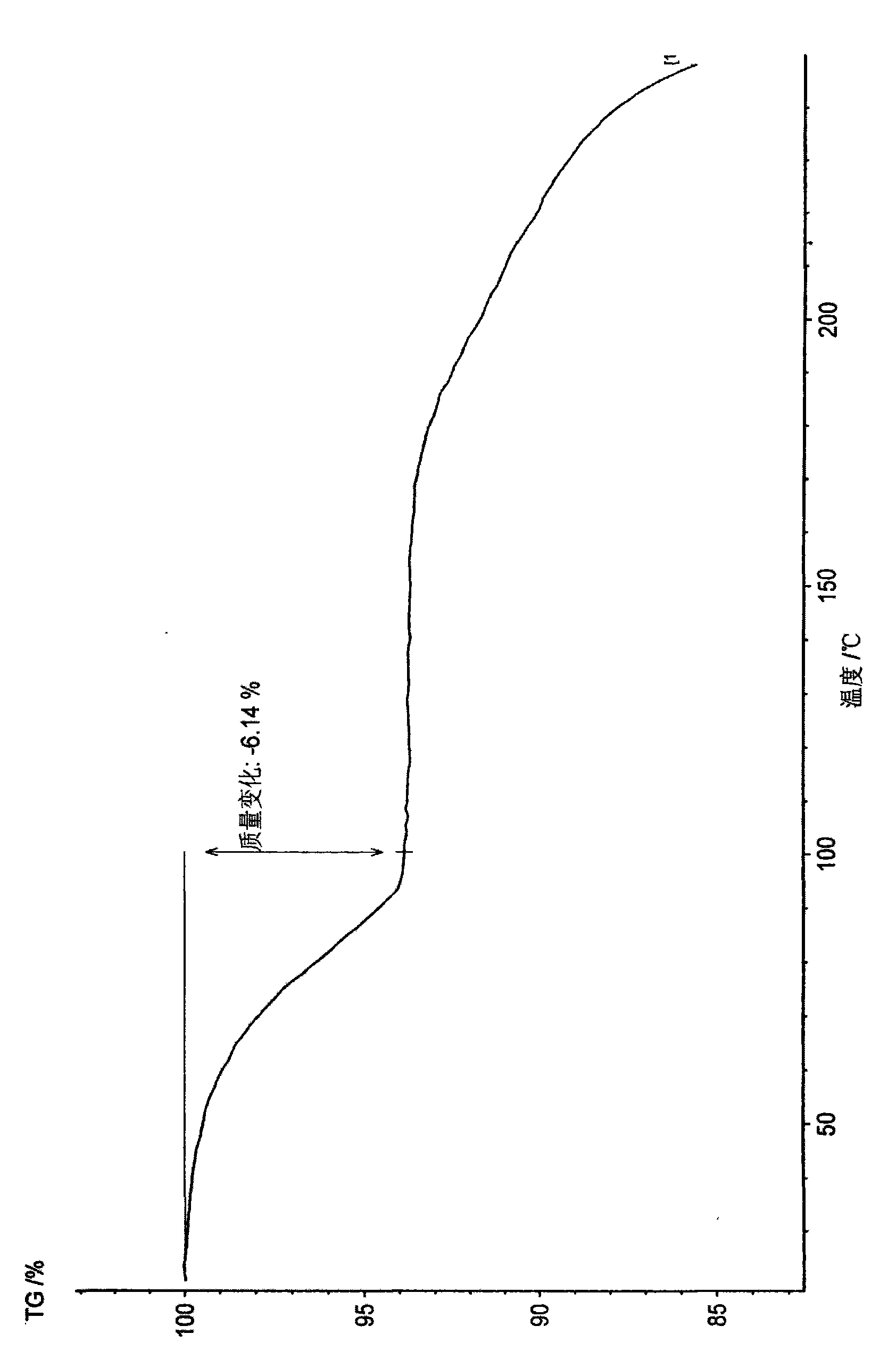

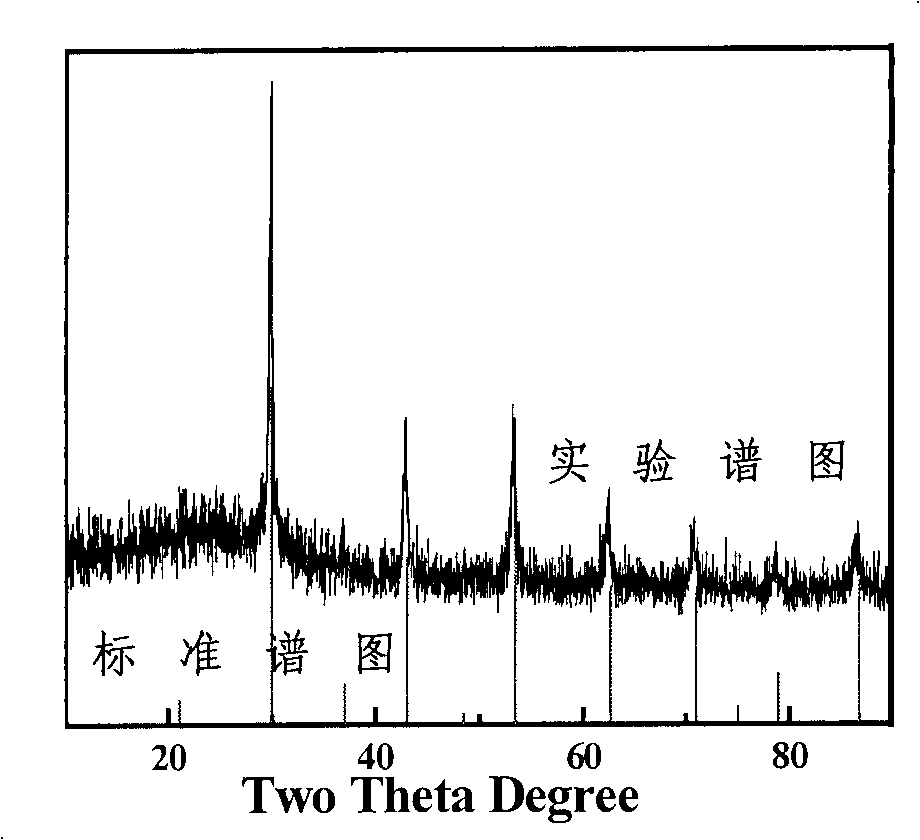

Methanol solvate of doripenem intermediate and preparation method thereof

The invention discloses a methanol solvate of a doripenem intermediate as shown by a formula I and a preparation method thereof, wherein PNB in an intermediate I represents para-nitrobenzyl, and PNZ represents para-nitro-carbobenzoxygroup. The methanol solvate has the advantages of high purity, good stability, and easy operation and storage; and the preparation method is simple and reliable, and is suitable for industrial implementation.

Owner:SHANGHAI INST OF PHARMA IND +1

Carbon Fiber Reinforcement Methods

InactiveCN102296458AHigh strengthGood efficiency and effectCarbon fibresCarbon nanotubeResidence time

A method for reinforcing carbon fibers, which uses electrostatic spraying to coat carbon nanotubes on the surface of carbon fibers to compensate for surface structural defects and increase its strength. One of carbon nanotubes, carboxylated carbon nanotubes or aminated carbon nanotubes, the dispersion liquid is one of dimethylformamide, acetone or ethanol; the spray liquid is applied with 10-40kV positive static electricity, and the carbon fiber tow Flattened and grounded to form a spray liquid receiver; the spray liquid is sprayed on the surface of the carbon fiber by electrostatic spraying, and the spray amount is controlled to 1000: (0.4-10) in terms of the weight ratio of carbon fiber to carbon nanotube. The residence time required for carbon fiber to reach the necessary amount of carbon nanotube coating is usually only 0.5 to 5 minutes, and the tensile strength of carbon fiber with increased strength after repair can be increased by more than 100%. The process is simple, the cost is low, the efficiency is high, and industrial application is easy to realize.

Owner:CHINA PETROLEUM & CHEM CORP

Method for preparing autoclaved brick by using refined magnesium slags and fly ash

InactiveCN102225852ARealize large-scale productionReduce pollutionSolid waste managementSteam pressureBrick

The invention discloses a method for preparing an autoclaved brick by using refined magnesium slags and fly ash. The method comprises the following steps: adopting refined magnesium slags, fly ash and aggregate as basic raw materials; mixing the refined magnesium slags, the fly ash and the aggregate through stirring, adding an exciting agent and water during the stirring process, followed by uniform mixing to obtain a mixing material; standing the mixing material to obtain a digested material; carrying out compression moulding to obtain a green brick after wheel rolling; placing the green brick in a autoclave and carrying out autoclave curing for 3-10 hours at a steam temperature of 150-200 DEG C under a steam pressure of 0.6-1.2 MPa to prepare the autoclaved brick. The method provided by the present invention has advantages of simple process, easy grasp, low production cost, short production period and high work efficiency. In addition, the obtained autoclaved brick prepared through the method provided by the present invention accords with a national standard of building bricks, and is applicable for industrial implementation.

Owner:SHENYANG POLYTECHNIC UNIV

Method of preparing perovskite type zirconate hollow nano material

InactiveCN101407337AControllable wall thicknessGood dispersionZirconium compoundsCooking & bakingZirconate

The invention relates to a preparation method of a perovskite type zirconate hollow nano-material, comprising the following steps: 1. under the condition of stirring, 0.001 to 0.005 Mol of perovskite type compound with general form of ABO3 and containing barium or strontium metal compounds at A and zirconium metal compounds at B is dissolved in 20 to 30mL of deionized water, a suitable amount of inorganic alkali is added and stirred for 20 to 60 minutes, the evenly dispersed mixed liquor is obtained; 2. the mixed liquor is put into a polyfluortetraethylene reaction container with the volume of 40mL, sealed and put into a baking oven, the temperature in which is 180 to 220 DEG C, and reacted for 12 to 48 hours; 3. after natural cooling of the reaction product, upper lye is removed, under the condition of magnetic stirring, the deionized water is used to wash the product powder for 30 to 60 minutes; 4. after centrifugal separation, ultrasonic cleaning is carried out for 20 to 40 minutes, then 10 to 30mL of the acetic acid or formic acid is added to wash for 30 to 60 minutes; and 5. after the centrifugal separation, washing by absolute ethyl alcohol and drying in the baking oven at the temperature of 50 to 60 DEG C of the product powder, the target product is obtained.

Owner:TIANJIN POLYTECHNIC UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com