Multistation material transmission manipulator

A manipulator and multi-station technology, applied in the direction of manipulators, program-controlled manipulators, manufacturing tools, etc., can solve the problems of high cost, low efficiency, poor quality, etc., and achieve the effect of low cost, low energy consumption, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] Further describe the present invention below in conjunction with embodiment and accompanying drawing thereof.

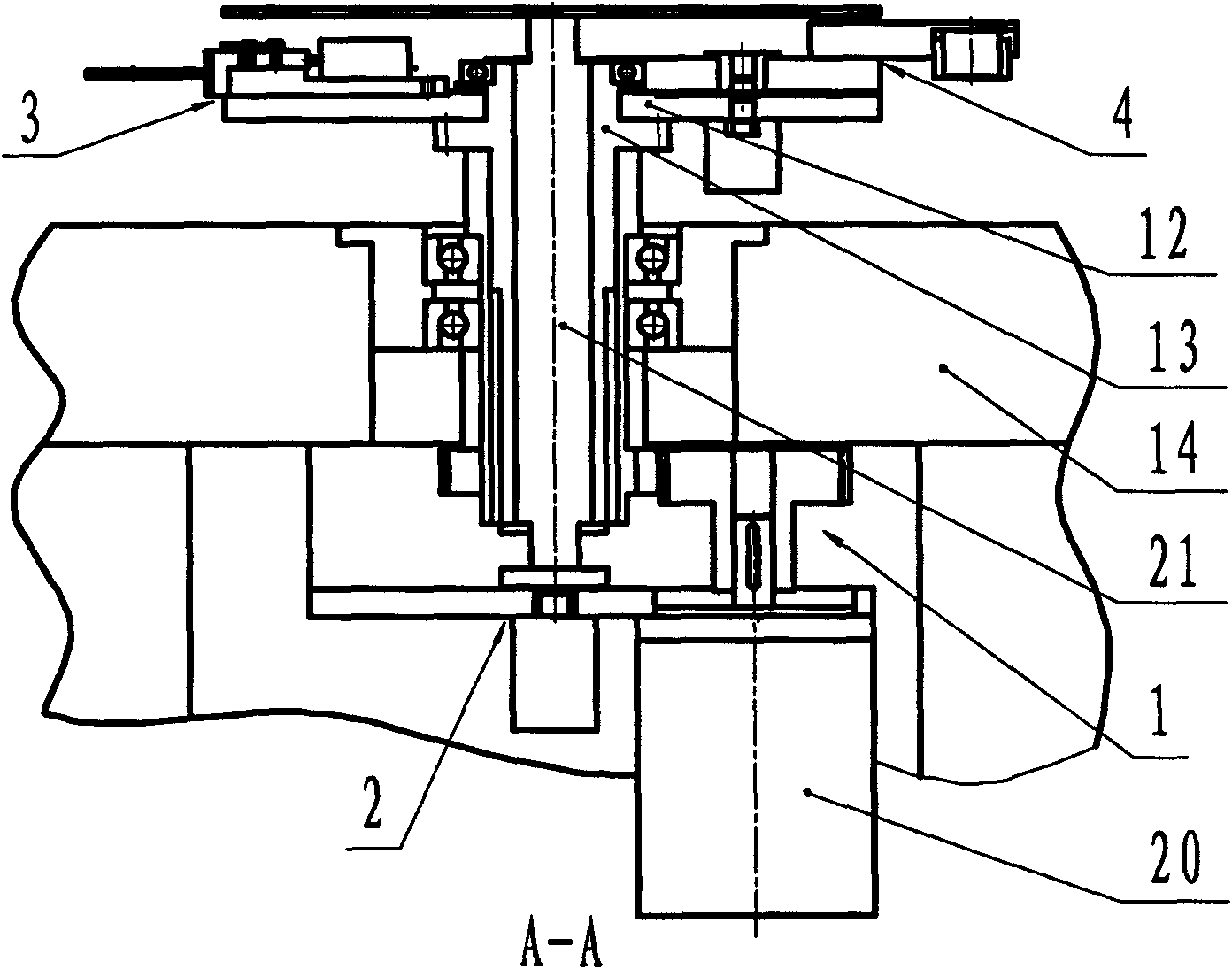

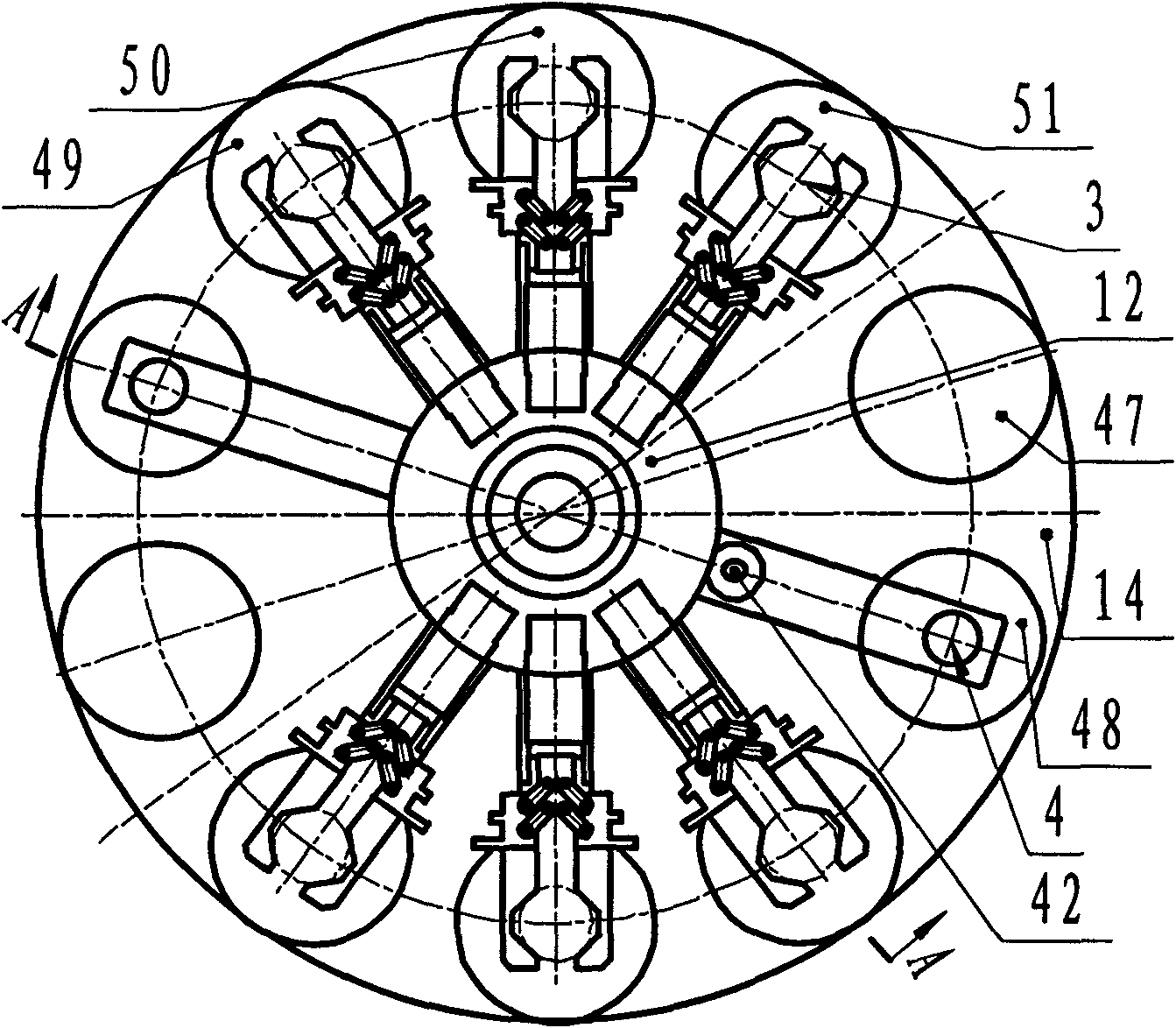

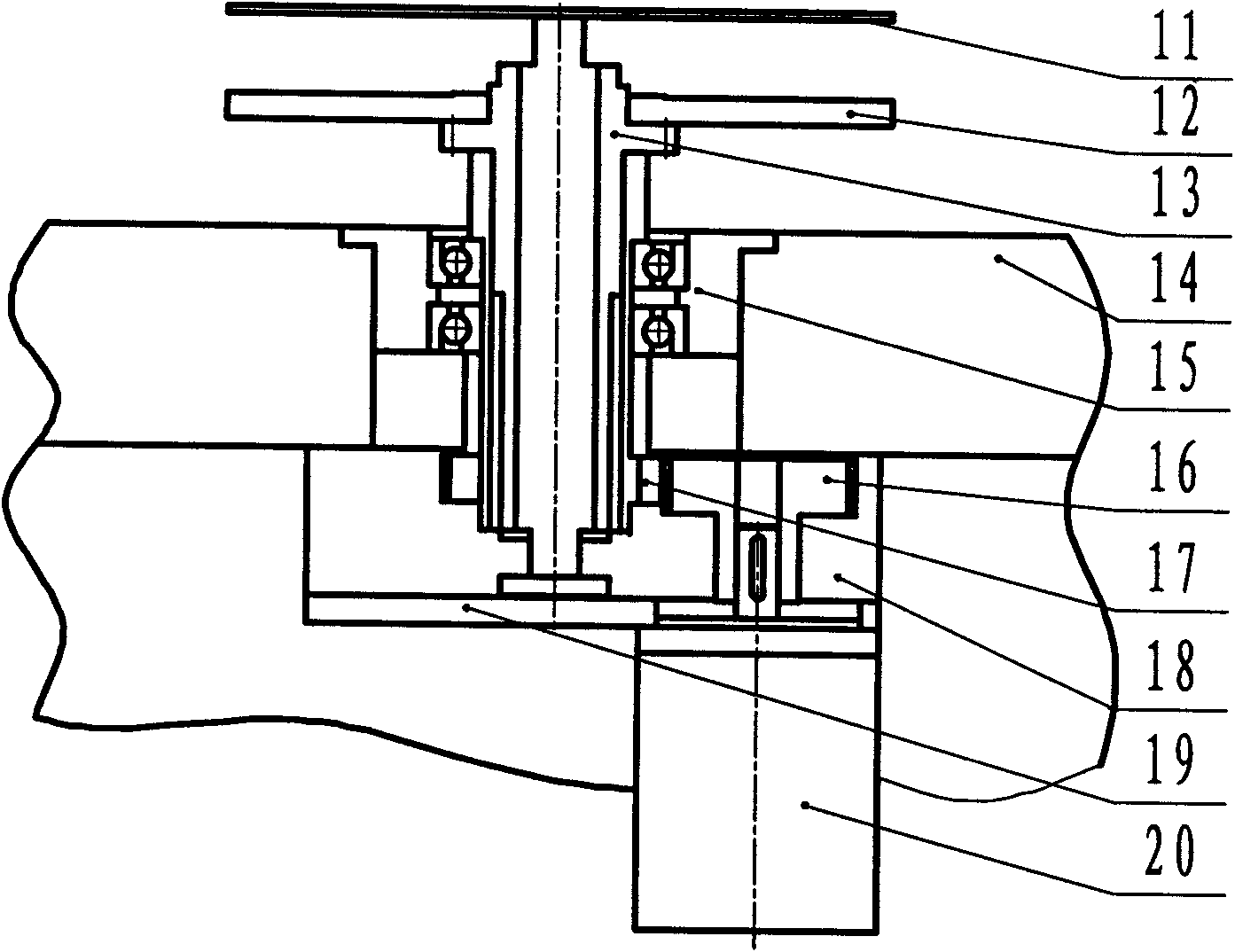

[0018] The multi-station material transfer manipulator designed by the present invention (abbreviated as manipulator, see Figure 1-7 ), which is characterized in that the manipulator is used for the stamping and forming process of the rotary seal ring skeleton, and mainly includes a large template 14, a rotary mechanism 1, a lifting mechanism 2, a finger mechanism 3 and an electromagnetic chuck mechanism 4; the large template 14 is circular, The center of the large formwork 14 is installed with the slewing mechanism 1 and the lifting mechanism 2 through the bearing pair. There are 10 positioning grooves or position grooves evenly distributed around the periphery of the large formwork 14. The positioning grooves are divided into two symmetrical groups in the circumferential direction, each group occupies 180 degree, respectively feeding position groove 47, dis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com