Polyolefin non-woven fabric enhanced gel polymer electrolyte membrane and preparation method thereof

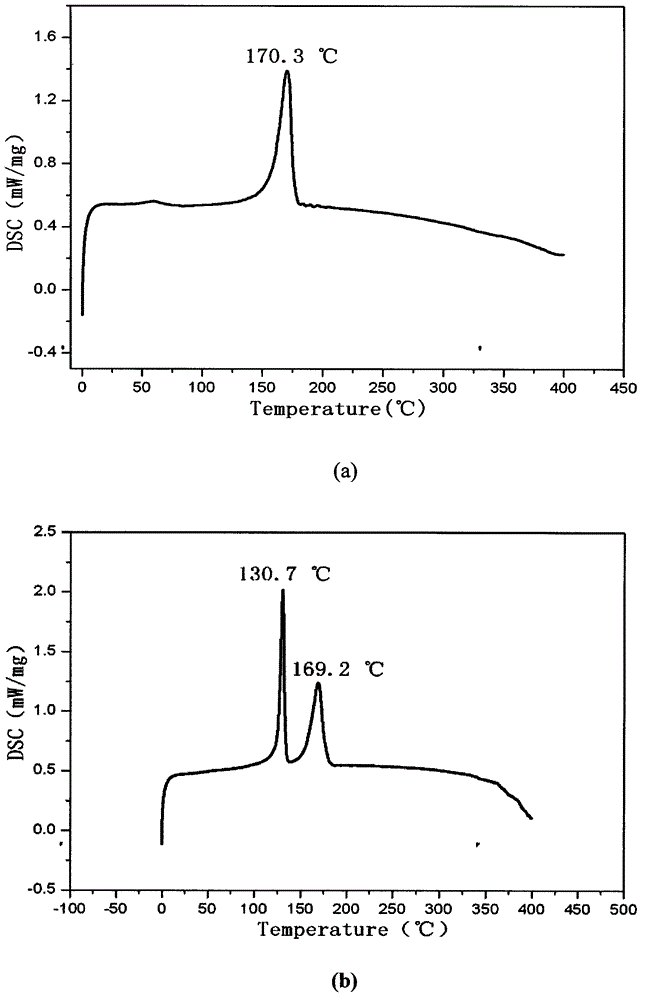

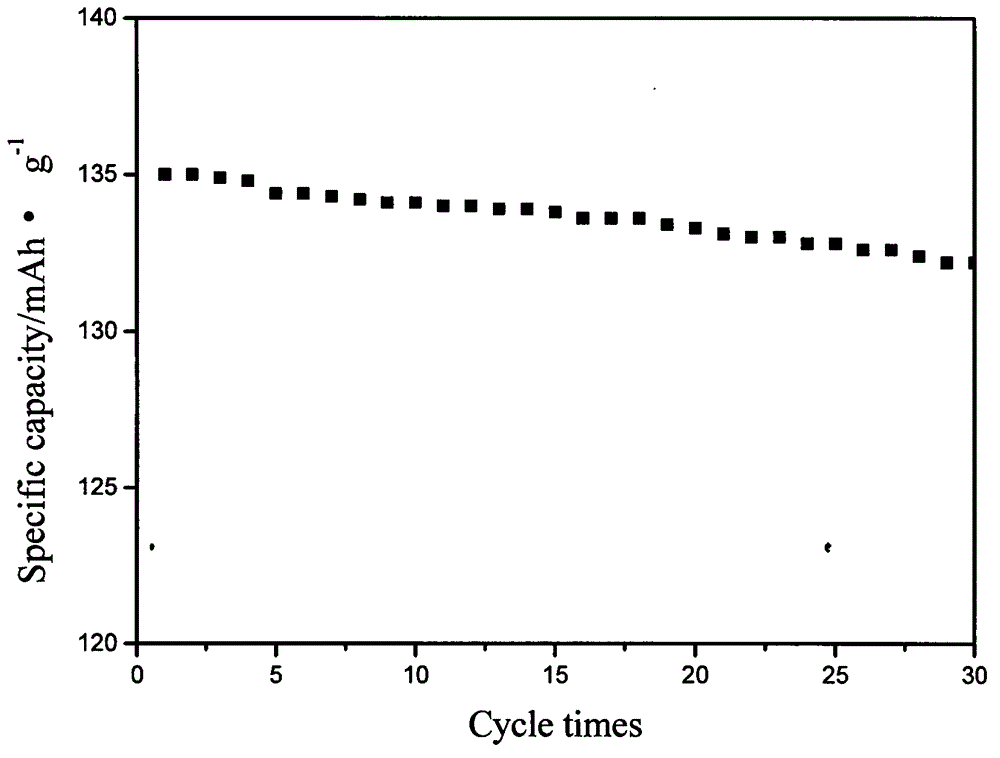

A technology of gel polymer and electrolyte membrane, which is applied in the direction of circuits, electrical components, secondary batteries, etc., can solve problems such as poor bonding force, battery short circuit, polymer shedding, etc., and achieve improved bonding force, excellent product performance, and good The effect of thermal performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] (1) Select polyvinylidene fluoride with a mass-to-mass ratio (the ratio of solute mass to solvent volume) of 20%, dissolve it in a solvent with a volume ratio of acetone:DMF=4:6, stir at 60°C for 60 minutes, and cool at room temperature , let stand for 50min for later use.

[0022] (2) The ES staple fiber nonwoven fabric with a thickness of 30 μm and a porosity of 44% was selected as the reinforcing substrate, immersed in a test tube filled with styrene, and modified by radiation grafting after sealing.

[0023] (3) Scrape-coat the solution prepared in (1) on the non-woven fabric after graft modification in (2) to obtain a non-woven fabric reinforced polymer film with a coating thickness of 10 μm and a coating speed of 1.2 m / min . The composite membrane was immersed in a 20°C water bath for 30 minutes to remove the solvent, rinsed with water and then dried.

[0024] (4) immerse the composite membrane prepared in (3) into the electrolyte for activation, and the selecte...

Embodiment 2

[0026] (1) Select polyvinylidene fluoride with a mass-to-mass ratio (the ratio of solute mass to solvent volume) of 30%, dissolve it in a solvent with a volume ratio of acetone:DMF=5:5, stir at a constant temperature of 50°C for 90min, and cool at room temperature , let it stand for 30min for later use.

[0027] (2) A polypropylene non-woven fabric with a thickness of 40 μm and a porosity of 70% was selected as the reinforcing substrate, immersed in a test tube filled with styrene, and modified by radiation grafting after sealing.

[0028] (3) Scrape-coat the solution prepared in (1) on the non-woven fabric after graft modification in (2) to obtain a non-woven fabric reinforced polymer film with a coating thickness of 20 μm and a coating speed of 2.5 m / min . The composite membrane was immersed in a 40°C water bath for 20 minutes to remove the solvent, rinsed with clean water and then dried.

[0029] (4) immerse the composite membrane prepared in (3) into the electrolyte for ...

Embodiment 3

[0031] (1) Select polyvinylidene fluoride with a mass-to-mass ratio (the ratio of solute mass to solvent volume) of 50% and dissolve it in a solvent with a volume ratio of acetone:DMF=6:4, stir at a constant temperature of 70°C for 30min, and cool at room temperature , stand for 40min for later use.

[0032] (2) Select ES staple fiber non-woven fabric with a thickness of 50 μm and a porosity of 50% as the reinforcing substrate, immerse it in a test tube filled with styrene, and modify it by radiation grafting after sealing.

[0033] (3) Scrape-coat the solution prepared in (1) on the non-woven fabric after graft modification in (2) to obtain a non-woven fabric reinforced polymer film with a coating thickness of 40 μm and a coating speed of 4.6 m / min . The composite membrane was immersed in a water bath at 60°C for 10 minutes to remove the solvent, rinsed with water and then dried.

[0034] (4) immerse the composite membrane prepared in (3) into the electrolyte for activation...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical conductivity | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com