Formula for preparing fluorocopolymer porous membranes and method for preparing porous membranes according to formula

A technology of copolymer and porous membrane is applied in the field of membrane preparation of fluorine-containing copolymer porous membrane and the preparation of porous membrane by using the formula, which can solve the problems of reducing production efficiency, fluoride is easy to corrode equipment, increasing cost, etc., and achieves saving Energy, high porosity, effect of reducing film formation temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] Table 1 provides the membrane formulations of 6 kinds of fluorine-containing copolymer porous membranes,

[0043] Table 1

[0044]

Ethylene-chlorotrifluoroethylene copolymer

Thinner: di-isooctyl adipate

1#

20wt%

80wt%

2#

30wt%

70wt%

3#

40wt%

60wt%

4#

50wt%

50wt%

5#

12wt%

85wt%

6#

20wt%

80wt%

[0045] Note: Ethylene-chlorotrifluoroethylene copolymer is made by Shanghai Solvay 902.

[0046] The first fluorine-containing copolymer flat porous membrane was prepared according to the following steps by using the above four membrane-making formulas 1 to 4#:

[0047] 1) According to the formula, ethylene-chlorotrifluoroethylene copolymer and diisooctyl adipate are mixed evenly in proportion to form a viscous mixture;

[0048]2) Preheat the mold of the hot press at 180°C. The mold is a groove with a thickness of 200 μm formed on opposite sides of a pair of stai...

Embodiment 2

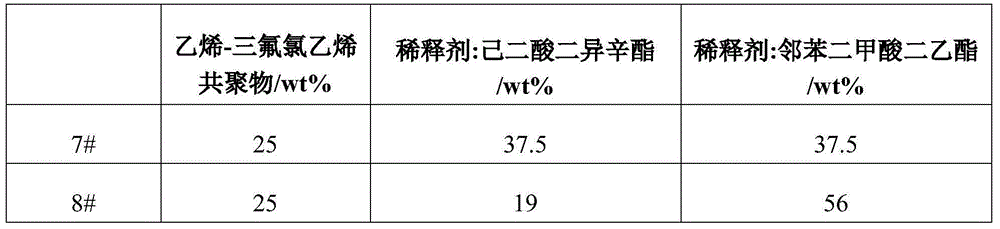

[0057] The film-making formulas of two kinds of fluorine-containing copolymer porous membranes are given in Table 2,

[0058] Table 2

[0059]

[0060] Note: Ethylene-chlorotrifluoroethylene copolymer is made by Shanghai Solvay 902.

[0061] The first kind of fluorine-containing copolymer flat porous membrane was prepared according to the following steps by using the above two membrane-making formulas of 7# and 8#:

[0062] 1) According to the formula, ethylene-chlorotrifluoroethylene copolymer, diisooctyl adipate and diethyl phthalate are mixed evenly in proportion to form a viscous mixture;

[0063] 2) Preheat the mold of the hot press at 180°C. The mold is a groove with a thickness of 200 μm formed on opposite sides of a pair of stainless steel plates. When the temperature of the mold is constant, pour the viscous mixture into it, and wait for the After the viscous mixture is completely melted into a homogeneous phase, it is pressed under a pressure of 15 MPa to obta...

Embodiment 3

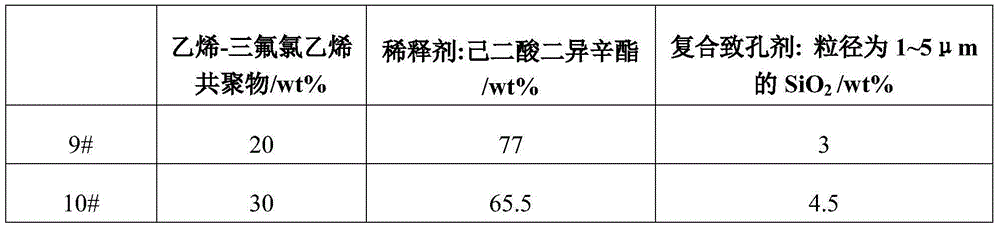

[0067] The film-making formulas of two kinds of fluorine-containing copolymer porous membranes are given in Table 3,

[0068] table 3

[0069]

[0070] Note: Ethylene-chlorotrifluoroethylene copolymer is made by Shanghai Solvay 902.

[0071] Use the above two membrane-making formulas of 9# and 10# to prepare the first flat porous membrane of fluorine-containing copolymer according to the following steps:

[0072] 1) According to the formula, ethylene-chlorotrifluoroethylene copolymer, diisooctyl adipate and silicon dioxide are mixed evenly in proportion to form a viscous mixture;

[0073] 2) Preheat the mold of the hot press at 180°C. The mold is a groove with a thickness of 200 μm formed on opposite sides of a pair of stainless steel plates. When the temperature of the mold is constant, pour the viscous mixture into it, and wait for the After the viscous mixture is completely melted into a homogeneous phase, it is pressed under a pressure of 15 MPa to obtain the first ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com