Single-component water-based wood paint

A wood coating, one-component technology, applied in the direction of polyurea/polyurethane coatings, coatings, etc., can solve the problems of limited application range, low coating film hardness, poor solvent resistance, etc., and achieve good wetting effect and good strength. , low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

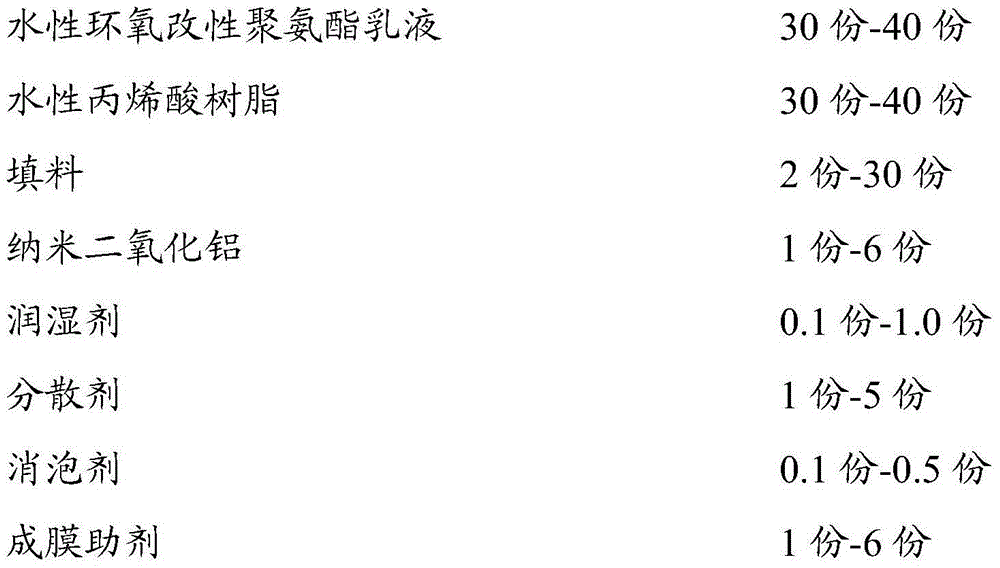

[0043] One-component water-based wood coating of the present invention comprises the components of following parts by weight:

[0044]

[0045]

[0046] Wherein, the film-forming aid is formed by mixing the following components by weight: tripropylene glycol butyl ether 80%, alcohol ester-1220%; the water-based acrylic resin is a hydroxy acrylic resin, and the mass content of the hydroxyl group is 0.4%.

[0047] The water-based epoxy-modified polyurethane emulsion was purchased from Yantai Yunqing Chemical Industry, with a solid content greater than 40%; the water-based acrylic resin was a hydroxyl acrylic resin, wherein the mass content of the hydroxyl group was 0.4%, and the solid content of the water-based acrylic resin was greater than 40%.

[0048] The anti-settling agent is the water-based anti-settling agent of model XH-301; the wetting agent is the polyether modified dimethyl siloxane series wetting agent of BYK; Foaming agent is BYK's water-based mineral oil def...

Embodiment 2

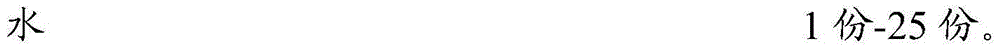

[0053] Different from Example 1, the one-component water-based wood coating of the present invention includes the following components by weight:

[0054]

[0055]

[0056] Wherein, the film-forming aid is formed by mixing the following components by weight: 60 parts of tripropylene glycol butyl ether, 1240 parts of alcohol ester; the water-based acrylic resin is a hydroxyl acrylic resin, and the mass content of the hydroxyl group is 0.2 parts.

[0057] The solid content of the water-based epoxy-modified polyurethane emulsion is greater than 40 percent; the water-based acrylic resin is a hydroxyl acrylic resin, wherein the mass content of the hydroxyl group is 0.2 percent, and the solid content of the water-based acrylic resin is greater than 40 percent.

[0058] The anti-sedimentation agent is organic bentonite; the wetting agent is polyoxyethylene alkylated ether wetting agent; the dispersant is the sodium acrylic acid series dispersant of Godess; the defoamer is water-ba...

Embodiment 3

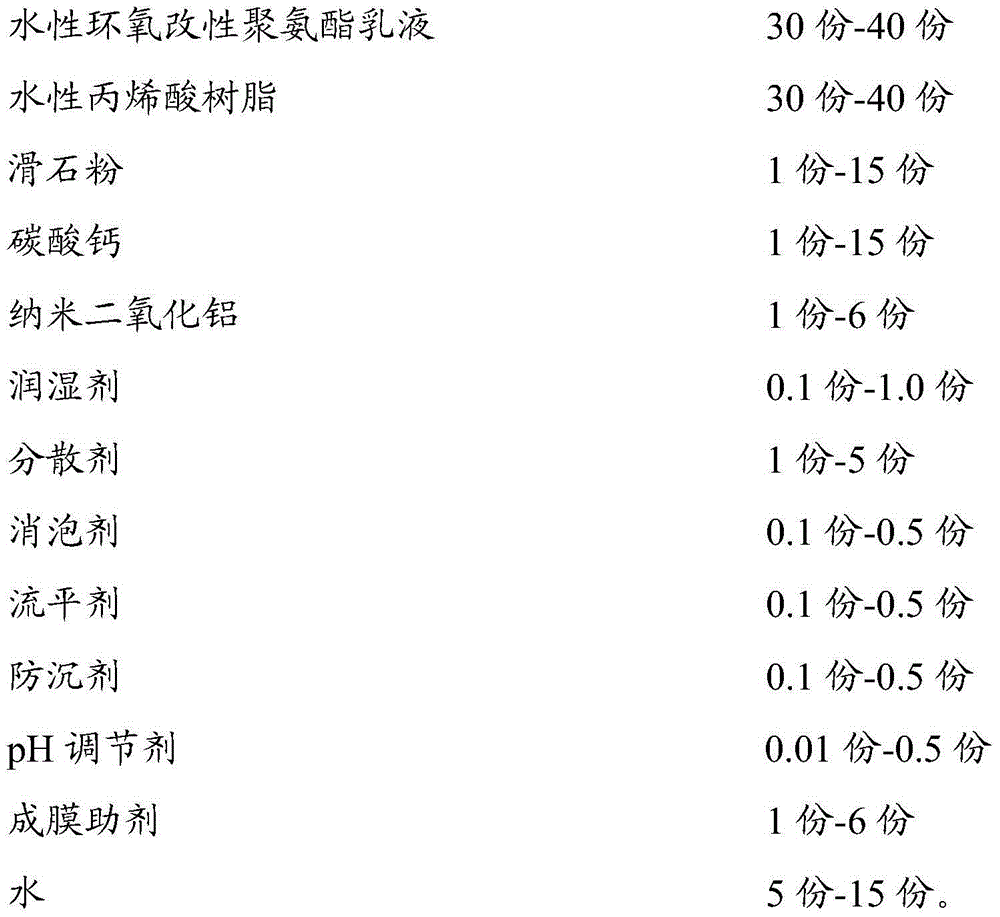

[0061] Different from Example 1, the one-component water-based wood coating of the present invention includes the following components by weight:

[0062]

[0063]

[0064] Wherein, the film-forming aid is formed by mixing the following components by weight: tripropylene glycol butyl ether 90%, alcohol ester-1210%; the water-based acrylic resin is a hydroxyl acrylic resin, and the mass content of the hydroxyl group is 0.3%.

[0065] The water-based epoxy-modified polyurethane emulsion was purchased from Yantai Yunqing Chemical Industry, with a solid content greater than 40%; the water-based acrylic resin was a hydroxyl acrylic resin, wherein the mass content of the hydroxyl group was 0.4%, and the solid content of the water-based acrylic resin was greater than 40%.

[0066] The anti-sedimentation agent is YH-C water-based anti-settling agent of Jinan Haide Chemical Co., Ltd.; the wetting agent is pull-open powder BX; the dispersant is the sodium acrylic acid series disper...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com