Method and device for preparing three-dimensional porous support for tissue engineering

A three-dimensional porous and tissue engineering technology, applied in the fields of biomedical engineering and advanced manufacturing, can solve the problems of wide particle size distribution of microcapsules, the inability to realize industrialization, and difficulty in satisfying the biological activity of biological scaffolds.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

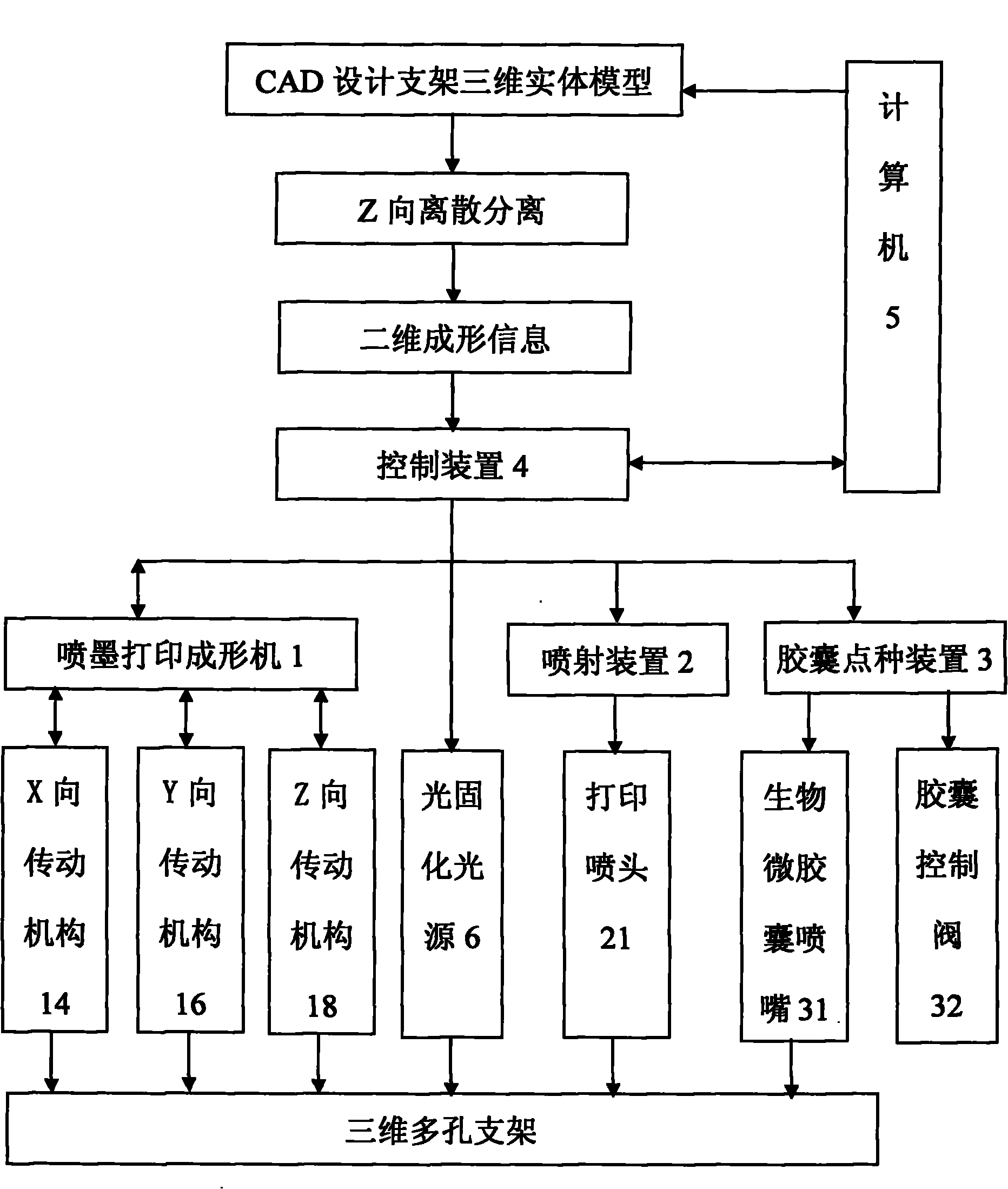

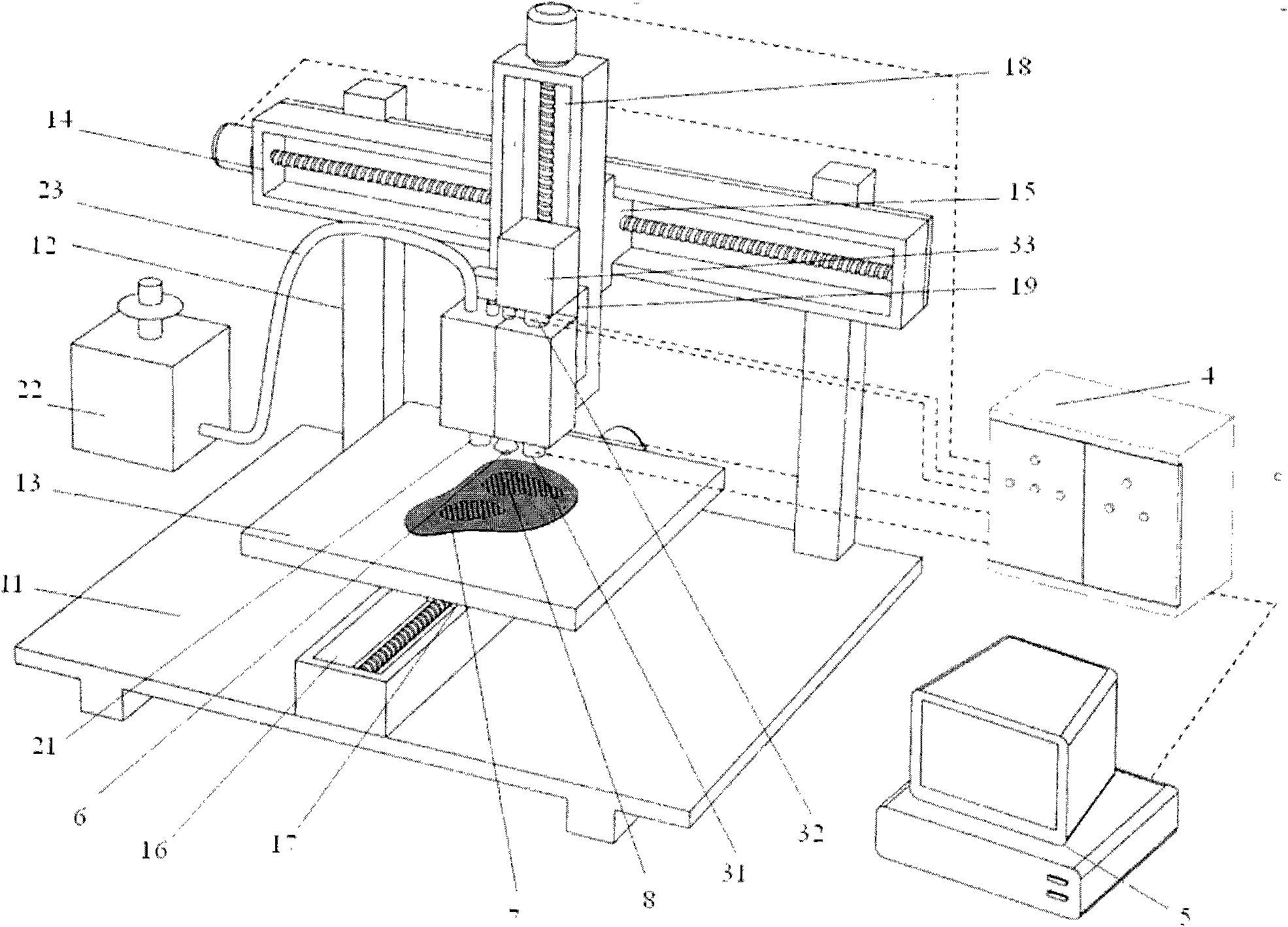

[0021] The preparation method (referred to as the preparation method) of the three-dimensional porous scaffold (abbreviated as the scaffold) for tissue engineering designed by the present invention, see figure 1 ) is based on the organic combination of three-dimensional inkjet printing method and biological microcapsule spotting method. Take the following steps:

[0022] (1) First, the shape of the bracket is designed by 3D CAD software, and then according to the process requirements of the product, the bracket is sliced and layered according to a certain thickness, and the two-dimensional cross-sectional information of each layer of the bracket is obtained;

[0023] (2) Under the control of CAD software, the three-dimensional inkjet printing nozzle runs along the X-axis and Y-axis direction, completes the printing movement set by the cross-sectional information of the first layer of the bracket, and sprays the liquid polymer according to the cross-sectional information to m...

Embodiment 1

[0039] Three-dimensional porous scaffolds for bone tissue engineering with a length of 50 mm were prepared from unsaturated polyphosphate (UPPE) materials. The particle size of the biocapsule particles is 20 μm, and the number of scaffold slices is 2500 pieces.

[0040] First use the 3D CAD software to design the 3D solid model of the bracket (see figure 1 ), and then according to the product design process requirements, it is sliced and layered according to a certain thickness to form a series of two-dimensional slices, and the slice thickness of each layer is 20 μm. The computer 5 controls each control mechanism to perform coordinated movement according to the two-dimensional forming information of each layer. Specifically, when the preparation starts, the computer 5 transmits the two-dimensional forming information of the first layer to the control device 4, and the capsule control valve 32 in the biological microcapsule spotting device 3 opens the valve under the contro...

Embodiment 2

[0042] It is basically the same as in Example 1, except that the particle size of the biocapsule particles is 18 μm, and active pharmaceutical molecules are added into the capsules, and the prepared scaffold has a pore size of 200-400 μm and a porosity of 90%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com