Three-group nitride micro-nano light-emitting device with embedded active layer and manufacturing method

A technology of light-emitting devices and nitrides, applied in semiconductor devices, electrical components, circuits, etc., can solve the problems of random distribution of positions, low quantum efficiency, poor size uniformity of quantum dots, etc., and achieve controllable position and size, high quantum efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

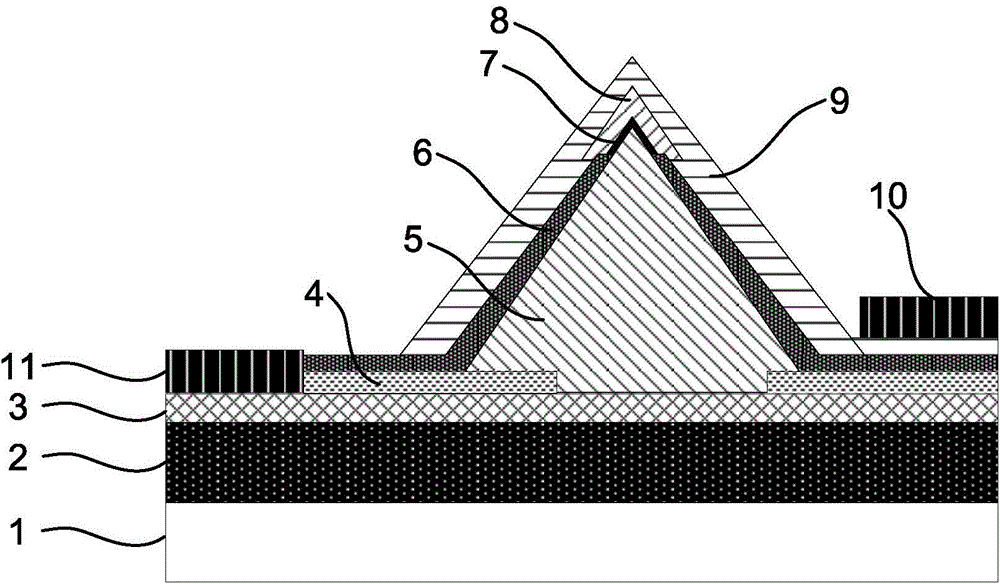

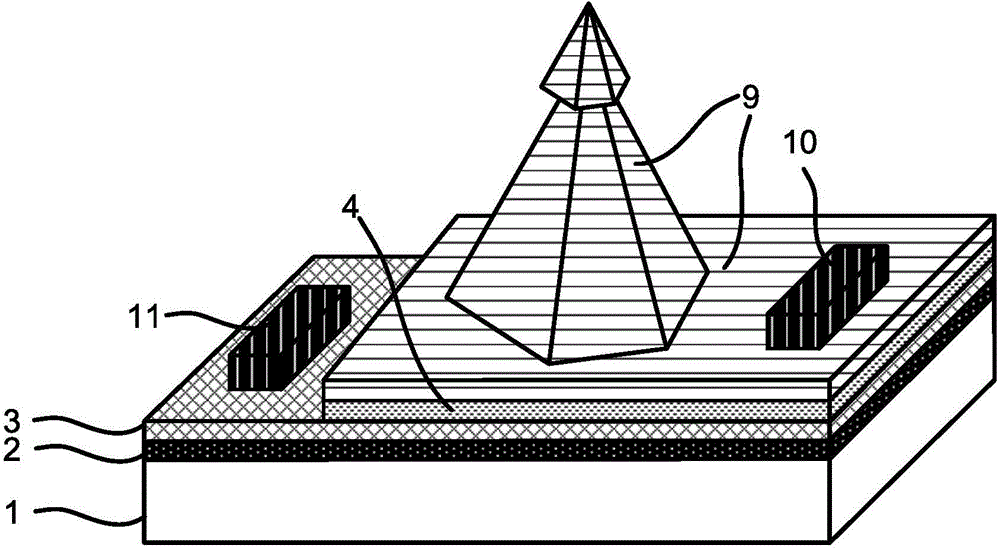

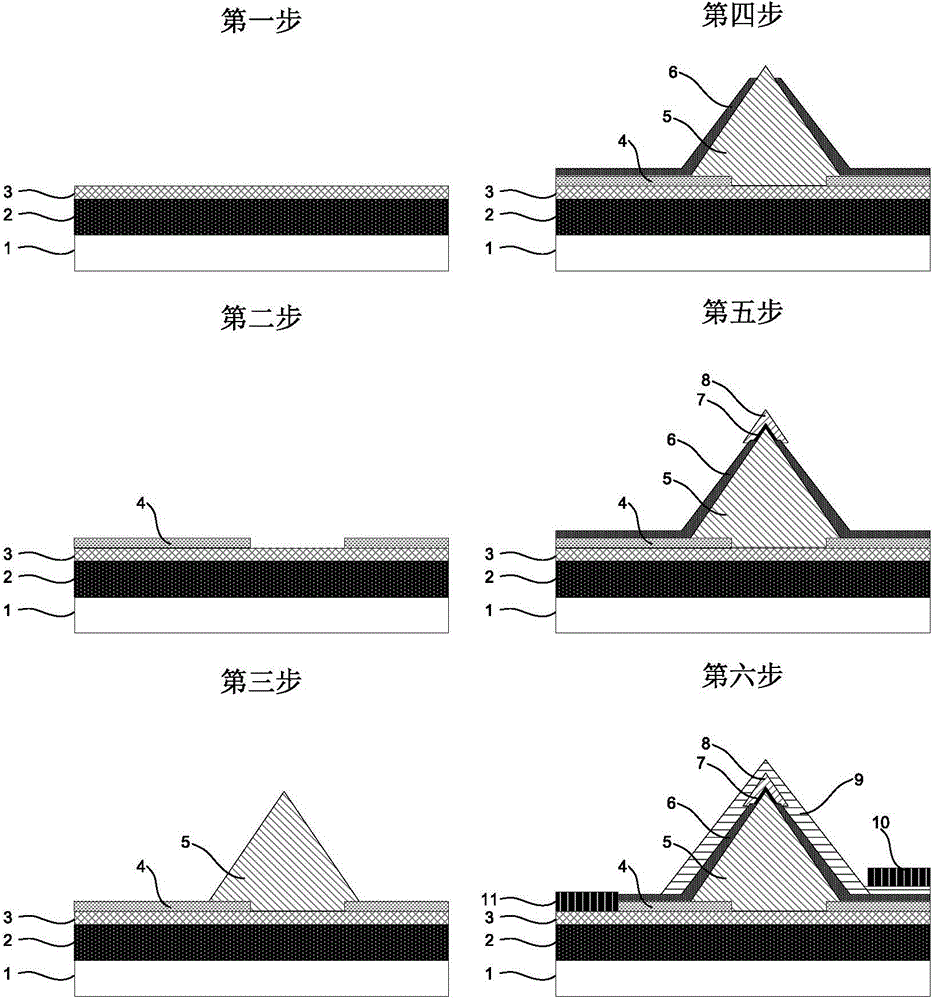

[0055] As shown in Figure 1, a Group III nitride light-emitting device with an embedded active layer, including an initial light-emitting device, a transparent conductive layer 9, a p-type electrode 10 and an n-type electrode 11;

[0056] Among them, the initial light-emitting device has a substrate 1, a nucleation layer and a buffer layer 2 of the III-nitride compound, an n-type III-nitride compound layer 3, a patterned masking film 4, and an n-type III-nitride compound for selective epitaxial growth from bottom to top. The nitride structure 5, the masking film 6 exposing the top of the selectively epitaxially grown n-type III-nitride structure, the III-group nitride active layer 7 and the p-type III-group nitride capping layer 8; wherein the III-group nitride active layer Layer 7 is arranged between the selectively epitaxially grown n-type III-group nitride structure 5 not covered by the masking film (6) and the p-type III-group nitride covering layer 8; wherein the selective...

Embodiment 2

[0068] This embodiment adopts the same device structure and preparation process as in Embodiment 1, wherein the nucleation AlN layer and buffer AlGaN layer in Embodiment 1, and the n-type GaN layer are replaced by the n-type AlGaN conductive nucleation in Embodiment 2 Layer 201. In addition, the front n-type electrode in Example 1 is replaced by the back n-type electrode at the bottom of the Si substrate in Example 2, thus successfully preparing a vertical conductor in which current is injected from the p-type electrode and flows out from the back n-type electrode. A single independent III-nitride micro-nano light-emitting device embedded with an InGaN active layer driven by electricity.

Embodiment 3

[0070] This embodiment adopts the epitaxial structure, device structure, and manufacturing process that are basically the same as those in Embodiment 2, wherein the pattern of the patterned masking film 4 in Embodiment 2 is changed to a periodic pattern with a period of 60 μm, a width of 5 μm, and a length of 500 μm. strip structure, while replacing the n-type GaN-based hexagonal pyramid structure in the epitaxial structure with the n-type GaN-based strip structure (trapezoid in cross section) in Embodiment 3. Similarly, the InGaN active layer 7 and the p-type GaN-based striped cladding layer (triangular in cross section) are epitaxially grown in sequence at the apex of the n-type GaN-based strip structure (trapezoidal in cross section) not covered by the masking film. ). This embodiment is a single independent Group III nitride micro-nano light-emitting device embedded with an InGaN active layer driven by vertical conduction of current injected from the p-type electrode and f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com