Polyarylether containing quaternary ammonium side group and its preparation method, and anion exchange membrane containing quaternary ammonium side group and its preparation method

A polyarylether and side group technology, applied in the field of polyarylether, can solve the problems of difficult control of the number of positions, high toxicity, difficulty in obtaining highly substituted chloromethylated polyarylether, etc., and achieve low water absorption and high ion conduction Effects that are easily controlled in rate, quantity and location

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0043] The preparation method of the polyarylene ether containing quaternary ammonium side group provided by the invention comprises the following steps:

[0044] (1) Under the condensation reaction conditions and in the presence of a catalyst, combine the bisphenol monomer having the structure shown in formula (5) with one of the halogen-containing compounds having the structure shown in formula (6)-(8) One or more reactions, so that the methoxy-containing polyarylether having the structure shown in formula (9) is obtained;

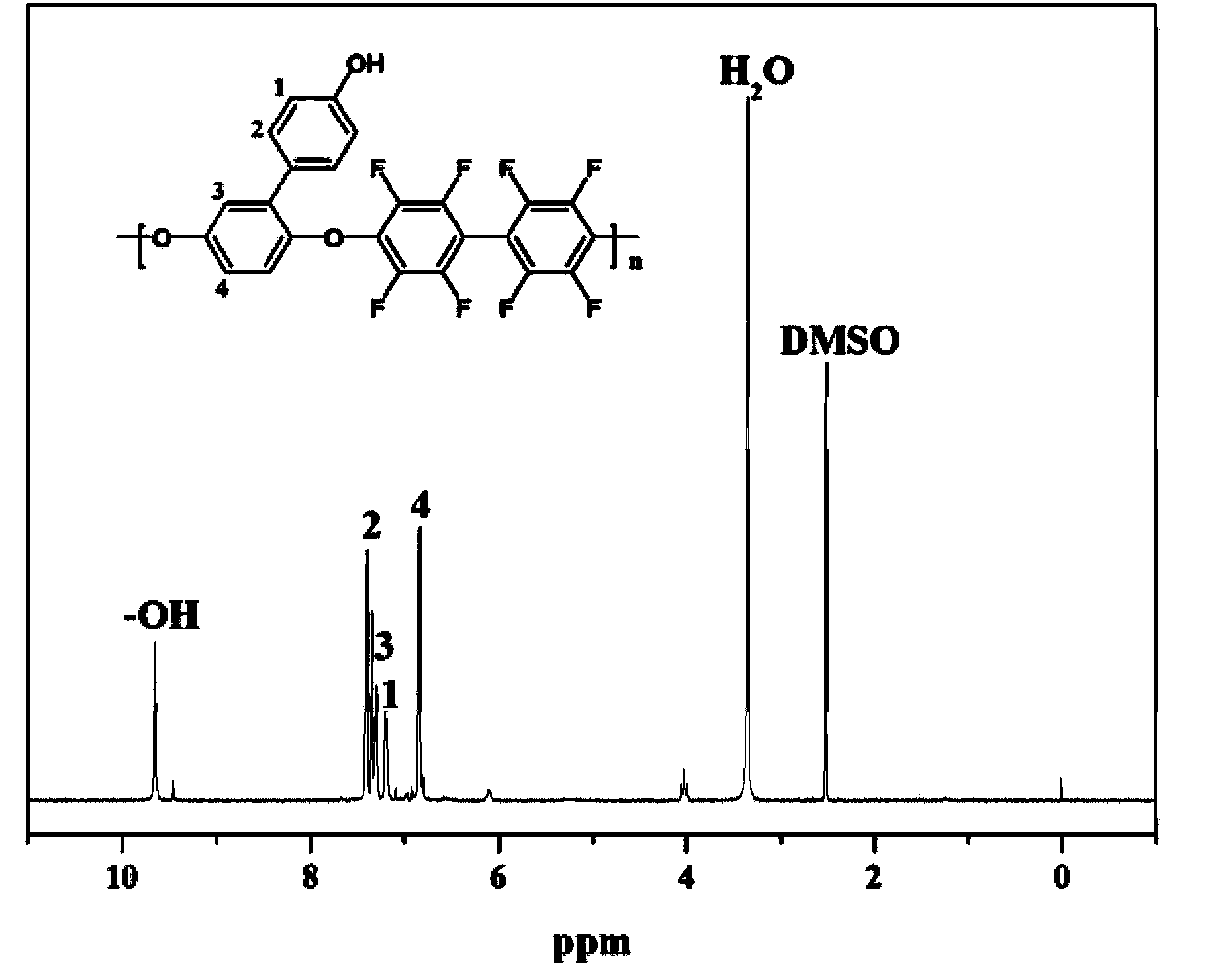

[0045] (2) Under the demethylation reaction conditions, the methoxy-containing polyarylether obtained in step (1) is reacted with a demethylation reagent, so that the phenolic hydroxyl-containing polyaryl ether having the structure shown in formula (10) is obtained Polyarylether;

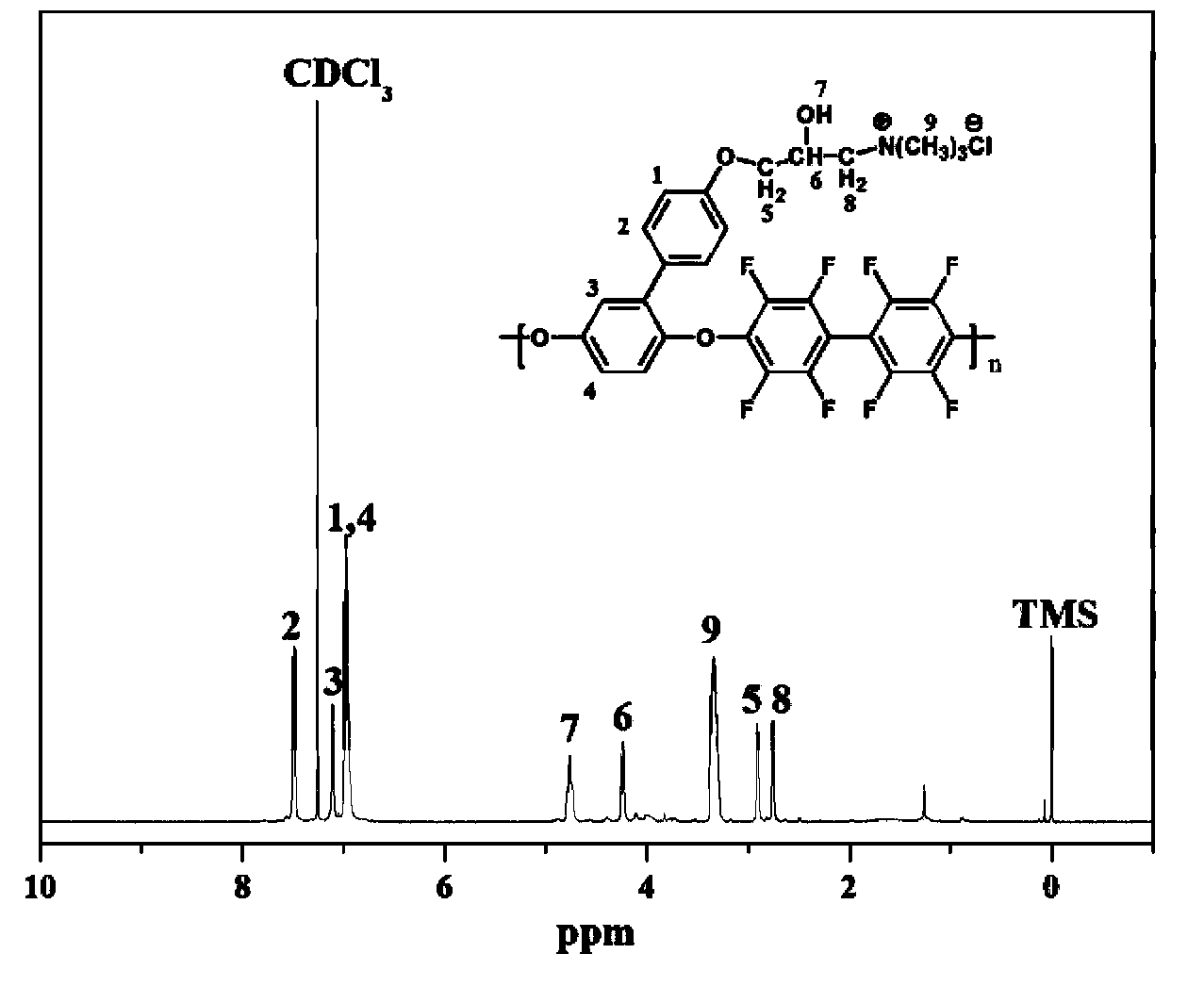

[0046] (3) Under the conditions of the ring-opening reaction, react the phenolic hydroxyl-containing polyarylether obtained in step (2) with the epoxide having the structure ...

preparation example 1

[0082] This preparation example is used to illustrate the polyarylether containing quaternary ammonium side groups provided by the present invention and its preparation method.

[0083] (1) Add 0.025mol of 4-methoxyphenylhydroquinone, 0.025mol of decafluorobiphenyl and 0.03mol of anhydrous potassium carbonate into a three-necked flask equipped with mechanical stirring and a thermometer. Add 30mL of N-methylpyrrolidone and 15mL of toluene under nitrogen protection, and raise the temperature to 140°C for 4 hours, then distill off the toluene, then raise the temperature to 150°C for 2 hours, then pour the reaction solution into deionized water, Crush and filter the polymer with a pulverizer, then boil and wash the polymer with distilled water, filter, repeat 6 times, and dry in an oven to obtain a methoxy-containing polyarylether (Me-PAE), wherein the degree of polymerization n is 85 .

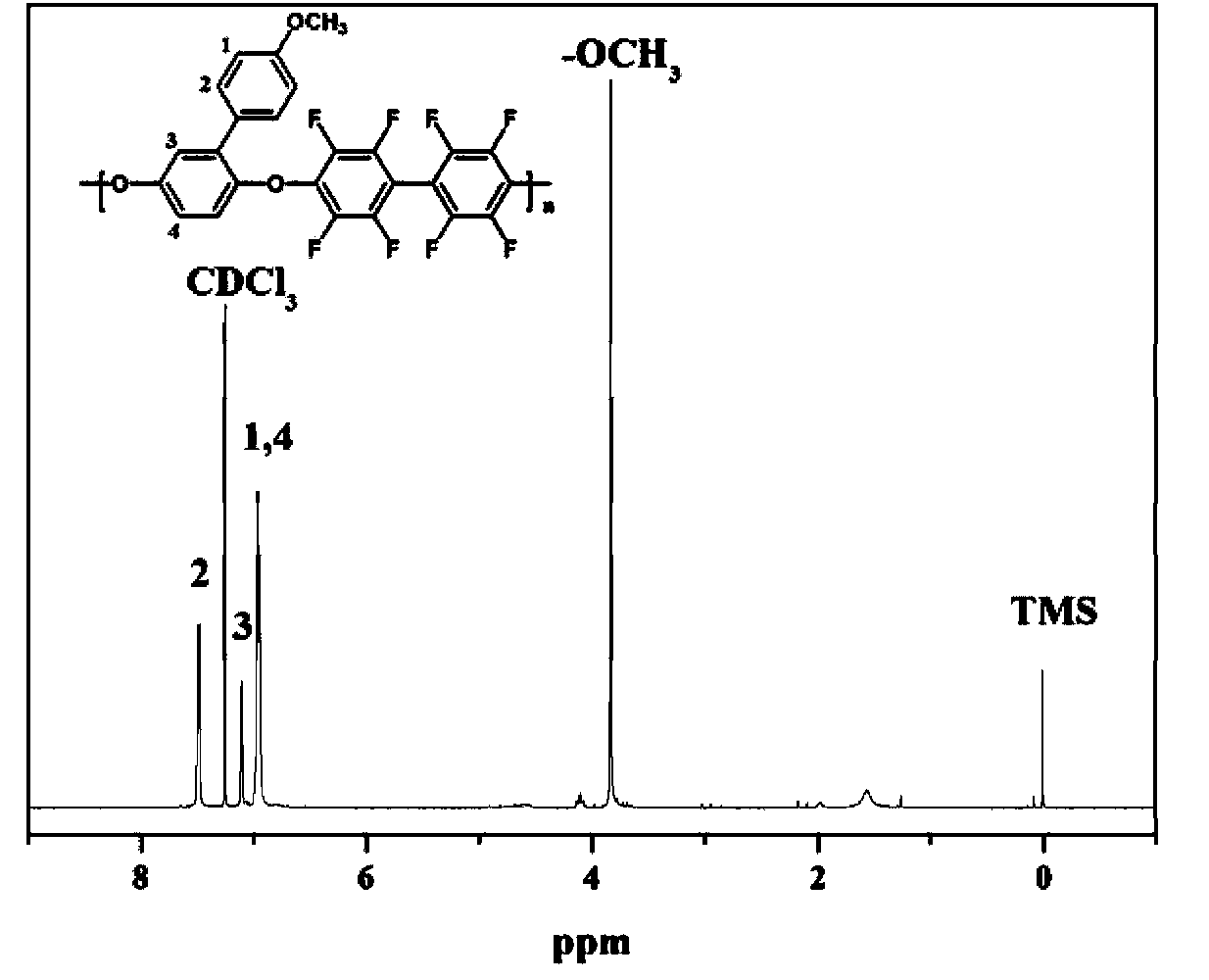

[0084] figure 1 It is the NMR spectrum of Me-PAE, in which, the signal peaks (that is, sign...

preparation example 2

[0092] This preparation example is used to illustrate the polyarylether containing quaternary ammonium side groups provided by the present invention and its preparation method.

[0093] (1) Add 0.025mol of 4-methoxyphenylhydroquinone, 0.025mol of 4,4′-difluorobenzophenone and 0.03mol of anhydrous potassium carbonate to a three-necked flask equipped with mechanical stirring and a thermometer middle. Add 30 mL of N-methylpyrrolidone and 15 mL of toluene under nitrogen protection, and raise the temperature to 140°C for 4 hours, then distill off the toluene, then raise the temperature to 190°C for 8 hours, then pour the reaction solution into deionized water, Crush and filter the polymer with a pulverizer, then wash the polymer with distilled water and filter, repeat 6 times, and then dry in an oven to obtain a methoxy-containing polyarylether (Me-PAEK), wherein the degree of polymerization n is 80 .

[0094] 1 H NMR analysis: the signal peak at the chemical shift of 6.0-8.0ppm...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com