Process for preparing nano structure of zinc oxide

A zinc oxide nano- and nano-structure technology, applied in nano-structure manufacturing, zinc oxide/zinc hydroxide, nanotechnology, etc., can solve problems such as unrealized position and number controllable

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

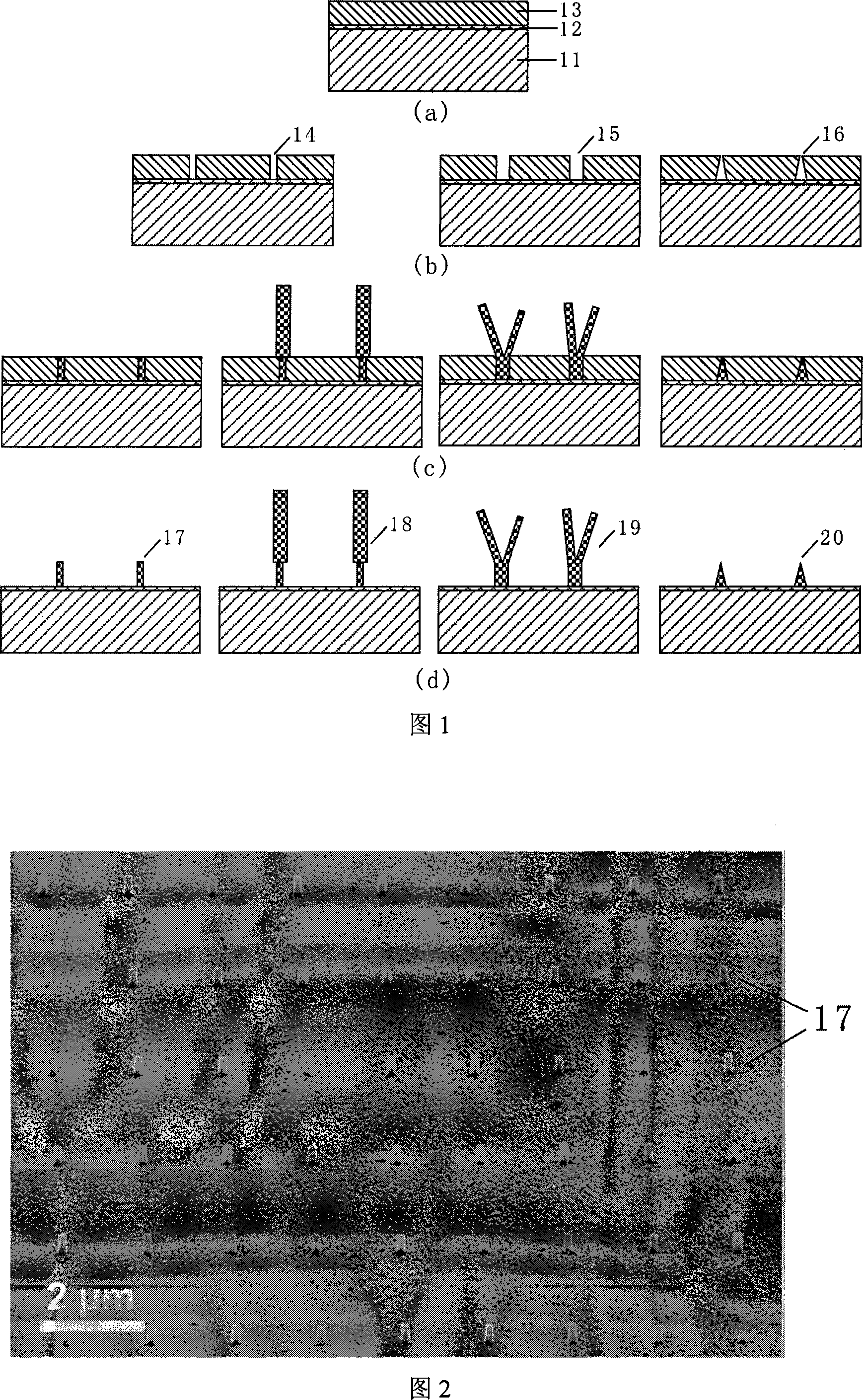

[0019] The present invention will be described in further detail below in conjunction with the accompanying drawings and a specific embodiment.

[0020] 1. Use n-type high-conductivity single crystal silicon with crystal orientation (resistivity 2.4~3.7×10 -3 Ω·cm)11 as the substrate.

[0021] 2. As shown in Figure 1(a), a 50nm-thick metal zinc (Zn)12 thin film was deposited on a single crystal silicon wafer using a SP-3 magnetron sputtering station. The film preparation conditions are as follows: background vacuum: 3.0×10 -3 Pa; process gas: high-purity argon (Ar) gas (flow rate: 60 sccm); sputtering power: DC sputtering 300W; time: 2 minutes; working temperature: room temperature.

[0022] 3. Use a KW-4AH type hot plate to bake the silicon substrate coated with the metal zinc film at a temperature of 180°C before gluing for 30 minutes.

[0023] 4. Utilize the Karl Suss RC8 glue coating machine, evenly spin-coat the PMMA (950K C4) 13 (Fig. The glue rotation speed is 3000...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com