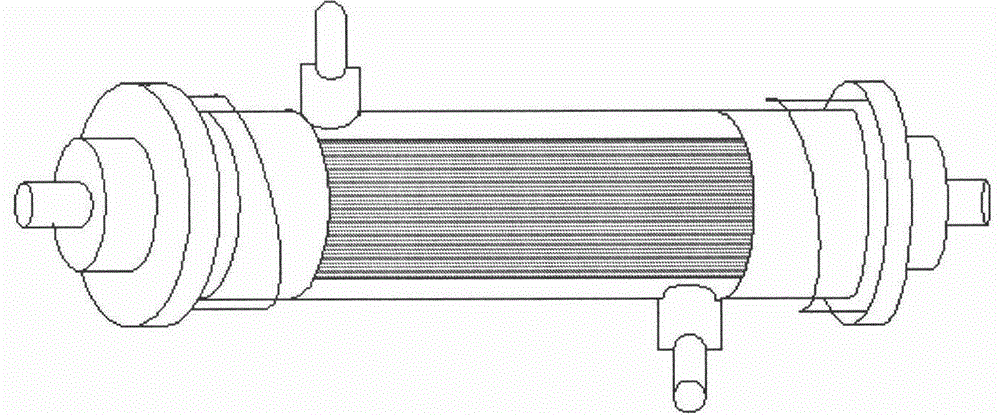

Catalytic hollow fiber membrane and preparation method thereof

A fiber membrane and hollow technology, applied in the field of catalytic hollow fiber membrane and its preparation, can solve problems such as difficulties in porous membranes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

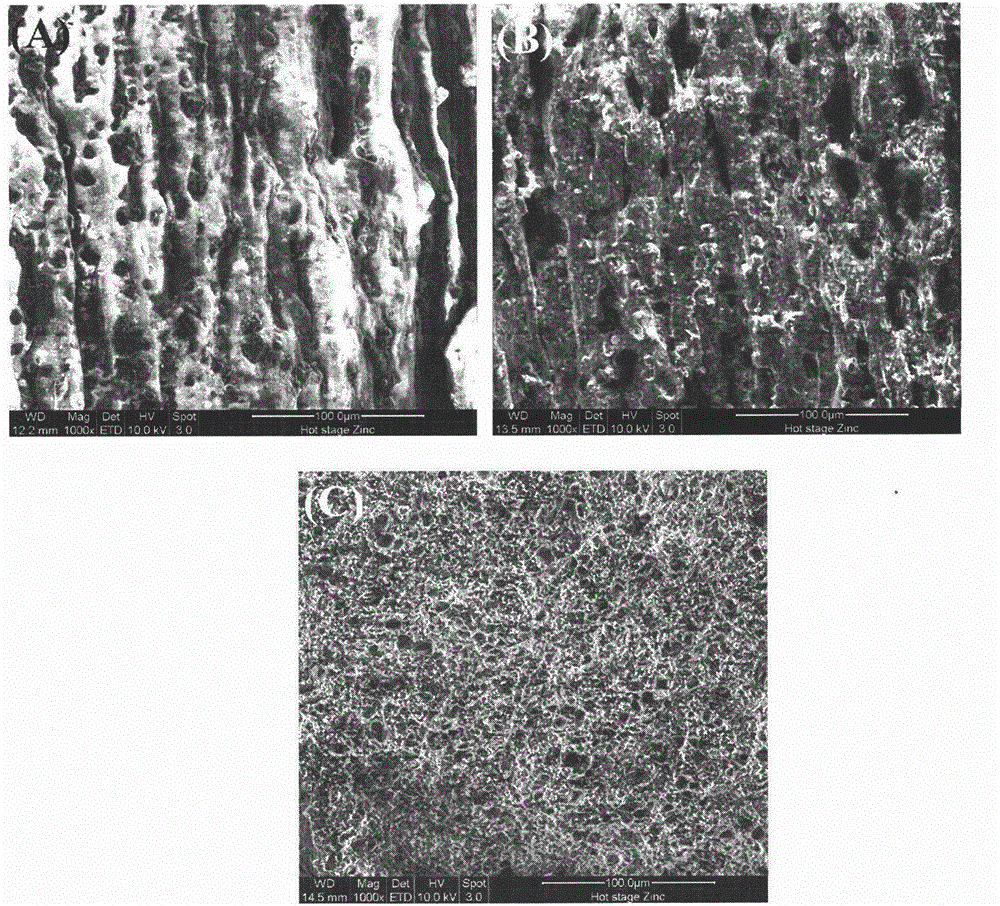

Embodiment 1

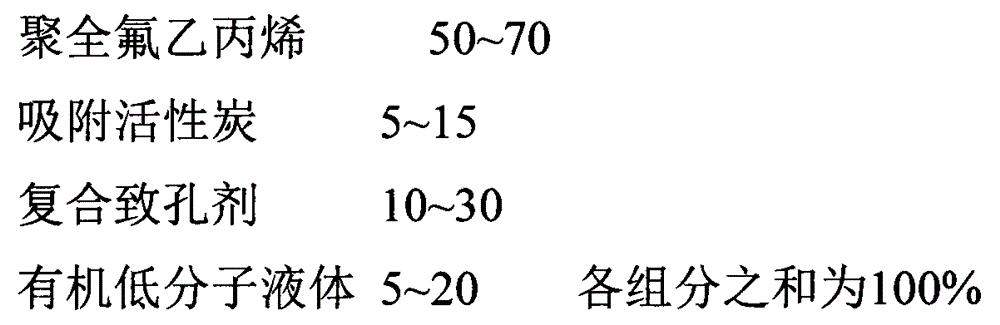

[0019] Polyperfluoroethylene propylene with a hexafluoropropylene content of 18% is used as the polymer matrix phase; the adsorption activated carbon content is 5%; the composite porogen is 0.01 μm SiO 2 A mixture of powder and PEO, the former is an insoluble porogen, accounting for 30% of the total composite porogen, and the latter is a soluble porogen, accounting for 70% of the total composite porogen; organic low molecular liquid Choose DOP. The distribution ratio of each component in the film-forming system is as follows:

[0020]

[0021] Adsorption activated carbon, composite porogen and organic low-molecular liquid are forced to mix uniformly through a mixing tank to obtain a viscous mixture, which is then mixed with polyperfluoroethylene propylene polymer resin and fed to a twin-screw extruder. The hollow fiber spinneret is used for melt blending and spinning to make membranes. The temperature of the five twin-screw zones is 270°C, 280°C, 290°C, 300°C, and 310°C, a...

Embodiment 2

[0023] In Example 1, the insoluble porogen SiO 2 The ratio of the porogen is adjusted to 10% of the total amount of the porogen, the ratio of the soluble porogen PEO is adjusted to 90%, and other conditions remain unchanged, and three kinds of hollow membranes are obtained. Correspondingly recorded as 4#, 5# and 6# film.

Embodiment 3

[0025] Polyperfluoroethylene propylene with a hexafluoropropylene content of 18% is used as the polymer matrix phase; the adsorption activated carbon content is 10%; the composite porogen is 0.01 μm SiO 2 Powder, 5μm CaCO 3 A mixture of powder and PEO, the former two are insoluble porogens, the mass ratio of the two is 1 / 1, accounting for 30% of the total composite porogen, and the latter is a soluble porogen, accounting for 30% of the total composite porogen 70% of the total amount of the agent; DOP is selected as the organic low molecular liquid. The distribution ratio of each component in the film-forming system is as follows:

[0026]

[0027] Adsorption activated carbon, composite porogen and organic low-molecular liquid are forced to mix uniformly through a mixing tank to obtain a viscous mixture, which is then mixed with perfluoropolymer resin and then fed into a twin-screw extruder. The filament assembly was melt-blended and spun into a film. The temperature in th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com