Aeration running water composite and its preparation method

A composite material and living water technology, applied in chemical instruments and methods, oxidized water/sewage treatment, other chemical processes, etc., can solve the problem of incomplete function of water living device, lack of mention of oxygenation function and adsorption function, poor performance, etc. problems, to achieve excellent ion exchange, excellent adsorption, and excellent performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] Raw material formula 1: bioactivation functional ceramic material 50%, sepiolite 30%, water glass binder 20%, wherein the bioactivation functional ceramic material is tourmaline 5-30% by weight, ferrite 10-30% , kaolin 10-20%, silicon oxide 5-20%, aluminum oxide 5-20%, calcium oxide 5-20%, cellulose 2-5%, polyacrylic acid 2-5%, castor oil 2-5%, and The composition of cerium nitrate is 1-5%, and the sum of each component is 100%.

[0035] The preparation method of the oxygen-increasing active water composite material is as follows:

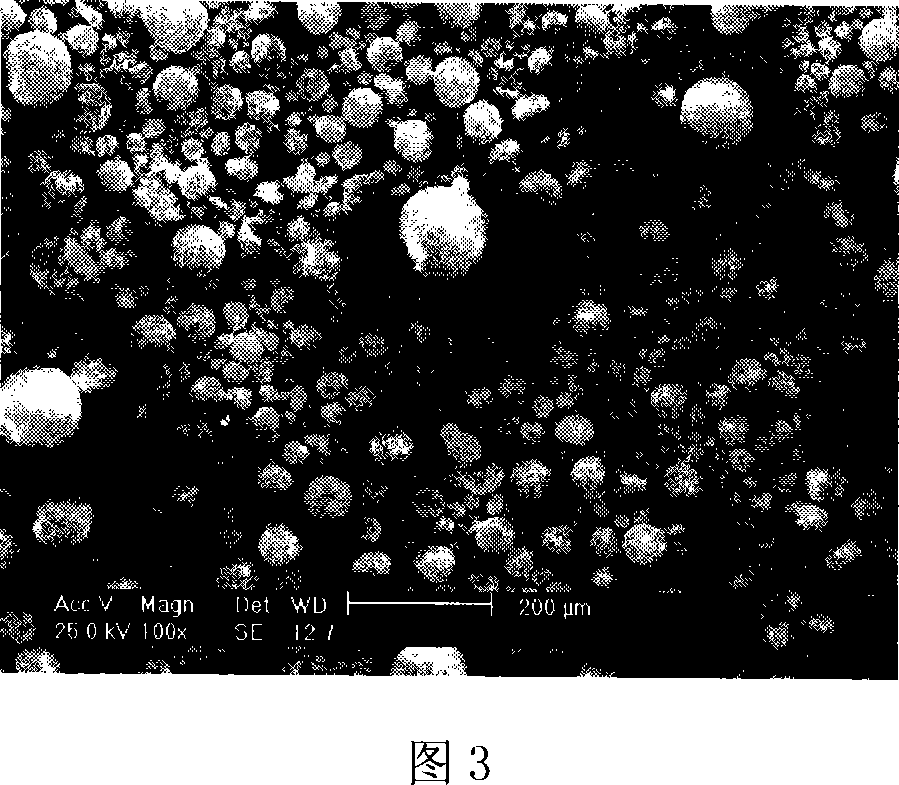

[0036] (1) Ingredients: According to the raw material formula 1, the bioactivation functional ceramic material is ground to an average particle size of 10.5 μm, and the sepiolite is respectively subjected to an acid concentration of 15%, a solid-liquid mass ratio of 1:10, and a time of 10 hours. Activation treatment and heat activation treatment at 150°C for 8 hours, and grinding to an average particle size of 5.5 μm; water glass is made in...

Embodiment 2

[0047] Raw material formula 2: 85% bioactivation functional ceramic material, 5% attapulgite, 10% water glass binder, wherein the bioactivation functional ceramic material is tourmaline 5-30% by weight and ferrite 10-30% , kaolin 10-20%, silicon oxide 5-20%, aluminum oxide 5-20%, calcium oxide 5-20%, cellulose 2-5%, polyacrylic acid 2-5%, castor oil 2-5%, and The mixture of cerium nitrate and neodymium nitrate in any proportion is composed of 1-5%, and the sum of each component is 100%.

[0048] The preparation method of the oxygen-increasing active water composite material is as follows:

[0049] (1) Ingredients: according to the raw material formula 1, the bioactivation functional ceramic material is ground to an average particle size of 7.5 μm, and the sepiolite is respectively subjected to an acid concentration of 10%, a solid-liquid mass ratio of 1:10, and a time of 10 hours. Activation treatment and heat activation treatment at 100°C for 8 hours, and grinding to an aver...

Embodiment 3

[0054] Raw material formula 1: 50% of bioactivation functional ceramic material, 30% of palygorskite, 20% of water glass binder, wherein the bioactivation functional ceramic material is 5-30% by weight of tourmaline, 10-30% of ferrite , kaolin 10-20%, silicon oxide 5-20%, aluminum oxide 5-20%, calcium oxide 5-20%, cellulose 2-5%, polyacrylic acid 2-5%, castor oil 2-5%, and The composition of cerium nitrate is 1-5%, and the sum of each component is 100%.

[0055] The preparation method of the oxygen-increasing active water composite material is as follows:

[0056] (1) Ingredients: According to the raw material formula 1, the bioactivation functional ceramic material is ground to an average particle size of 1 μm, and the sepiolite is activated by acid with an acid concentration of 5%, a solid-liquid mass ratio of 1:10, and a time of 10 hours. Treatment and heat activation treatment at 250°C for 8 hours, and grinding to an average particle size of 1 μm; water glass is made into...

PUM

| Property | Measurement | Unit |

|---|---|---|

| emissivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com