Preparation method of flame retarding styrene polymer composite material

A technology of styrene polymers and composite materials, which is applied in the field of composite materials, can solve problems affecting the original performance of styrene polymers, difficulties in personnel evacuation and rescue work, and negative effects on the comprehensive performance of the composition, so as to be beneficial to popularization Use, high production efficiency, and the effect of reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

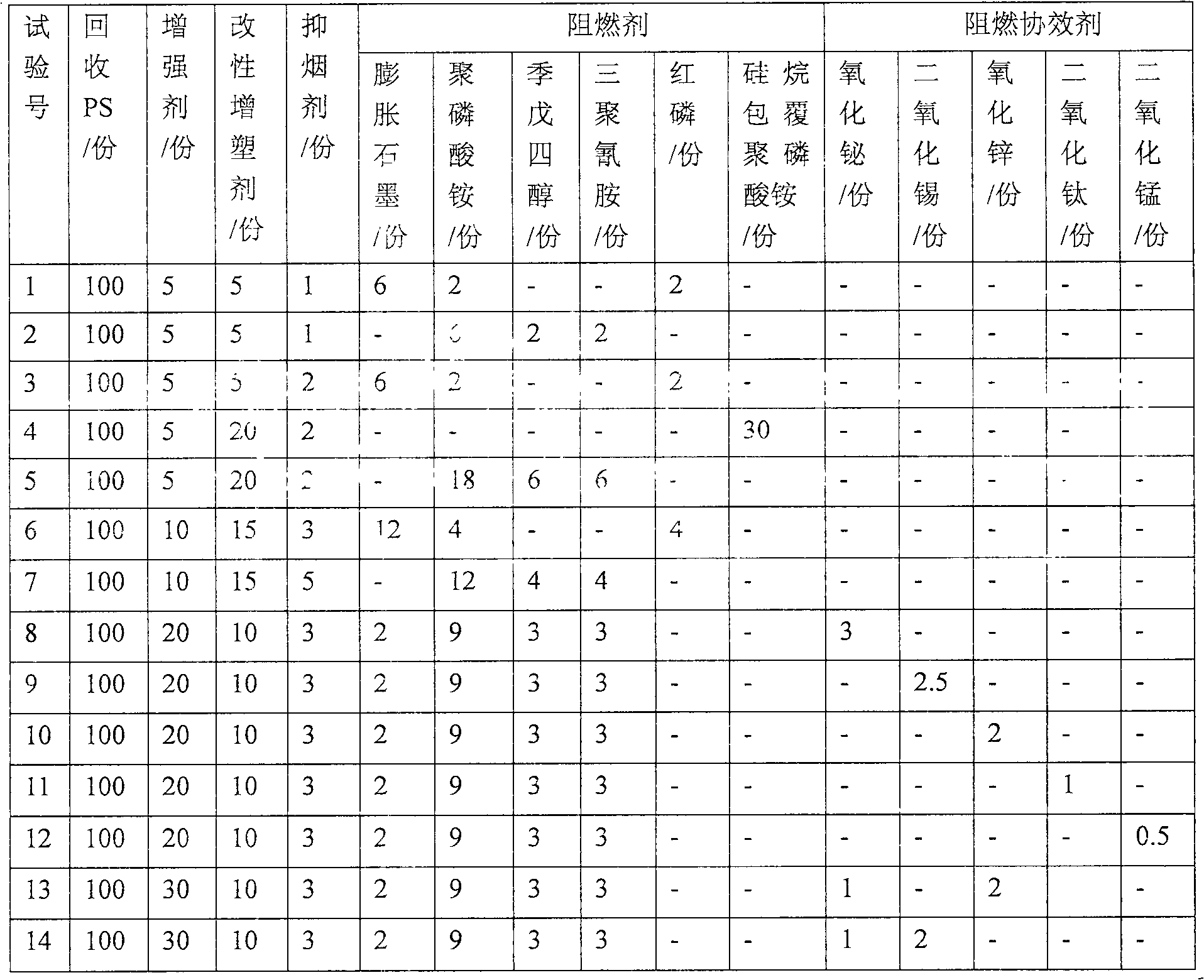

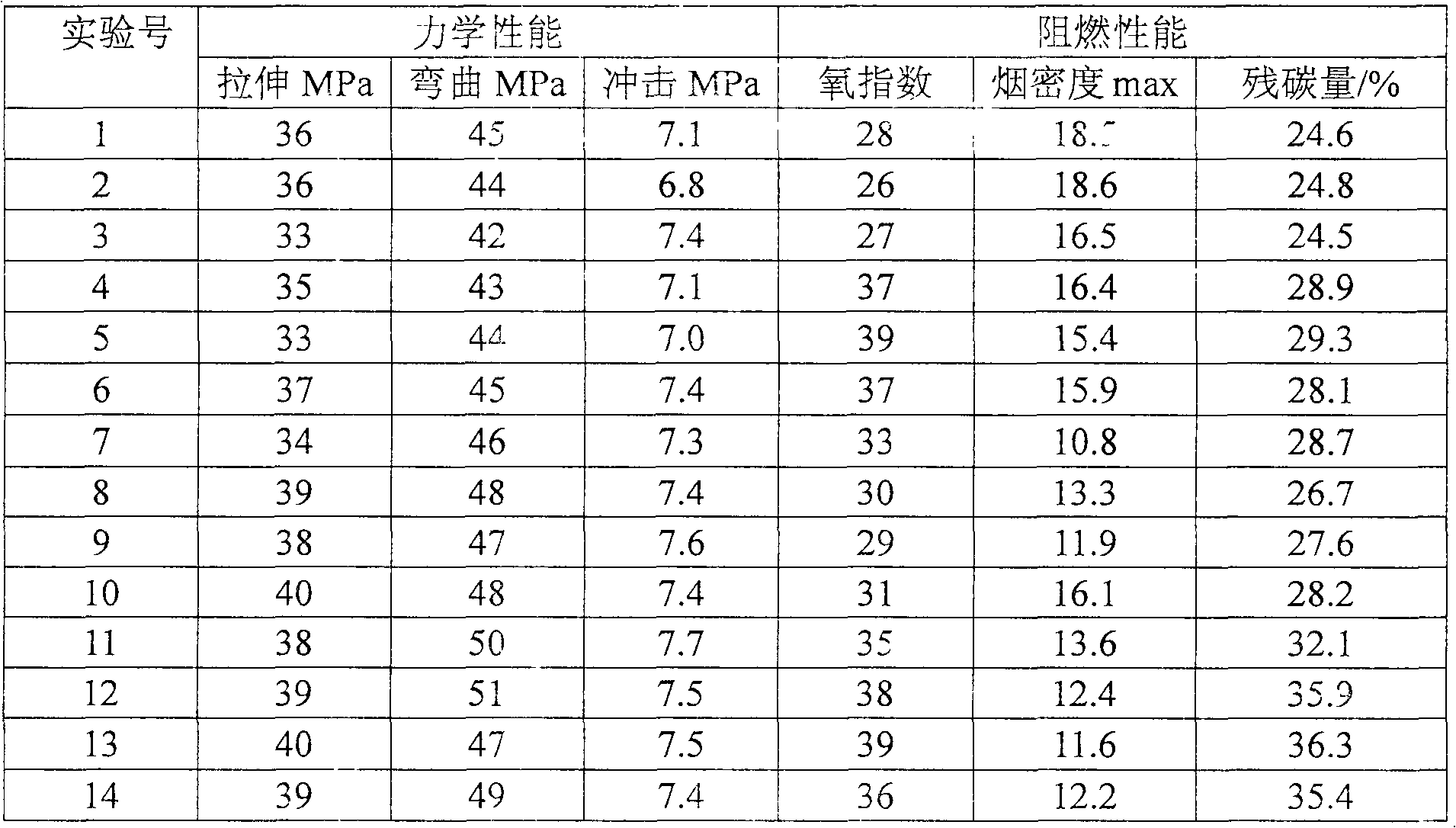

Embodiment 1

[0022] The raw materials for the preparation of the composite material in this embodiment include: 100 parts by weight (the same below) recycled polystyrene material; 5 parts of 20-mesh reinforcing agent wood flour; 5 parts of modified plasticizer dicyclohexyl phthalate (CCHP) ; 10 parts of flame retardant, specifically composed of 6 parts of expanded graphite, 2 parts of ammonium polyphosphate and 2 parts of red phosphorus, and 1 part of ammonium octamolybdate smoke suppressant. The steps of the preparation method are as follows: (1) under the condition of 120° C. and a rotating speed of 800 r / min, stir the wood flour in a high-speed mixer until the moisture content is 1%; Carry out physical defoaming in the machine, then join the large polystyrene (product) material after defoaming into the high-speed pulverizer to pulverize, then join in the twin-screw extruder to extrude and granulate; (3) will make The polystyrene pellets, plasticizing modifier, flame retardant and smoke ...

Embodiment 2

[0024]The difference between this example and Example 1 is that the reinforcing material is 5 parts of 200 mesh wood flour, the flame retardant includes 6 parts of ammonium polyphosphate, 2 parts of pentaerythritol and 2 parts of melamine, and the others are the same as in Example 1.

Embodiment 3

[0026] The difference between this embodiment and Example 1 is that the reinforcing material is 5 parts of 20 mesh bamboo powder, the modified plasticizer is dioctyl isophthalate (DOIP), the smoke suppressant is 2 parts of ammonium octamolybdate, and other Same as Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com