Nitrogen-doped p-type tin dioxide film and preparation method thereof

A tin dioxide and nitrogen doping technology, applied in ion implantation plating, metal material coating process, coating and other directions, can solve the problems of increasing the process, unable to obtain a doped tin dioxide film, time-consuming, etc. Scientific method, the effect of excellent light transmission performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

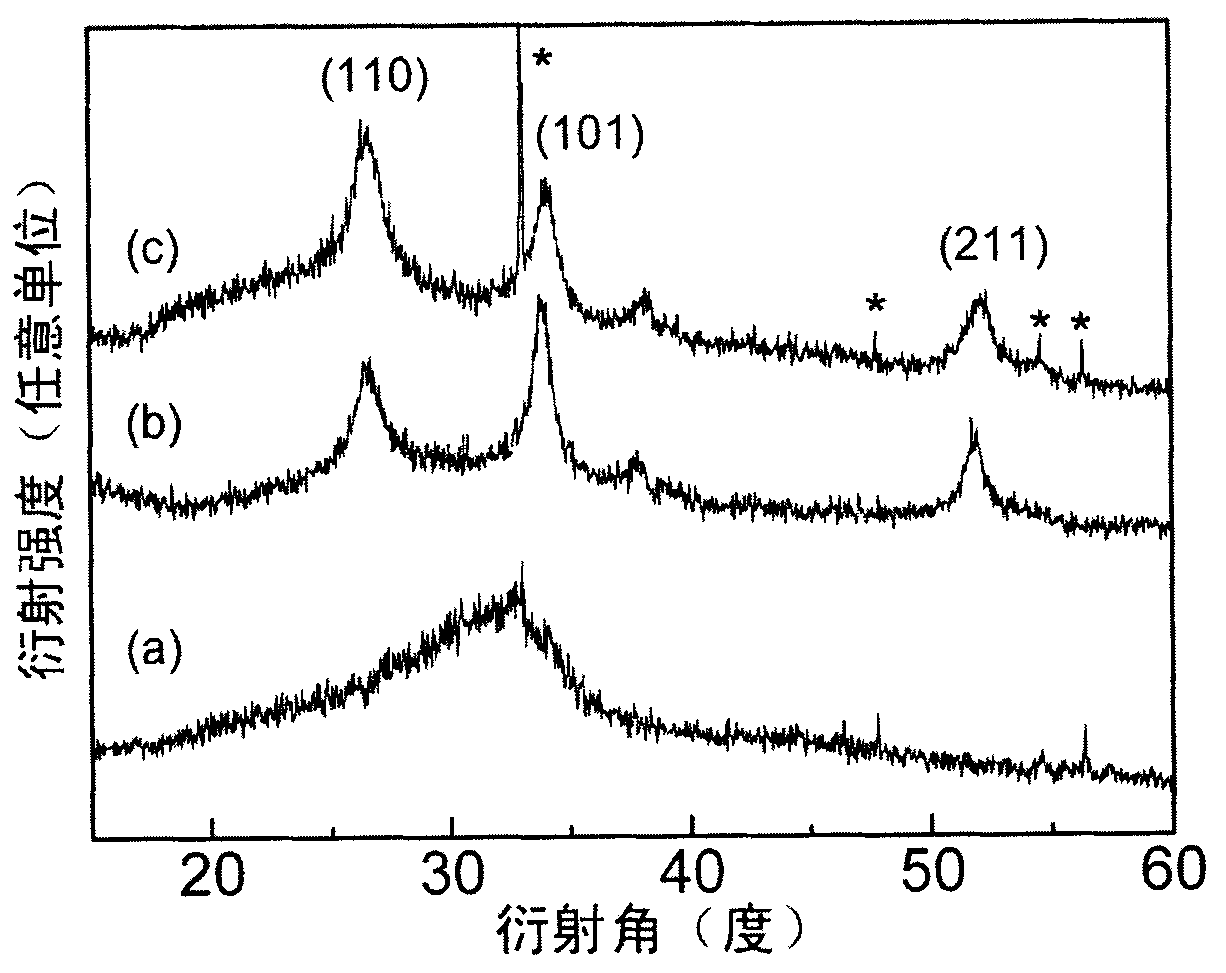

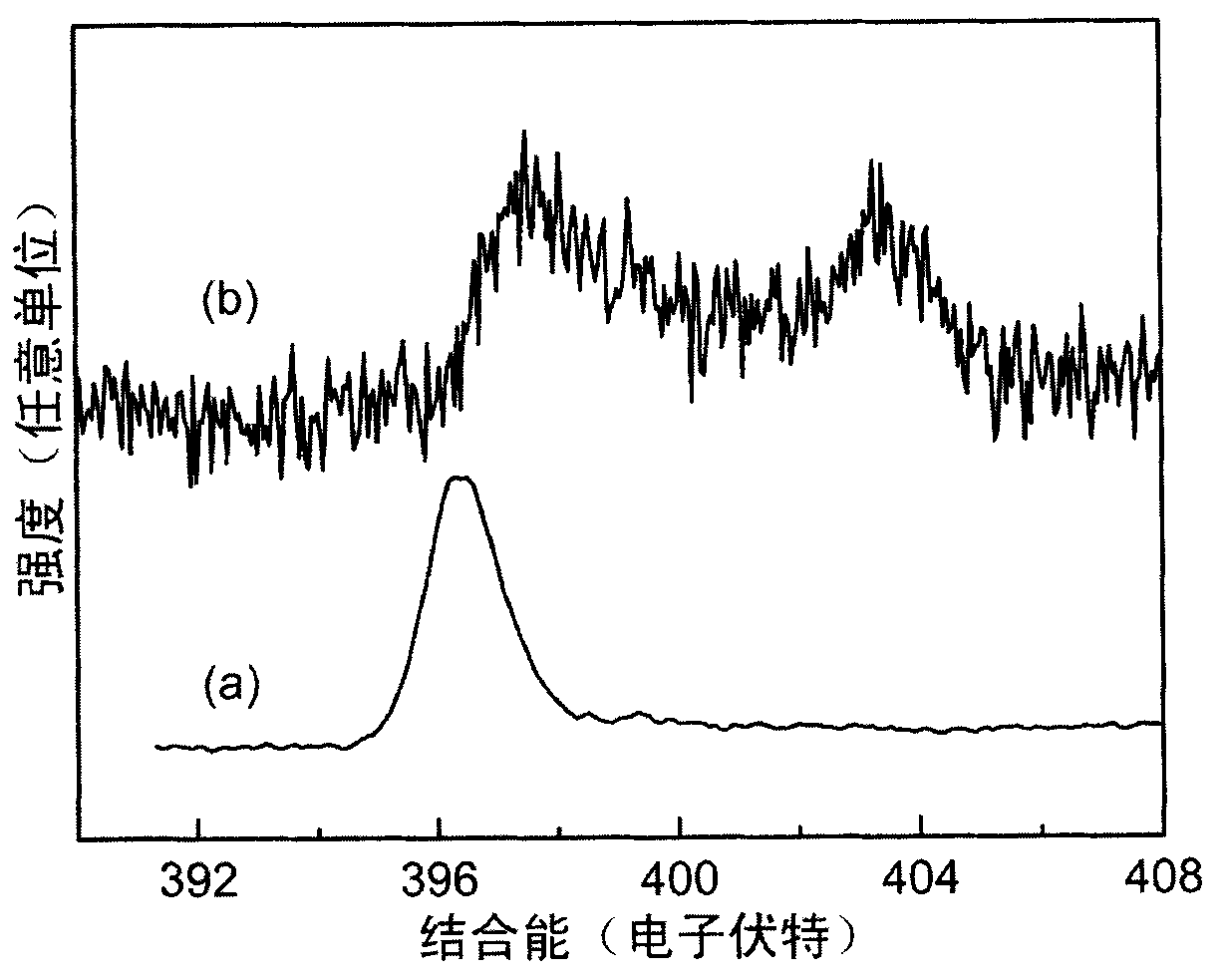

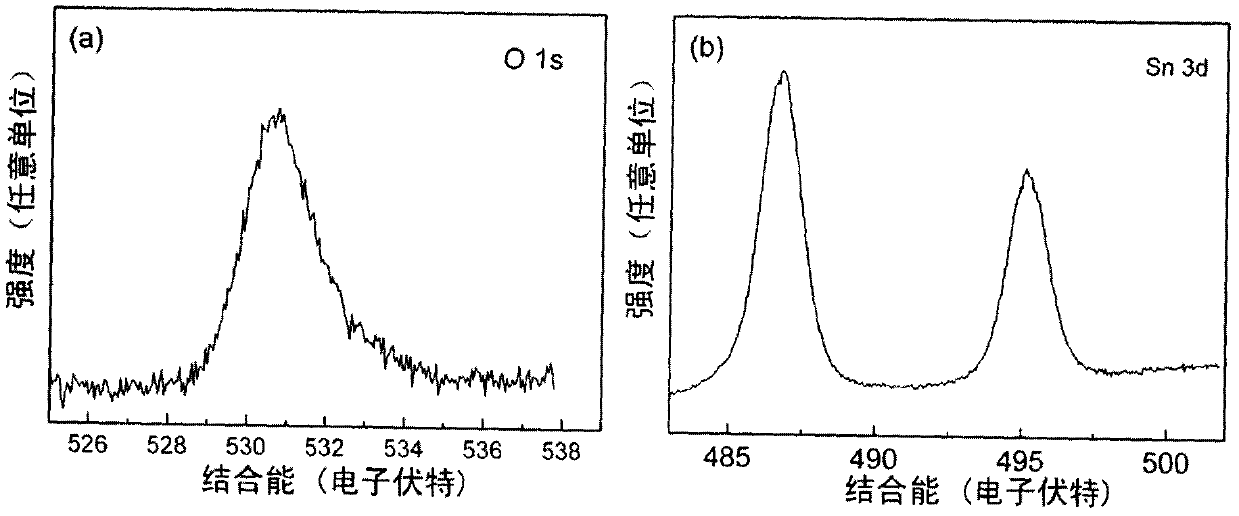

Embodiment 1

[0023] The concrete steps of preparation are:

[0024] Step 1, first place the tin metal target and the substrate on the cathode and the sample stage in the vacuum chamber of the magnetron sputtering equipment respectively; wherein, the distance between the tin metal target and the substrate is 8cm, and the substrate is monocrystalline silicon. Wait until the vacuum degree of the vacuum chamber is ≤5.0×10 -4 After Pa, make the vacuum chamber in a nitrogen-argon mixed atmosphere, and sputter for 30 minutes; wherein, the volume ratio of nitrogen and argon in the nitrogen-argon mixed atmosphere is 1:2, and the pressure under the nitrogen-argon mixed atmosphere is 0.8 Pa, and the sputtering The source is a DC power source with an output power of 30W, and a tin nitride film is obtained.

[0025]Step 2, place the tin nitride film in an argon-oxygen mixed atmosphere, and anneal at 350°C for 120 minutes; wherein, the volume ratio of argon to oxygen in the argon-oxygen mixed atmospher...

Embodiment 2

[0027] The concrete steps of preparation are:

[0028] Step 1, first place the tin metal target and the substrate on the cathode in the vacuum chamber of the magnetron sputtering equipment and in the sample stage respectively; wherein, the distance between the tin metal target and the substrate is 9 cm, and the substrate is monocrystalline silicon. Wait until the vacuum degree of the vacuum chamber is ≤5.0×10 -4 After Pa, the vacuum chamber was placed in a nitrogen-argon mixed atmosphere, and the sputtering was performed for 38 minutes; wherein, the volume ratio of nitrogen and argon in the nitrogen-argon mixed atmosphere was 1:3, and the pressure under the nitrogen-argon mixed atmosphere was 1.4 Pa. The source is a DC power source with an output power of 38W, and a tin nitride film is obtained.

[0029] Step 2, place the tin nitride film in an argon-oxygen mixed atmosphere, and anneal at 410°C for 105 minutes; wherein, the volume ratio of argon to oxygen in the argon-oxygen ...

Embodiment 3

[0031] The concrete steps of preparation are:

[0032] Step 1, first place the tin metal target and the substrate on the cathode in the vacuum chamber of the magnetron sputtering equipment and in the sample stage respectively; wherein, the distance between the tin metal target and the substrate is 10 cm, and the substrate is monocrystalline silicon. Wait until the vacuum degree of the vacuum chamber is ≤5.0×10 -4 Pa, put the vacuum chamber in a nitrogen-argon mixed atmosphere, and sputter for 45 minutes; wherein, the volume ratio of nitrogen and argon in the nitrogen-argon mixed atmosphere is 1:4, the pressure under the nitrogen-argon mixed atmosphere is 2Pa, and the sputtering source A tin nitride thin film was obtained for a DC power source with an output power of 45W.

[0033] Step 2, place the tin nitride film in an argon-oxygen mixed atmosphere, and anneal at 480°C for 90 minutes; wherein, the volume ratio of argon to oxygen in the argon-oxygen mixed atmosphere is 2:1, t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com